Method for eroding 2Cr12Ni1Mo1Vsteel grain boundary

A grain boundary and sample technology, applied in the field of steel grain boundary corrosion, can solve problems such as the inability to truly respond to 2Cr12Ni1Mo1V steel grain boundaries, and achieve the effects of easy mastery, high corrosion efficiency, and fast corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

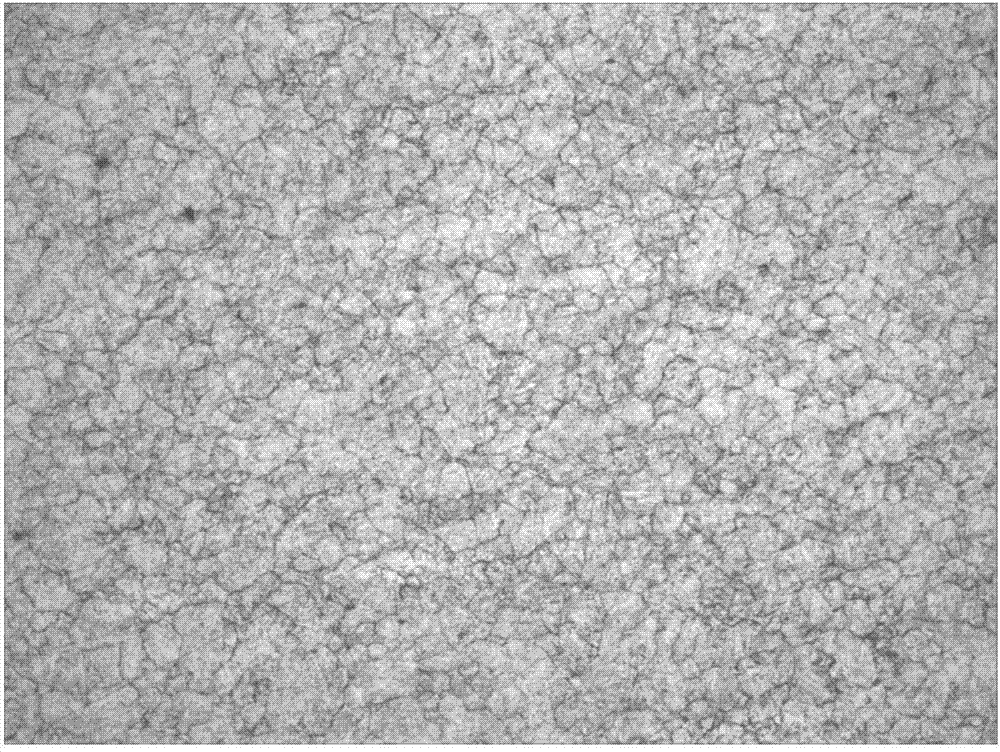

[0020] Specific embodiment 1: This embodiment provides a method for corroding the grain boundaries of 2Cr12Ni1Mo1V steel, which is specifically completed according to the following steps:

[0021] 1. Take picric acid and put it into water to prepare a supersaturated picric acid solution;

[0022] 2. To the supersaturated picric acid solution obtained in step 1, add Seagull brand shampoo, stir to completely dissolve the shampoo in the saturated picric acid solution, and obtain the supersaturated picric acid dissolved in the seagull brand shampoo Solution; Among them, the ratio of the mass of the added Seagull shampoo to the volume of the supersaturated picric acid solution is (2.5mg~5mg): 1mL;

[0023] 3. Add hydrochloric acid to the supersaturated picric acid solution with Seagull brand shampoo obtained in step 2, and stir to obtain a corrosive reagent; wherein the mass percentage concentration of hydrochloric acid is 36%~38%; added hydrochloric acid The volume ratio of the supersat...

