Patents

Literature

82results about How to "Improve corrosion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

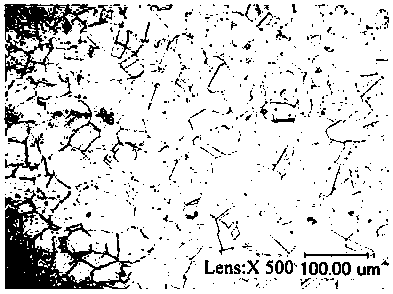

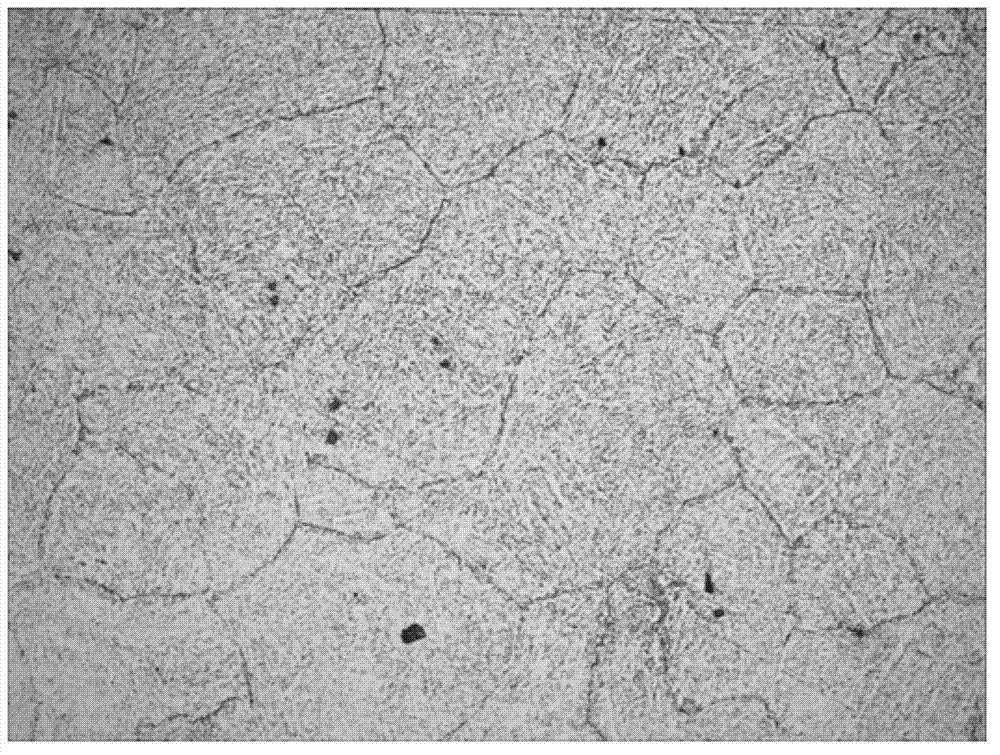

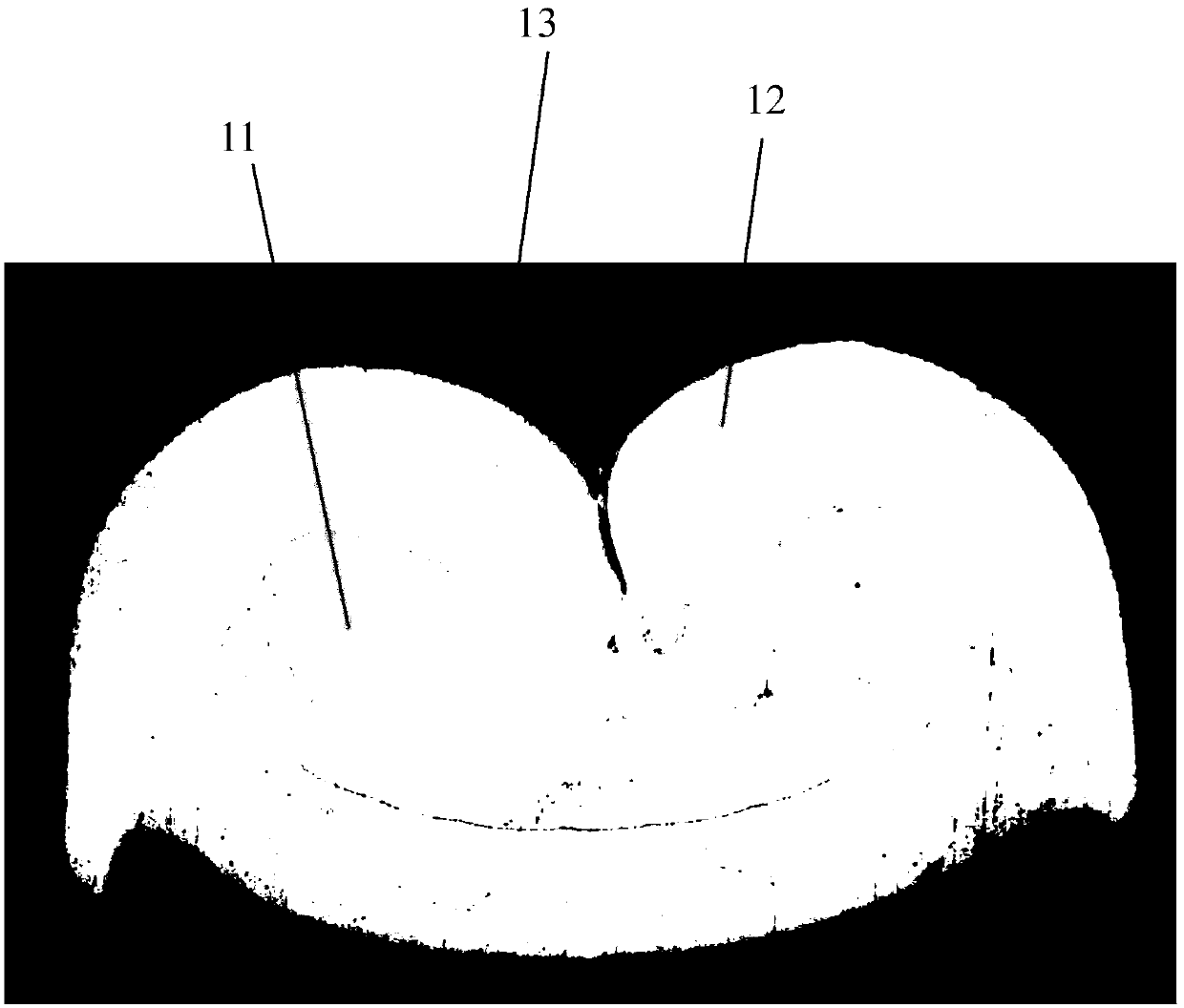

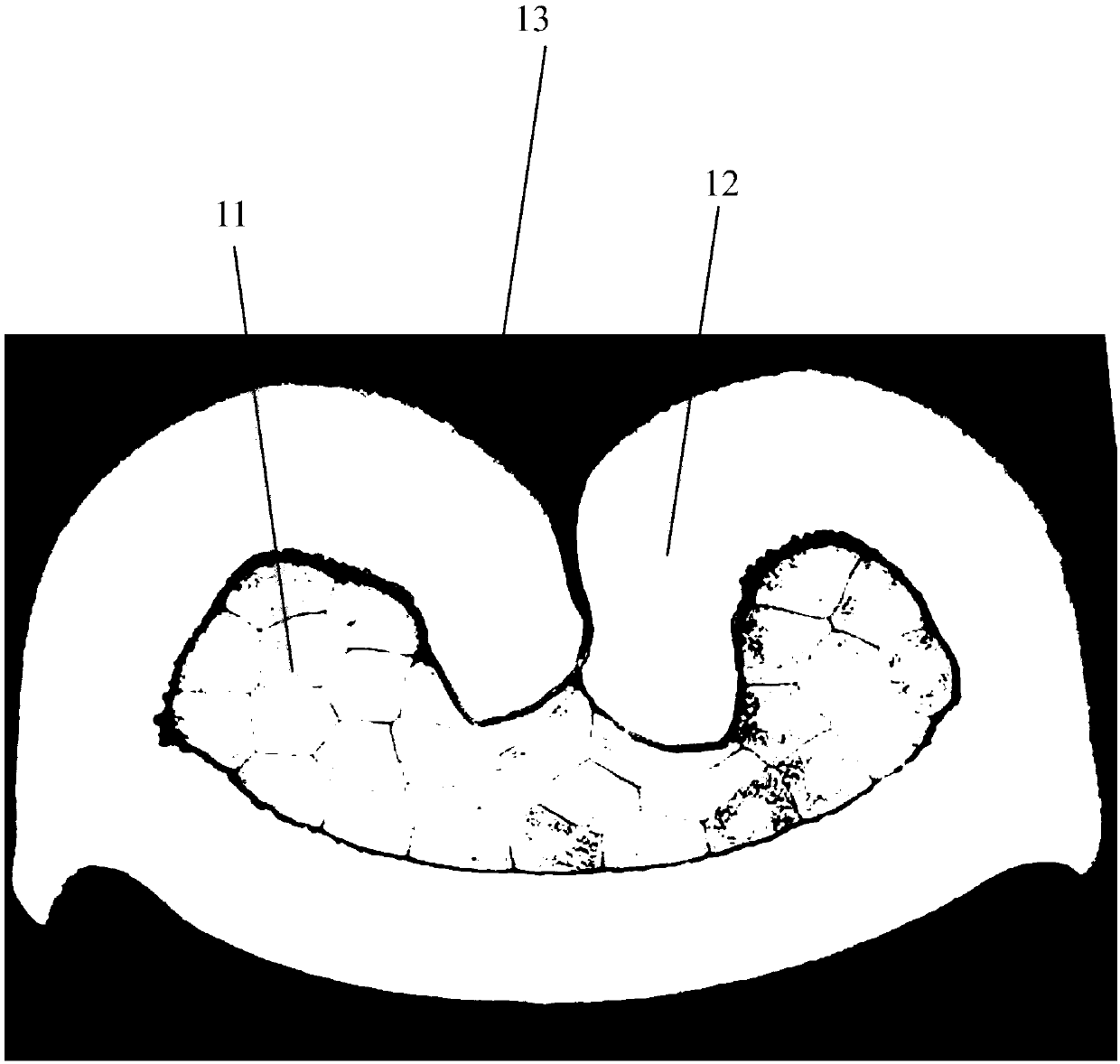

Ultra-supercritical martensite heat resisting cast steel original austenite grain size display method

ActiveCN105092437ASimple ingredientsEasy access to raw materialsPreparing sample for investigationParticle size analysisAlcoholNitric acid

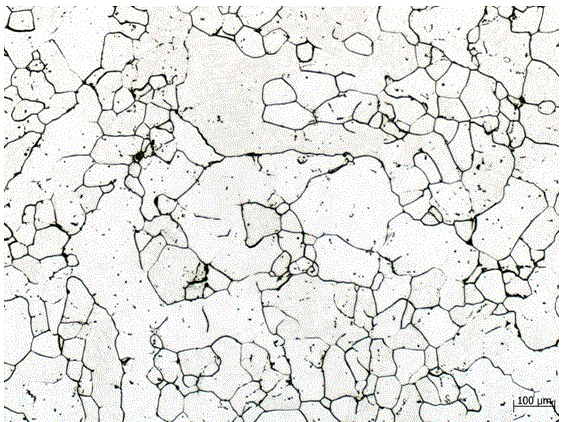

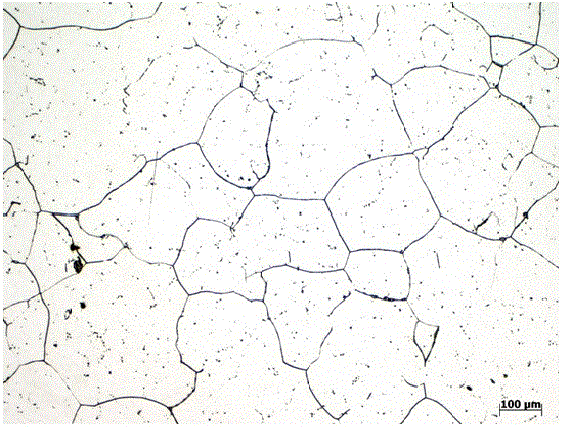

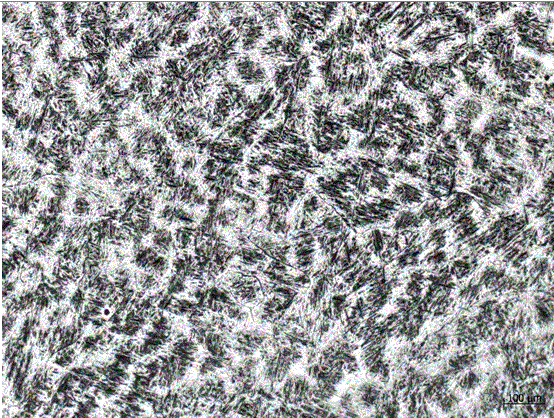

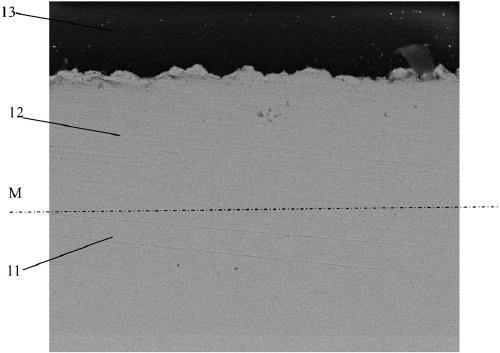

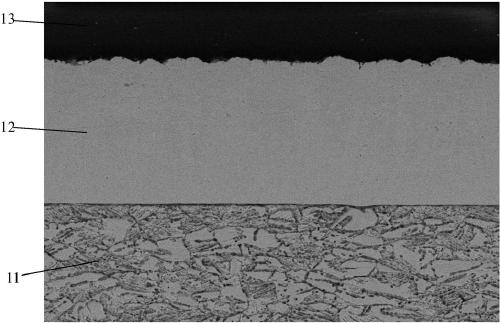

The invention discloses an ultra-supercritical martensite heat resisting cast steel original austenite grain size display method, and belongs to the technical field of smelting metallographic structure sample analysis and inspection. The method comprises the steps that 1, austenitizing heat preservation is performed on a sample, wherein the temperature of a high-temperature furnace is increased to 1100 DEG C to 1150 DEG C, the sample is placed in the furnace for heat preservation, the temperature of the sample is quickly lowered to 800 DEG C in the furnace, heat preservation is performed, and then the temperature is lowered to the room temperature; 2, metallographic sample cutting is performed, wherein oxidation and decarbonization portions on the surface of a metallographic sample, with the specification of 15*15 mm, of the sample material processed through heat treatment are removed, and metallographic sample grinding and polishing are performed, wherein the surface of the sample is washed clean, and the sample is placed on a polishing machine to be polished; 3, a corrosive agent is prepared, wherein the volume ratio of nitric acid to alcohol is (6-10):(94-90), and chemical corrosion is performed, wherein the polished surface of the sample is upwards placed in a corrosive solution to enable the solution to cover the surface of the sample, and then the sample is taken out after being stood for 15-30 minutes on the room temperature condition; 4, grain size observation and statistics are performed, wherein a metallograph is taken for the sample.

