Patents

Literature

39results about How to "Fast corrosion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

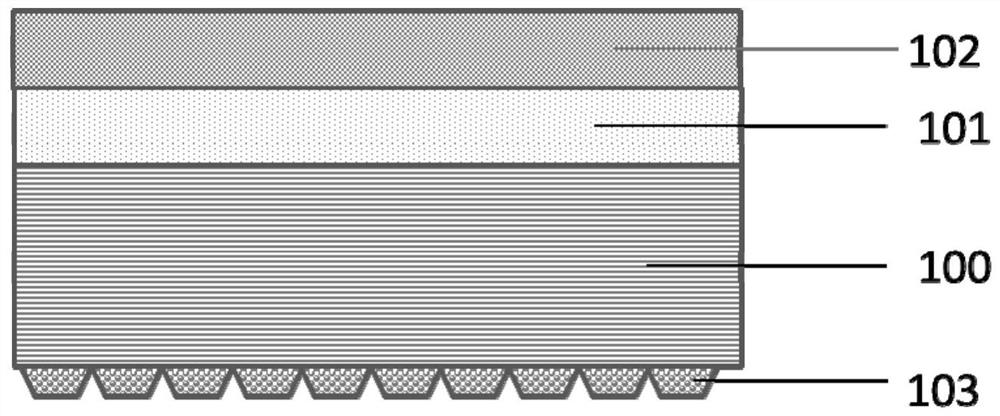

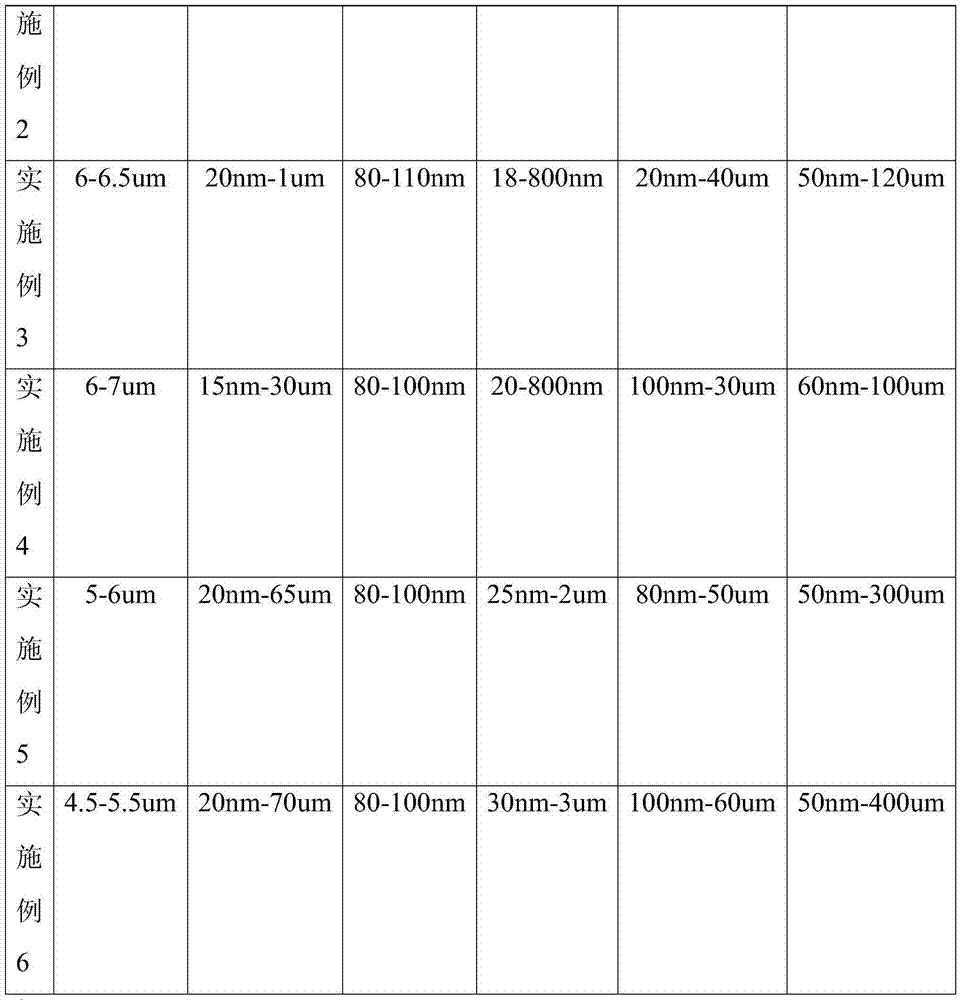

Surface treated metal and surface treatment method thereof and metal resin complex and preparation method of metal resin complex

ActiveCN103451701AIncrease corrosion rateReduce corrosion rateAnodisationPore diameterAnodic oxidation

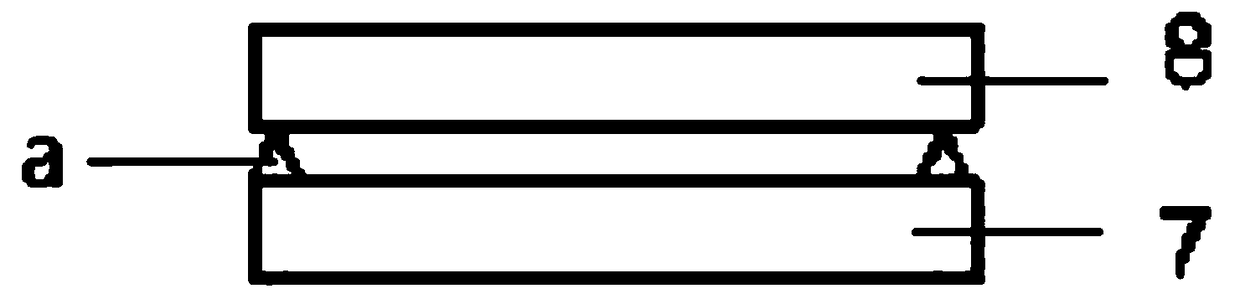

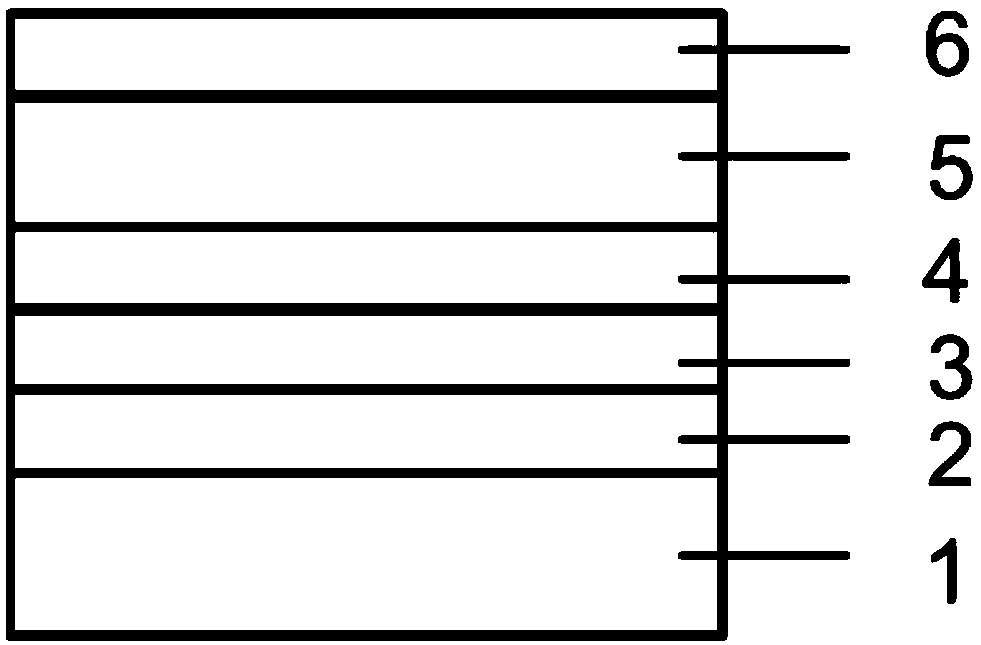

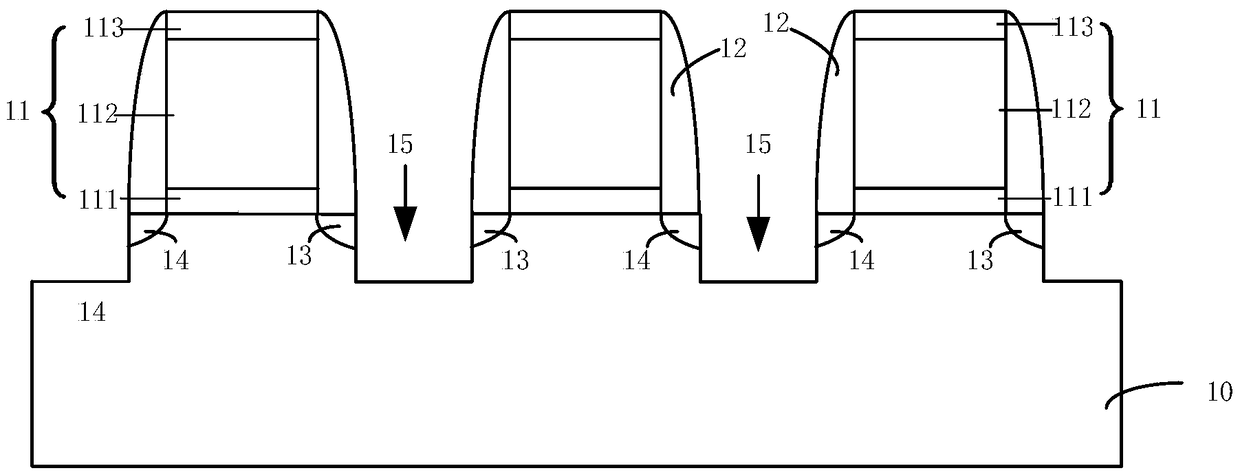

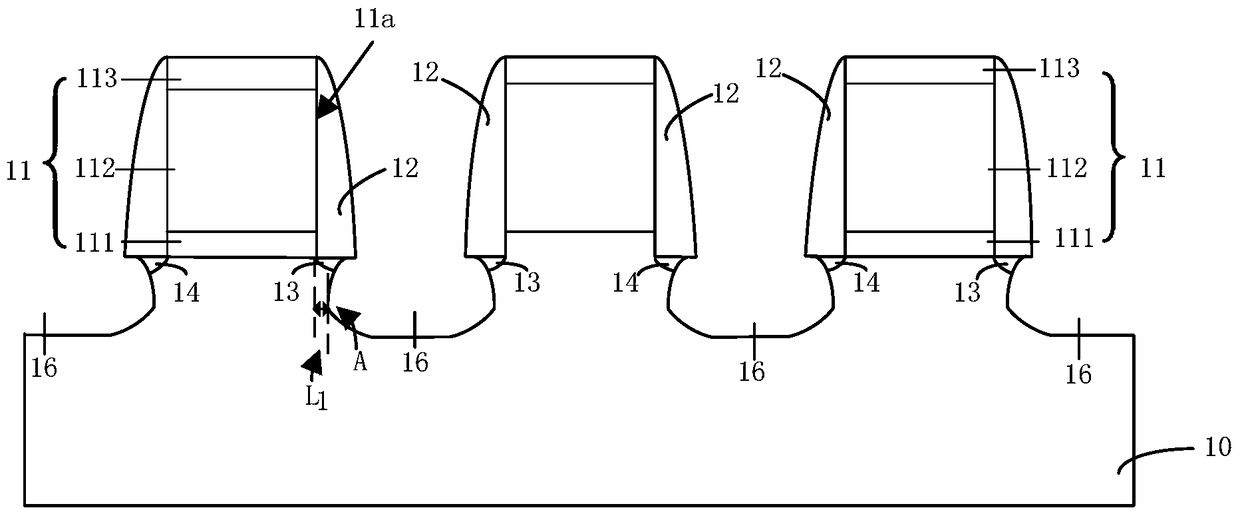

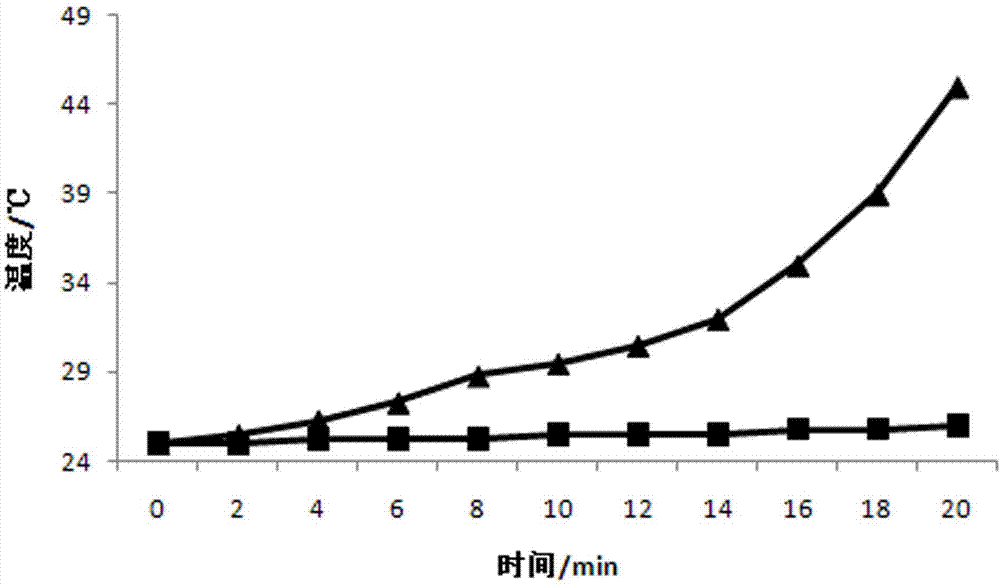

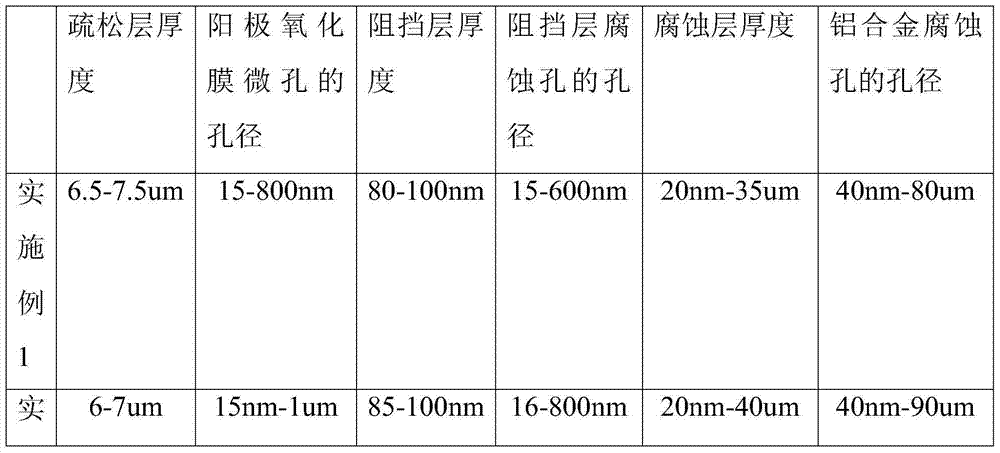

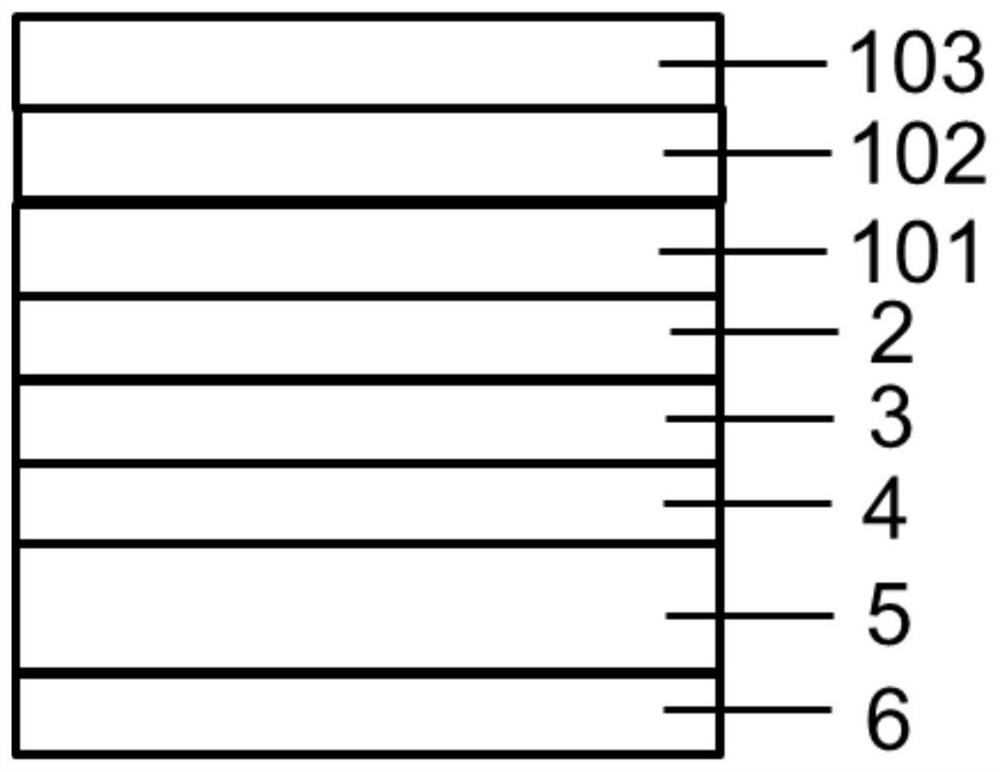

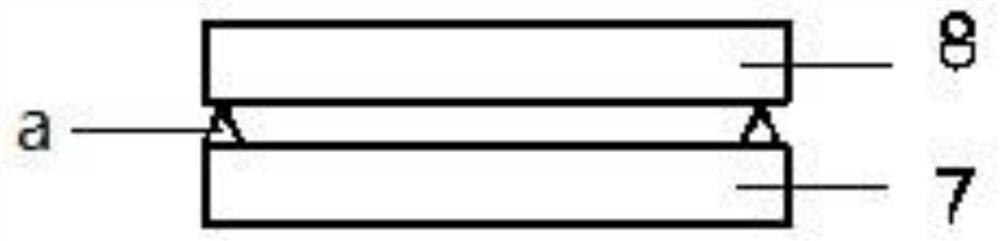

The invention provides a surface treated metal and a surface treatment method thereof and a metal resin complex and a preparation method of the metal resin complex. The surface treated metal comprises a metal body and an anodic oxidation film layer which is located on the surface of the metal body, the anodic oxidation film layer includes a barrier layer which is in contact with the metal body and a loose layer located on the outer surface of the barrier layer, the loose layer contains anodic oxidation film micropores, the pore diameter of the anodic oxidation film micropores is 10 nm-800 mum, the barrier layer contains barrier layer corrosion pores, the pore diameter of the barrier layer corrosion pores is 10 nm-800 mum, the metal body includes a corrosion layer which is in contact with the barrier layer, the corrosion layer contains metal corrosion pores, the pore diameter of the metal corrosion pores is 10 nm-1 mm, the metal is aluminum alloy or aluminum, the bonding force between the metal and resin is strong, and the surface treated metal is simple in process, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

