Corrosive liquid, and preparation method and application thereof

A technology for corrosive liquids and substrates, which can be used in chemical instruments and methods, final product manufacturing, surface etching compositions, etc., and can solve problems such as corrosion and narrow application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides a kind of corrosion solution, comprises the potassium hydroxide of 2.6%, the potassium sorbate of 0.05%, the sodium acetate of 0.05%, the sodium dodecylbenzene sulfate of 0.05%, the defoamer of 0.5% (model LJ-618, manufacturer Beijing Ruilangjie), 0.2% surfactant (model ZJ-821, manufacturer Guangzhou Zhijing), 0.12% dispersant (model ZJ-855, manufacturer Guangzhou Zhijing) and the rest of the water .

[0054] The preparation method of the corrosion solution is as follows: stirring and mixing the above raw materials to obtain the corrosion solution.

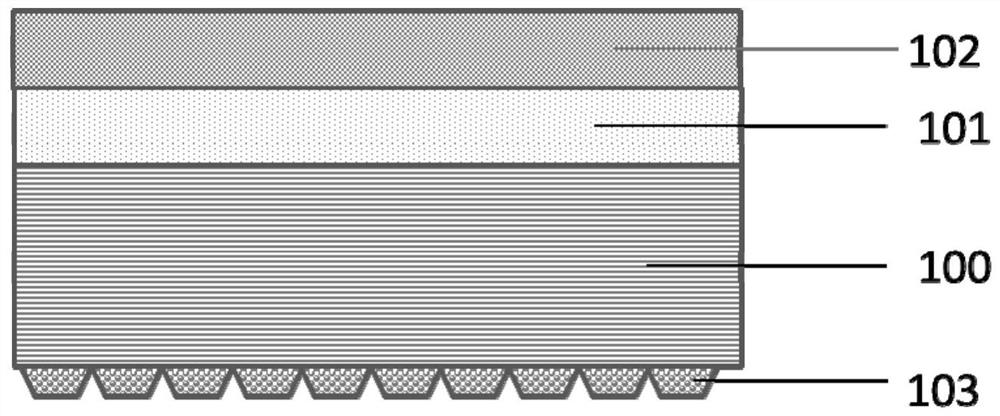

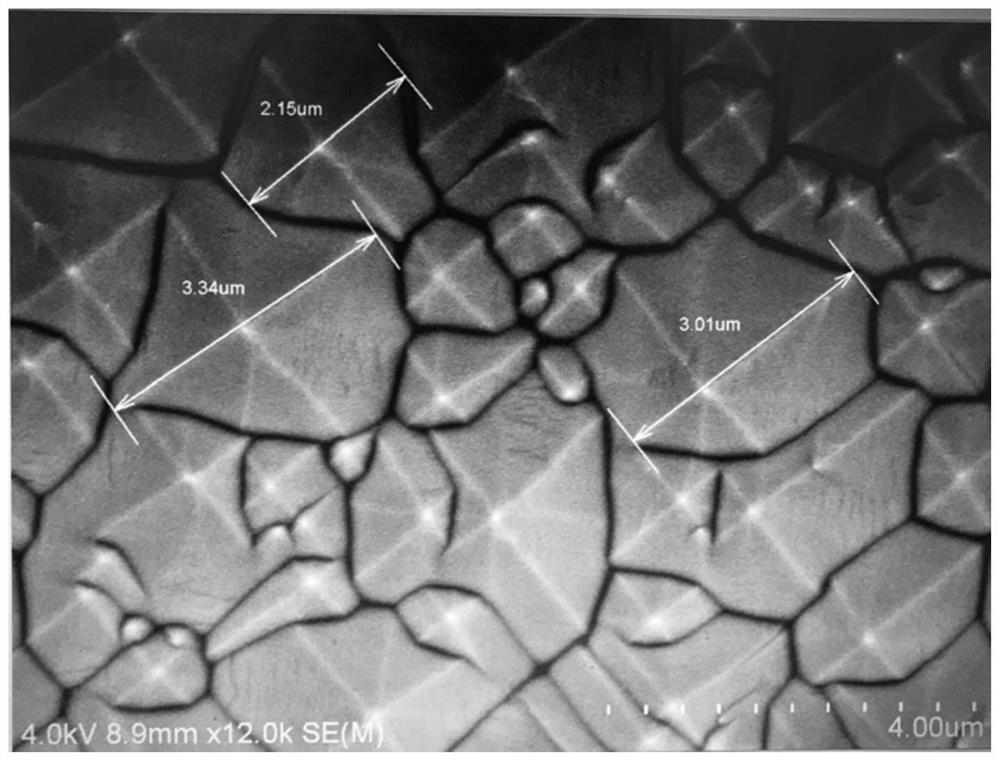

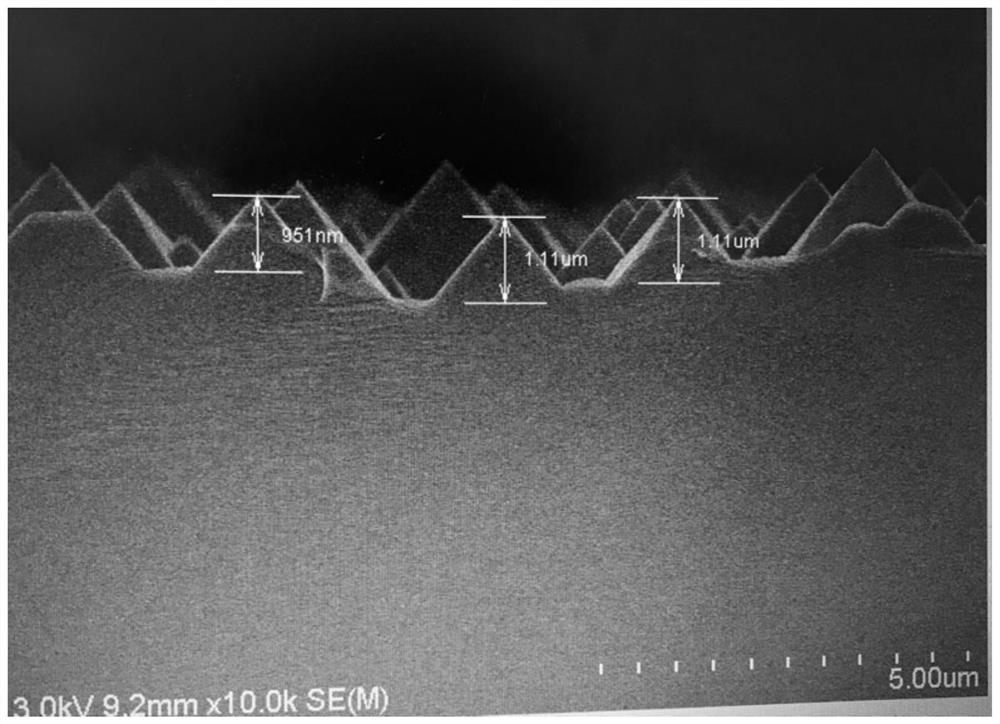

[0055] This embodiment also provides a substrate layer, such as figure 1 As shown, it includes an N-type base layer 100, an emitter layer 101 and a borosilicate glass layer 102 arranged in sequence on the front side of the N-type base layer, and a pyramid-shaped suede surface 103 arranged on the back side of the N-type base layer, and the suede surface is It is formed by etching with the above-men...

Embodiment 2

[0062] This embodiment provides a kind of corrosion solution, comprises the potassium hydroxide of 2.4%, the potassium sorbate of 0.105%, the sodium acetate of 0.015%, the sodium dodecylbenzene sulfate of 0.075%, the defoamer of 0.105% (Model LQ-0907, manufactured by Tianjin Kailangqi), 0.36% surfactant (model FP415, manufactured by Guangzhou Runhong), 0.066% dispersant (model 5027, manufactured by Runxin Chemical) and the rest of water.