Owner:CHINA FIRST HEAVY IND

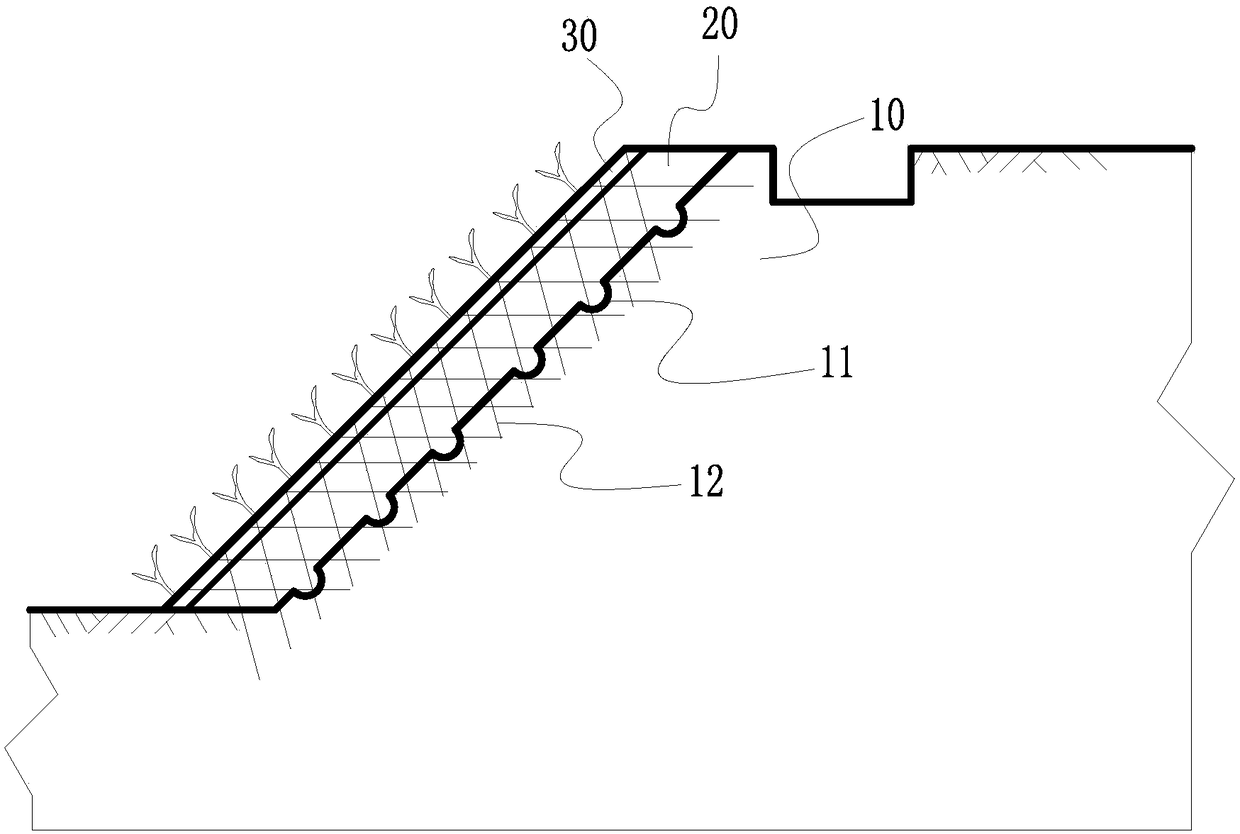

Ecological vegetation concrete slope protection structure and construction method thereof

ActiveCN108570993AFull of corruptionGood corrosion environmentCoastlines protectionGrowth substratesVegetationEngineering

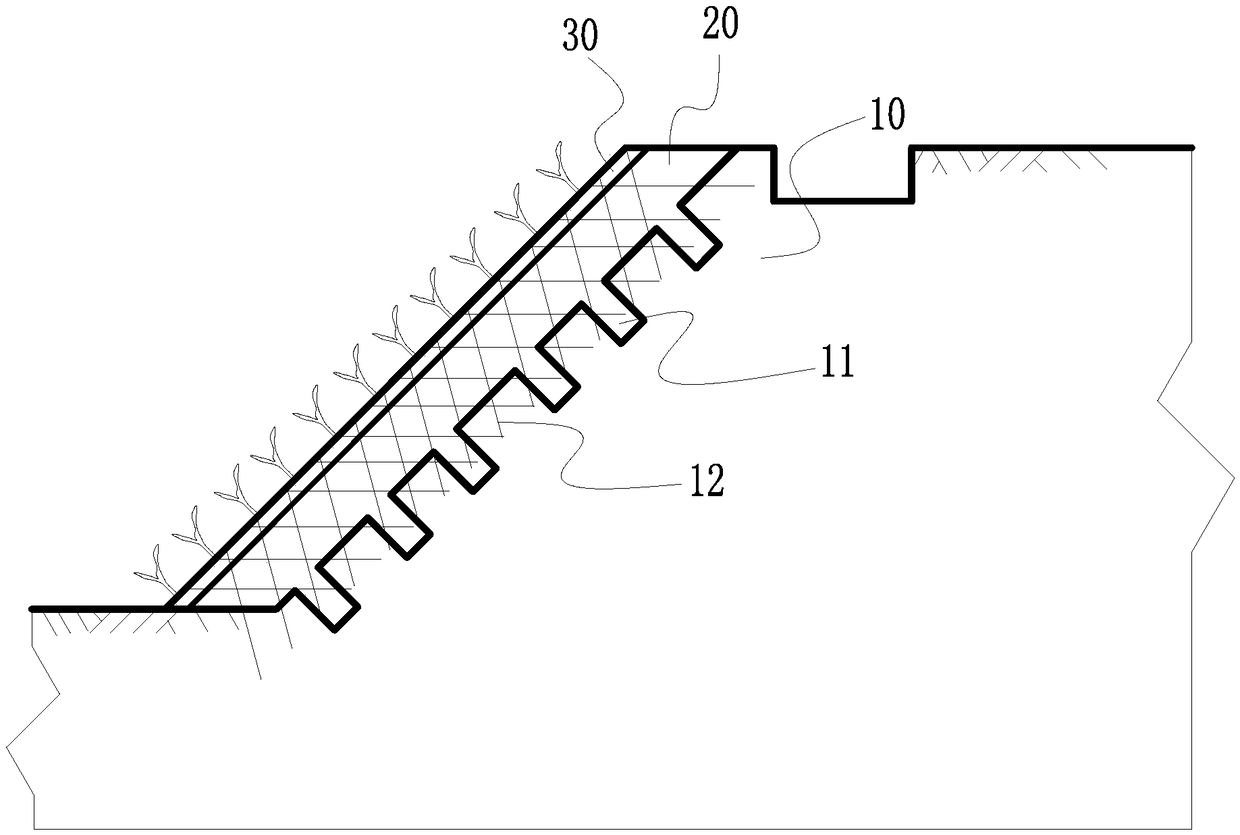

The invention provides an ecological vegetation concrete slope protection structure. The structure comprises a slope surface, a vegetation concrete layer jetted along the slope surface as well as a vegetation seed layer located on the vegetation concrete layer, wherein a plurality of concave grooves are distributed in the slope surface at intervals; the vegetation concrete layer is jetted into theconcave grooves to form a sawtooth connection structure with the slope surface; a plurality of recovered disposable chopsticks are arranged in the vegetation concrete layer in a staggered manner at intervals. Strength and adhesion of the concrete layer and the slope surface are improved by the physical structure and the recovered disposable chopsticks, the structure is simple, household waste canbe used, and the structure is environmentally friendly and energy-saving. The invention further provides a construction method of the ecological vegetation concrete slope protection structure. The method comprises steps of preparing vegetation concrete and the like. The method adopts simple process, immediate mixing can be performed before construction, so that activity of organic matter and activity of wood-rotting fungi in the vegetation concrete can be guaranteed, and the organic matter and the wood-rotting fungi in the vegetation concrete can persistently have decay fertilizer efficiencyafter concrete pouring.