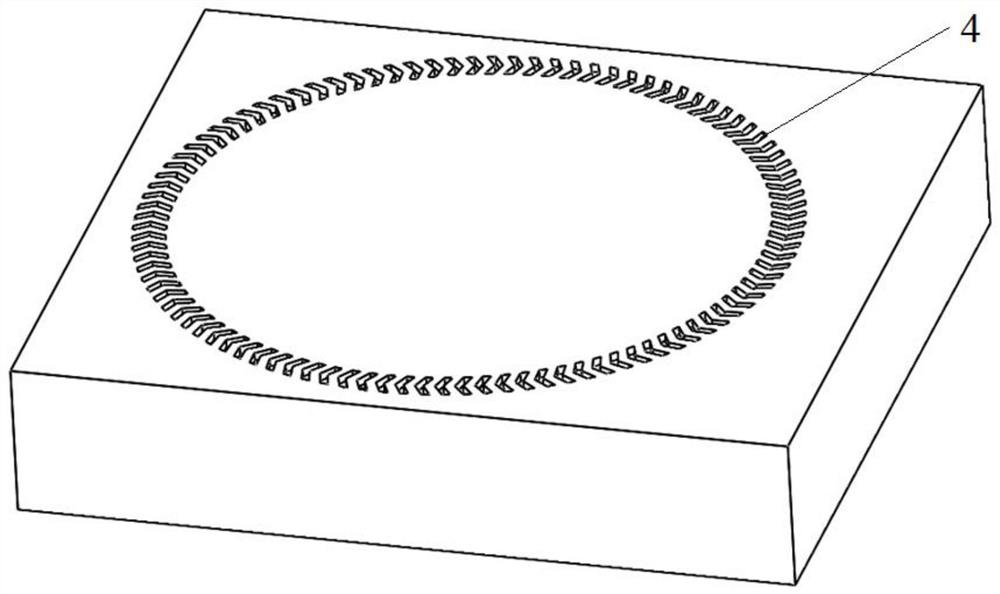

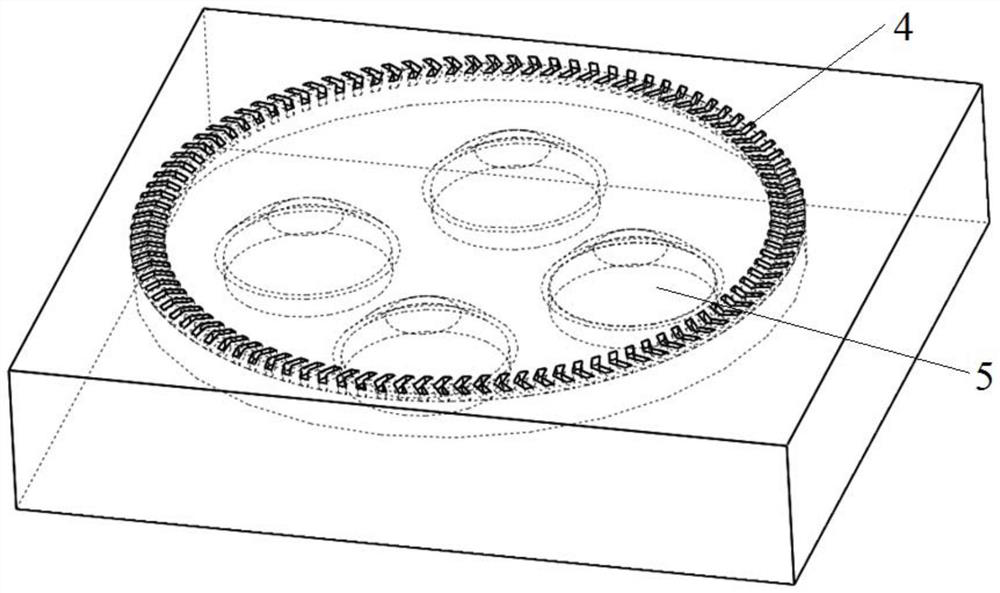

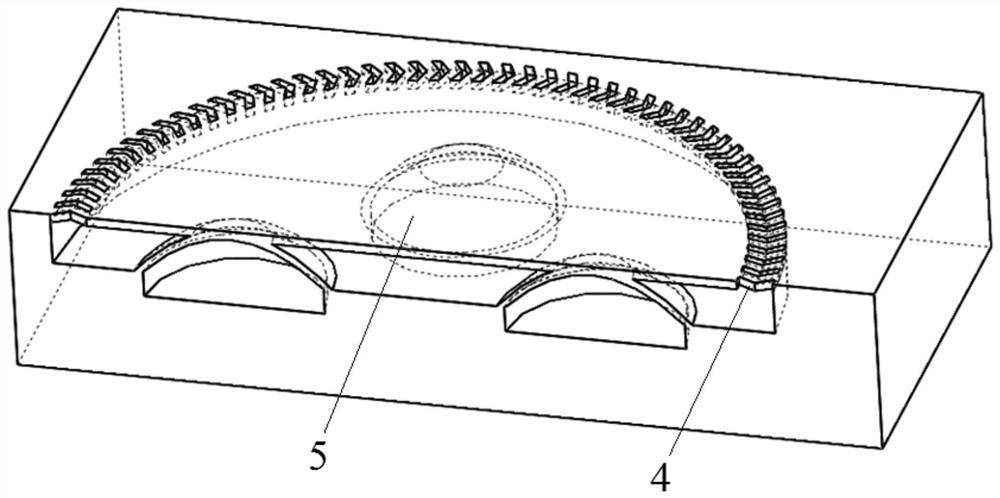

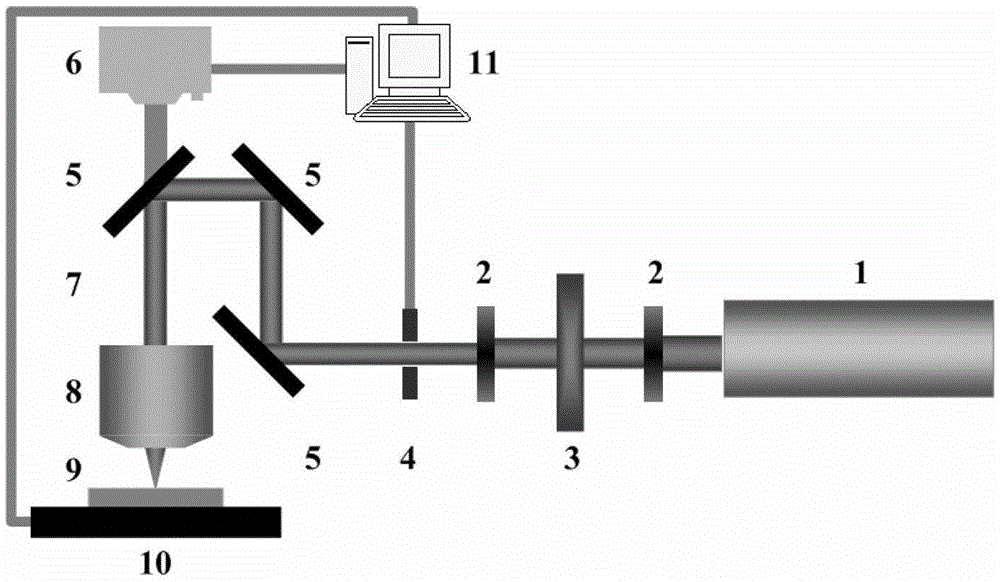

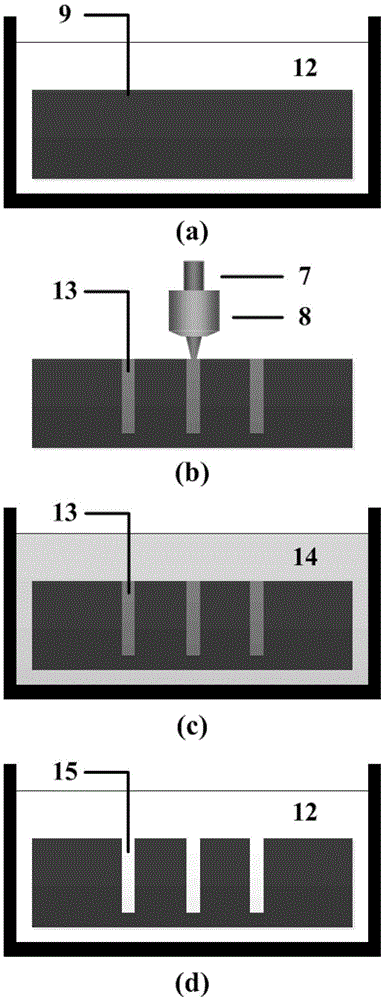

Method for preparing three-dimensional fluid channel in transparent material

InactiveCN102627257AUniform corrosionReduce corrosionMicrostructural devicesLaser beam welding apparatusPolymer chemistryCircular polarization

The invention discloses a method for preparing a three-dimensional fluid channel in a transparent material. The complex three-dimensional fluid channel is prepared inside the transparent material by utilizing femtosecond lasers of circular polarization. The three-dimensional fluid channel prepared by the method disclosed by the invention has the advantages of same anisotropic etch rate and faster etch rate for a complex structure.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

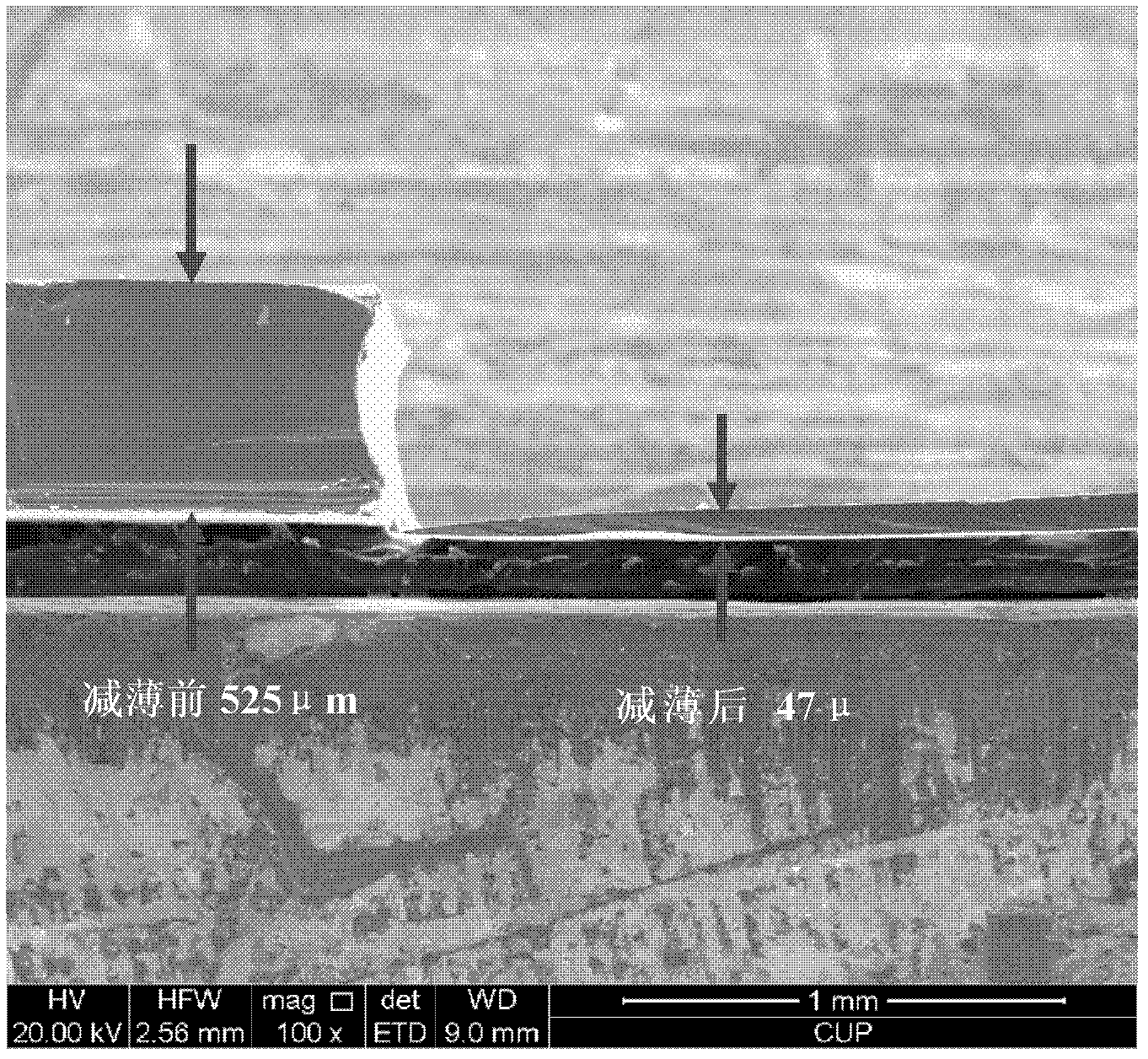

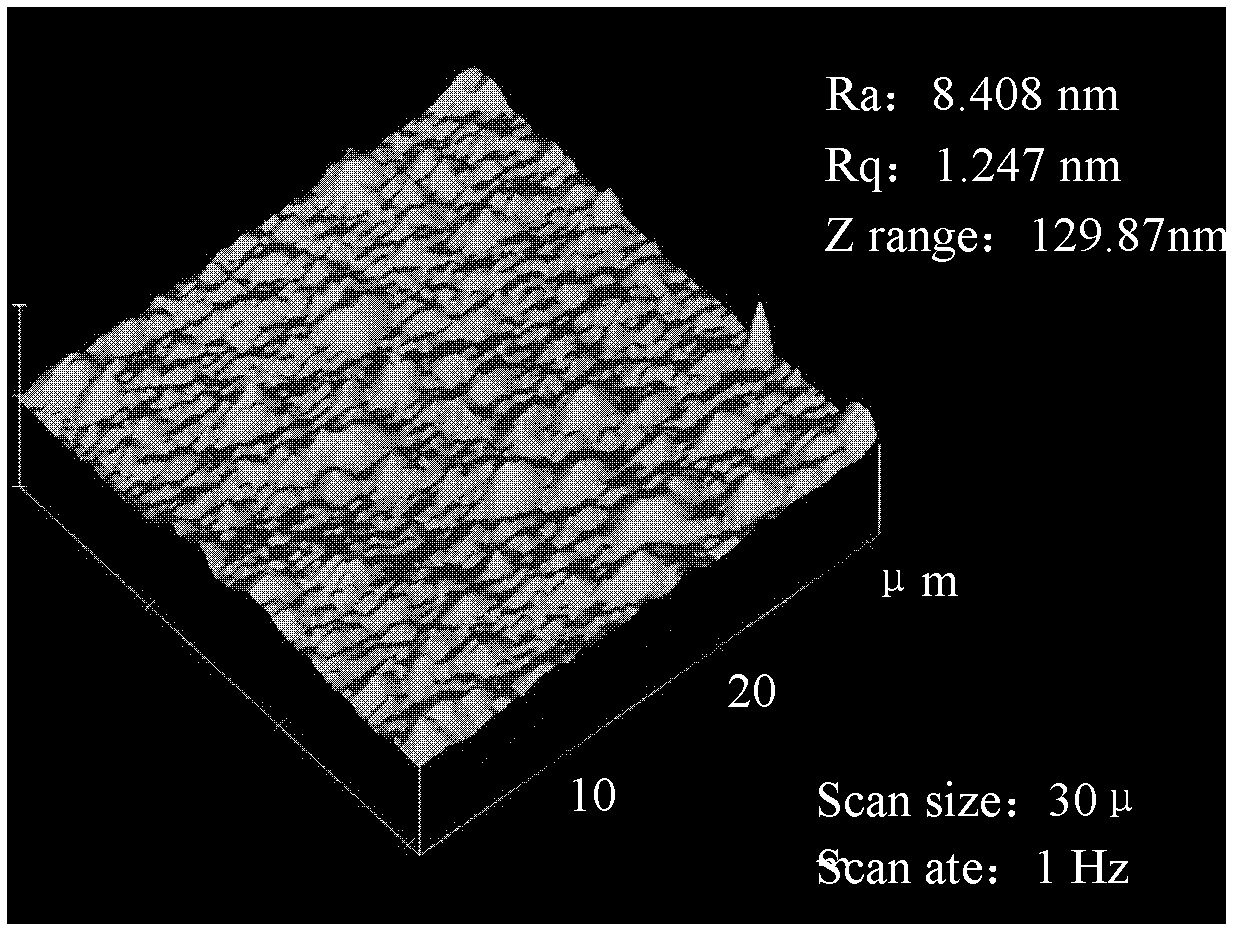

Silicon slice thinning method based on metal nano particle catalysis

ActiveCN102354661AUniform corrosionGood repeatabilitySemiconductor/solid-state device manufacturingWater bathsEtching

The invention discloses a silicon slice thinning method based on metal nano particle catalysis in the technical field of microelectronics. The method comprises the following steps of: pretreating a silicon slice (100) or (111) at normal temperature by using acetone, a CP4-A solution and hydrofluoric acid so as to obtain a clean silicon surface; and preparing a thinning solution which is formed byuniformly mixing silver nitrate, hydrogen peroxide and hydrofluoric acid, putting the thinning solution into a water bath for preheating, immersing the silicon slice into the thinning solution, and thus obtaining an ultrathin silicon slice with a required thickness by controlling reaction time, temperature and a solution ratio. In the method, the silicon slice can be uniformly etched by using a metal nano particle catalysis characteristic at the first time; a silicon slice thinning process is simplified by using a one-step method; characteristics of wet etching at near normal temperature and normal pressure can be retained, so the ultrathin silicon slice with the thickness of less than 50 microns can be obtained; furthermore, an application range of metal nano particle catalysis silicon etching is expanded; and a new idea and a new technical measure can be supplied to the silicon slice thinning process.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

3cr oil well pipe and its production method

InactiveCN102268602ALow threshold for resistance to hydrogen sulfide stress corrosionFast corrosion rateDrilling rodsDrilling casingsRare-earth elementImpurity

The invention discloses a 3Cr oil well pipe and a production method thereof, relates to a 3Cr oil well pipe for an acid oil-gas field and a manufacturing method thereof, and belongs to the technical field of metallurgy. The 3Cr oil well pipe comprises C, Si, Mn, S, P, Cr, Mo, V, Mo, Al, B, a rare-earth element and the balance of Fe and inevitable impurities. The production method for the 3Cr oil well pipe comprises the following steps of: selecting raw materials; smelting; continuously casting; continuously rolling; performing reheating and stretch sizing; and performing thermal refining. A treatment technology of removing stress by secondary sizing and hot straightening in the step of performing reheating and stretch sizing solves the technical problem that an S and CO2 resistant oil sleeve positioned in a hydrogen sulfide stress corrosion sensitive area has a low hydrogen sulfide stress corrosion resistant threshold value, is quickly corroded and is easily penetrated locally throughcorrosion.

Owner:WUXI SEAMLESS OIL PIPE

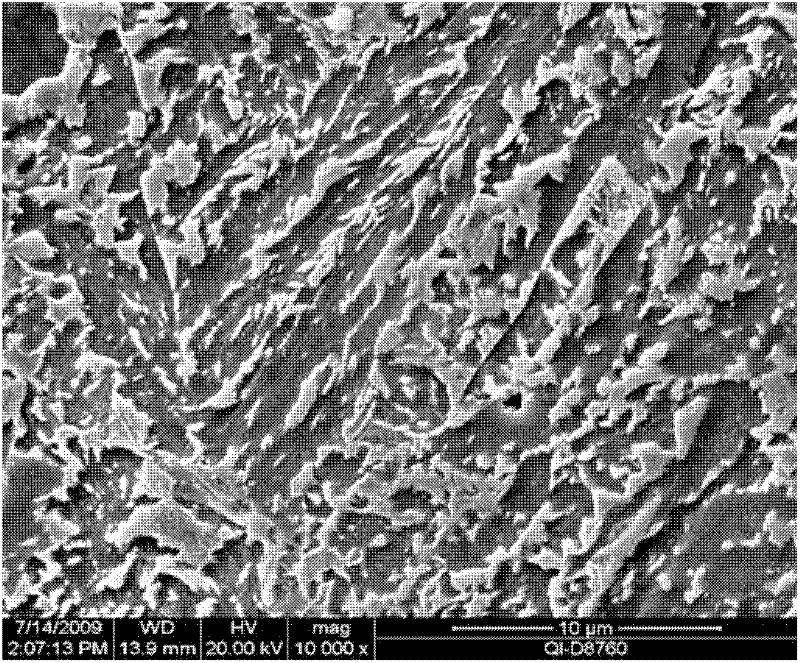

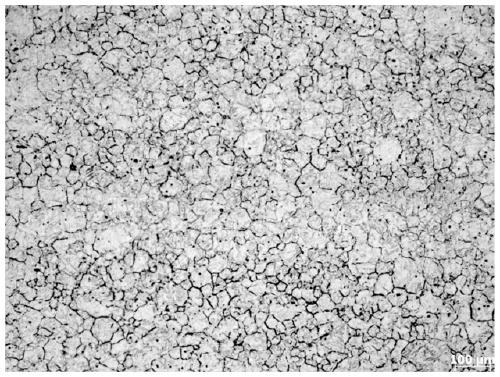

Method for eroding 2Cr12Ni1Mo1Vsteel grain boundary

InactiveCN102879253AAccurate responseAccurate ratingPreparing sample for investigationGrain boundaryReagent

The invention discloses a method for eroding 2Cr12Ni1Mo1V steel grain boundary, relating to a method for eroding the steel grain boundary. According to the method, solves the problem that the existing method for eroding 2Cr12Ni1Mo1V steel grain boundary can not really respond to the problem of 2Cr12Ni1Mo1Vsteel grain boundary usually. A method for eroding 2Cr12Ni1Mo1V steel grain boundary comprises the steps of 1. preparing a corrosion reagent; and 2. eroding 2Cr12Ni1Mo1V steel. The method for eroding 2Cr12Ni1Mo1V steel grain boundary is applied in evaluating grain degree of 2Cr12Ni1Mo1V steel.