[0063] The preparation method of the corrosion solution is as follows: stirring and mixing the above raw materials to obtain the corrosion solution.

[0064] This embodiment also provides a substrate layer, including an N-type substrate layer, an emitter layer and a borosilicate glass layer arranged in sequence on the front side of the N-type substrate layer, and a pyramid-shaped suede surface arranged on the back side of the N-type substrate layer , the suede is formed by etching with the above-mentioned corrosive solution.

[0065] The pr...

Embodiment 3

[0068] This embodiment provides a kind of corrosion solution, comprises the potassium hydroxide of 3%, the potassium sorbate of 0.0195%, the sodium acetate of 0.1%, the sodium dodecylbenzene sulfate of 0.012%, the antifoaming agent of 0.31% (Model LJ-618, manufacturer Beijing Ruilangjie), 0.105% surfactant (model FP415, manufacturer Guangzhou Runhong), 0.195% dispersant (model ZJ-855, manufacturer Guangzhou Zhijing) and the rest of water.

[0069] The preparation method of the corrosion solution is as follows: stirring and mixing the above raw materials to obtain the corrosion solution.

[0070] This embodiment also provides a substrate layer, including an N-type substrate layer, an emitter layer and a borosilicate glass layer arranged in sequence on the front side of the N-type substrate layer, and a pyramid-shaped suede surface arranged on the back side of the N-type substrate layer , the suede is formed by etching with the above-mentioned corrosive solution.

[0071] The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com