Owner:广东长海建设工程有限公司

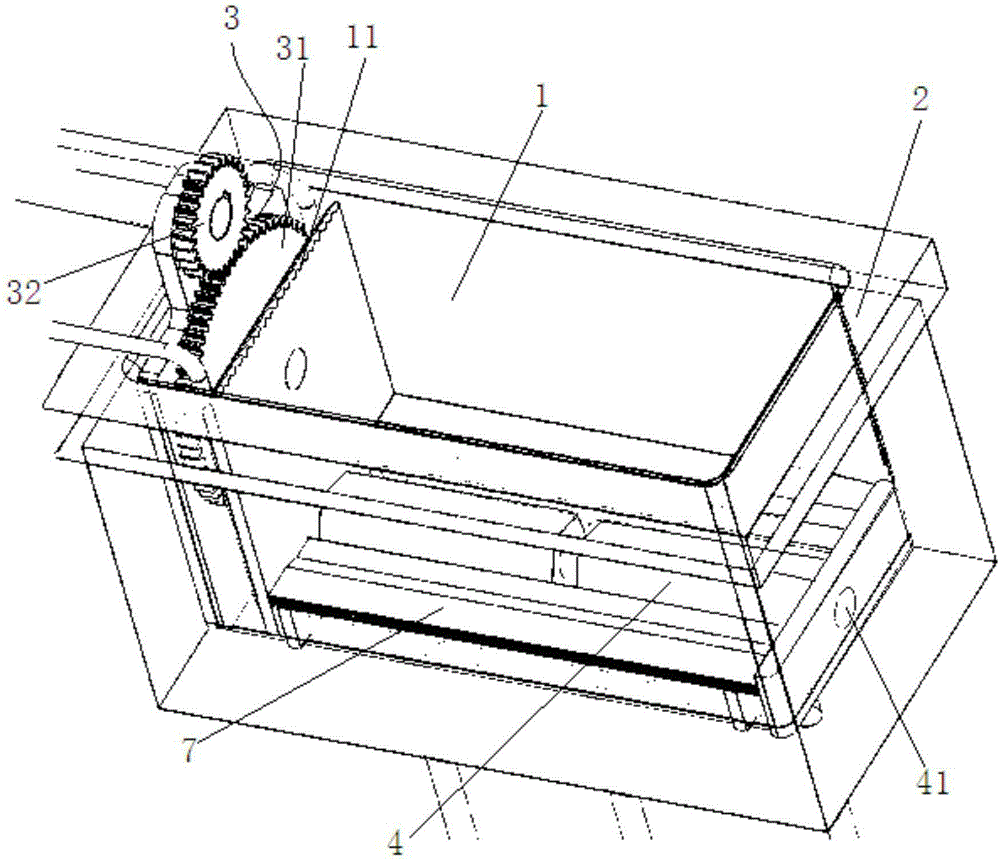

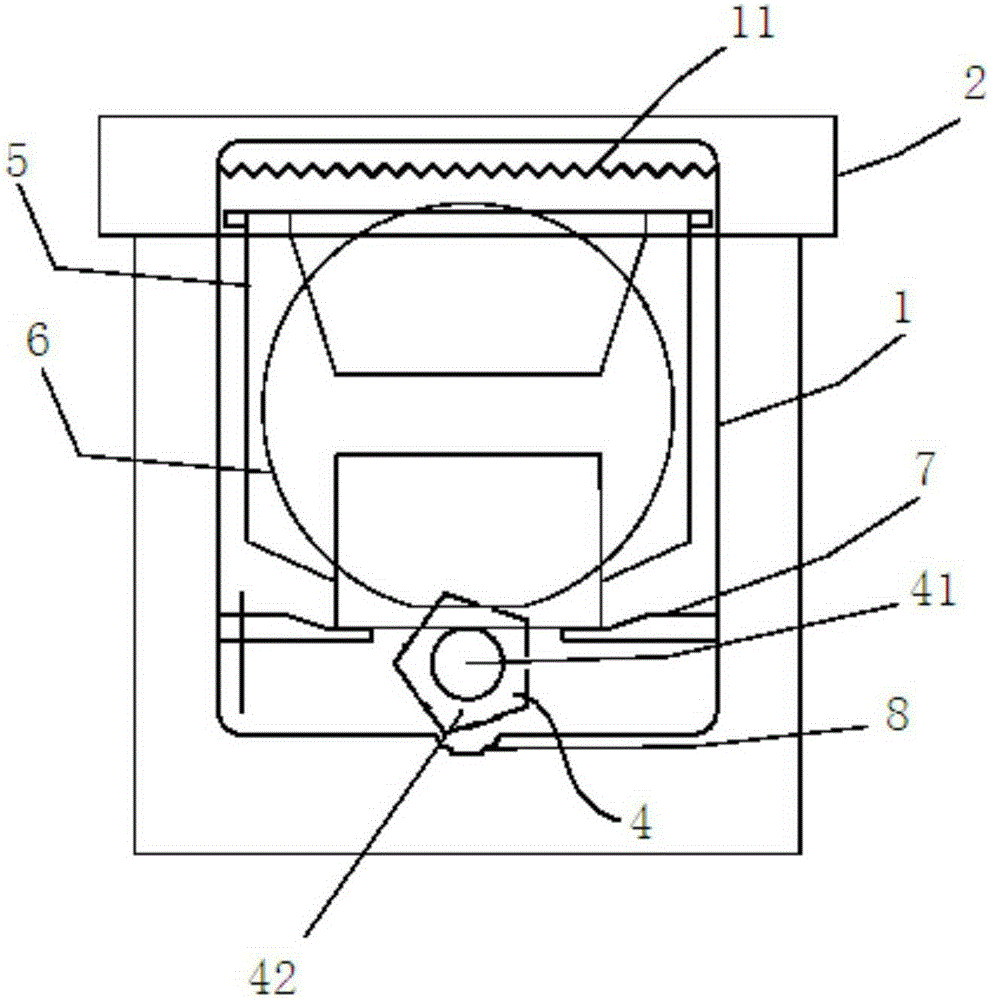

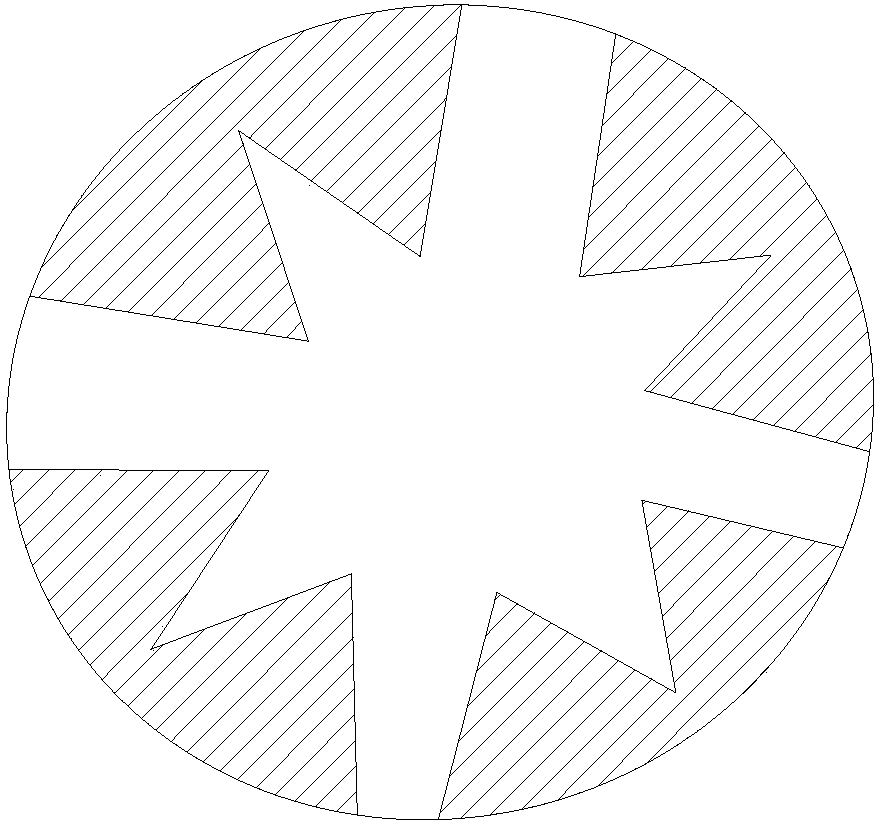

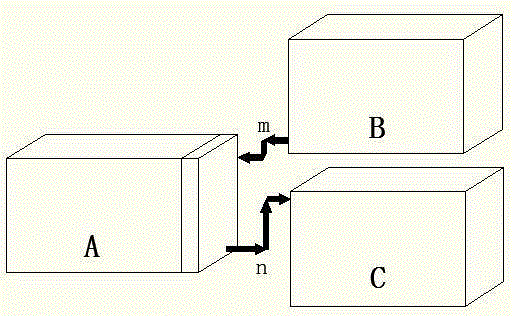

Wafer corrosion device

InactiveCN105336649AAchieve rotationMentioned uniformitySemiconductor/solid-state device manufacturingManufacturing technologyEngineering

The invention relates to the technical field of semiconductor manufacturing, in particular to a wafer corrosion device. The wafer corrosion device is applied to wafer surface substance corrosion processing. The wafer corrosion device comprises an inner box, an outer box, a transmission device and an overflowing pump, wherein a detachable cavity with a wafer box containing a plurality of wafers is formed inside the inner box, and a groove matched with a polygonal rotating column is formed in the bottom of the inner box; the outer box and the inner box are arranged at a preset interval, and the outer box completely covers the inner box; the driving end of the transmission device is connected with a driving unit, and the output end of the transmission device is connected with the polygonal rotating column; the overflowing pump is arranged inside the inner box and used for providing pushing force for pushing a corrosion solution contained inside the inner box to overflow into the outer box. When the overflowing pump pushes the corrosion solution to overflow into the outer box, the polygonal rotating column is driven by the transmission device to drive the wafers to rotate in the flowing corrosion solution.