Owner:HARBIN TURBINE

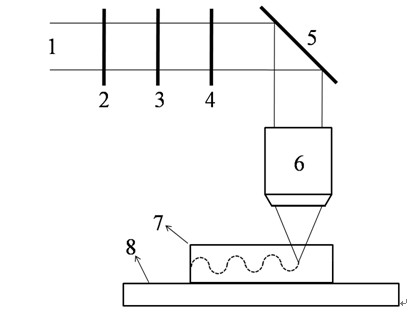

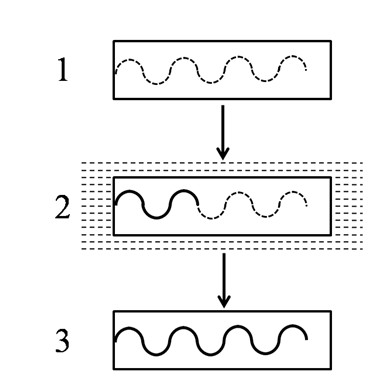

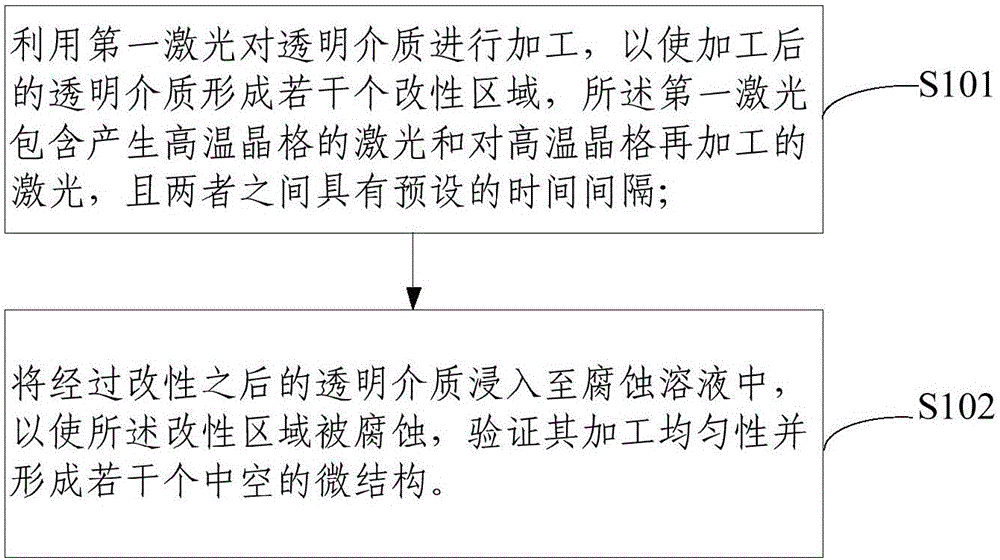

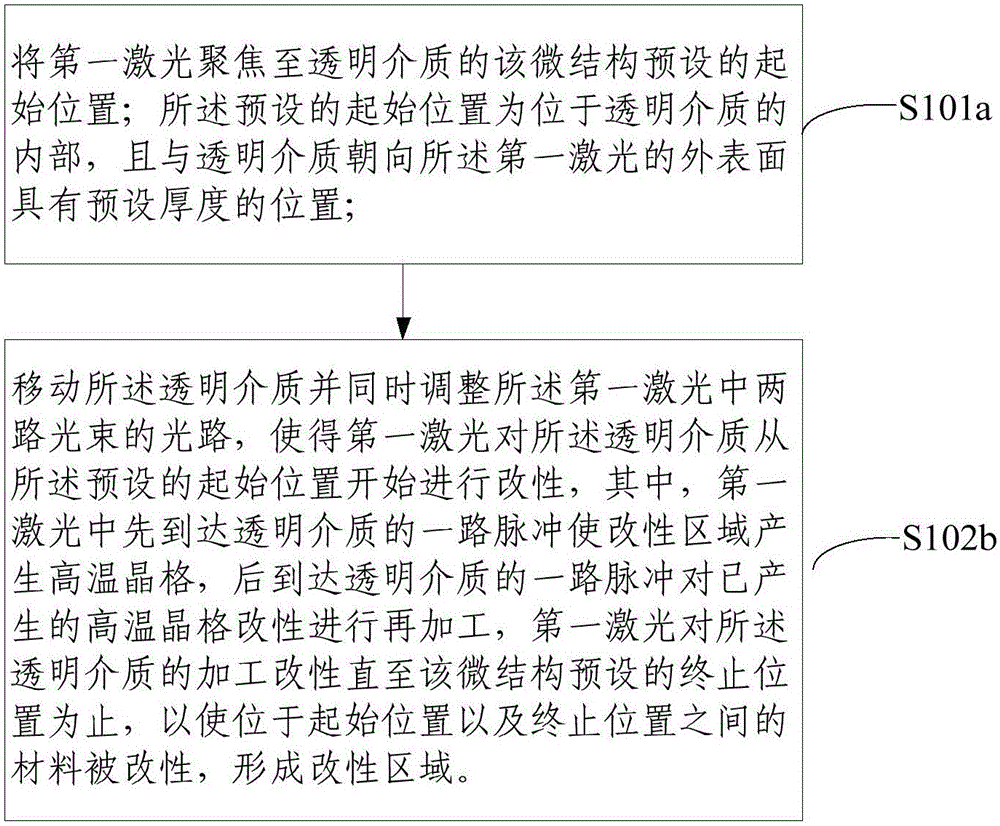

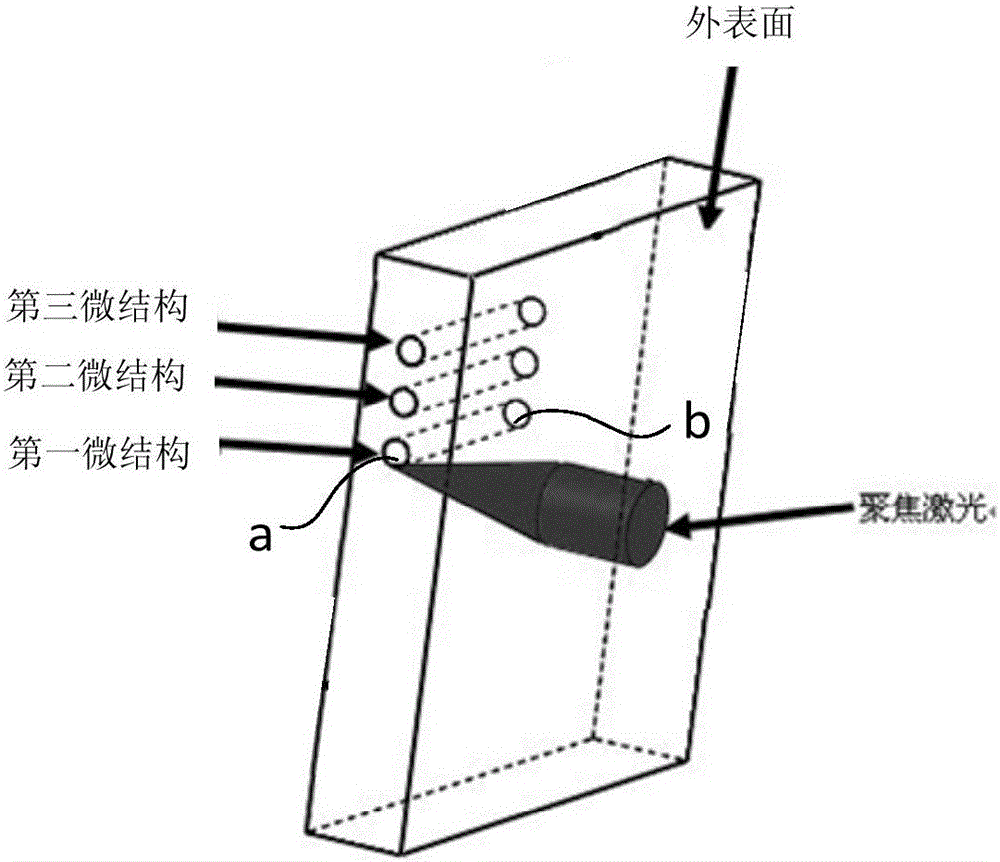

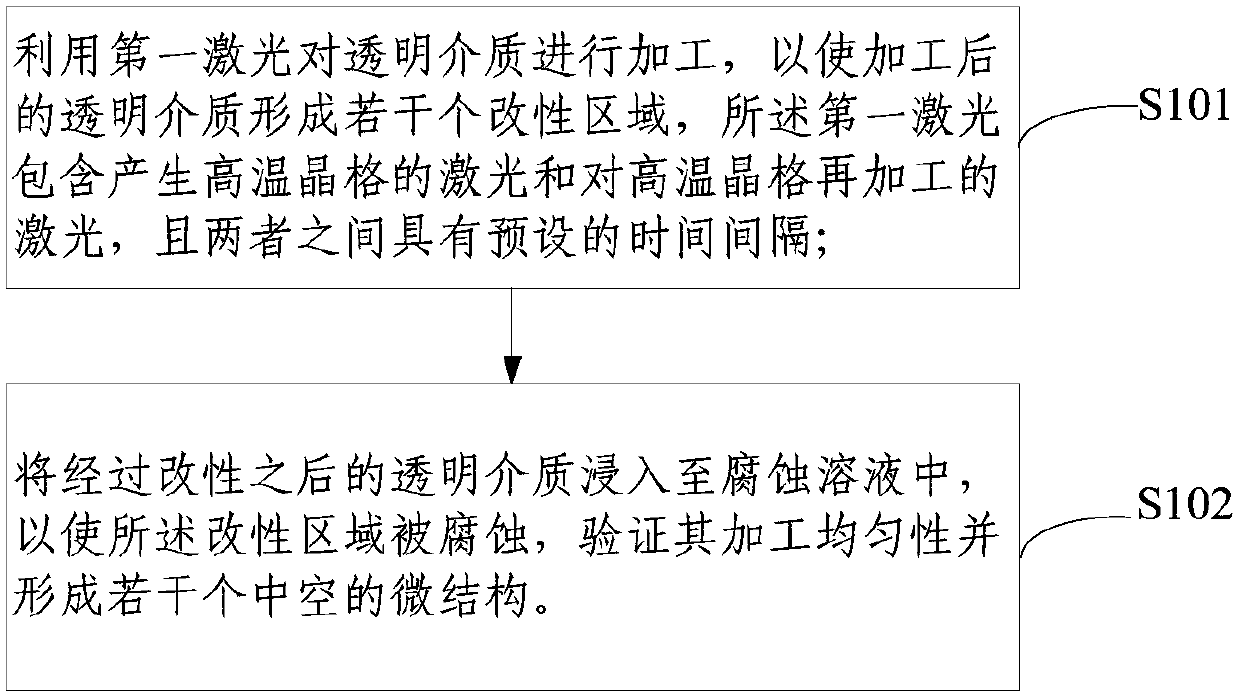

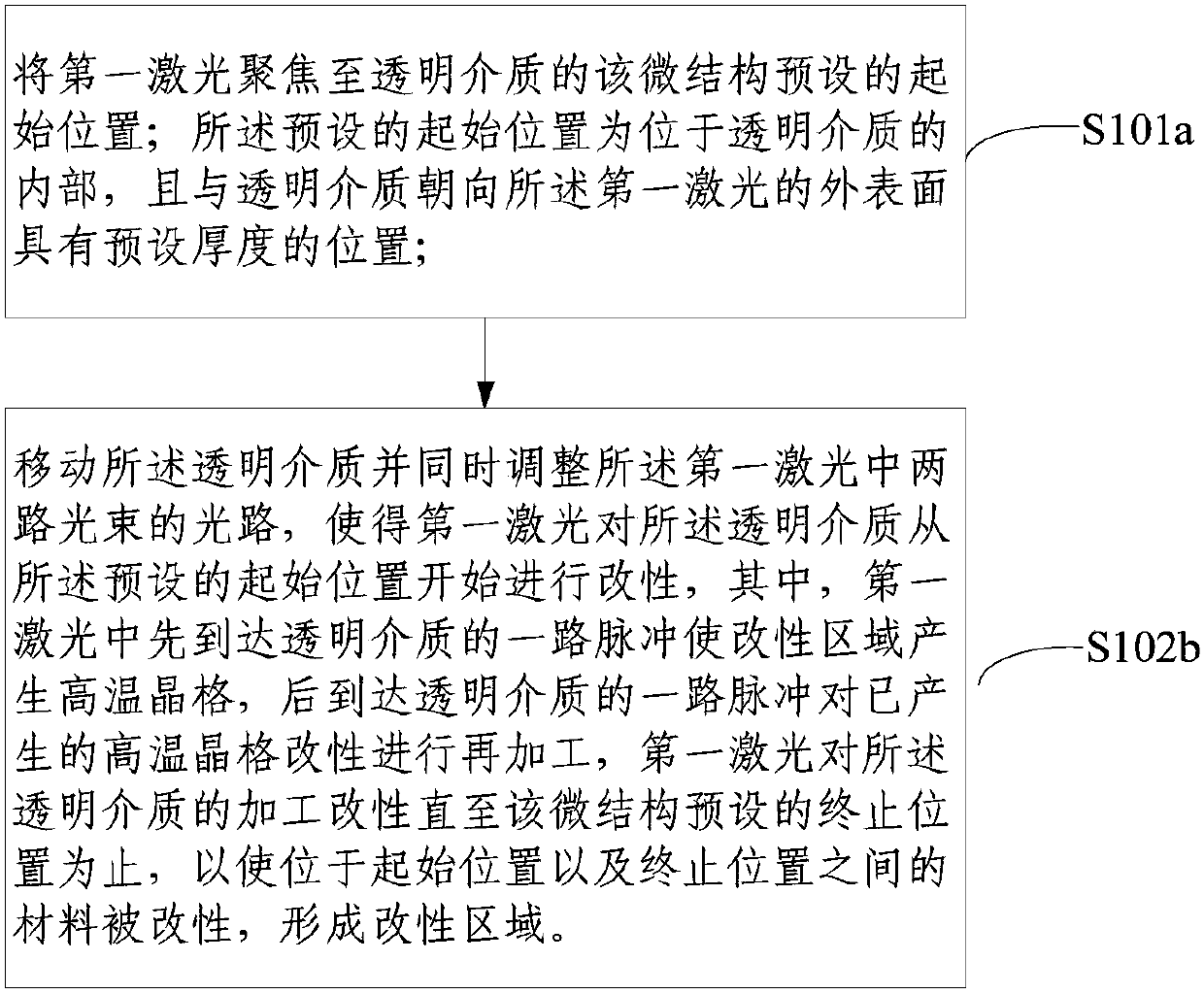

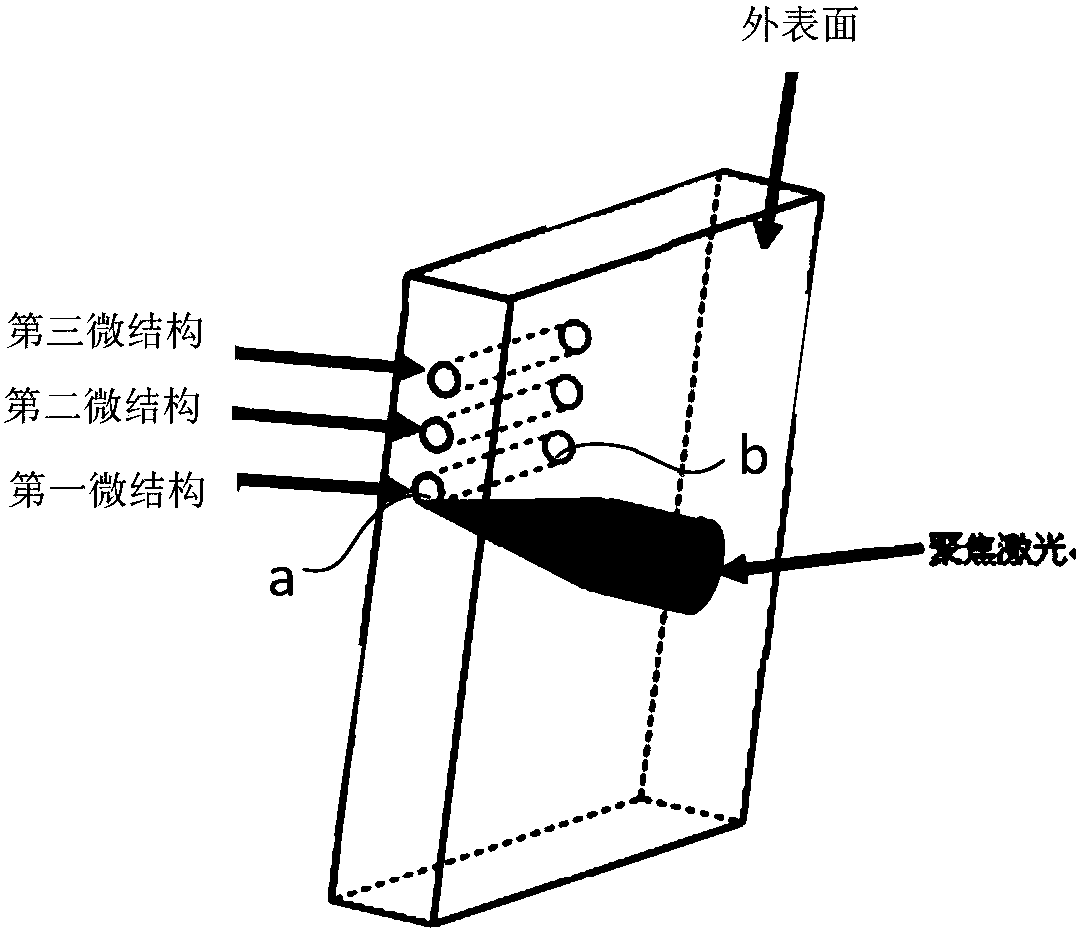

Uniform modification processing method of transparent medium microstructures

ActiveCN106041313AImprove uniformityFast corrosion rateLaser beam welding apparatusLight beamComputer science

The invention provides a uniform modification processing method of transparent medium microstructures. The uniform modification processing method comprises the following steps: processing a transparent medium by using first laser so that a plurality of modification regions are formed on the processed transparent medium; immersing the modified transparent medium into a corrosion solution to corrode the modification regions, verifying processing uniformity of the transparent medium and forming a plurality of hollow microstructures. The invention provides the uniform modification processing method of the transparent medium microstructures, the first laser comprises laser for generating high-temperature lattices and laser for reprocessing the high-temperature lattices, a preset time interval is reserved between the laser for generating the high-temperature lattices and the laser for reprocessing the high-temperature lattice, when the transparent medium is processed, by light beams which reach the transparent medium at first, the high-temperature lattice can be generated at a gathering position of the light beams by the transparent medium, light beams which reach the transparent medium later immediately process the high-temperature lattice, so that the uniformity of the transparent medium processed by the method is good, and the ideal design effect can be achieved.

