A kind of preparation method of silicon carbide microstructure

A technology of silicon carbide and microstructure, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of complex process flow and low material etching rate, and achieve the effect of good corrosion selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

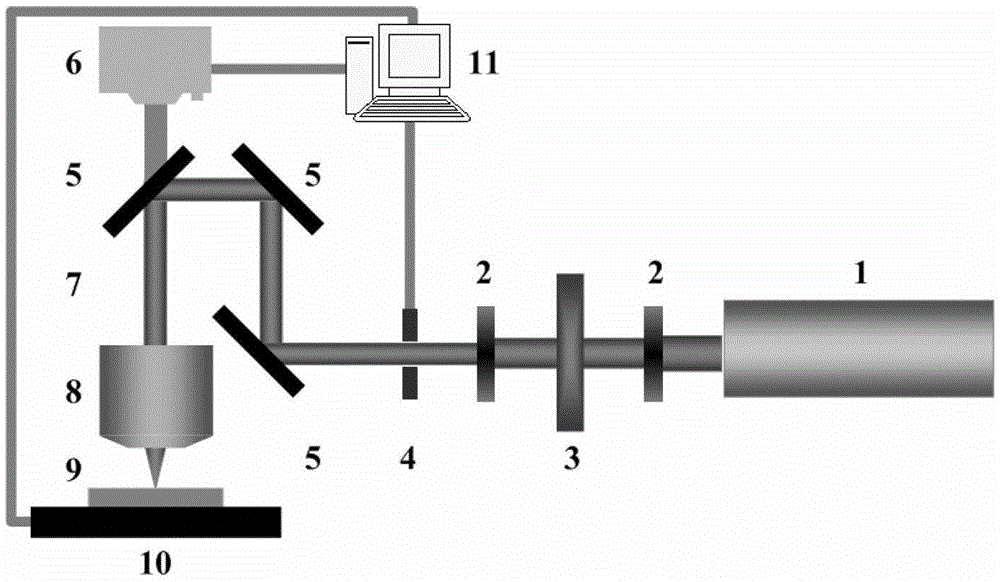

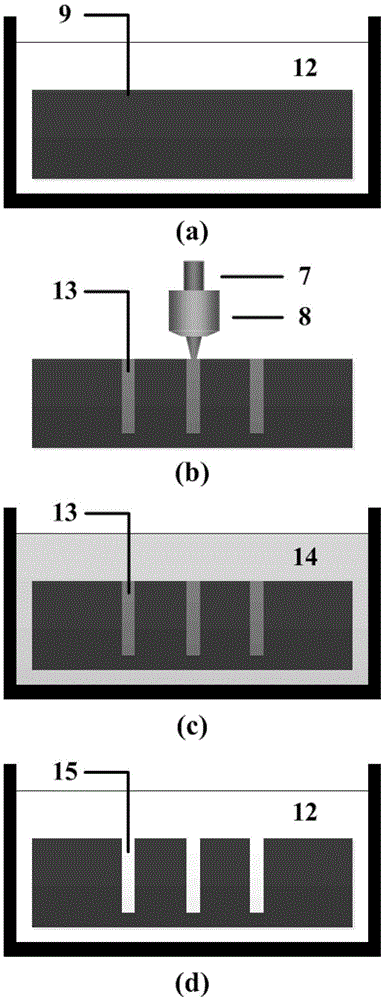

[0025] The preparation method of the silicon carbide microstructure of the present invention is to use femtosecond laser irradiation in a gas environment to induce a silicon carbide-based refractive index change structure on a silicon carbide substrate by means of scanning, and then pass hydrofluoric acid and The mixed solution of nitric acid is etched to remove the area of refractive index change, thereby preparing the silicon carbide microstructure. The present invention is applicable to silicon carbide crystals of various types and crystal orientations, and the commonly used 6H-SiC crystals with hexagonal close packing and crystal orientation are preferred. The method specifically follows the steps below:

[0026] (1) Select a silicon carbide wafer as the substrate, and ultrasonically clean it in acetone, alcohol, and deionized water in sequence; the crystal type of the silicon carbide substrate is any crystal orientation, such as or . Alternatively, the crystal type o...

Embodiment 1

[0035] (1) Select a 6H-SiC crystal with a crystal orientation of , a thickness of 300 μm, and double-sided polishing as the substrate, and ultrasonically clean it in acetone, alcohol, and deionized water in sequence, and the cleaning time is 20 minutes;

[0036] (2) In the air environment, using femtosecond laser irradiation, the refractive index change area is induced on the silicon carbide substrate by scanning; in this step, the depth, width and aspect ratio of the refractive index change structure can be By changing the laser irradiation conditions, such as laser power, scanning rate and focusing conditions, etc., flexible control can be achieved; the laser-induced refractive index change depth can reach 300 μm;

[0037] (3) The silicon carbide substrate irradiated by femtosecond laser is chemically wet-etched in a mixed solution of hydrofluoric acid and nitric acid to remove the area where the refractive index changes; in this step, the mass percentages are 40% Mix with 6...

Embodiment 2

[0040] The original material used in this embodiment: double-sided polished 6H-SiC, crystal orientation , and a thickness of 300 μm. The specific steps of preparation are as follows:

[0041] (1) Use acetone, alcohol and deionized water to clean silicon carbide in an ultrasonic cleaner in sequence, each cleaning time is 20mins, such as figure 2 as shown in (a);

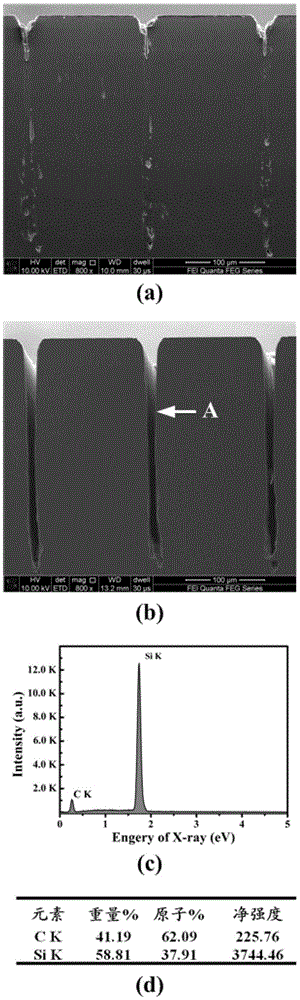

[0042] (2) Fix the cleaned sample on the three-dimensional mobile platform 10, select an optical microscope 8 with a magnification of 5×, and a numerical aperture of 0.30, focus the femtosecond laser beam 7 on the silicon carbide substrate 9, and perform the test on the computer 11 Set the scan rate as 5 μm / s above, and set the laser power as 40 mW by adjusting the variable attenuation sheet. By scanning, a refractive index change microstructure 13 is induced on the silicon carbide substrate, such as figure 2 As shown in (b), its depth is about 280 μm, its half-maximum width is about 10 μm, and its aspect ratio i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com