Owner:SHANGHAI VASTITY ELECTRONICS TECH

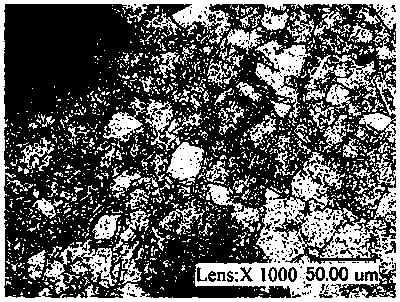

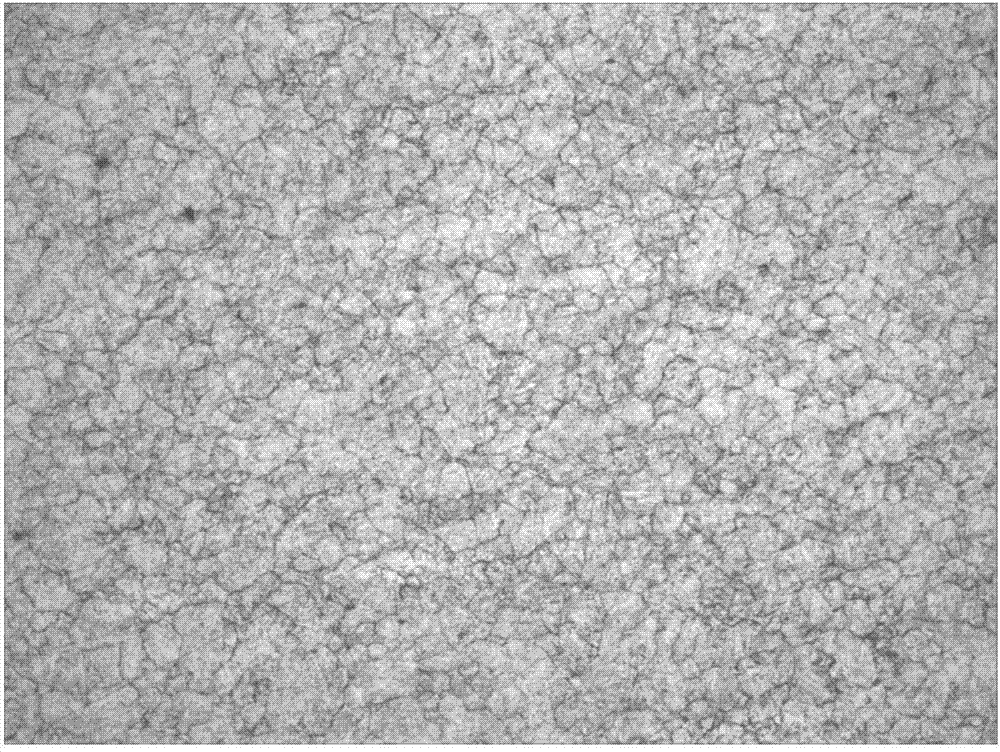

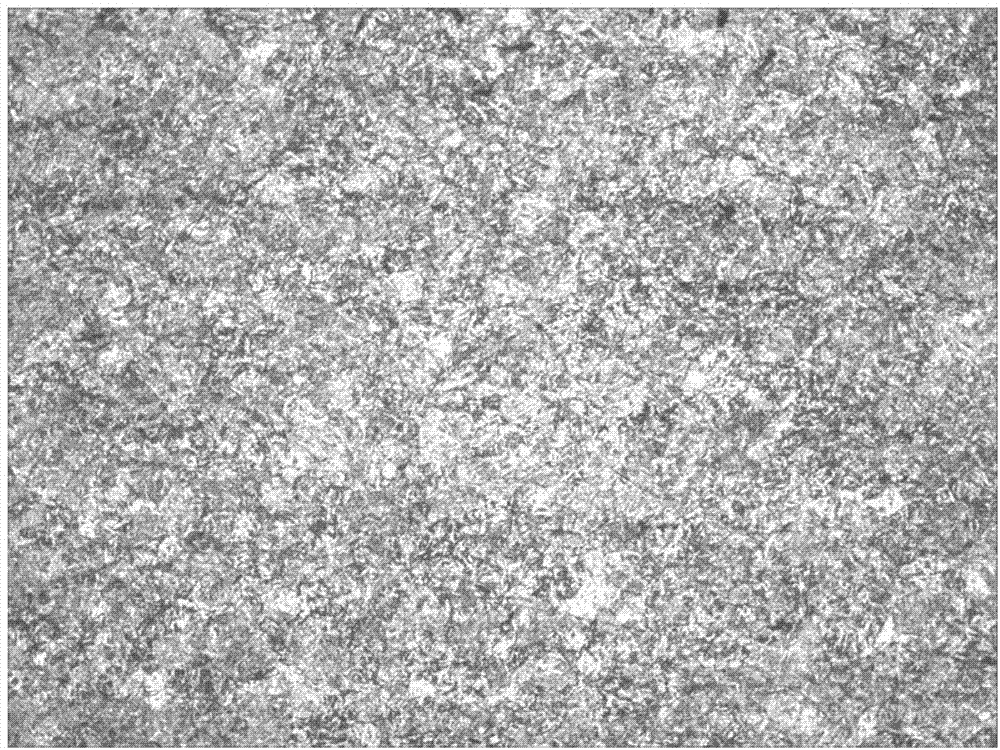

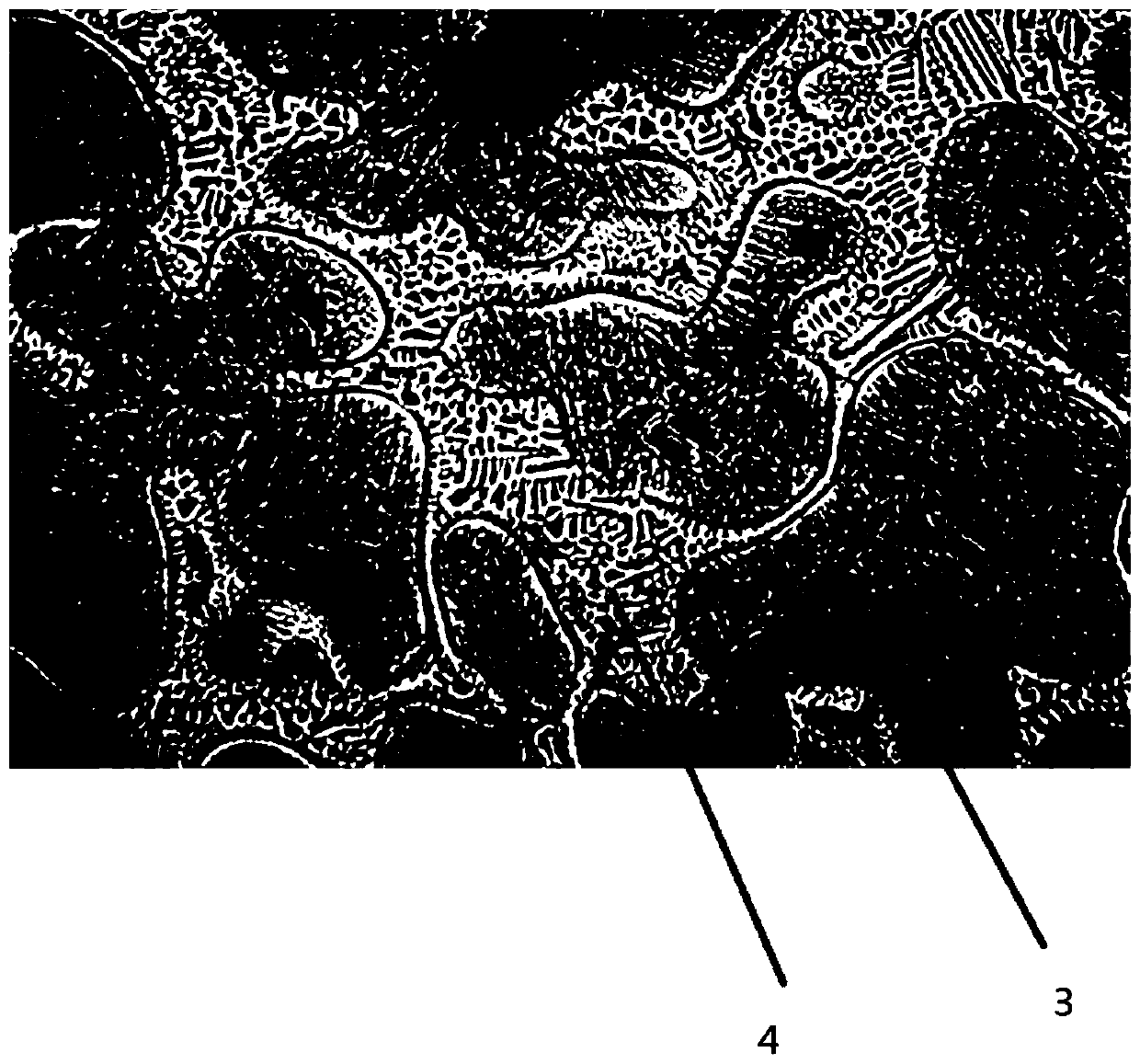

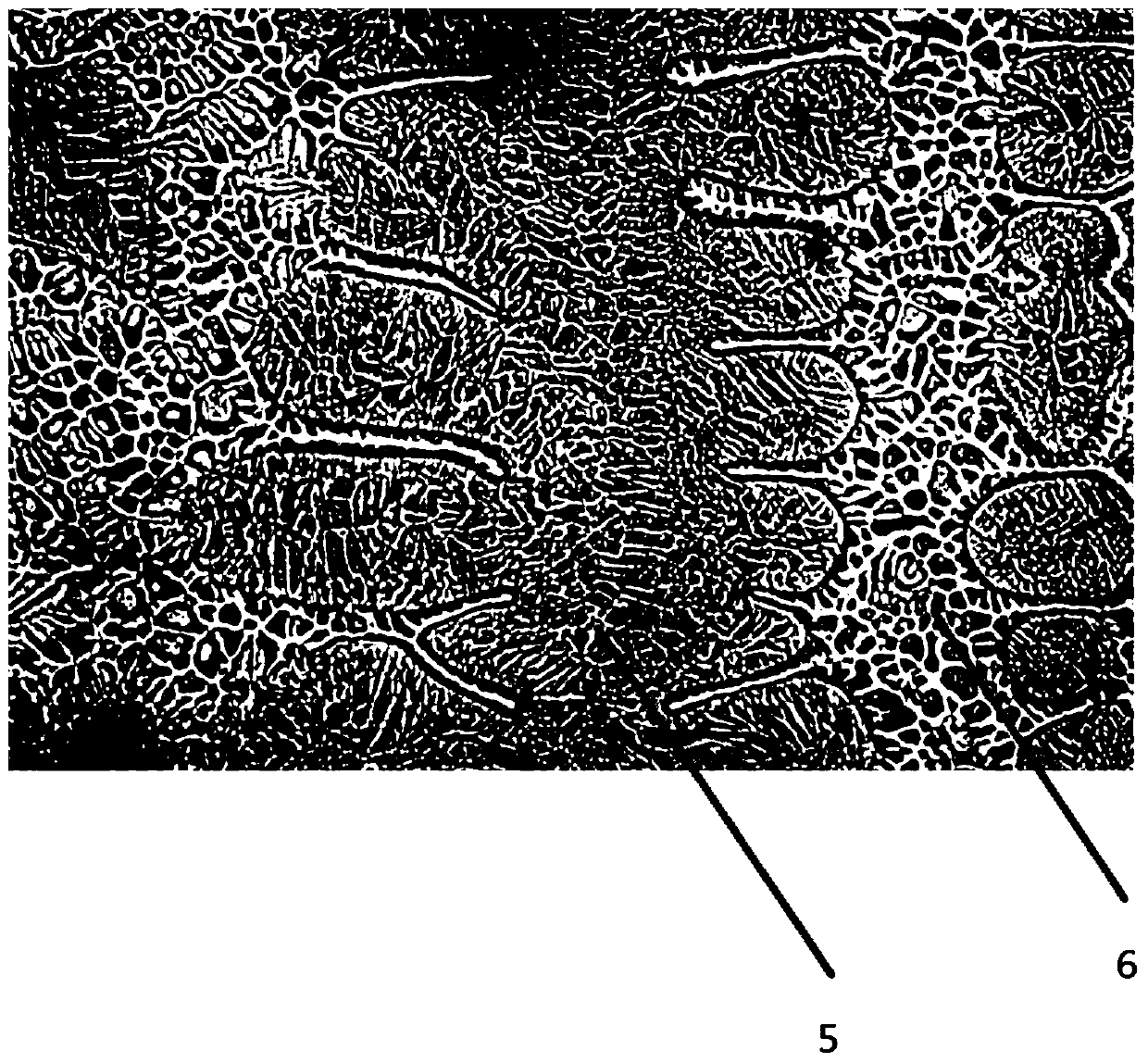

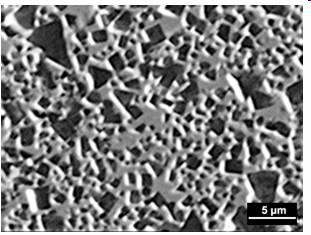

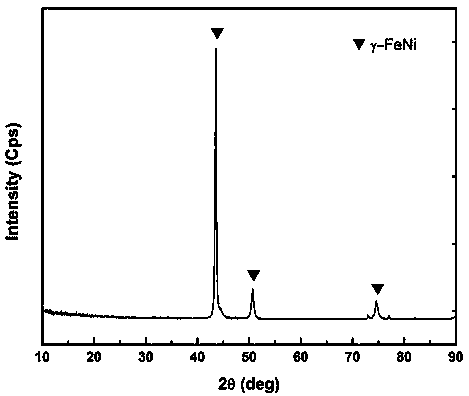

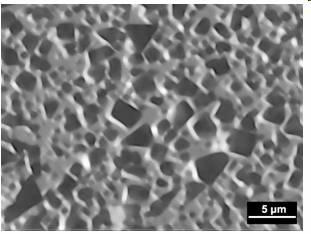

Showing and quantitative evaluation methods of gamma' phase in nickel-based superalloy

InactiveCN108760452AReduce pollutionGood effectPreparing sample for investigationScanning probe techniquesMaterials scienceMicroscope

The invention provides a scheme for quantitatively evaluating content of gamma' phase. The scheme comprises the following two aspects: firstly, a corrosive agent which has good corrosion effect and can show the strengthened phase gamma' form of nickel-based superalloy and a preparation method of the corrosive agent are provided, and a corrosion method for corroding the nickel-based superalloy by the corrosive agent is also provided. According to the corrosive agent and the corrosion method, the strengthened phase gamma' form of the nickel-based superalloy can be clearly shown, and observationand measurement of processed surface strengthened phase gamma' of the nickel-based superalloy are facilitated; on the basis, an obtained microscope gamma' phase image is processed by drawing analysissoftware, and the volume fraction of the nickel-based superalloy gamma' phase is obtained. Steps are simple, operation is convenient, and practicality is high.

Owner:SHANDONG UNIV

Etching machine

The invention discloses an etching machine, wherein an etching groove, a flushing tank and a driving device are arranged in a chassis; a basket is connected to the driving device, a first rotary shaft and a second rotary shaft are arranged on the basket, and the driving device drives the basket to rotate around the first rotary shaft and drives the first rotary shaft to rotate around the second rotary shaft. The etching machine disclosed by the invention improves the corrosive uniformity and corrosive speed as well as the uniformity of backwashing and the flushing speed.

Owner:菏泽力芯电子科技有限公司

Method for eroding 2Cr12Ni1Mo1Vsteel grain boundary

InactiveCN102879253AAccurate responseAccurate ratingPreparing sample for investigationGrain boundaryReagent

The invention discloses a method for eroding 2Cr12Ni1Mo1V steel grain boundary, relating to a method for eroding the steel grain boundary. According to the method, solves the problem that the existing method for eroding 2Cr12Ni1Mo1V steel grain boundary can not really respond to the problem of 2Cr12Ni1Mo1Vsteel grain boundary usually. A method for eroding 2Cr12Ni1Mo1V steel grain boundary comprises the steps of 1. preparing a corrosion reagent; and 2. eroding 2Cr12Ni1Mo1V steel. The method for eroding 2Cr12Ni1Mo1V steel grain boundary is applied in evaluating grain degree of 2Cr12Ni1Mo1V steel.

Owner:HARBIN TURBINE

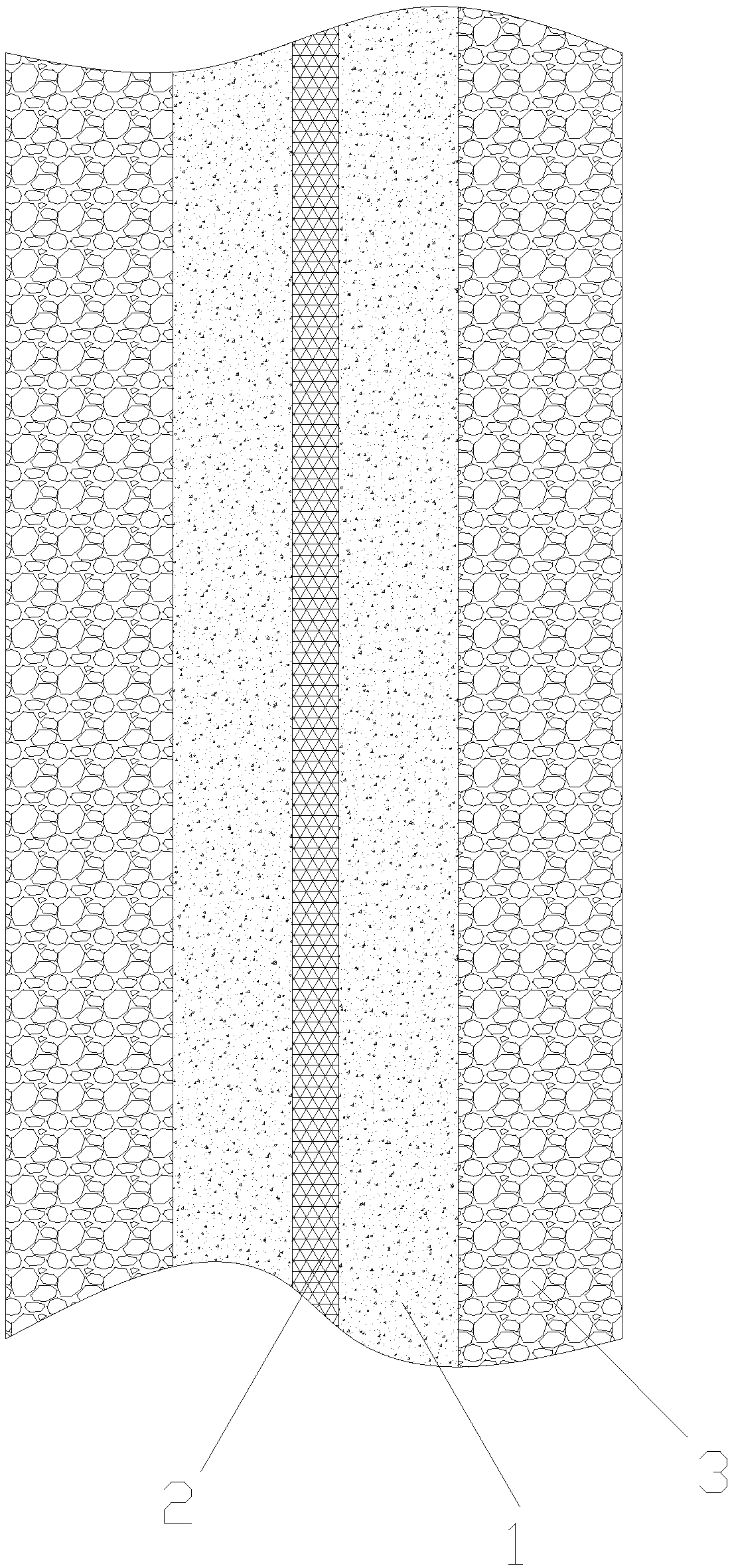

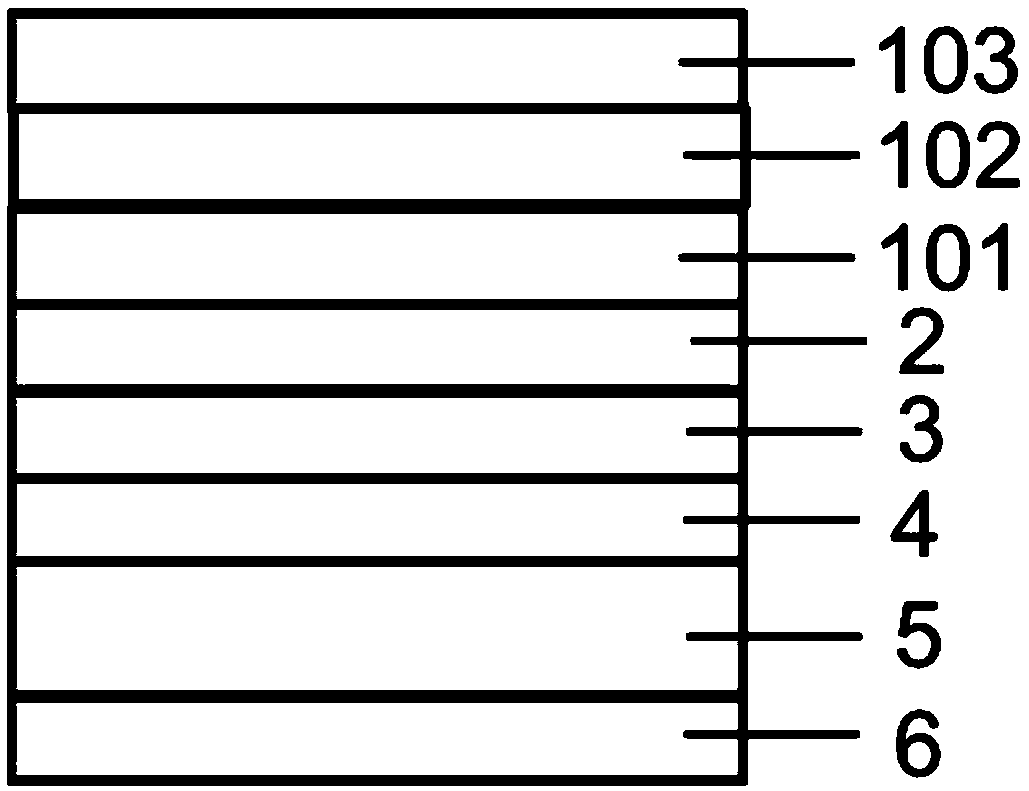

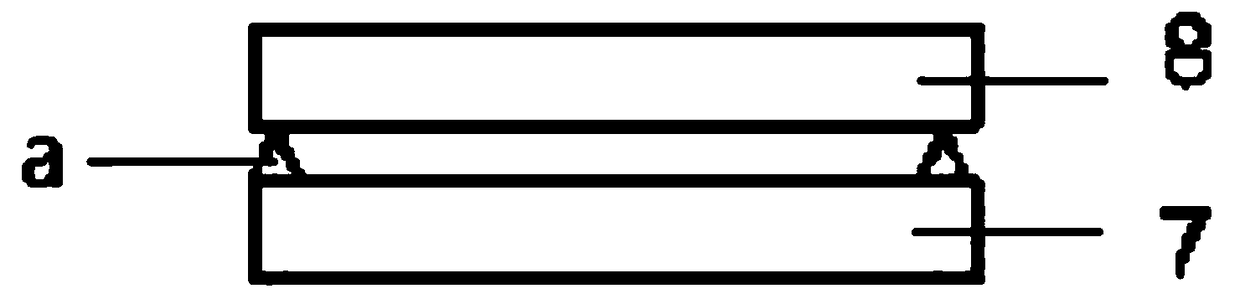

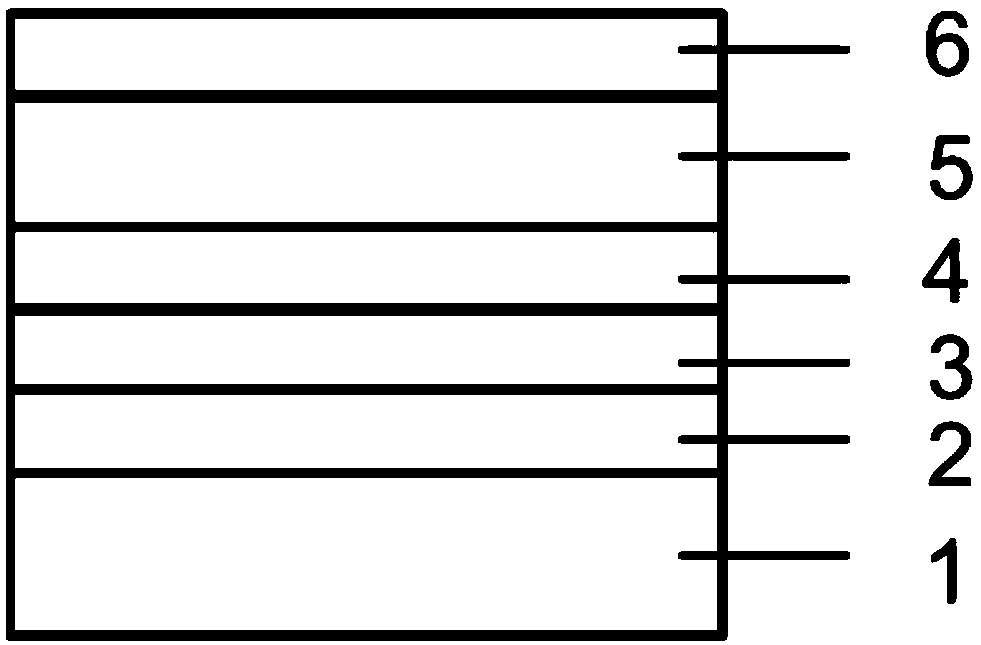

Lightweight composite organic heat preservation and sound insulation prefabricated board for fabricated buildings and preparation method

InactiveCN108505636AGood coating effectStrong enoughHeat proofingSound proofingCompound organicFoaming agent

The present invention provides a lightweight composite organic heat preservation and sound insulation prefabricated board for fabricated buildings. The lightweight composite organic heat preservationand sound insulation prefabricated board for the fabricated buildings comprises two organic sound absorption boards, a damping silicone rubber layer, two fiber cement pressure plates, wherein the twoorganic sound absorption boards are made of wood organic matter, white rot fungus hyphae and foaming agents; the damping silicone rubber layer is arranged between the two organic sound absorption boards, and is used for being connected with the organic sound absorption boards and cutting off the transmission of a sound wave; and the two pieces of fiber cement pressure plates are arranged on the outside side of the organic sound absorption boards. According to the lightweight composite organic heat preservation and sound insulation prefabricated board for the fabricated buildings, the wood organic matter is decomposed by wood rot fungi to produce dense pores, the covering effect of wood rot fungi hyphae is used, so that the organic sound absorption boards have excellent sound-absorption effect on the basis of meeting the use requirements of strength characteristic. The invention further provides a preparation method for the lightweight composite organic heat preservation and sound insulation prefabricated board for the fabricated buildings, the preparation process is simple, and the production cycle is short.