Owner:CENT SOUTH UNIV

Transferring method of edge-free vertical structure LED chip substrate

ActiveCN108878596AExcellent substrate transfer processSolve the problem of fragmentationSemiconductor devicesEngineeringThinning

The invention discloses a transferring method of an edge-free vertical structure LED chip substrate. The transferring method of the edge-free vertical structure LED chip substrate comprises a metal layer depositing step, an epitaxial wafer surface treatment step, a substrate deposition transferring step, a bonding step, a thinning step, a residual silicon removal step, and a vertical LED chip preparation step. The transferring method of the edge-free vertical structure LED chip substrate disclosed by the invention can solve the problems in the current substrate transferring process by means ofthe epitaxial wafer surface treatment step, the thinning step, the residual silicon removal step and the like, which can obtain a comparatively excellent substrate transferring technology.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

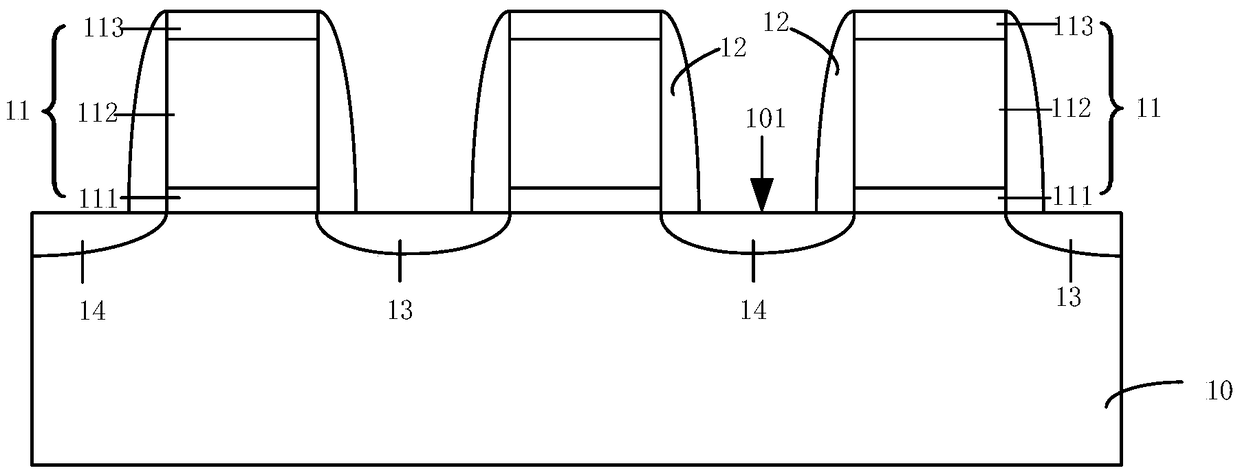

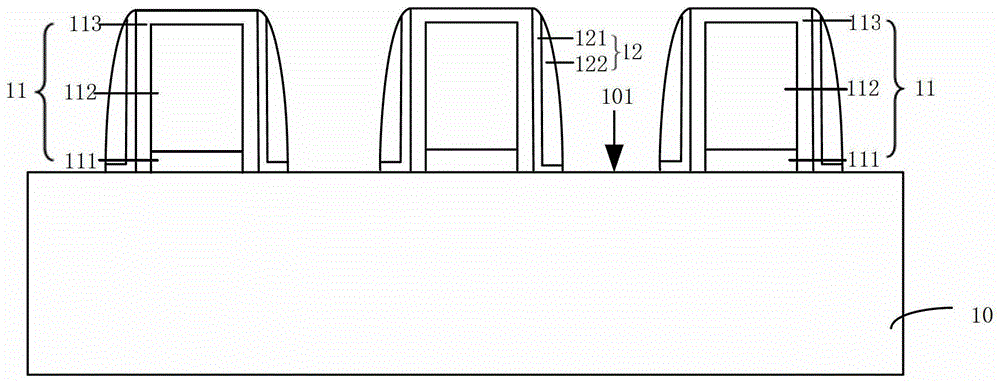

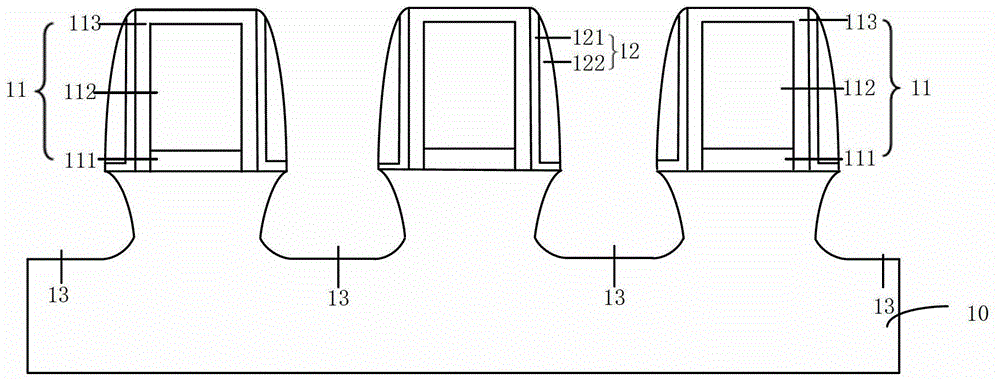

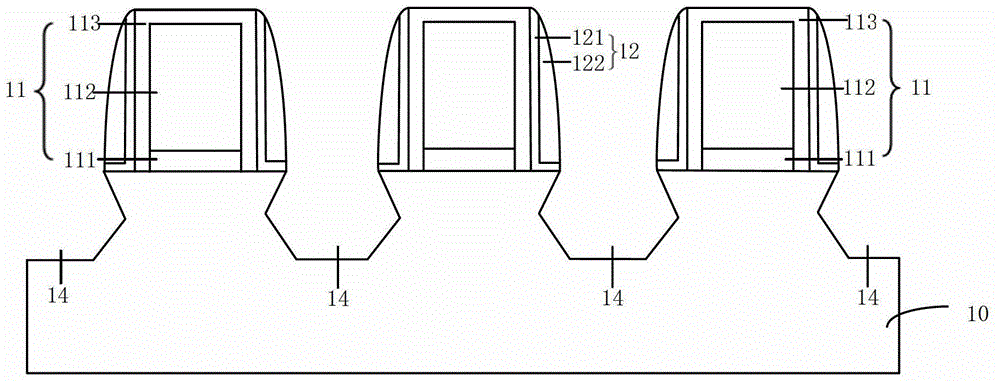

MOS transistor and manufacturing method therefor

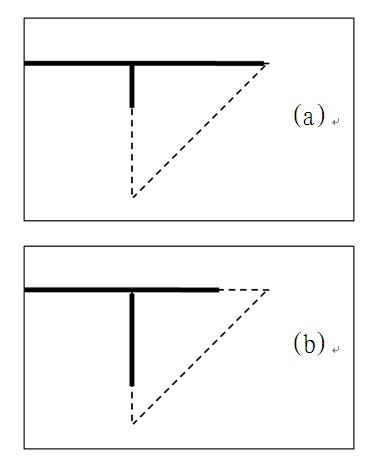

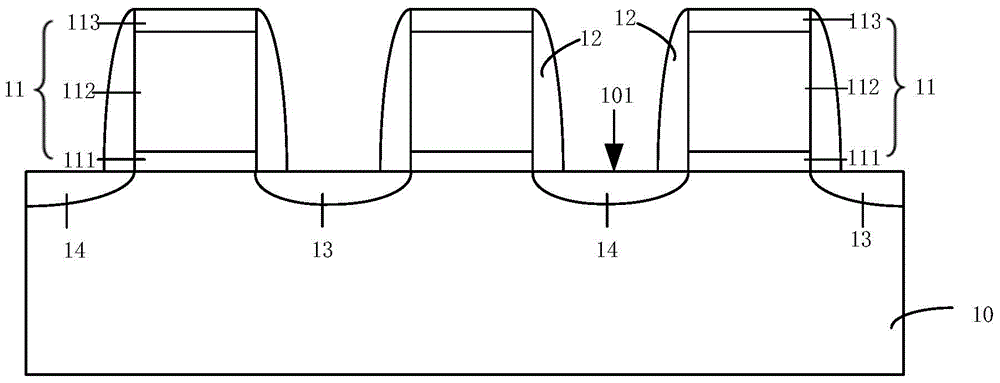

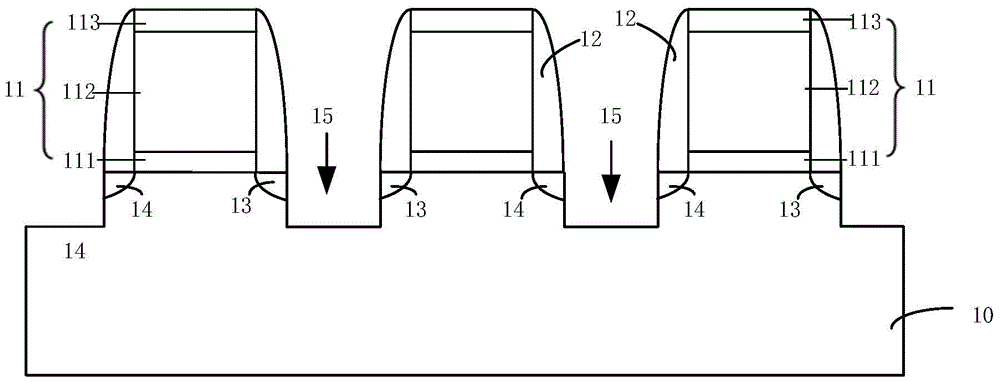

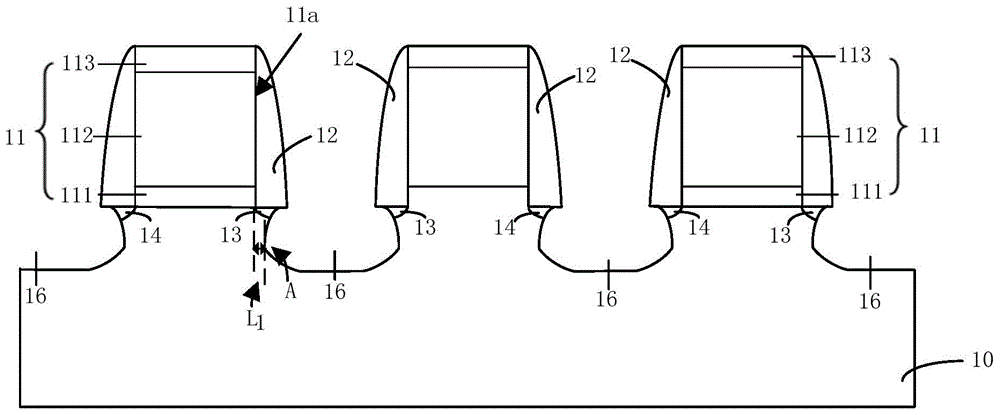

ActiveCN105448982AFast migration rateFast corrosion rateSemiconductor/solid-state device manufacturingSemiconductor devicesTension stressCorrosion

The invention discloses a MOS transistor and a manufacturing method therefor. In order to improve the carrier migration rate of the MOS transistor, the size of an opening of a bowl-shaped groove is controlled during the forming of a sigma-shaped groove, so as to enable the size of the opening to be greater than the distance between side walls of the adjacent grid structures. In other words, the size of the opening of the bowl-shaped groove is controlled to be great as much as possible, thereby enabling the size of the opening of the sigma-shaped groove formed by the corrosion of the bowl-shaped groove to be greater, enabling pressure stress materials or tensile stress materials placed in a source-drain region to be more, enabling the tensile stress or pressure stress applied to a trench to be greater, and enabling the carrier migration rate to be greater.

Owner:SEMICON MFG INT (SHANGHAI) CORP

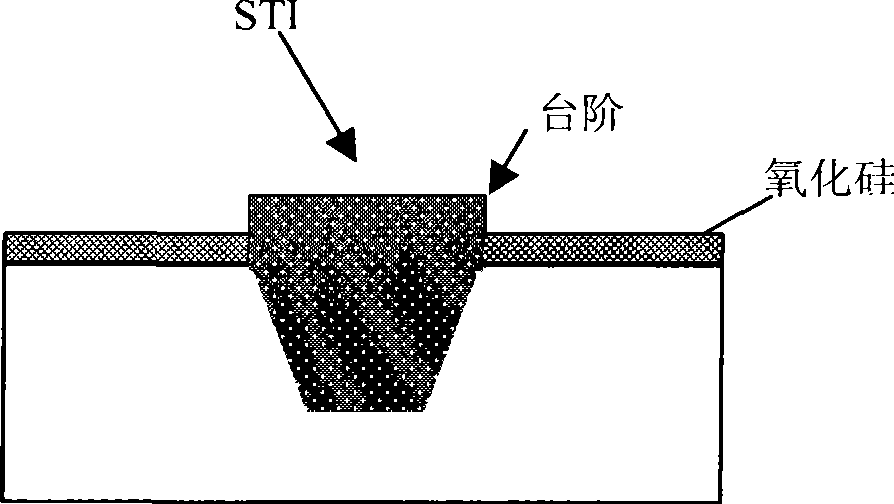

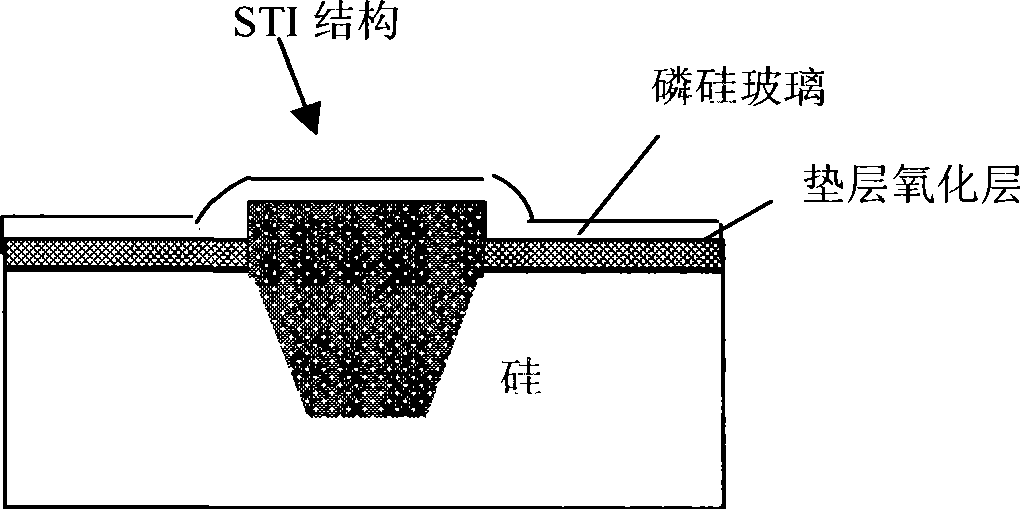

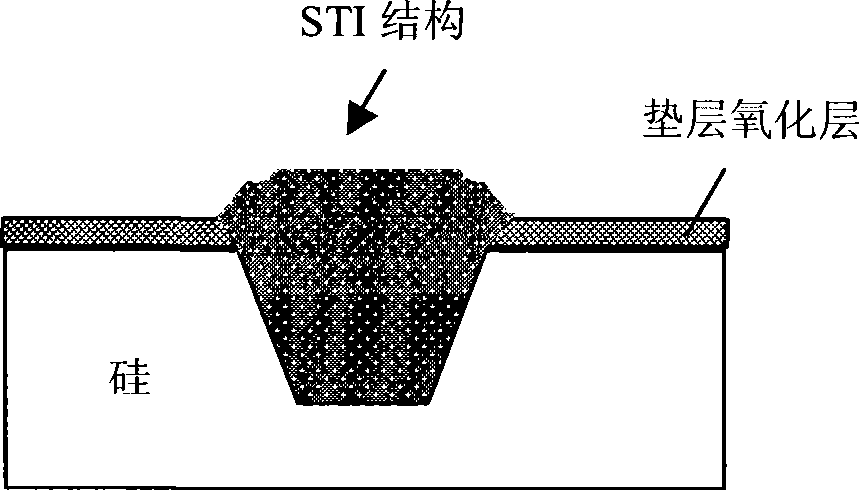

Manufacturing method for STI isolation structure

ActiveCN101452871AMuch lossFast corrosion rateSemiconductor/solid-state device manufacturingPhosphorHard mask

The invention discloses a method for preparing an STI isolation structure. After completing a filling of a shallow groove and removing a hard mask, the method also comprises the following steps: depositing one layer of phosphor on the surface of an oxide layer of a cushion layer; diffusing the phosphor on the surface of the oxide layer of the cushion layer to form phosphorosilicate glass while depositing; and eroding the phosphorosilicate glass through a wet method. The preparation method utilizes the phosphor doping distribution to decide the corrosion speed of each region, finally carries out rounding treatment on corners of the STI structure and is suitable for manufacturing an integrated circuit.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

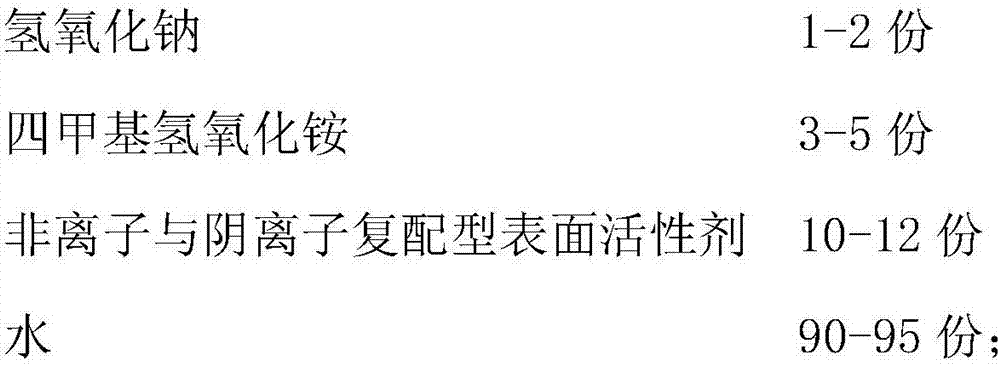

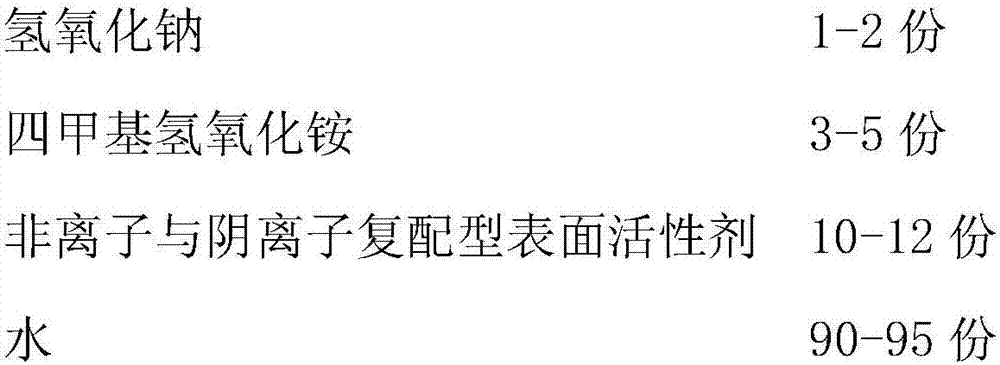

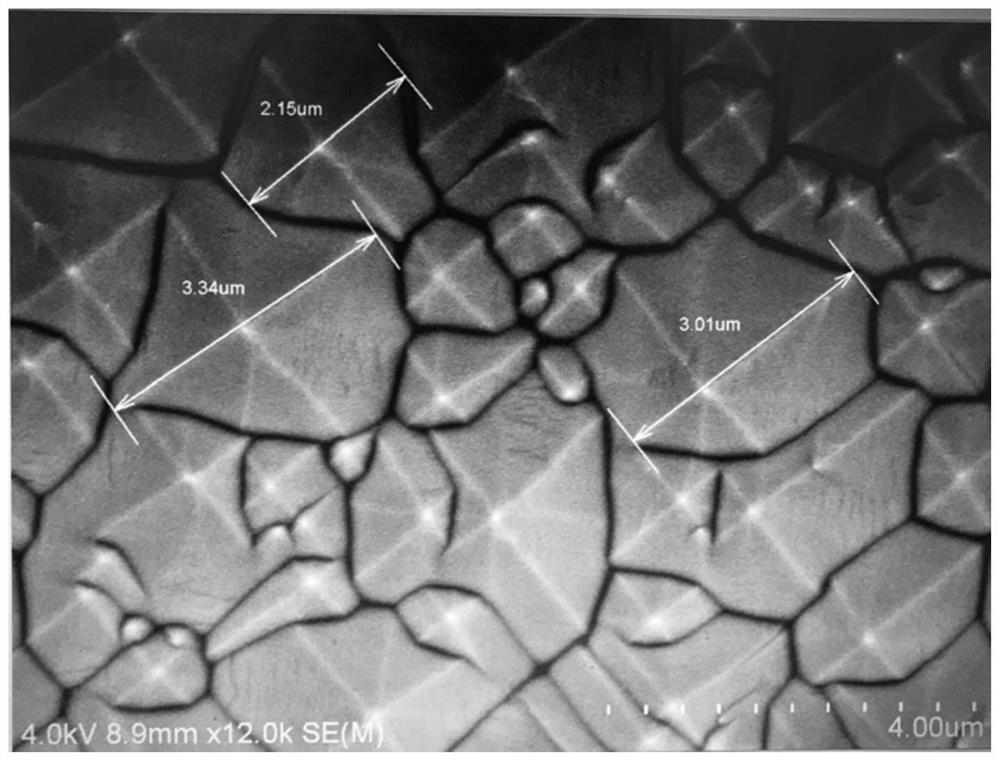

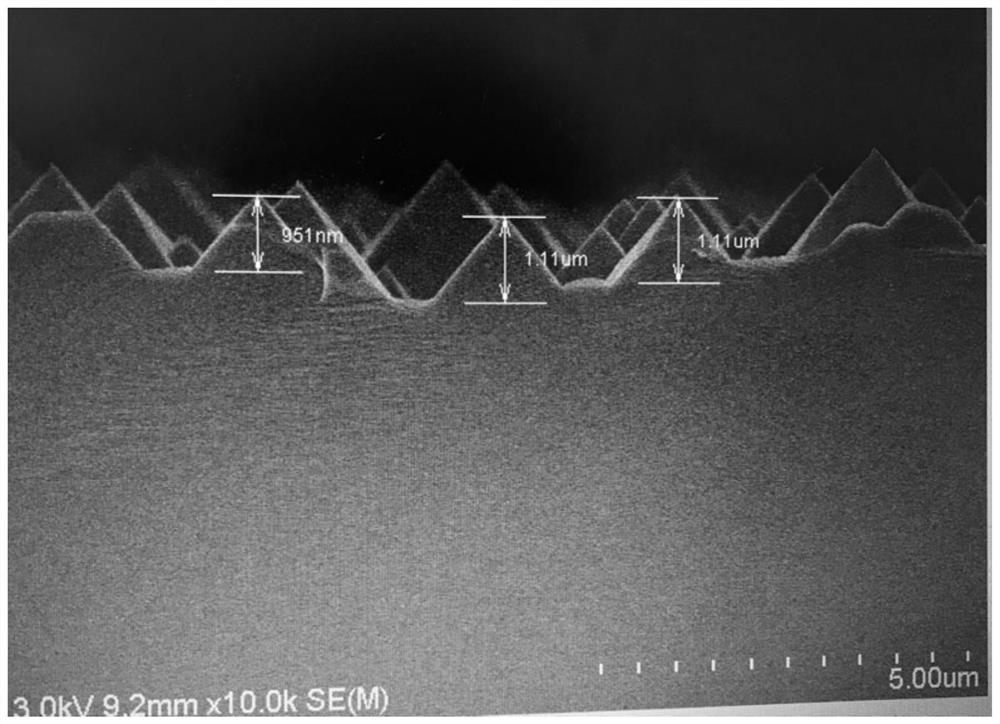

Battery piece wool making corrosive liquid and preparation process thereof

InactiveCN107400926AImprove surface activityReduce reflectivityPolycrystalline material growthAfter-treatment detailsTetramethylammonium hydroxideElectrical battery