specific Embodiment approach 2

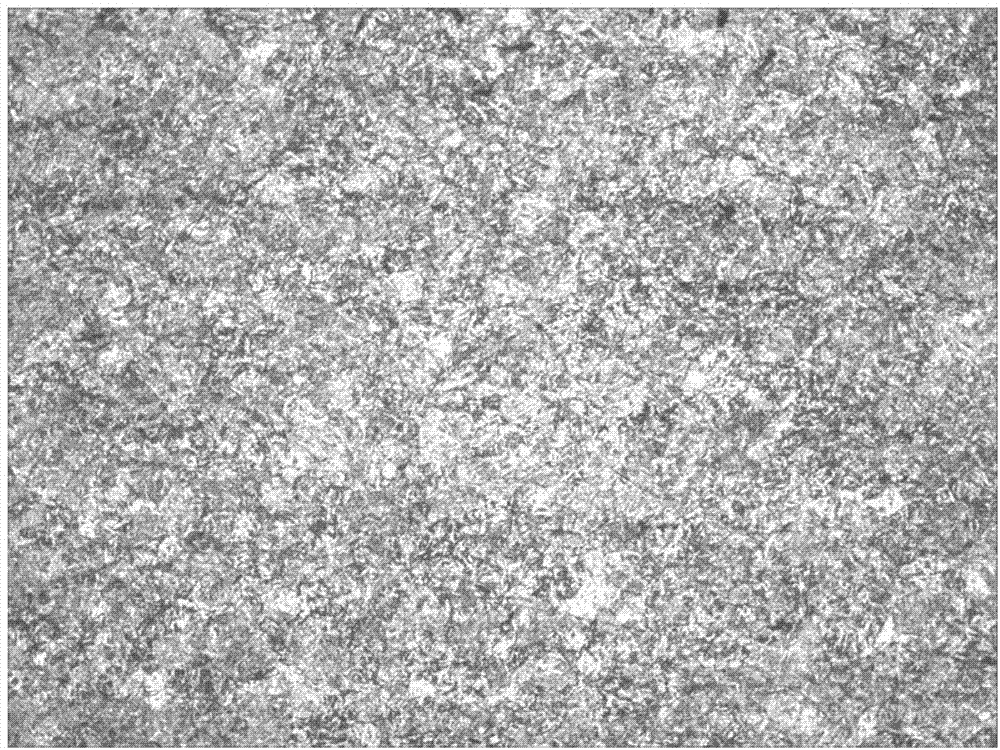

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ratio of the mass of the added Seagull shampoo in step 2 to the volume of the supersaturated picric acid solution is 2.5 mg: 1 mL. Others are the same as the first embodiment.

specific Embodiment approach 3

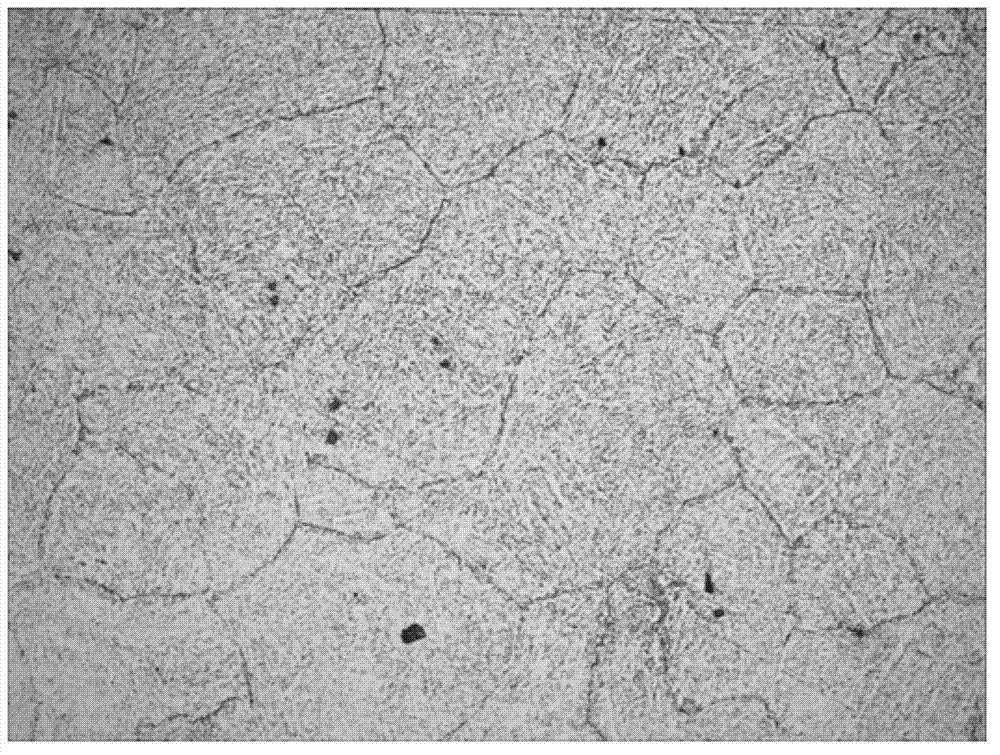

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the ratio of the mass of the added Seagull shampoo in step 2 to the volume of the supersaturated picric acid solution is 4 mg: 1 mL. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com