Owner:熊远

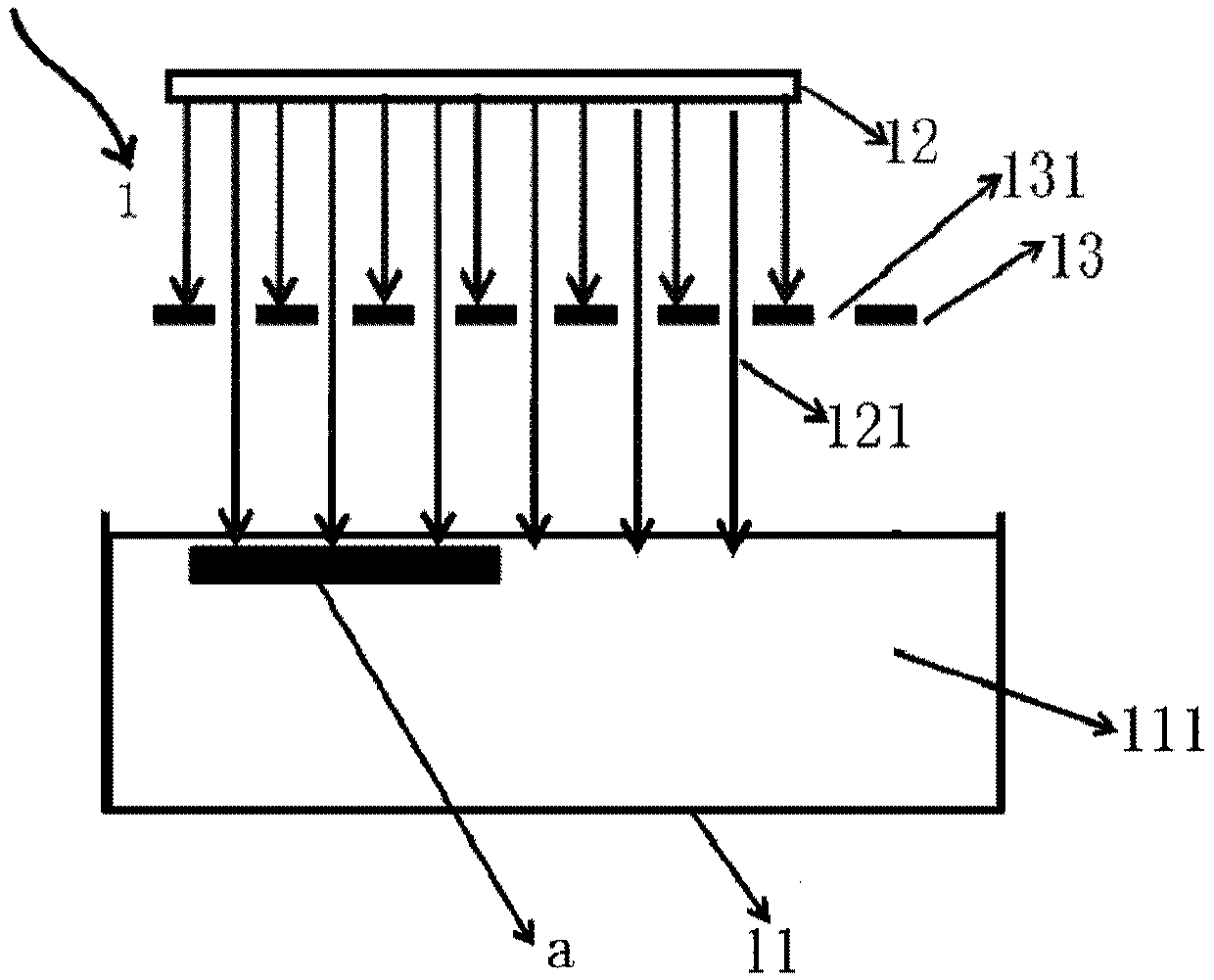

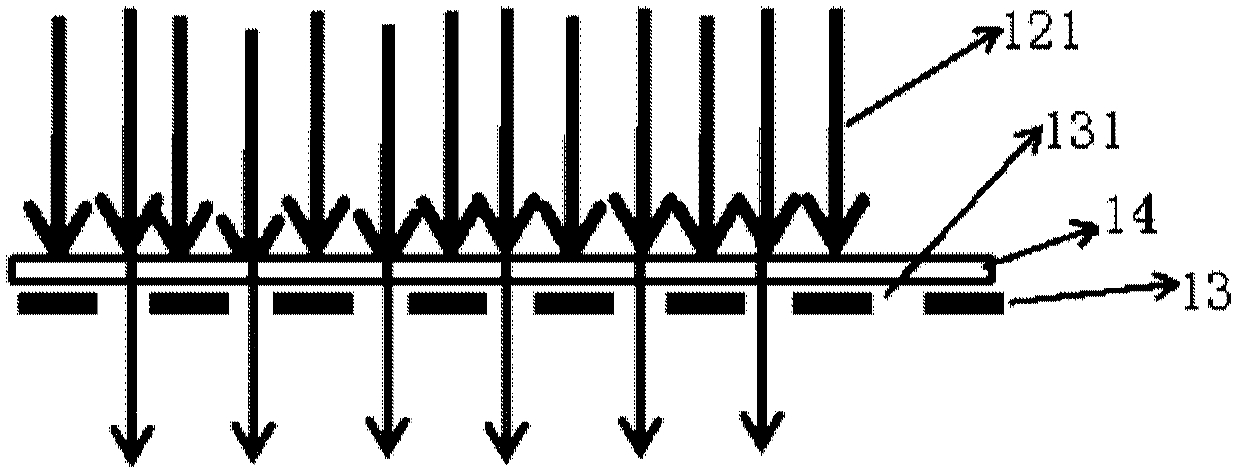

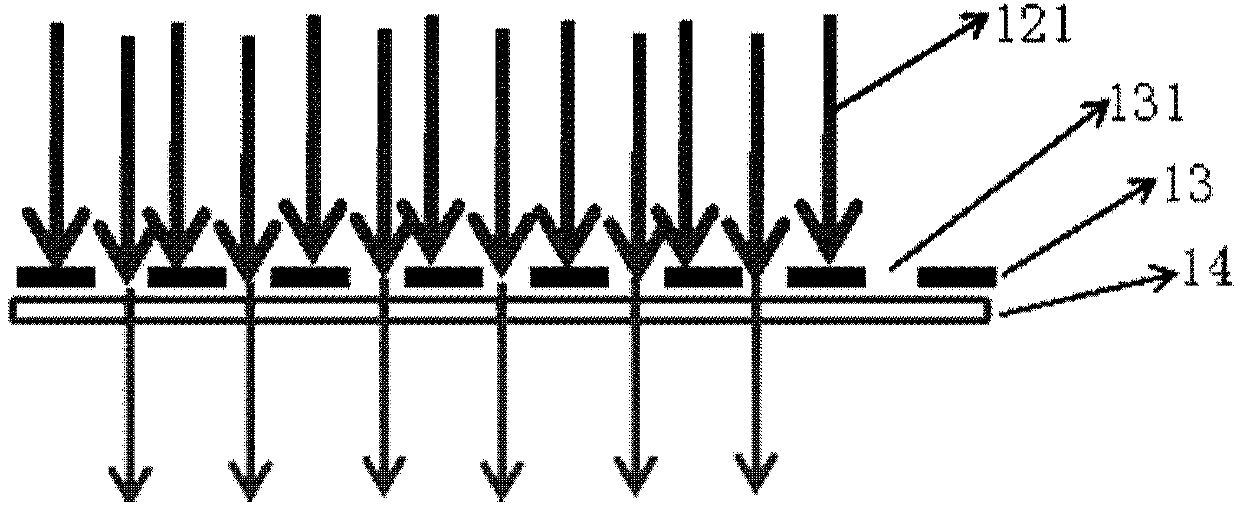

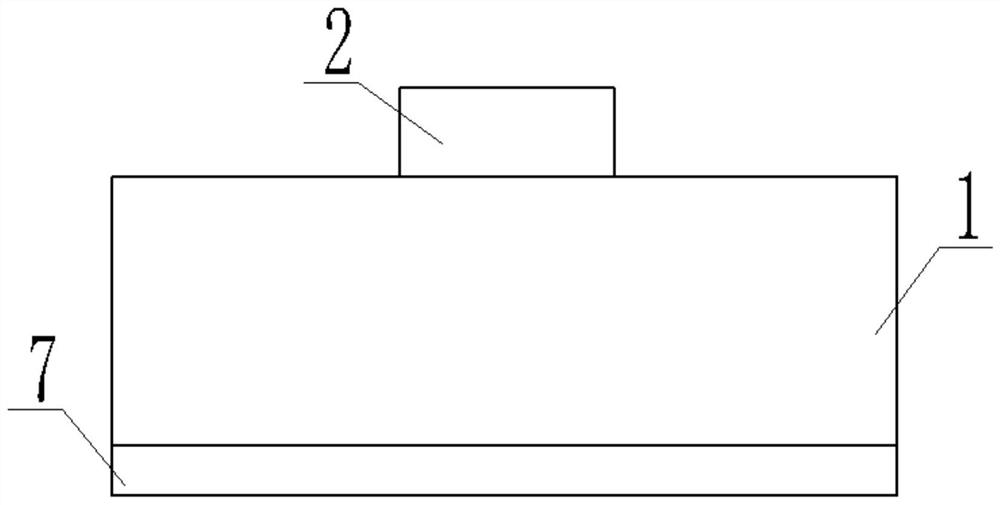

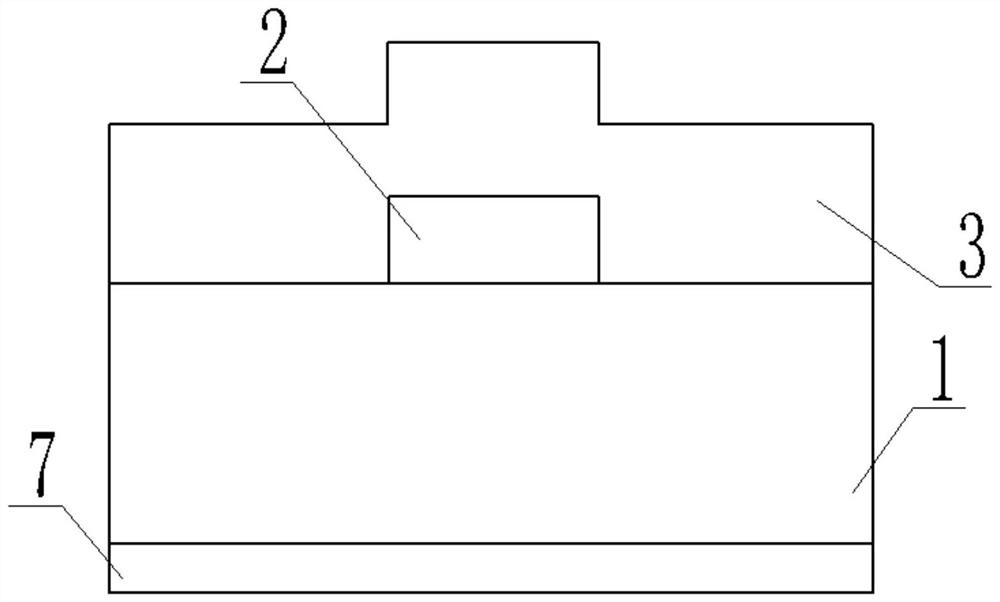

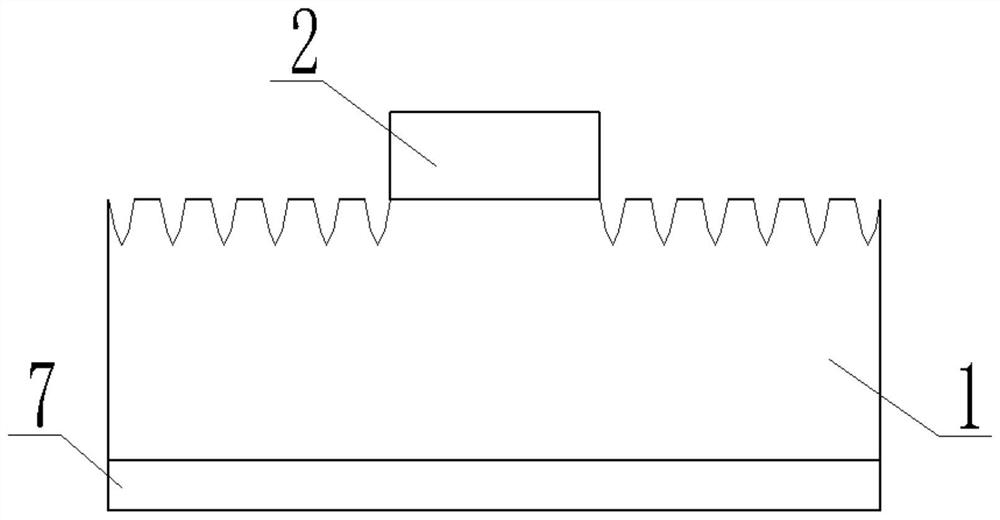

Fabrication device and fabrication method of substrate surface light trapping structure

InactiveCN107658247AAchieve mass productionImprove efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationPhotovoltaic detectorsTrapping

The invention relates to a fabrication device and fabrication method of a substrate surface light trapping structure. The fabrication device of the substrate surface light trapping structure comprisesa corrosion groove, a light source and a light transmitting plate, wherein the corrosion groove is used for loading a corrosion liquid and a substrate to be corroded, the light source is used for emitting catalytic light, the light transmitting plate is arranged above the corrosion groove, periodic gaps are formed in the light transmitting plate and are used for enabling the catalytic light to irradiate the corrosion groove, and a substrate surface is corroded by the corrosion liquid the effect of the catalytic light to obtain the light trapping structure. Photocatalysis is used for corrosionreaction, mass production of the light trapping structure can be achieved compared with a traditional light trapping structure mask, a nanoscale light trapping structure can be fabricated compared with a traditional scratching or simple corrosion method, the light receiving area can be greatly expanded, reflection resistance is effectively achieved, so that technical inspiration is provided for improving efficiency of a solar cell and a photoelectric detector.