The invention discloses a battery piece wool making corrosive liquid which contains sodium hydroxide, tetramethylammonium hydroxide, nonionic and anion compounded surfactant and water, wherein the nonionic surfactant in the nonionic and anion compounded surfactant is sodium silicate; and the anion surfactant in the nonionic and anion compounded surfactant is one or two of lauryl sodium sulfate fatty alcohol ether sodium sulfate. Due to adoption of the nonionic and anion compounded surfactant in the corrosive liquid, an ideal texture effect is achieved when being compared with that of IPA (Isopropanol), and a silicon piece is low in reflection rate and relatively good in surface cleanliness after wool making; meanwhile tetramethylammonium hydroxide has a corrosion selective ratio approximate to that of NaOH, a pyramid formed on a woof surface on the surface of the silicon piece is small in size and high in corrosion velocity, and then the wool making time is effectively shortened; and in addition, the surfactants in the solution act up together, so that the smoothness and the uniformity of the wool surface are improved, and the surface reflection rate is reduced.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

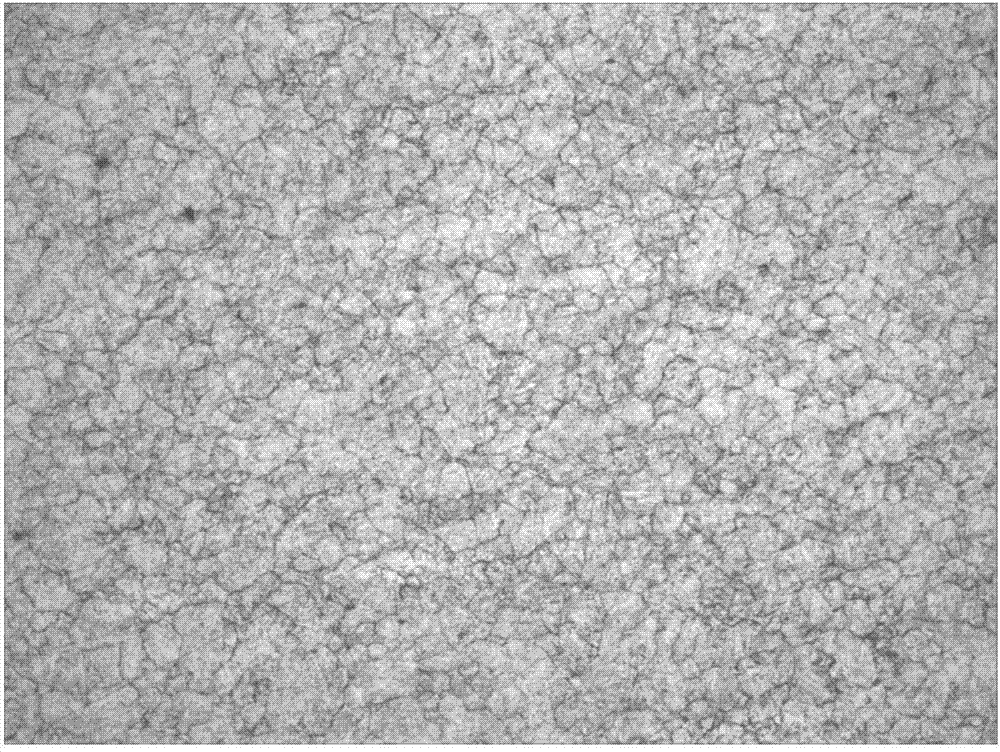

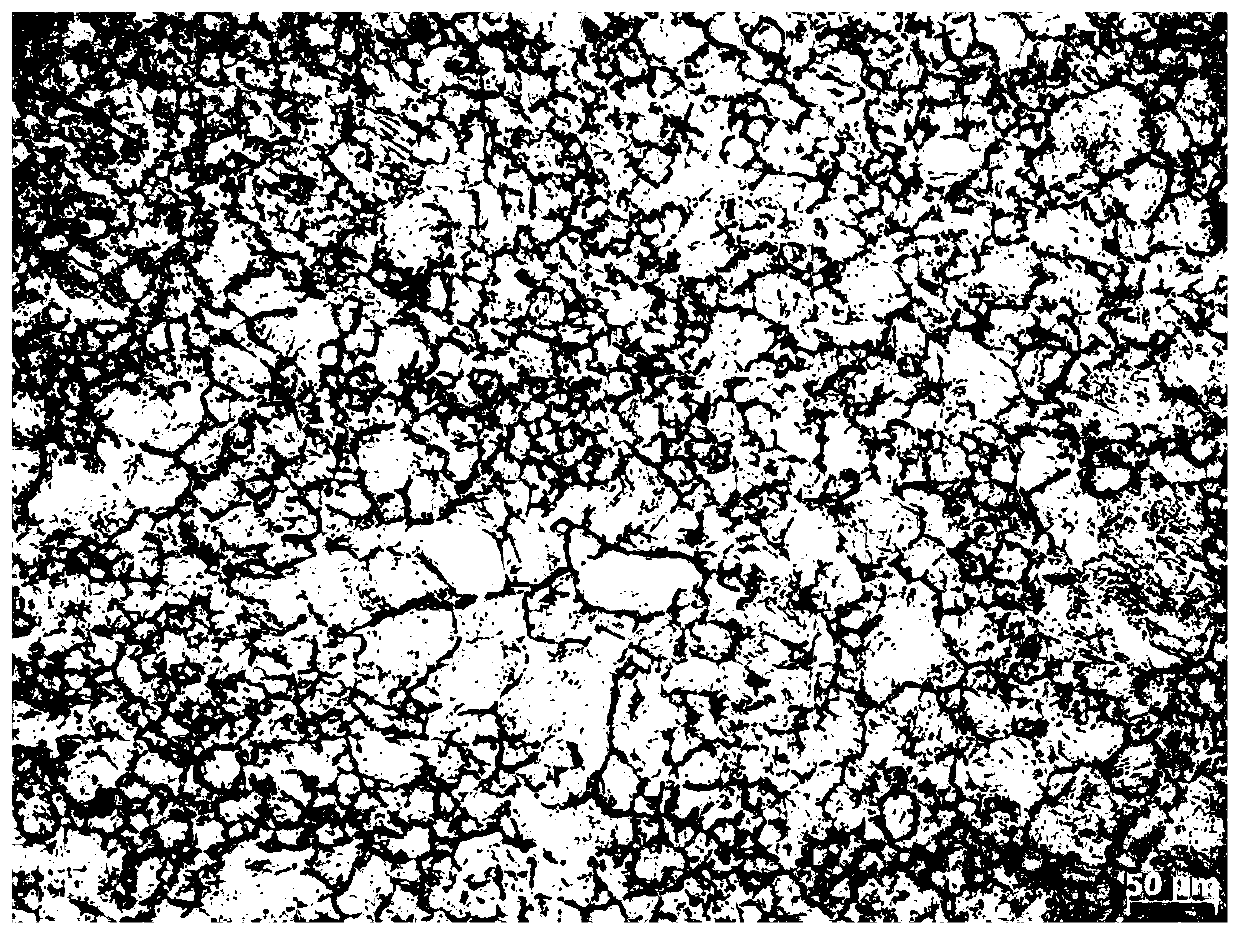

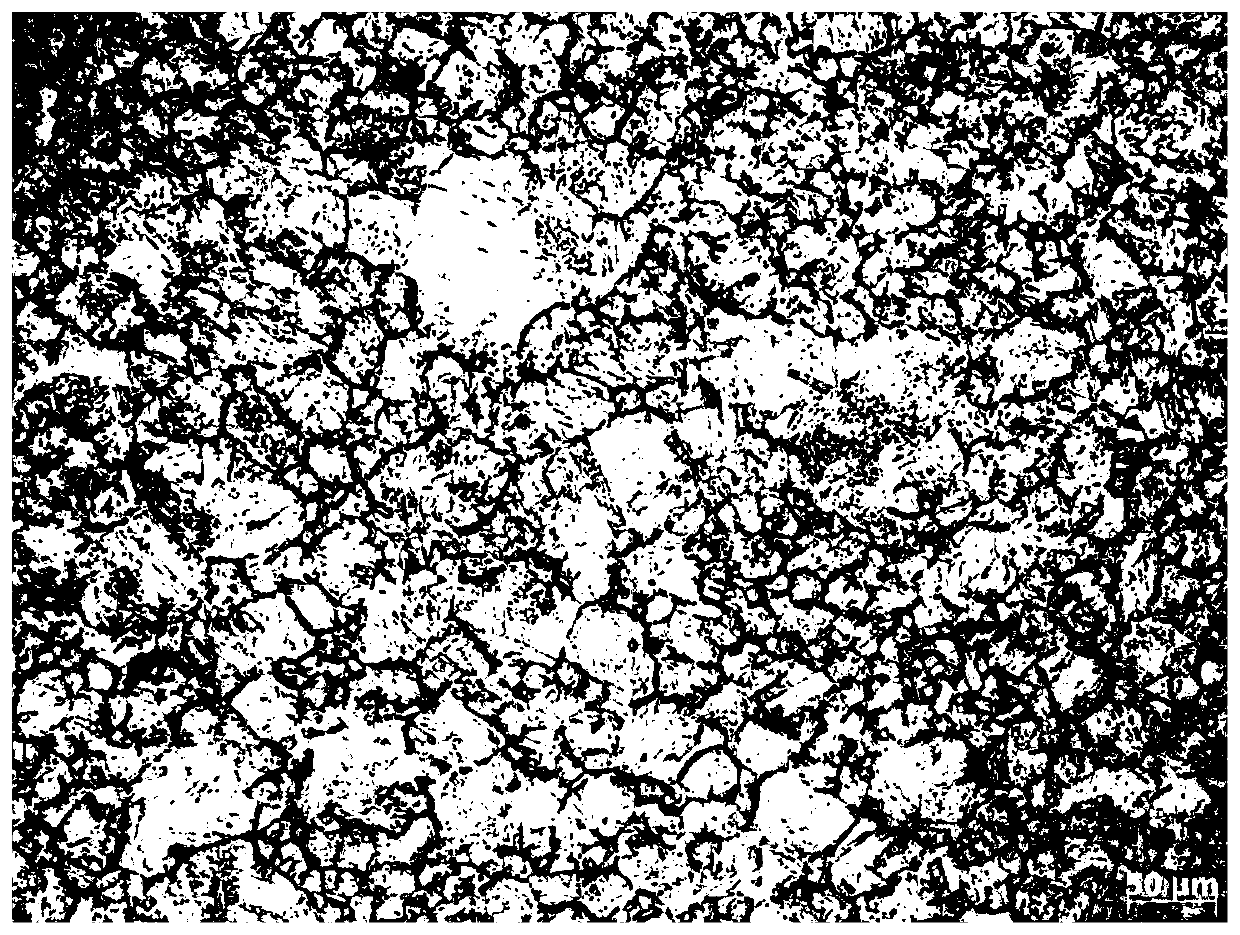

Corrosion method for quickly, simply, conveniently and clearly displaying original austenite grain boundary of pipeline steel

InactiveCN111060384AReduce unsafe hazardsOperational securityPreparing sample for investigationAustenite grainSafe operation

The invention belongs to the technical field of metallographic detection, and particularly relates to a corrosion method for rapidly, simply, conveniently and clearly displaying the original austenitegrain boundary of pipeline steel. The corrosion method comprises the following steps: (1) carrying out conventional austenitizing heat treatment to obtain a quenched pipeline steel corrosion sample;(2) putting the polished surface of the sample upwards into an ultrasonic cleaner which is heated to 65-80 DEG C and contains a containing corrosive solution, and carrying out vibration etching for 2-5 minutes; and (3) taking out the sample, carrying out cleaning, blow-drying the polished surface of the sample treated in the step (2), and observing the sample under an optical microscope. The corrosion method provided by the invention can quickly, simply, conveniently, clearly and completely display the original austenite grain boundary of the quenched pipeline steel, and has the characteristics of simple and safe operation and high corrosion efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Corrosive liquid, and preparation method and application thereof

InactiveCN112812776ASmall sizeNot destroyedPolycrystalline material growthAfter-treatment detailsSodium acetateSolar energy conversion efficiency

The invention provides a corrosive liquid, and a preparation method and application thereof. The corrosive liquid is prepared from, by mass, 0.5-4.5% of alkali, 0.01-0.225% of potassium sorbate, 0.01-0.225% of sodium acetate, 0.005-0.15% of sodium dodecyl benzene sulfate, 0.055-0.46% of a de-foaming agent, 0.055-0.78% of a surfactant, 0.035-0.42% of a dispersing agent, 0.47-4.42% of a functional auxiliary agent, and the balance of water. When the corrosive liquid is used for preparing a substrate layer, the corrosive liquid can control the back surface of a substrate to form a relatively uniform pyramid-shaped suede, can ensure that an emitter layer on the front surface of the substrate is not damaged, and can control the size of the pyramid to keep a relatively low pyramid-shaped height-width ratio, so that the specific surface area of the suede on the back surface is reduced, the back surface passivation is facilitated, and the composition is reduced; and the solar energy conversion efficiency of the N-type contact cell is improved.

Owner:CSI CELLS CO LTD +1

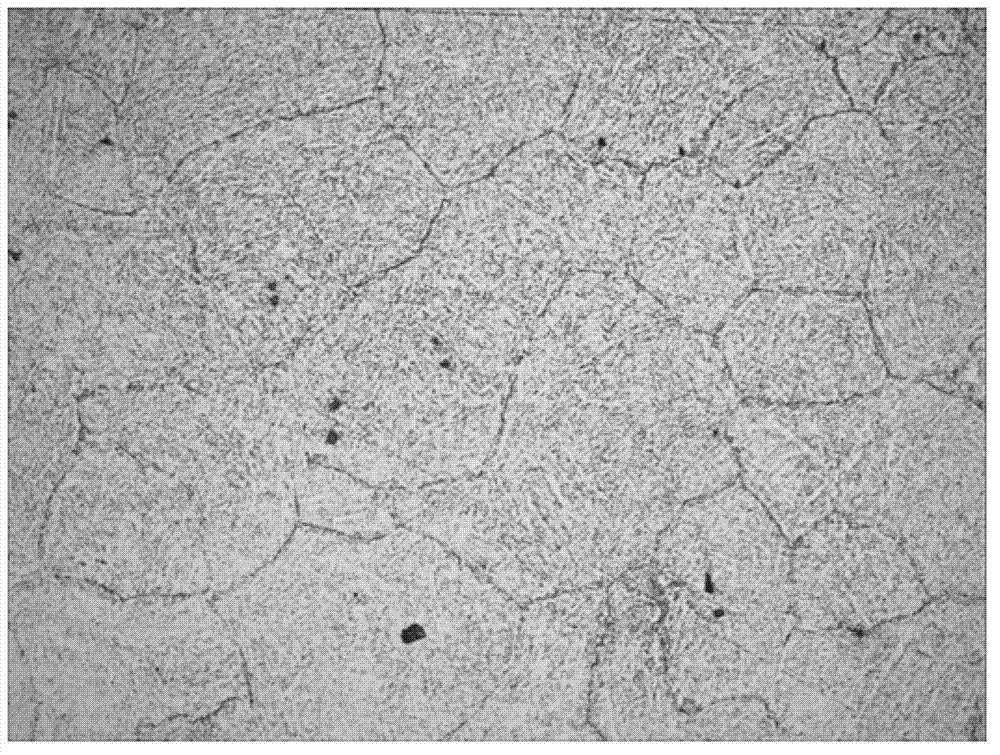

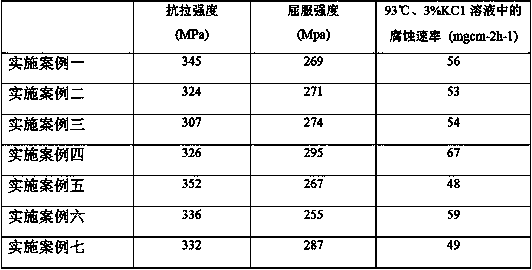

Low-cost rapid-corrosion magnesium alloy and preparation method thereof

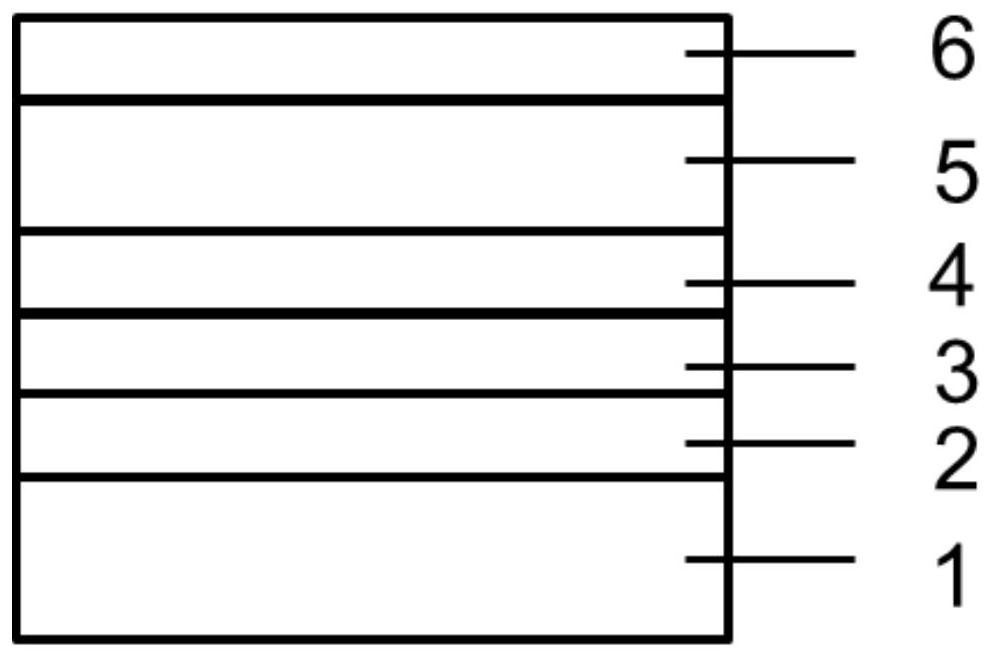

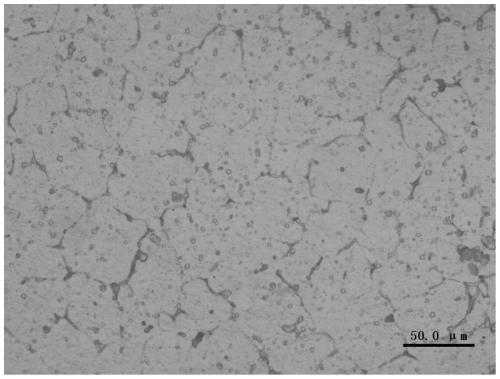

The invention discloses a low-cost rapid-corrosion magnesium alloy and a preparation method thereof. The alloy comprises the following elements of, by mass, 3.0wt%-25wt% of Al, 0.20wt%-1.0wt% of Ca, 2.0wt%-15wt% of Zn, 1.20wt%-3.0wt% of Cu, 1.50wt%-5.0wt% of Fe and the balance Mg and other impurity elements. According to the low-cost rapid-corrosion magnesium alloy and the preparation method thereof, a Mg-Al-Ca-Zn-Cu-Fe alloy is adopted, the grain size of a cast ingot is refined through the Ca, then the segregation of the cast ingot is reduced, the Cu and the Fe in the material are uniformly distributed, fine dispersed Mg2Cu and Mg2Fe are formed, and the purpose of rapid corrosion dissolution is achieved; meanwhile, the basal texture of the magnesium alloy is weakened, so that the elongation of the material is improved; and in addition, the Ca has flame-retardant and anti-oxidation effects, so that the ignition point of the alloy is improved, and therefore, the using amount of protective gas is reduced in the smelting process, and no gas protection is required during the homogenization process.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

