Battery piece wool making corrosive liquid and preparation process thereof

A technology for preparation process and corrosion solution, which is applied in the field of cell texturing corrosion solution and its preparation process, can solve the problems of not improving the corrosion effect of single crystal silicon, etc., and achieve good surface cleanliness, improved surface activity, and reflection low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

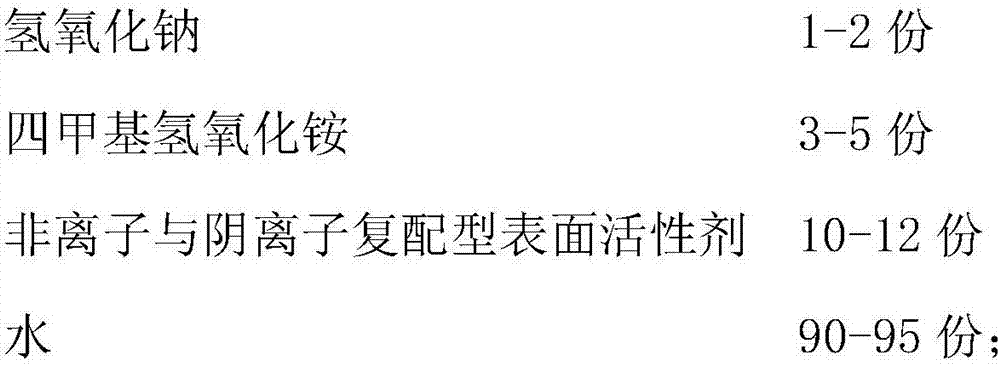

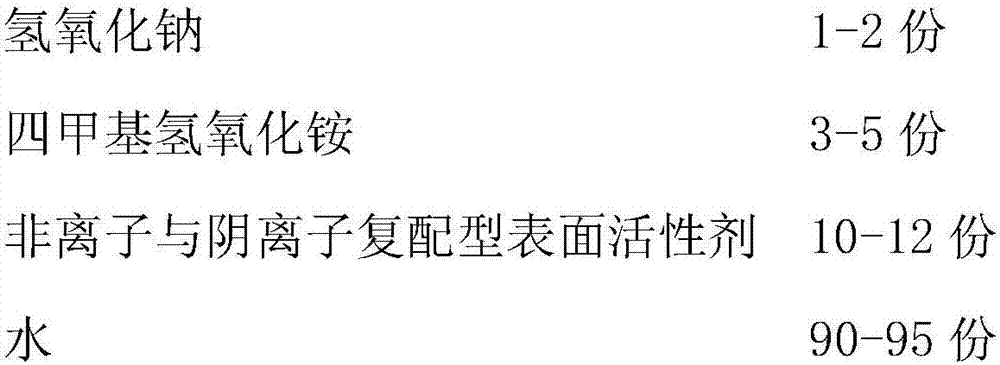

Method used

Image

Examples

Embodiment 1

[0018] First, add 90 parts of water into the texturing tank, then add 2 parts of tetramethylammonium hydroxide and 5 parts of sodium hydroxide, control the temperature at 80°C, add 10 parts of compound surfactant, and stir to obtain the battery sheet Texturing corrosion solution;

[0019] Wherein the nonionic surfactant is sodium silicate, the anionic surfactant is sodium lauryl sulfate, and the molar ratio of the two is 1:1.2.

Embodiment 2

[0021] First, add 90 parts of water into the texturing tank, then add 2 parts of tetramethylammonium hydroxide and 5 parts of sodium hydroxide, control the temperature at 80°C, add 10 parts of compound surfactant, and stir to obtain the battery sheet Texturing corrosion solution;

[0022] Among them, the nonionic surfactant is sodium silicate, and the anionic surfactant is fatty alcohol ether sodium sulfate, and the molar ratio of the two is 1:1.2.

Embodiment 3

[0024] First, add 90 parts of water into the texturing tank, then add 2 parts of tetramethylammonium hydroxide and 5 parts of sodium hydroxide, control the temperature at 80°C, add 10 parts of compound surfactant, and stir to obtain the battery sheet Texturing corrosion solution;

[0025] Among them, the nonionic surfactant is sodium silicate, and the anionic surfactant is a mixture of sodium lauryl sulfate and sodium fatty alcohol ether sulfate, and the molar ratio of the three is 1:0.6:0.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com