Owner:北京旭日龙腾新能源科技有限公司

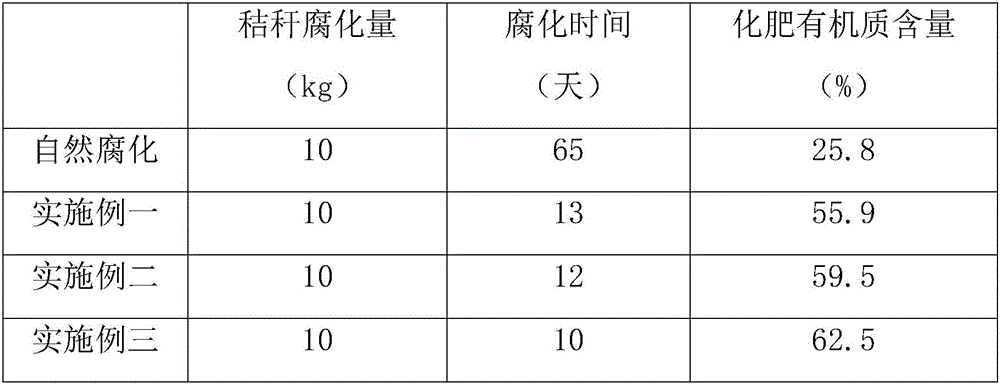

Composite microbial agent for rot decomposition of straw and application method thereof

PendingCN109749971ASimplify the application process and methodsPromote softening and browningFungiBio-organic fraction processingDecompositionBacillus amyloliquefaciens

The invention relates to a composite microbial agent for the rot decomposition of straw and an application method thereof. The composite microbial agent for the rot decomposition of the straw is prepared from, by the number of effective viable bacteria, 3-30 parts of bacillus subtilis, 50-99 parts of bacillus amyloliquefaciens, 1-5 parts of trichoderma asperellum and 1-15 parts of trichoderma longibrachiatum Rifai. The application method of the composite microbial agent for the rot decomposition of the straw comprises the following steps of (1) harvesting and pulverizing the straw; (2) scattering and flat spreading the straw; (3) turning up the soil / conducting rotary tillage; (4) conducting irrigation and soaking; (5) dissolving and spraying the microbial agent; (6) 14-30 days after treatment, completing the rot decomposition of the straw. The composite microbial agent for the rot decomposition of the straw and the application method thereof have the following advantages that the rotof the straw is accelerated; the content of organic matter in the soil is increased; the pollution and fermentation barriers are reduced; the cost is reduced.

Owner:深圳市励泽农业高科技发展有限公司

Automatic PCB board corrosion chamber

InactiveCN104630773AImprove corrosion efficiencyReduce waste of resourcesPrinted circuit manufactureIonAutomatic control

The invention discloses an automatic PCB board corrosion chamber. The automatic PCB board corrosion chamber comprises a central control module, a frequency modulation vibration module, a mechanical transmission module, a temperature detection and feedback module, a heating module, a liquid-level sensor module, a stroke control module, an alarm reminding module, an OLED liquid crystal display module, a button module, a drive module and a power supply module. According to the working mode of the automatic PCB board corrosion chamber, the temperature detection and feedback module and the heating module form a closed loop so that the temperature of a corrosion solution is maintained at optimum corrosion temperature range; the PCB board is driven to be vibrated by the vibration of a vibration motor so as to greatly speed up the contact rate of PCB board and effective ions in the corrosion solution; the corrosion solution inside the corrosion chamber is stirred through the gas generated from a gas pump so that the effective ions inside the corrosion chamber are uniformly distributed in the corrosion solution, the corrosion rate is accelerated, the corrosion quality is improved, the erosion waiting time is reduced, the manpower is released through automatic control and the corrosion quality is improved by setting and establishing a delay control mechanism. The automatic PCB board corrosion chamber is simple in operation and is convenient to popularize.

Owner:博罗县亿阳电子有限公司

Corrosion method for germanium substrate sheet of solar battery

InactiveCN103233228AHigh strengthReduce breakage rateFinal product manufactureSemiconductor devicesHydrogen NitrateElectrical battery

The invention discloses a corrosion method for germanium substrate sheet of solar battery, comprising the following steps of: preparing No.1 corrosion liquid medicine by 1200-1300ml of pure water and 140-150ml of hydrofluoric acid with mass concentration of 48-50%, orderly placing the germanium sheet in a clamping plug, showering the clamping plug with the pure water and then dipping the clamping plug into the No.1 corrosion liquid medicine, shaking the clamping plug, after corroding the germanium sheet for 7-10 seconds, taking out the germanium sheet, quickly placing the germanium sheet into a pure water tank for washing, and showering the germanium sheet with the pure water; preparing a No.2 corrosion liquid medicine by 150-160ml of glacial acetic acid with mass concentration of not less than 99.7%, 3-5ml of bromine water with mass concentration of 99.5% and 250-260ml of hydrogen nitrate with mass concentration of 98%; dipping the clamping plug with the germanium sheet into the No.2 corrosion liquid medicine, shaking the clamping plug, taking out the germanium sheet after corroding for 20-30 seconds, placing the germanium sheet into the pure water tank for washing, showering the germanium sheet with the pure water, and finally, placing the clamping plug and the germanium sheet into a flowing water tank. By corrosion according to the method provided by the invention, the strength of the germanium sheet is enhanced, the strength is more than 18bf, and the breakage rate of the germanium sheet is greatly reduced.

Owner:中锗科技有限公司

Metallographic corrosive and metallographic structure display method of copper and copper alloy

PendingCN109580315AImprove corrosion efficiencyImprove the display effectPreparing sample for investigationMicroscopic observationCopper alloy

The invention provides a metallographic structure display method of copper and a copper alloy. The metallographic structure display method of the copper and the copper alloy comprises the steps of: (1), providing a metallographic sample of the copper and the copper alloy, wherein the metallographic sample comprises a copper layer and a copper alloy layer plated on the copper layer; (2), providinga container, fixing the metallographic sample into the container, and adding polyflor resin; (3), taking out the metallographic sample encircled by the polyflor resin, mechanically grinding the metallographic sample, and then, mechanically polishing the grinded metallographic sample; (4), providing a metallographic corrosive, wherein the metallographic corrosive is mixed solution of ferric trichloride and hydrochloric acid, and performing metallographic micro-corrosion by dip dyeing of the polished metallographic sample through the metallographic corrosive; and (5), washing and drying the corroded metallographic sample, observing the copper layer and the copper alloy layer of the dried metallographic sample by using a microscope, so that the boundary of the copper and the copper alloy canbe displayed clearly, and measurement of the thickness of the copper layer can be easily carried out.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

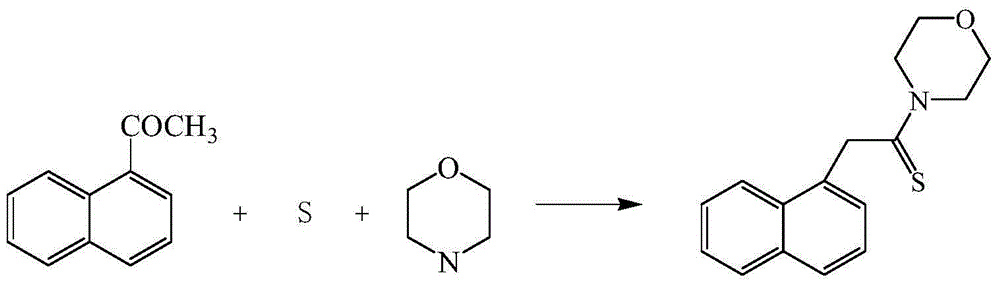

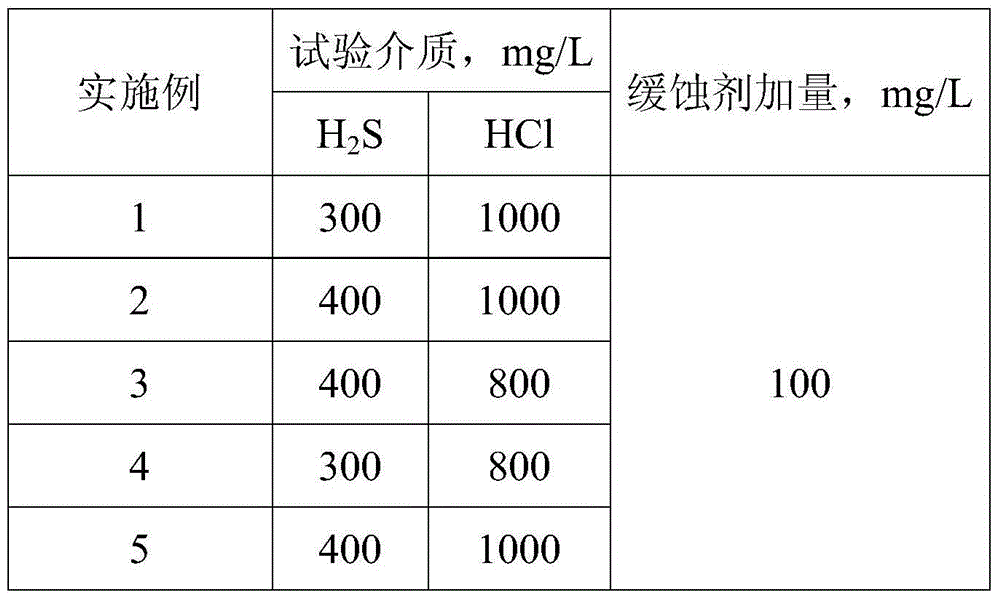

High-temperature corrosion inhibitor for H2S-HCl-H2O system and preparation method of high-temperature corrosion inhibitor

The invention relates to a high-temperature corrosion inhibitor for an H2S-HCl-H2O system and a preparation method of the high-temperature corrosion inhibitor. According to the preparation method, methyl-alpha-naphthyl ketone, morpholine and sulfur are taken as main raw materials and are subjected to a Willgerodt-Kindler method to generate naphthylethyl thioacylmorpholine. The high-temperature corrosion inhibitor comprises the following components in percentage by weight: 30%-50% of ethyl thioacylmorpholine, 5%-15% of hexadecyl pyridine, 10%-15% of alcohol amine compounds, 1%-3% of potassium molybdate or potassium tungstate and 29%-57% of a solvent. The high-temperature corrosion inhibitor belongs to strong-adsorption mixed type corrosion inhibitors, is capable of forming a layer of compact protecting film on the surface of metal and particularly applicable to the corrosion prevention of the H2S-HCl-H2O system and can be generalized and used for the prevention of sulfuretted hydrogen corrosion in the industries of oil fields, boilers and steel mills. The use temperature of the high-temperature corrosion inhibitor during the use can reach 120 DEG C; the high-temperature corrosion inhibitor has the characteristics of low consumption, high efficiency, wide use temperature range, good dispersity and low environmental pollution and is simple and convenient to produce.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Device for corroding silicon carbide wafer by alkali steam

ActiveCN113550012AEasy to installEasy to movePolycrystalline material growthAfter-treatment detailsCarbide siliconWafering

The invention discloses a device for corroding a silicon carbide wafer by alkali steam, and the device comprises a reaction part comprising a silicon wafer installation part and a corrosion-resistant cavity, a heating part connected with the reaction part and used for heating the corrosion-resistant cavity, and a plugging part comprising a first pipe plug and a second pipe plug. By arranging the pipe plugs, the reaction part is sealed, and the corrosion effect is guaranteed; and by arranging a condensation area and a reaction area on each pipe plug, absorption and reaction of high-temperature alkaline steam are achieved, and the influence on human health caused by the fact that the alkaline steam is diffused into air is reduced.