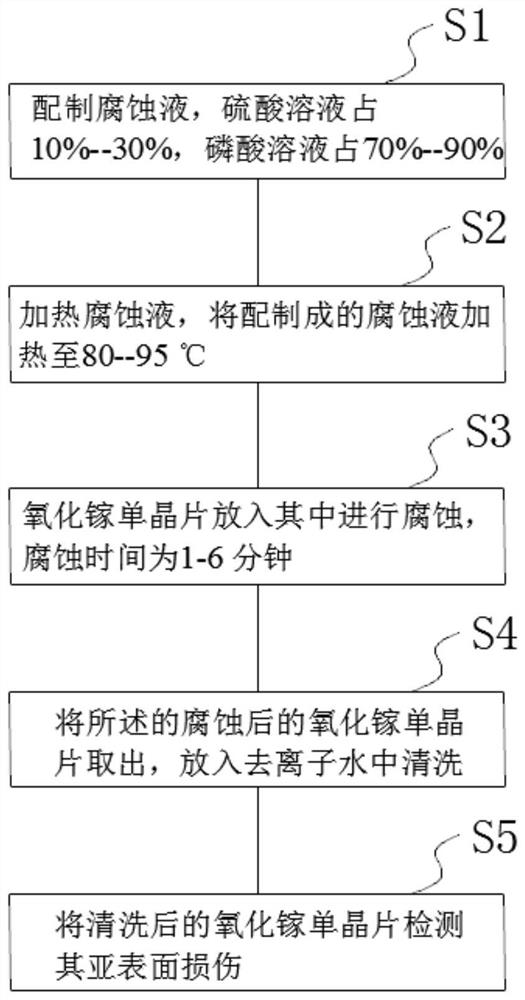

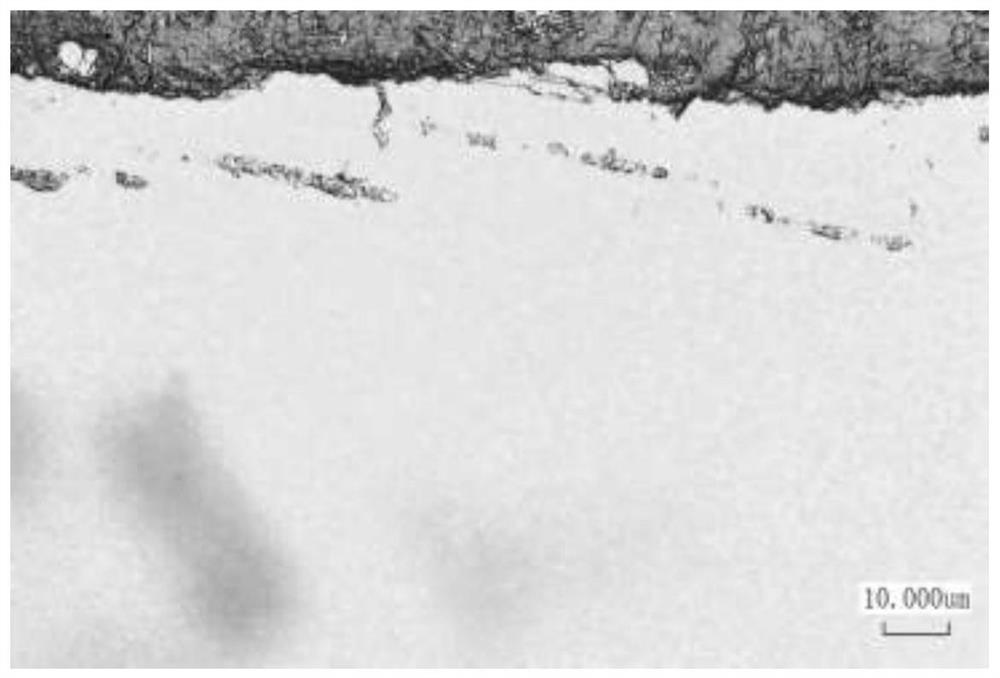

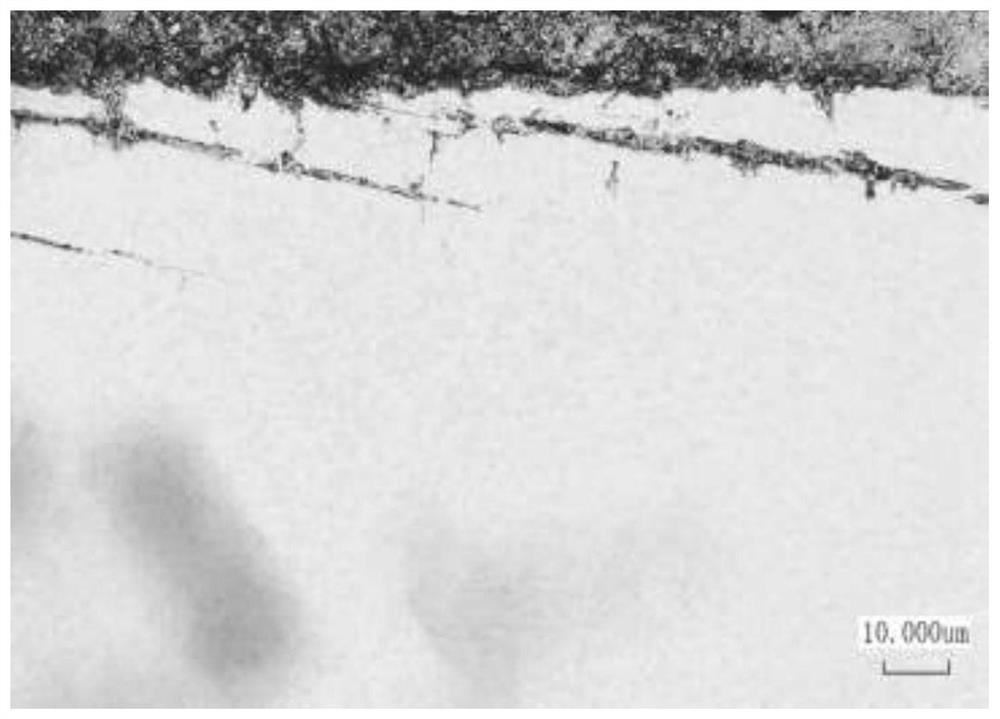

Corrosive liquid for detecting layer damage layer after gallium oxide single crystal processing and detection method

PendingCN111829941AAccelerated corrosionLow corrosion temperatureWeather/light/corrosion resistanceOptically investigating flaws/contaminationO-Phosphoric AcidSingle crystal

The invention discloses a corrosive liquid for detecting surface layer damage after gallium oxide single crystal processing and a corrosion method. The corrosive liquid comprises a sulfuric acid solution and a phosphoric acid solution, wherein the sulfuric acid solution accounts for 10%-30% by volume, and the concentration is not lower than 98%, and the phosphoric acid solution accounts for 70-90%, and the concentration is not lower than 85%. The detection method comprises the following steps: preparing the corrosive liquid which comprises the following components in percentage by volume: 10-30% of sulfuric acid solution with the concentration not less than 98%, and 70-90% of the phosphoric acid solution with the concentration not lower than 85%; heating the corrosive liquid: heating the prepared corrosive liquid to 80-95 DEG C; carrying out corrosion: putting the gallium oxide single crystal wafer into the liquid for corrosion, wherein the corrosion time is 1-6 minutes; carrying out cleaning: taking out the corroded gallium oxide single crystal wafer, and cleaning the gallium oxide single crystal wafer in deionized water; and carrying out detecting: detecting the sub-surface damage of the cleaned gallium oxide single crystal wafer. The corrosive liquid provided by the invention has very good selective corrosivity, the surface layer damage of the corroded gallium oxide single crystal is clearly displayed, the corrosion temperature is relatively low, and the rate is high.

Owner:YANCHENG INST OF TECH

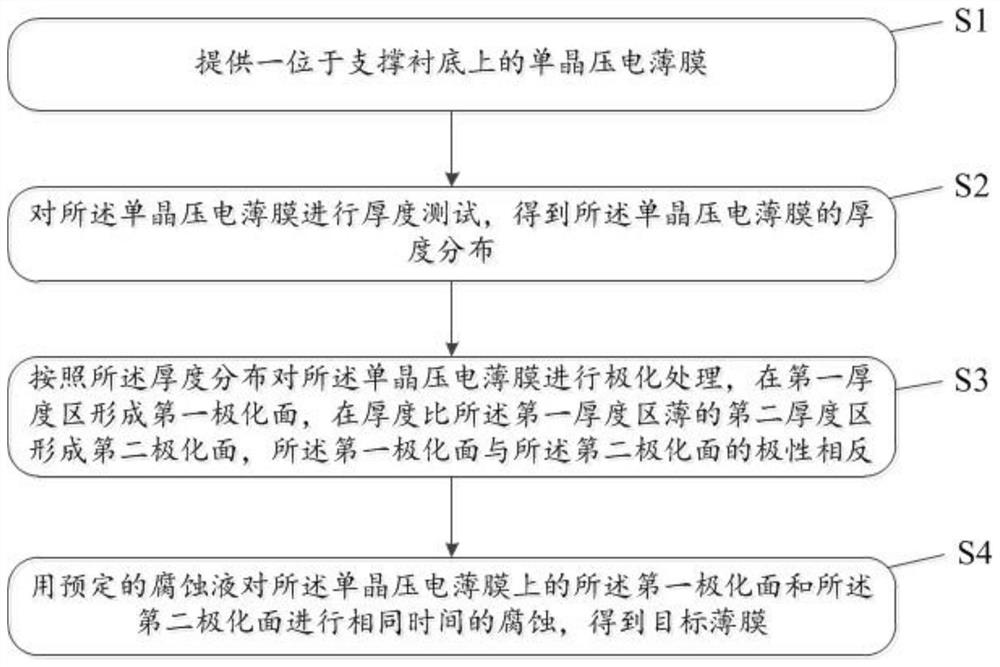

Method for improving thickness uniformity of single crystal piezoelectric film

ActiveCN111834519AImprove thickness uniformityFast corrosion rateSemiconductor/solid-state device testing/measurementPiezoelectric/electrostrictive/magnetostrictive devicesThin membraneSingle crystal

The invention discloses a method for improving the thickness uniformity of a single crystal piezoelectric film, and belongs to the technical field of semiconductor manufacturing. According to the method for improving the thickness uniformity of the single crystal piezoelectric film, polarization processing is carried out according to the thickness distribution of the single crystal piezoelectric film on a support substrate, a first polarization surface is formed in a first thickness region, a second polarization surface is formed in a second thickness region which is thinner than the first thickness region, and the polarities of the first polarization surface and the second polarization surface are opposite. The anisotropic characteristic of the piezoelectric single crystal material is utilized, under the same corrosive liquid, the first polarization surface obtained through polarization of a thicker area is corroded at a high speed, and the second polarization surface obtained throughpolarization of a thinner area is corroded at a low speed, so that differential corrosion of different polarization surfaces of the single crystal piezoelectric film is achieved. Compared with the prior art, the method has the advantages that the thickness uniformity of the single crystal piezoelectric film can be optimized, and the thickness uniformity of the single crystal piezoelectric film isgreatly improved.

Owner:SHANGHAI NOVEL SI INTEGRATION TECH CO LTD

mos transistor and method of making the same

ActiveCN105448982BFast migration rateFast corrosion rateSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMechanical engineering

Owner:SEMICON MFG INT (SHANGHAI) CORP

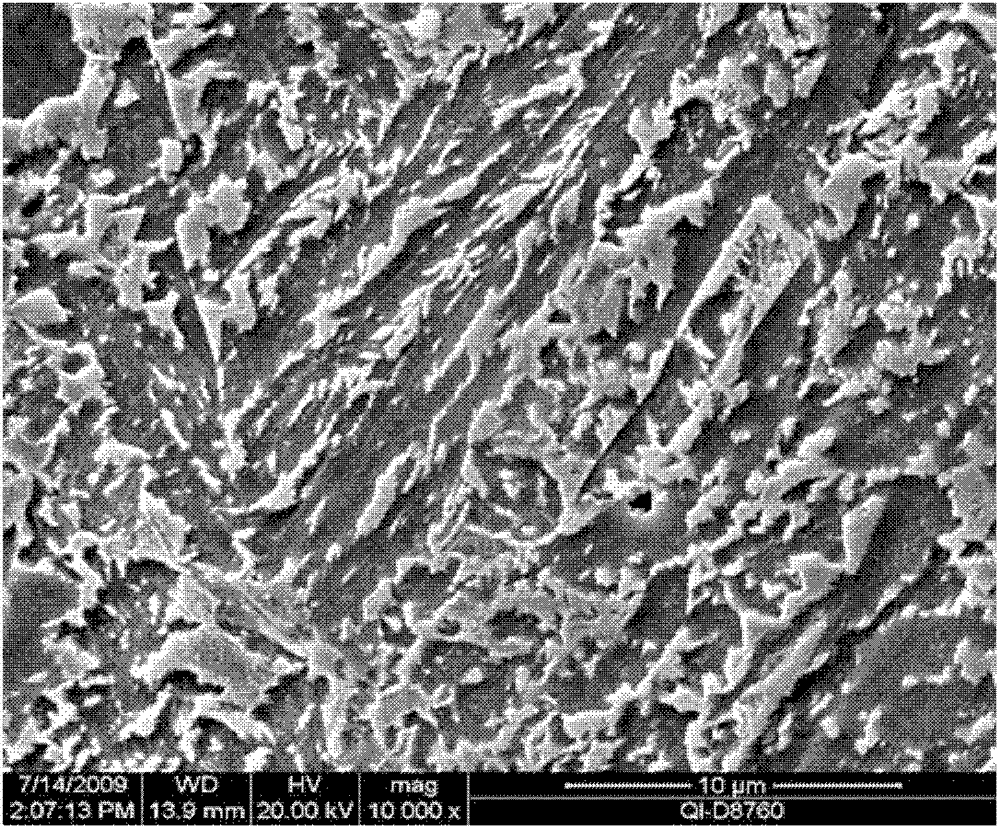

A surface-treated metal and a method for surface treatment thereof, a metal-resin composite and a preparation method thereof

ActiveCN103451701BIncrease corrosion rateReduce corrosion rateAnodisationPore diameterAnodic oxidation

The invention provides a surface treated metal and a surface treatment method thereof and a metal resin complex and a preparation method of the metal resin complex. The surface treated metal comprises a metal body and an anodic oxidation film layer which is located on the surface of the metal body, the anodic oxidation film layer includes a barrier layer which is in contact with the metal body and a loose layer located on the outer surface of the barrier layer, the loose layer contains anodic oxidation film micropores, the pore diameter of the anodic oxidation film micropores is 10 nm-800 mum, the barrier layer contains barrier layer corrosion pores, the pore diameter of the barrier layer corrosion pores is 10 nm-800 mum, the metal body includes a corrosion layer which is in contact with the barrier layer, the corrosion layer contains metal corrosion pores, the pore diameter of the metal corrosion pores is 10 nm-1 mm, the metal is aluminum alloy or aluminum, the bonding force between the metal and resin is strong, and the surface treated metal is simple in process, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