Owner:ZHEJIANG UNIV HANGZHOU GLOBAL SCI & TECH INNOVATION CENT

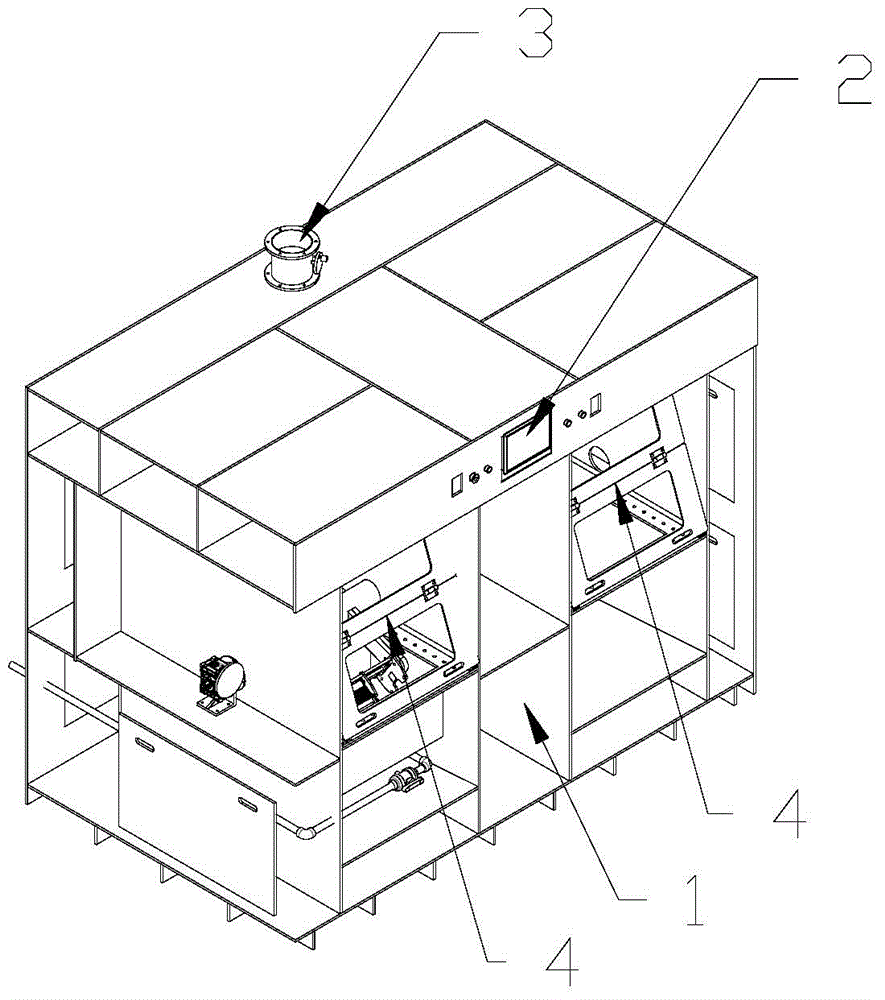

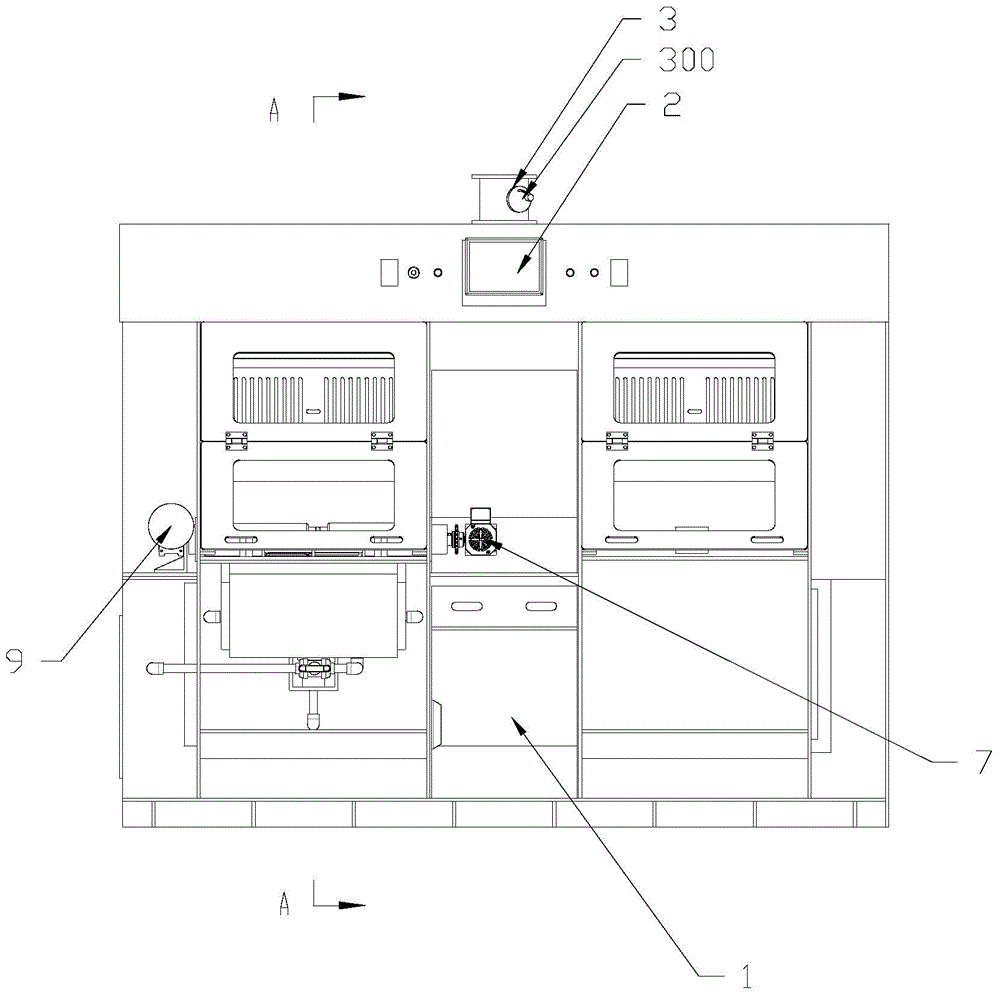

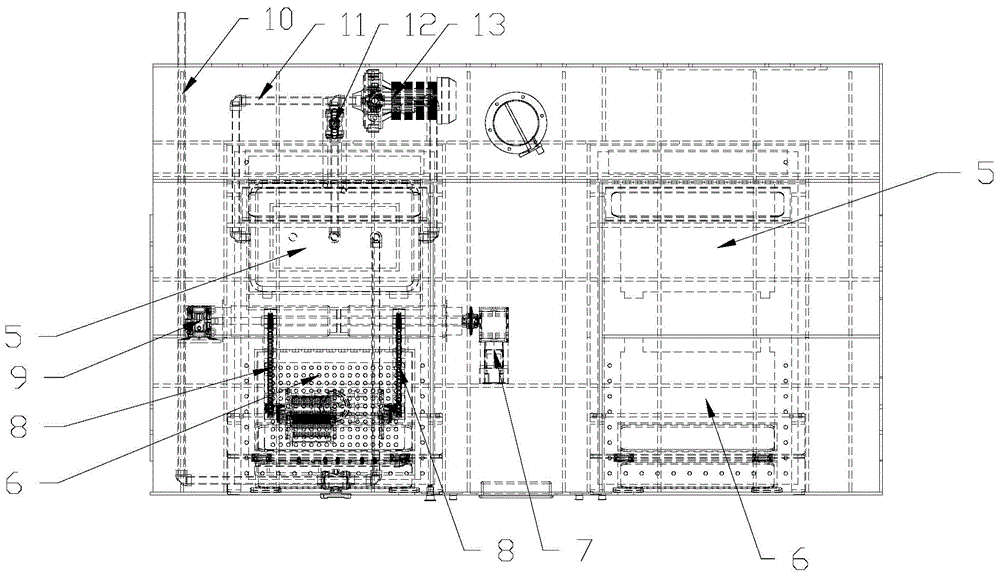

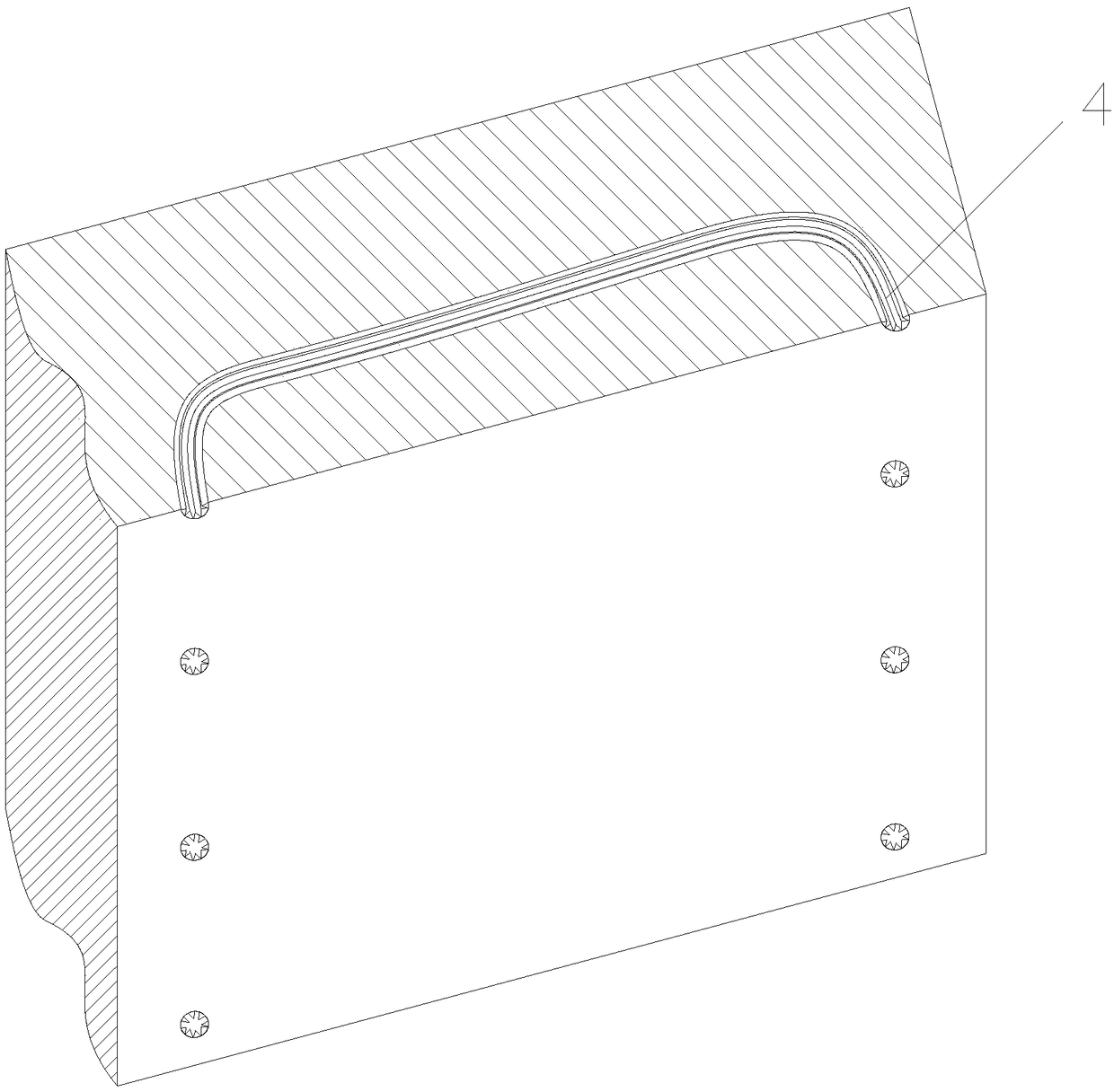

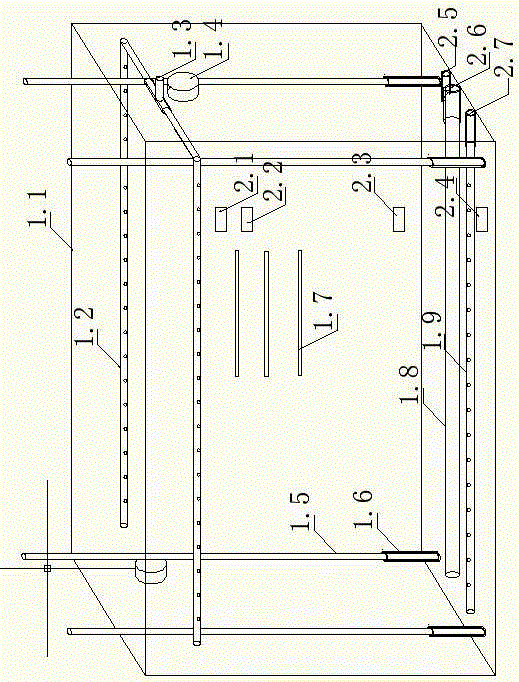

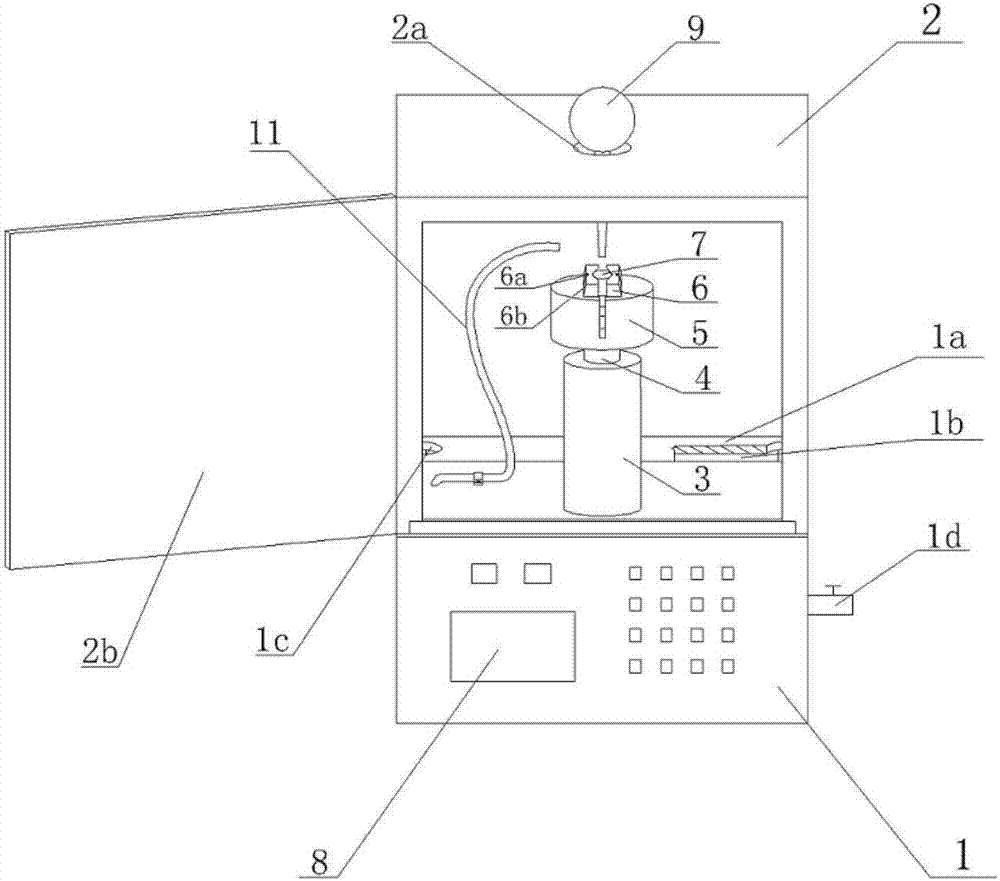

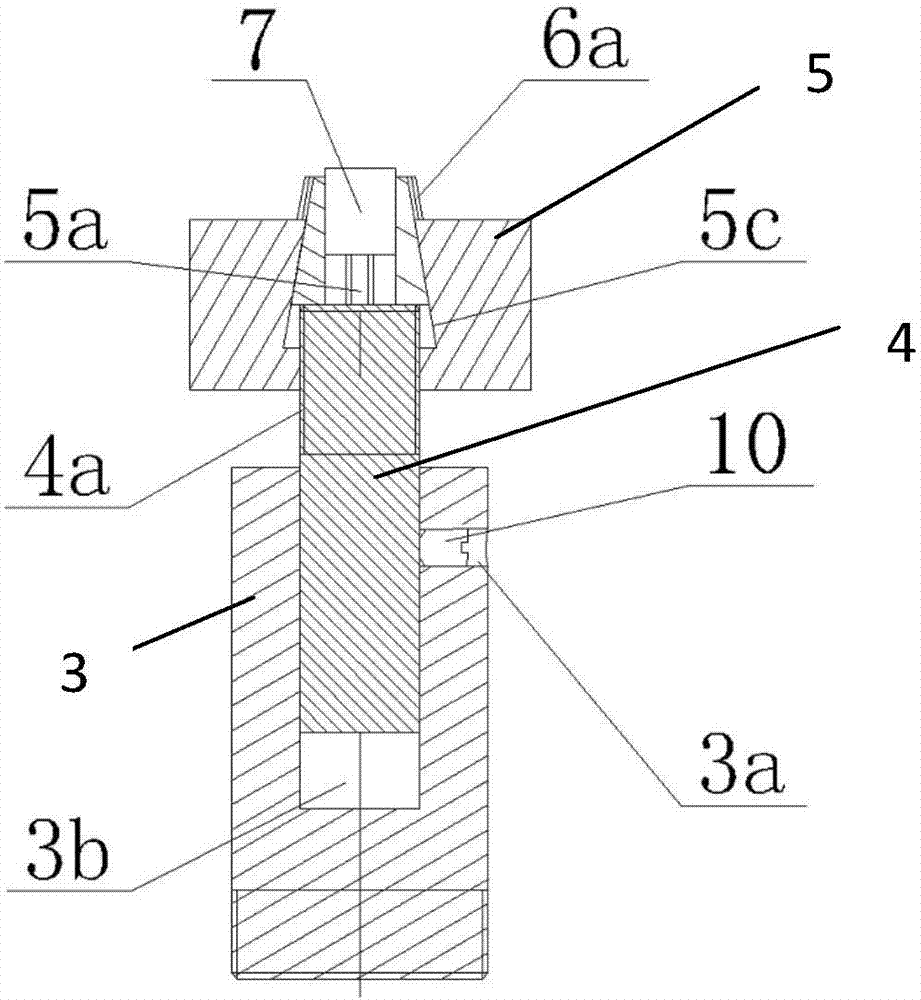

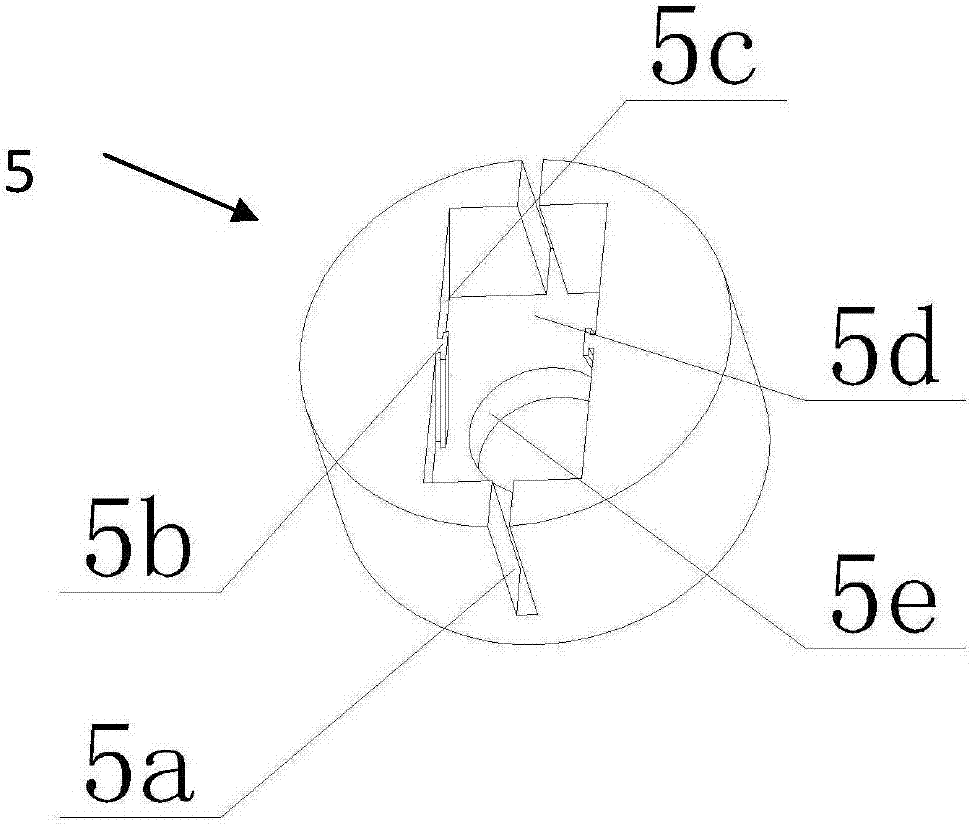

Metallographic sample chemical immersion corrosion instrument

ActiveCN107063818AShorten the timeLow costPreparing sample for investigationElectronic control systemEngineering

The invention relates to a metallographic sample chemical immersion corrosion instrument, which comprises a box body, a sample flushing system, an electronic control system, a sample clamping mechanism and a corrosive liquid dropper. Specifically, the box body comprises a base and a cover arranged at the upper end of the base; the sample flushing system comprises a flushing water tank, an electronic control pump and a water spray pipe; the electronic control system comprises a controller and a control panel; and the sample clamping mechanism comprises a support rod, a lifting rod, a trapezoidal block seat, two trapezoidal blocks, and a stop screw. Compared with the manual corrosion way, the metallographic sample chemical immersion corrosion instrument provided by the invention saves labor, improves the corrosion efficiency, reduces the metallographic sample making time and cost, also ensures the corrosion quality, avoids the risk of corrosive liquid damage to operation staff, and solves the sample over-corrosion problem.

Owner:CIVIL AVIATION UNIV OF CHINA

Metallographic corrosive agent and metallographic structure display method of crimped core wire

PendingCN109580614AImprove corrosion efficiencyImprove the display effectPreparing sample for investigationMaterial analysis by optical meansAlcoholCopper wire

The invention provides a metallographic structure display method of a crimped core wire. The display method comprises the following steps: step1, providing a metallographic sample of a plurality of copper wire and copper alloy wires, wherein the metallographic sample comprises a plurality of core wire copper layers and copper alloy layers surrounding and crimping outside the plurality of core wirecopper layers; step2, adding a polyster; step3, mechanically grinding the metallographic sample, and performing mechanical polishing on the grinded metallographic sample; step4, providing a metallographic corrosive agent, and impregnating the metallographic corrosive agent with the metallographic sample for metallographic micro corrosive, wherein the metallographic corrosive agent is a mixed solution of ferric