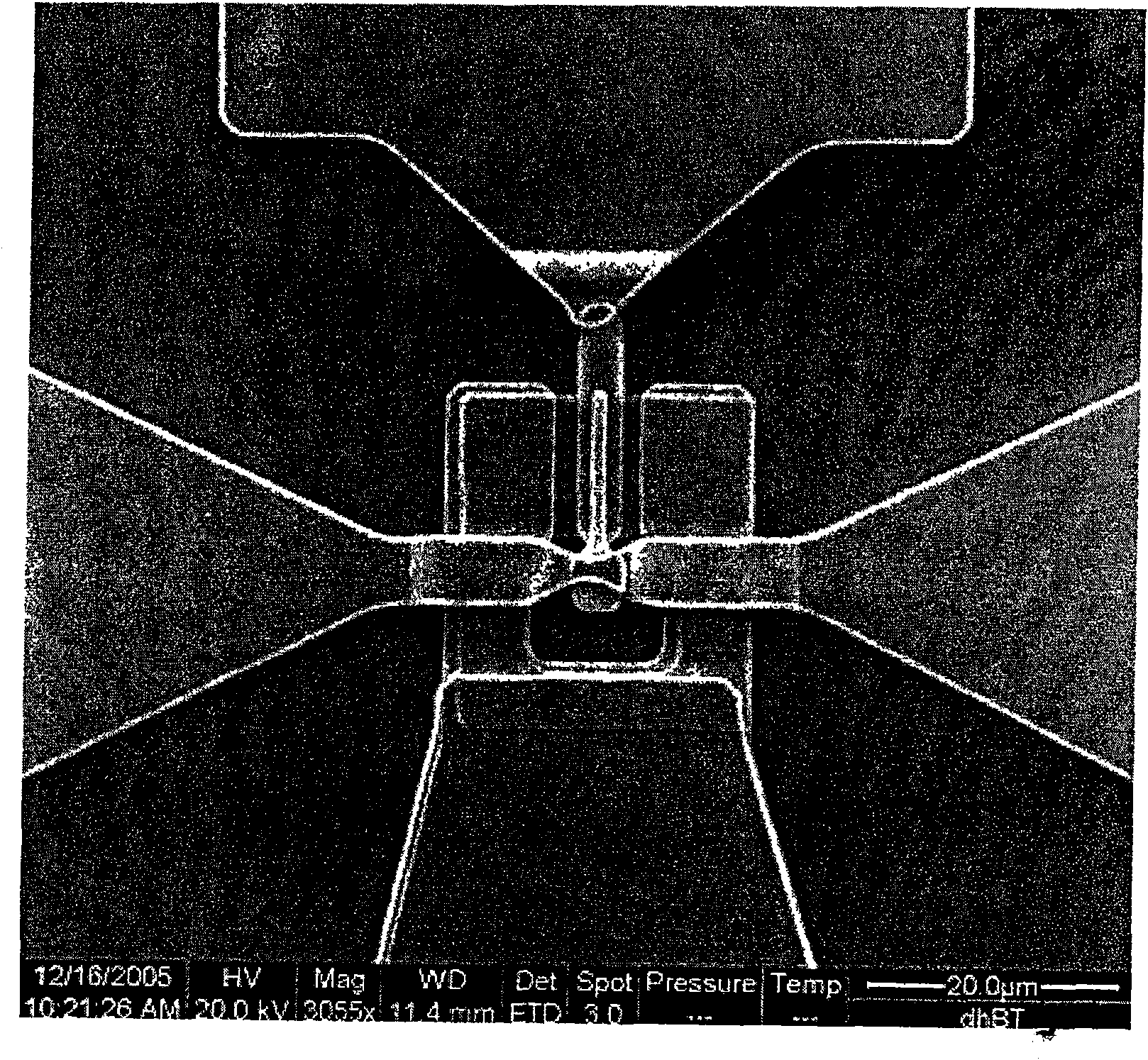

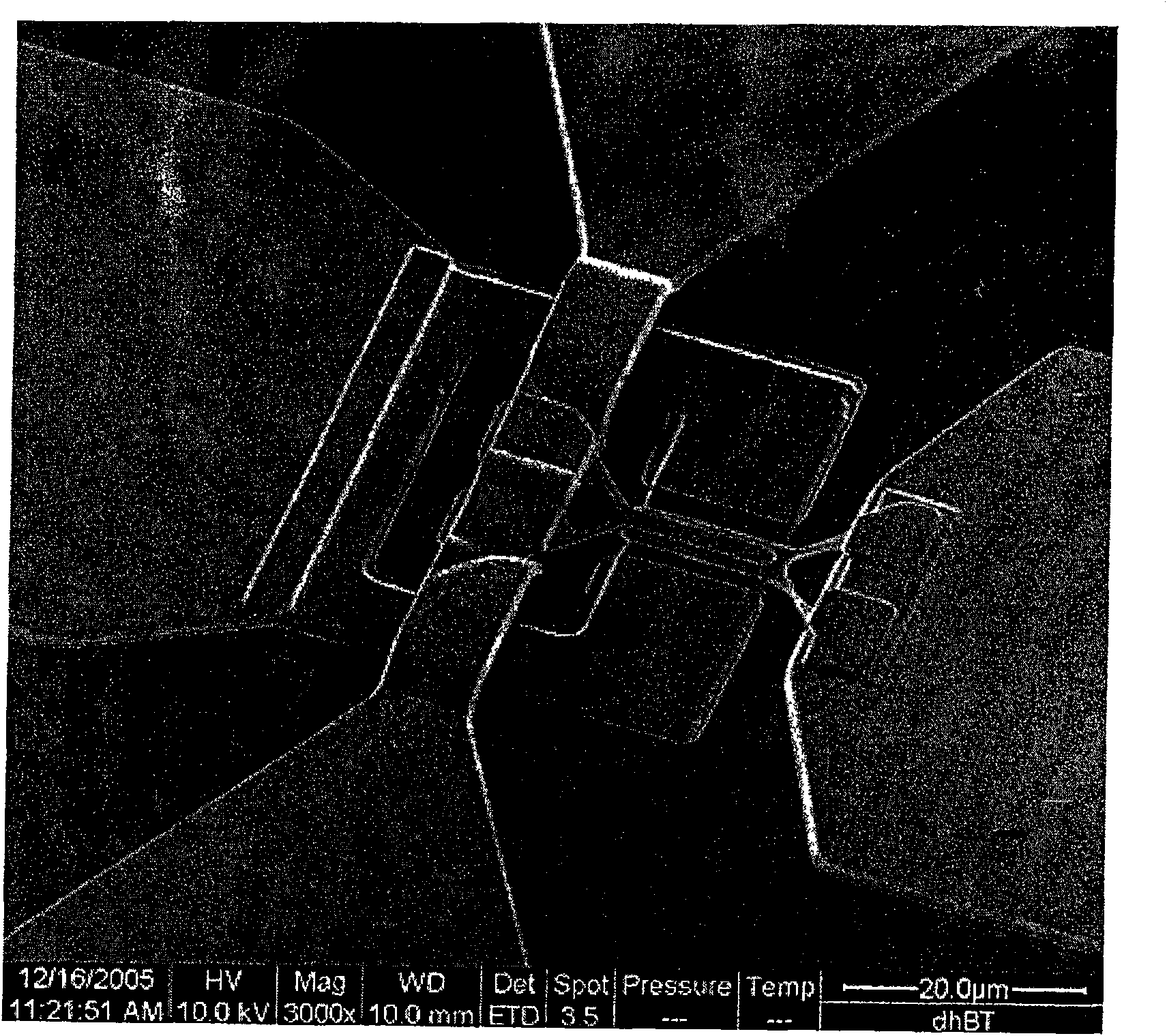

Method for eliciting sub-micron HBT emitter/HEMT grid

ActiveCN100580898CDecontaminationPoor contactSolid-state devicesSemiconductor/solid-state device manufacturingProcess complexityDielectric layer

The invention discloses a method for eliciting sub-micron HBT emitter / HEMT grid, comprising the following steps: a sacrificial dielectric layer is manufactured on manufactured sub-micron HBT emitter metal / HEMT grid metal; the HBT emitter metal / HEMT grid metal provided with the sacrificial dielectric layer is formed by peeling; the substrate is coated with smoothing material on the surface provided with the HBT emitter / HEMT grid, so as to smooth the surface of the substrate; the smoothing material is etched and the sacrificial dielectric layer is exposed; the sacrificial dielectric layer is removed and the metal which requires interconnect is exposed; and the metal are interconnected by photo-etching and evaporating after washing. The method can be adopted to improve reliability and stability of elicitation and reduce process complexity.

Owner:北京中科微投资管理有限责任公司

A method for transferring a vertically structured LED chip substrate without loss of edge

ActiveCN108878596BExcellent substrate transfer processSolve the problem of fragmentationSemiconductor devicesEngineeringMaterials science

The invention discloses a transferring method of an edge-free vertical structure LED chip substrate. The transferring method of the edge-free vertical structure LED chip substrate comprises a metal layer depositing step, an epitaxial wafer surface treatment step, a substrate deposition transferring step, a bonding step, a thinning step, a residual silicon removal step, and a vertical LED chip preparation step. The transferring method of the edge-free vertical structure LED chip substrate disclosed by the invention can solve the problems in the current substrate transferring process by means ofthe epitaxial wafer surface treatment step, the thinning step, the residual silicon removal step and the like, which can obtain a comparatively excellent substrate transferring technology.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

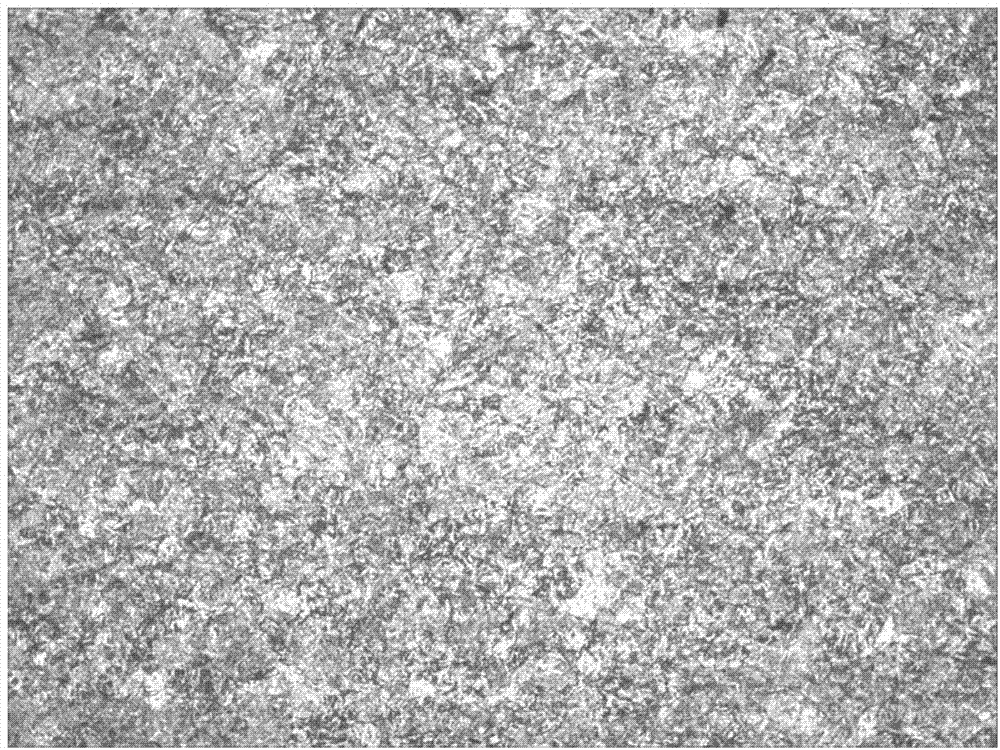

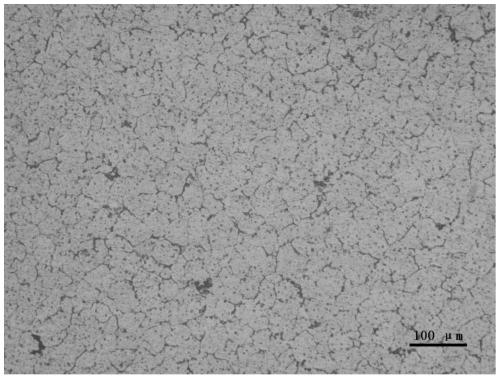

A kind of etchant and corrosion method for displaying aluminum-magnesium alloy metallographic structure

InactiveCN108893772BImprove the display effectFast corrosion ratePreparing sample for investigationMg alloysO-Phosphoric Acid

The invention discloses a corrosive agent for displaying the metallographic structure of an aluminum-magnesium alloy. The corrosive agent comprises an electrolytic corrosive agent and a chemical corrosive agent, wherein the electrolytic corrosive agent is composed of a sulfuric acid solution having the concentration of 18.4 mol / L, glycerin and water, and the volume ratio of the sulfuric acid solution to the glycerin to the water is 50-58: 20-40: 22; and the chemical corrosive agent is a phosphoric acid solution with the volume fraction of 20%, can make the metallographic structure of the corroded aluminum-magnesium alloy visible under an ordinary optical microscope, and has a good corrosion effect. The invention also discloses a corrosion method for displaying the metallographic structureof the aluminum-magnesium alloy. The method is simple in operation, and can be applied to the preparation of a metallographic specimen of the aluminum-magnesium alloy.

Owner:XIAN UNIV OF TECH

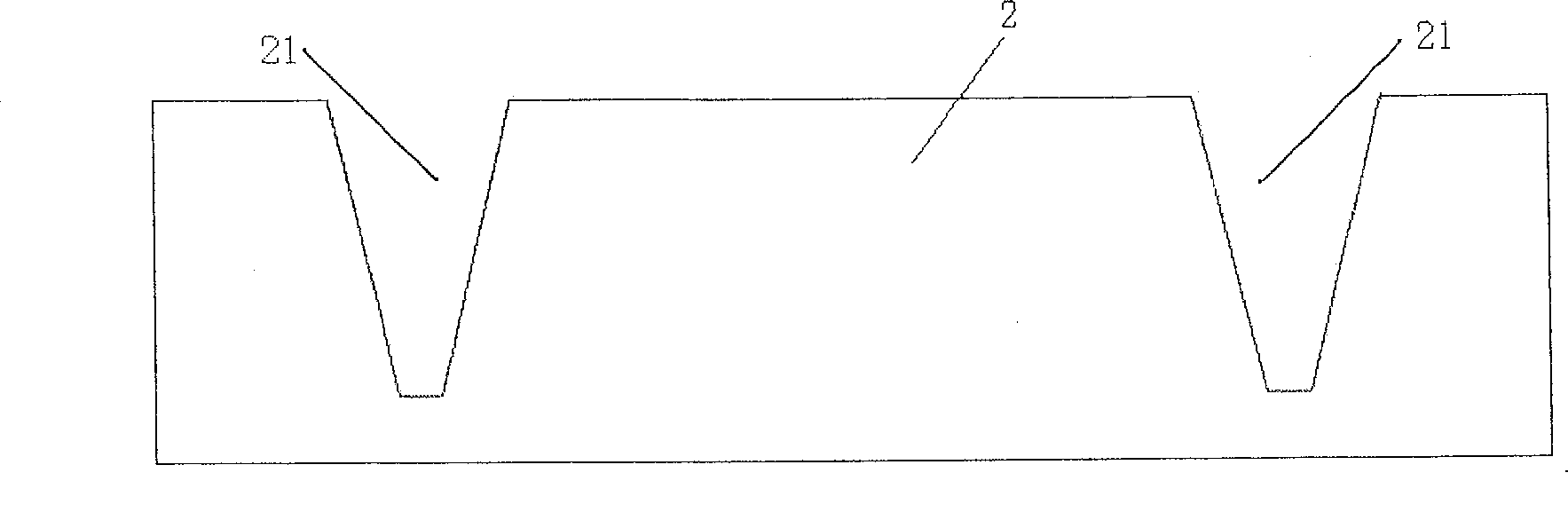

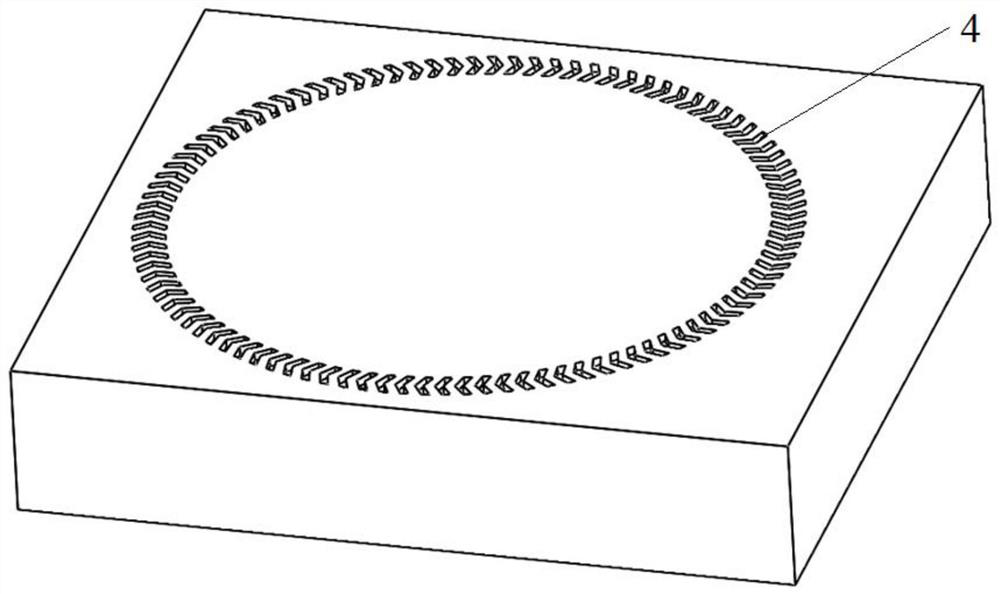

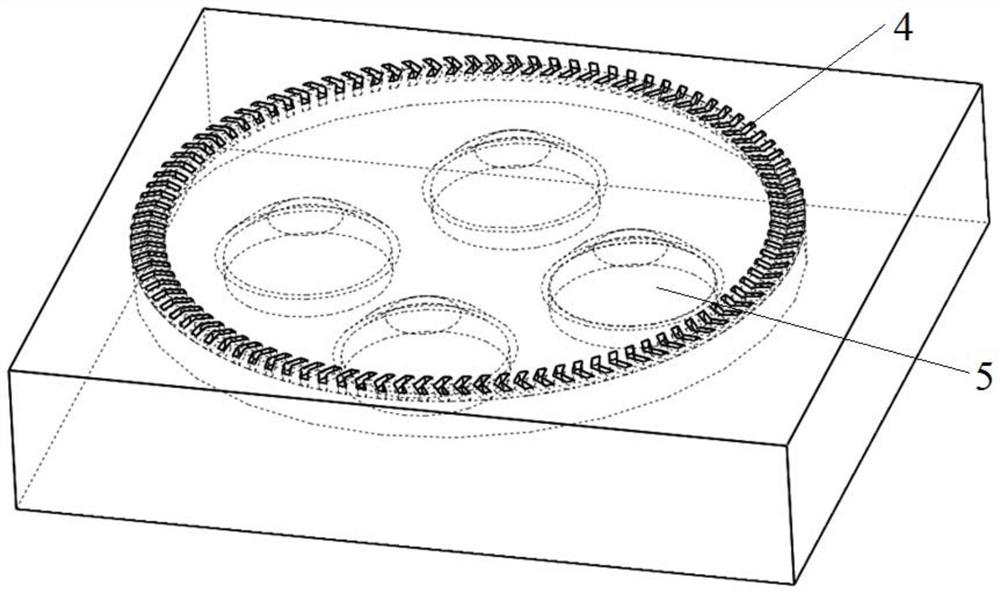

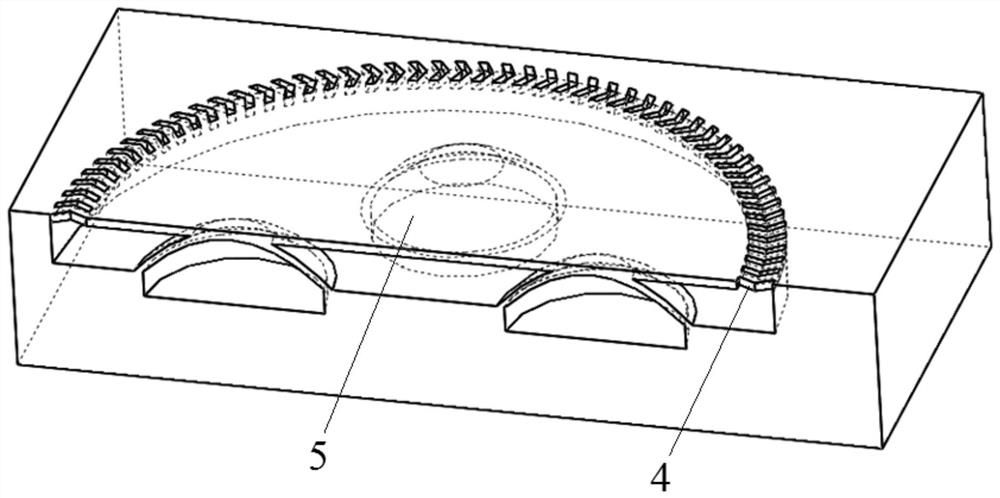

A pmut unit driven by an embedded arched film and its preparation method

ActiveCN111644362BChange structureChange the proportional relationshipPrecision positioning equipmentSoldering apparatusPMUTThin membrane

The invention discloses a PMUT unit driven by embedded arch thin films and a preparation method thereof. The PMUT unit comprises vibration thin films, a driving layer and a substrate sequentially arranged from top to bottom, wherein the driving layer comprises a supporting structure and a driving structure, the substrate comprises a back cavity and a base, and the back cavity is formed by the driving layer and the base in an enclosing mode; and the driving structure is provided with a horizontal part and a plurality of arch parts, the arch parts are marked as the embedded arch driving films, the embedded arch driving films are located right above the back cavity, and the lower end surface of the horizontal part is connected with the upper end surface of the base. According to the PMUT unit, the purpose of improving the resonant frequency under the condition of the same area of the vibration thin films is achieved, electrodes and the driving layer are sealed in the back cavity, only thevibration thin films playing a role in vibration and support make contact with the outside, and the direct contact between the sensitive element part of a PMUT chip and the outside is completely isolated, so that PMUT is more durable.

Owner:XI AN JIAOTONG UNIV

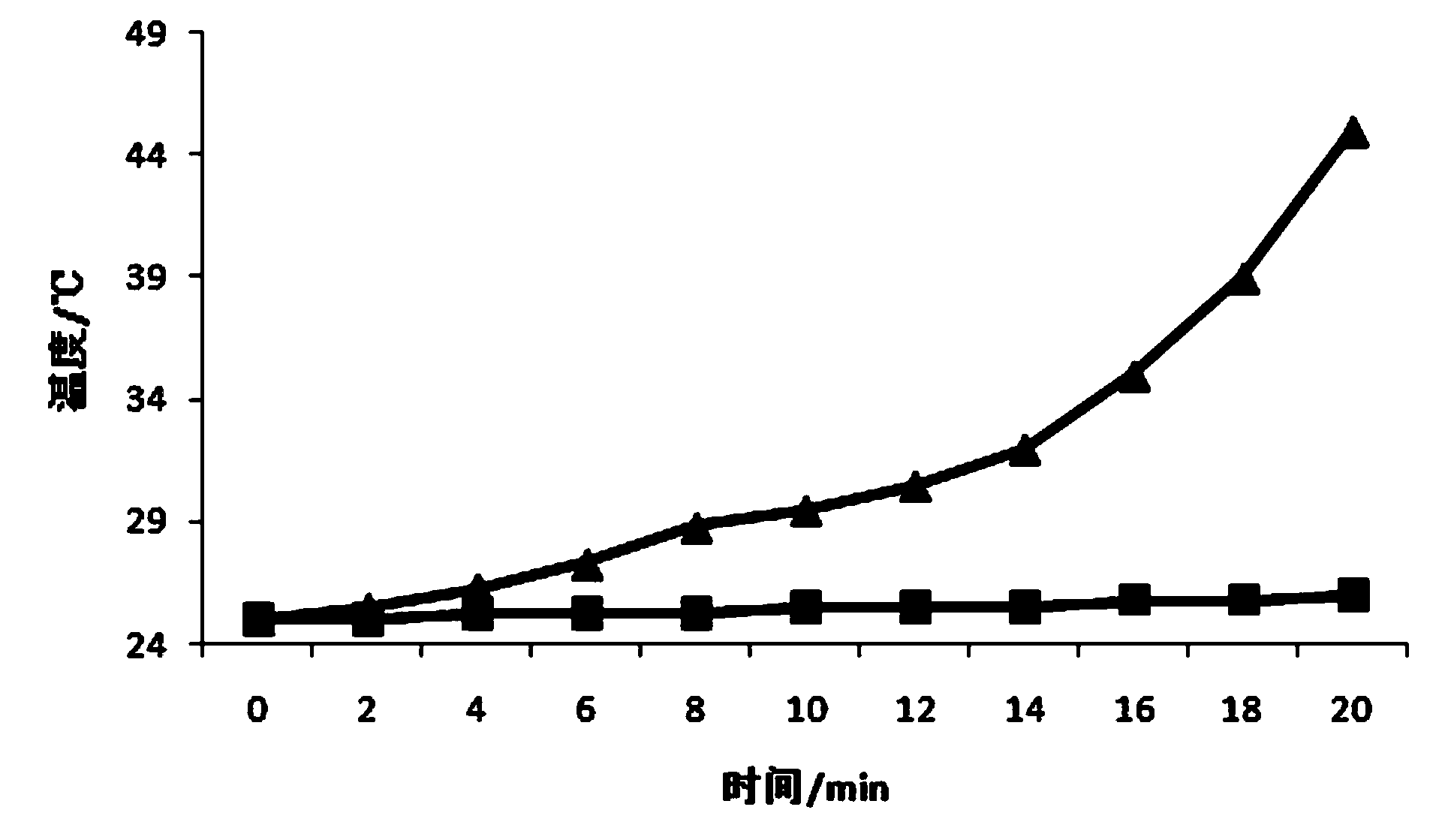

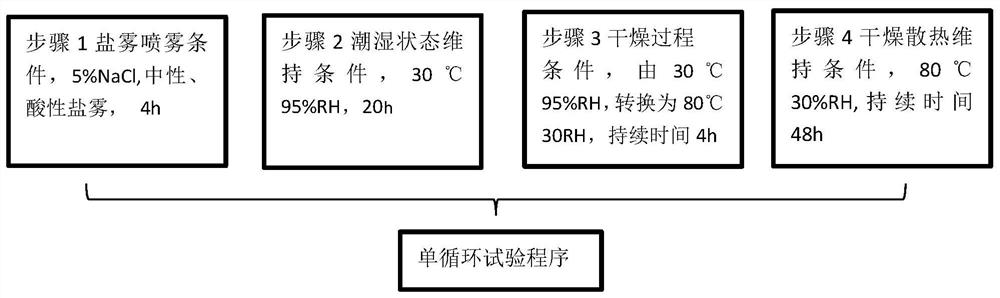

Test method for accelerating reproduction of salt spray corrosion pulverization effect of binding post of electric energy meter

ActiveCN111829942AFast corrosion rateImprove test efficiencyWeather/light/corrosion resistanceTest efficiencyHigh humidity

The invention relates to a test method for accelerating reproduction of the salt spray corrosion pulverization effect of binding posts of an electric energy meter. The method comprises the following steps of: step 1, spraying salt spray to the binding post of the electric energy meter in a standard neutral salt spray test box, and continuously spraying the salt spray for 4 hours; 2, after finishing spraying, transferring the binding post of the electric energy meter into a damp-heat test box, and duration time being 20 h; 3, keeping the binding post of the electric energy meter in the damp-heat test box, and converting from a low-temperature and high-humidity damp stage to a high-temperature and low-humidity drying stage for 4 hours; step 4, maintaining a drying stage, and continuing the drying stage for 48 hours; and 5, repeating the steps 1-4 until a corrosion form distribution type and a corrosion area proportion are close to the actual corrosion form distribution type and corrosionarea proportion. Compared with constant and alternating salt spray test conditions in general standards, the test method has the advantages of higher corrosion speed and greatly improved test efficiency.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

A kind of low-cost rapid corrosion magnesium alloy and preparation method thereof

The invention discloses a low-cost rapid corrosion magnesium alloy and a preparation method thereof. The mass percentage of each element in the alloy is: Al: 3.0-25wt%, Ca: 0.20-1.0wt%, Zn: 2.0-15wt%, Cu: 1.20-3.0wt%, Fe: 1.50-5.0wt%, the balance is Mg and other impurity elements. The invention adopts the Mg-Al-Ca-Zn-Cu-Fe alloy to refine the grain size of the ingot through Ca, thereby reducing the segregation of the ingot, so that the Cu and Fe in the material are evenly distributed, and finely dispersed Mg is formed. 2 Cu and Mg 2 Fe, achieves the purpose of rapid corrosion and dissolution; at the same time, it weakens the basal texture of magnesium alloys, thereby improving the elongation of the material. In addition, Ca itself has flame retardant and anti-oxidation effects, which improves the ignition point of the alloy. Thus, the amount of shielding gas is reduced during the smelting process; no gas shielding is required during the homogenization process.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Gallium arsenide surface chemical etching method and chemical etchant

ActiveCN102618936BFast corrosion rateImprove corrosion efficiencyAfter-treatment detailsEtchingWafering

The invention provides a method for chemical etching of gallium arsenide wafers, which includes: using metal cleaner to rinse the gallium arsenide wafers; rinsing the gallium arsenide wafers in ammonia water; putting the gallium arsenide wafers into chemical etchant, etching the surface of each chip at 10-40 DEG C; using deionized water to flush the surface of each chip; and drying the chips. The invention further provides the chemical etchant for chemical etching of the gallium arsenide wafers, which comprises, in mass ratio, 3.2-20% of ammonia water, 8.3-33.0% of hydrogen peroxide and water. By the effective etching process using the chemical liquor, chip affected layers caused by machining procedures are removed, internal stress of the wafers is eliminated, the wafers meeting the requirement on epitaxial growth back roughness are produced, and the wafers have uniform backs and are free of back invasion and back scratch.

Owner:BEIJING TONGMEI XTAL TECH CO LTD

pmos transistor and its manufacturing method

ActiveCN104217956BIncrease migration rateIncrease filling volumeSemiconductor/solid-state device manufacturingSemiconductor devicesCharge carrierP channel

Owner:SEMICON MFG INT (SHANGHAI) CORP

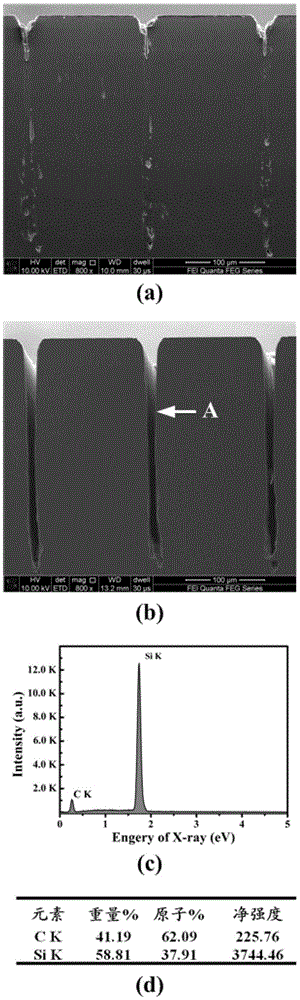

A kind of preparation method of silicon carbide microstructure

ActiveCN103441063BNo pollution in the processGood corrosion selectivityDecorative surface effectsSemiconductor/solid-state device manufacturingRefractive indexImpurity

The invention discloses a method for preparing silicon carbide micro-structures. The method includes the steps that in a gaseous environment, femtosecond laser irradiation is utilized, a refractive index change region is generated on a silicon carbide substrate in an induced mode in a scanning mode, the refractive index change region is corroded and removed by mixed liquor of hydrofluoric acid and nitric acid, and then the silicon carbide micro-structures are prepared. The method is simple in technological process, and distribution of the micro-structures does not need to be defined by a mask plate. Compared with a current frequently-used wet etching method and a current frequently-used dry etching method, the method is better in corrosion selectivity, and an etching region is totally determined by a laser irradiation region. By the utilization of the method, a slot which is high in aspect ratio and free of being polluted by impurity elements can be prepared on the silicon carbide substrate by regulating and controlling laser irradiation parameters. The method can be applied to the field of semiconductor devices and a micro mechanical electronic system.

Owner:XI AN JIAOTONG UNIV

3Cr oil well pipe and production method thereof

InactiveCN102268602BLow threshold for resistance to hydrogen sulfide stress corrosionFast corrosion rateDrilling rodsDrilling casingsRare-earth elementImpurity

The invention discloses a 3Cr oil well pipe and a production method thereof, relates to a 3Cr oil well pipe for an acid oil-gas field and a manufacturing method thereof, and belongs to the technical field of metallurgy. The 3Cr oil well pipe comprises C, Si, Mn, S, P, Cr, Mo, V, Mo, Al, B, a rare-earth element and the balance of Fe and inevitable impurities. The production method for the 3Cr oil well pipe comprises the following steps of: selecting raw materials; smelting; continuously casting; continuously rolling; performing reheating and stretch sizing; and performing thermal refining. A treatment technology of removing stress by secondary sizing and hot straightening in the step of performing reheating and stretch sizing solves the technical problem that an S and CO2 resistant oil sleeve positioned in a hydrogen sulfide stress corrosion sensitive area has a low hydrogen sulfide stress corrosion resistant threshold value, is quickly corroded and is easily penetrated locally throughcorrosion.

Owner:WUXI SEAMLESS OIL PIPE

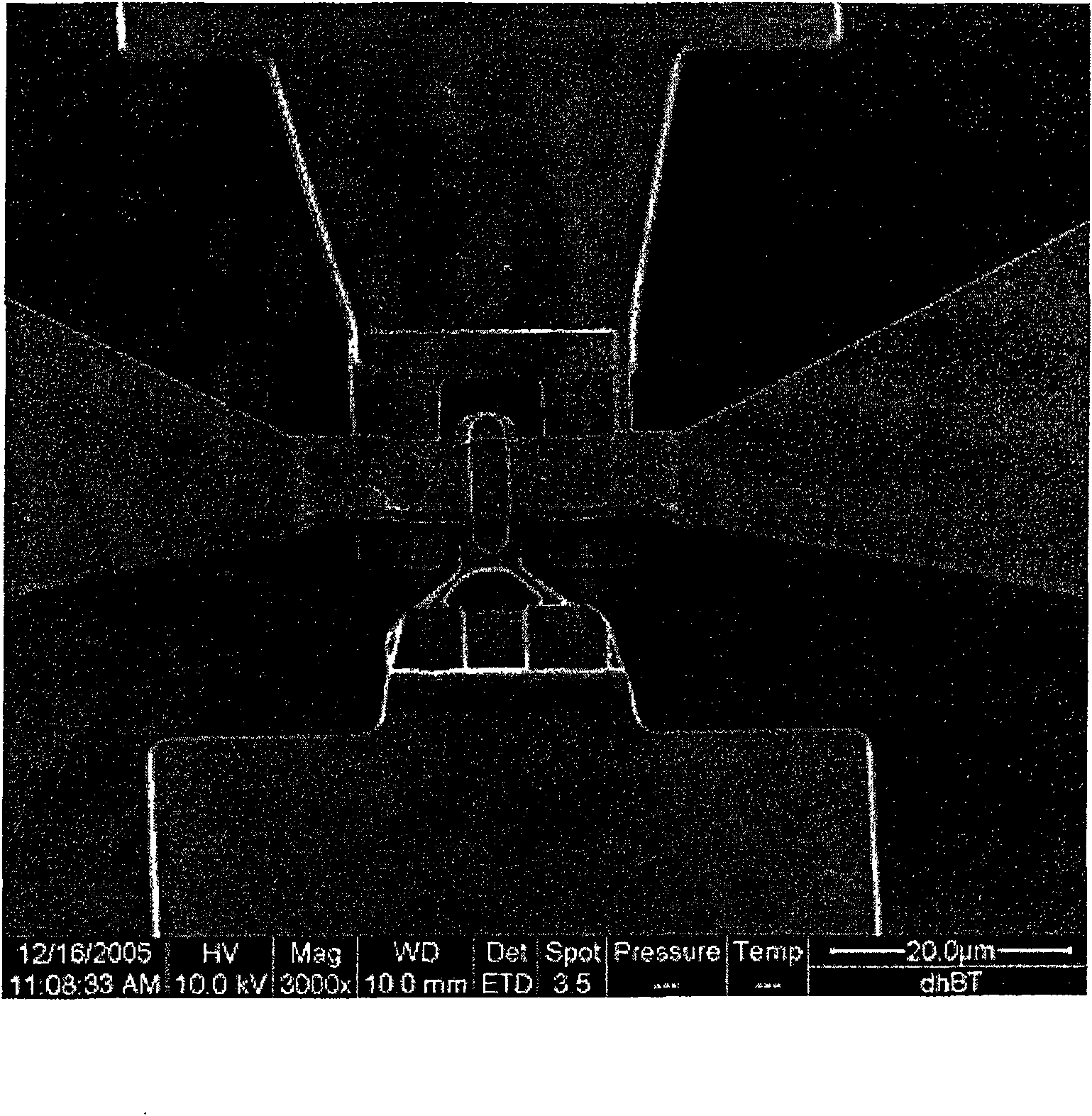

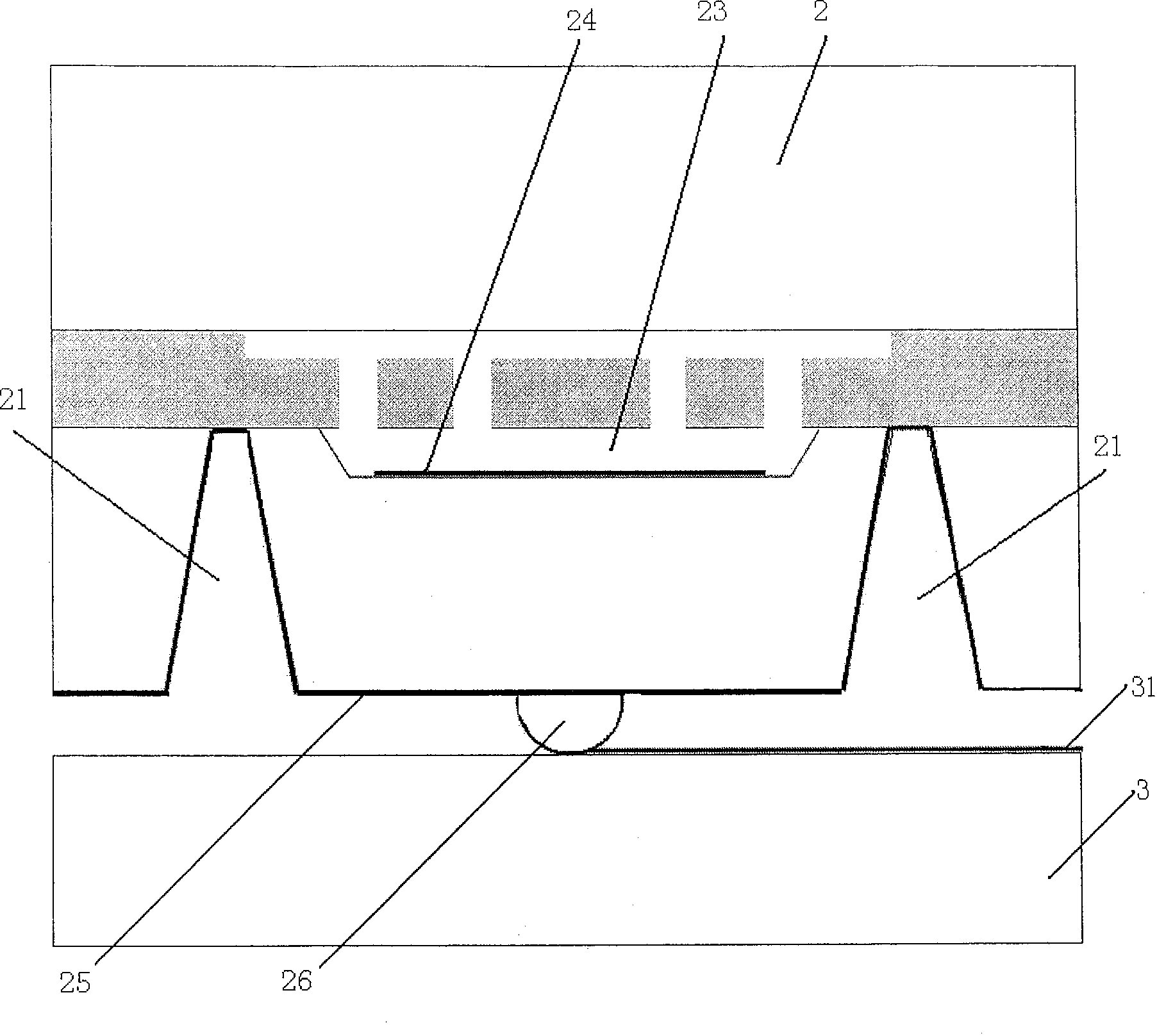

Wafer level vacuum encapsulation of microelectron mechanical system and upside-down mounting soldering method thereof

InactiveCN100513299CProtective structureHigh precisionSemi-permeable membranesPrecision positioning equipmentPass rateMicroelectromechanical systems

The invention relates to the wafer level vacuum package and the flip chip method of the microelectromechanical system, which comprises the following steps: nut cap glass sheets are perforated without getting through; tungsten alloy or chrome alloy is spattered on one side without perforating pin holes on the nut cap glass sheets and photoetching and corrosion are performed to form masks; the hydrofluoric acid is used to erode the glass cavity and erode through the pin holes without puncturing through; getter is spattered in the glass cavity; MEMS static electricity device structure wafers and the nut cap glass sheets are bonded by static electricity under the high temperature and the low pressure; metal electrodes are fabricated on the nut cap glass sheets and metal bumps are fabricated on the metal electrodes; single MEMS device chip after cutting is packaged with processing circuits by flip chip. The method package of the invention can be used in batch production, protect the MEMS device chips from outer pollution and damage and increase the pass-rate of production. The invention can be widely applied in the MEMS system.

Owner:PEKING UNIV

PMUT unit driven by embedded arch thin films and preparation method thereof

ActiveCN111644362AChange structureChange the proportional relationshipPrecision positioning equipmentSoldering apparatusPMUTThin membrane

The invention discloses a PMUT unit driven by embedded arch thin films and a preparation method thereof. The PMUT unit comprises vibration thin films, a driving layer and a substrate sequentially arranged from top to bottom, wherein the driving layer comprises a supporting structure and a driving structure, the substrate comprises a back cavity and a base, and the back cavity is formed by the driving layer and the base in an enclosing mode; and the driving structure is provided with a horizontal part and a plurality of arch parts, the arch parts are marked as the embedded arch driving films, the embedded arch driving films are located right above the back cavity, and the lower end surface of the horizontal part is connected with the upper end surface of the base. According to the PMUT unit, the purpose of improving the resonant frequency under the condition of the same area of the vibration thin films is achieved, electrodes and the driving layer are sealed in the back cavity, only thevibration thin films playing a role in vibration and support make contact with the outside, and the direct contact between the sensitive element part of a PMUT chip and the outside is completely isolated, so that PMUT is more durable.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com