chloride, hydrochloric acid and alcohol; and step5, washing and drying the corroded metallographic sample, and observing a multi-core copper layer and the copper alloy layer of the dried metallographic sample by a microscope, thereby clearly showing the boundary between the core wire copper layer and the copper alloy layer after crimping, and facilitating observation of the crimpingeffect between the core wires and between the core wires and the alloy copper layer.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Method decaying crop straw to produce matrix

InactiveCN105837343APromote growthRapid decayExcrement fertilisersAmmonium salt fertilisersPlastic mulchSoil fertility

The invention discloses a method decaying crop straw to produce matrix. The method includes: digging a decaying tank, preparing a decaying agent, crushing the straw, laying farm manure at the bottom of the decaying tank, spraying the decaying agent to the exterior of the straw, covering, mulching and fermenting and decaying. The method has the advantages that the method is simple to operate, capable of fast decaying the crop straw, high in decaying efficiency and capable solving the problems that the straw is piled randomly and causes pollution due to uncontrolled incineration; the decaying agent used by the method is easy in preparation process, free of environment pollution, capable of increasing soil fertility and promoting crop growth.

Owner:ANHUI XIYANGYANG AGRI TECH

Transferring method of edge-free vertical structure LED chip substrate

ActiveCN108878596AExcellent substrate transfer processSolve the problem of fragmentationSemiconductor devicesEngineeringThinning

The invention discloses a transferring method of an edge-free vertical structure LED chip substrate. The transferring method of the edge-free vertical structure LED chip substrate comprises a metal layer depositing step, an epitaxial wafer surface treatment step, a substrate deposition transferring step, a bonding step, a thinning step, a residual silicon removal step, and a vertical LED chip preparation step. The transferring method of the edge-free vertical structure LED chip substrate disclosed by the invention can solve the problems in the current substrate transferring process by means ofthe epitaxial wafer surface treatment step, the thinning step, the residual silicon removal step and the like, which can obtain a comparatively excellent substrate transferring technology.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

Three-dimensional flower-ball-shaped lanthanum bismuth ferrite powder and preparation method thereof

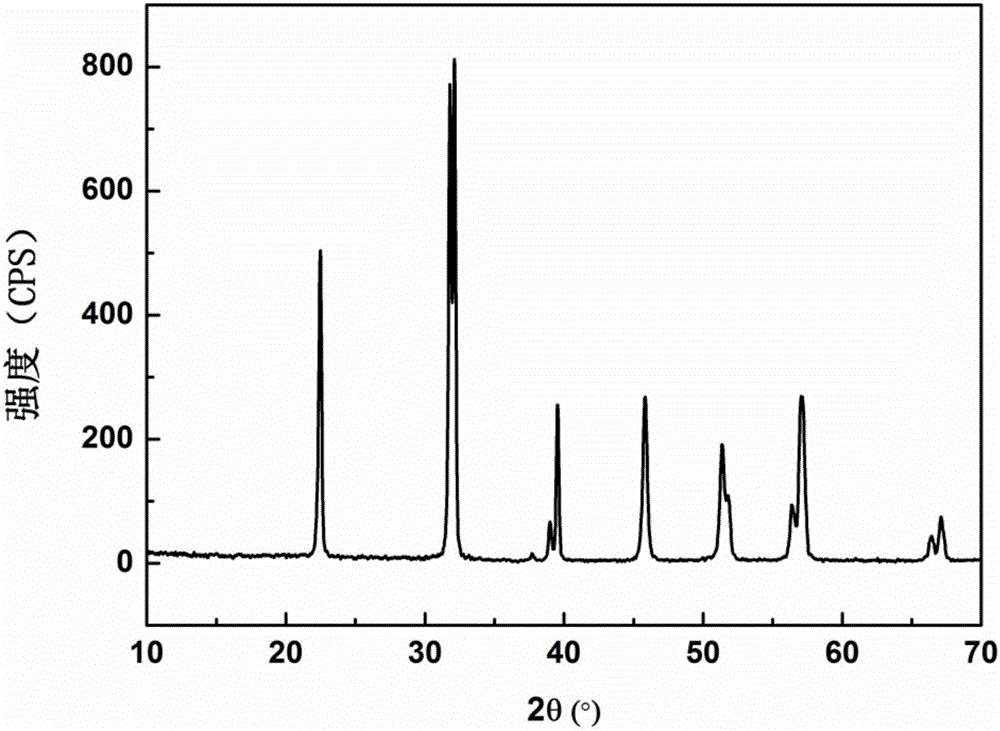

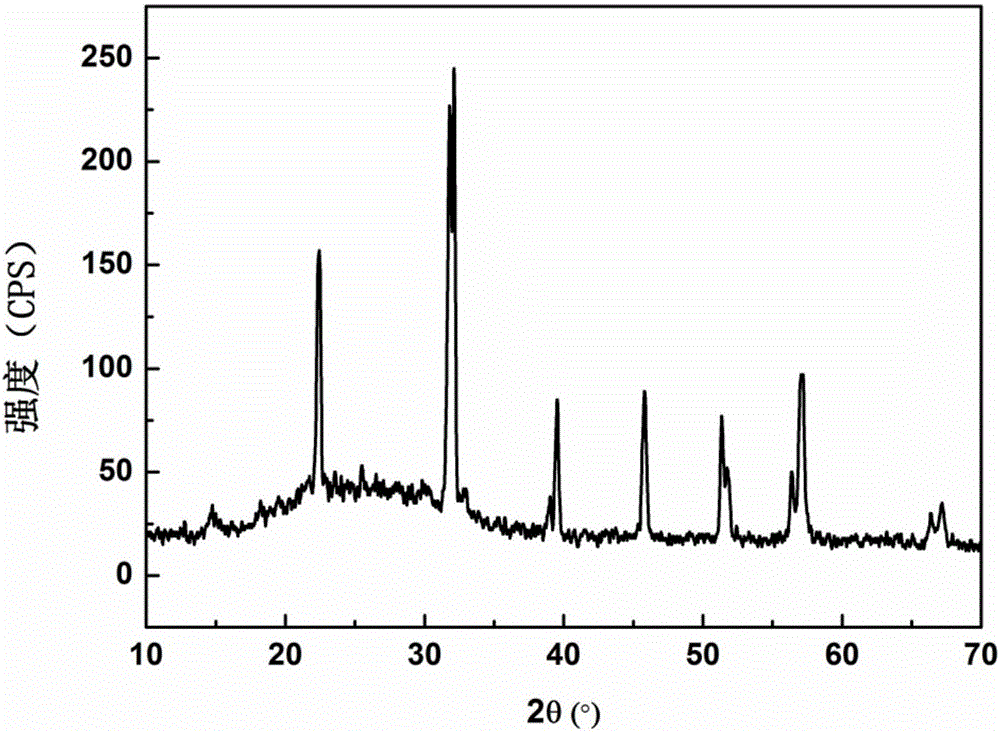

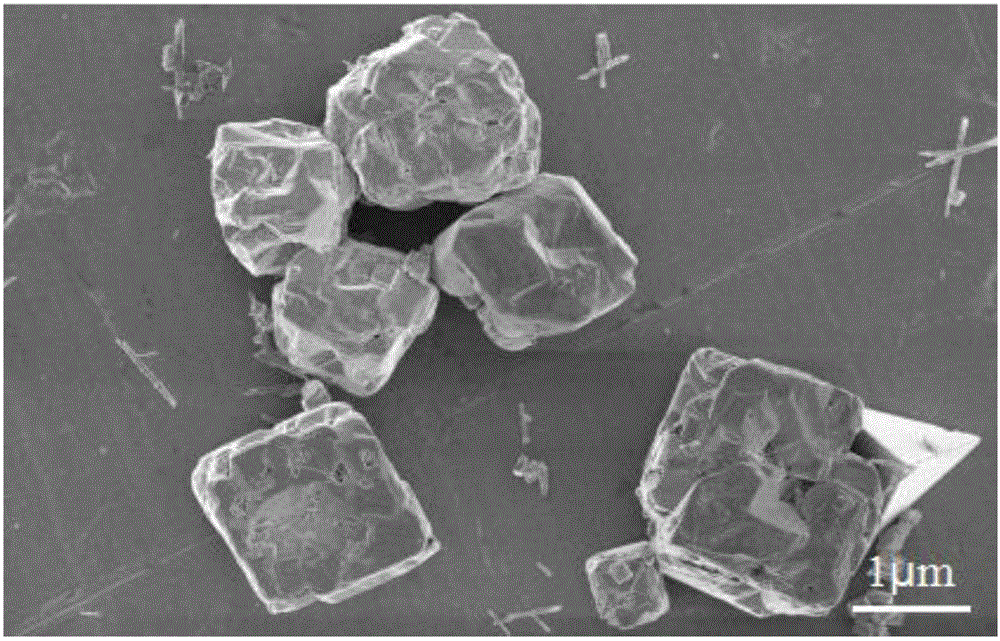

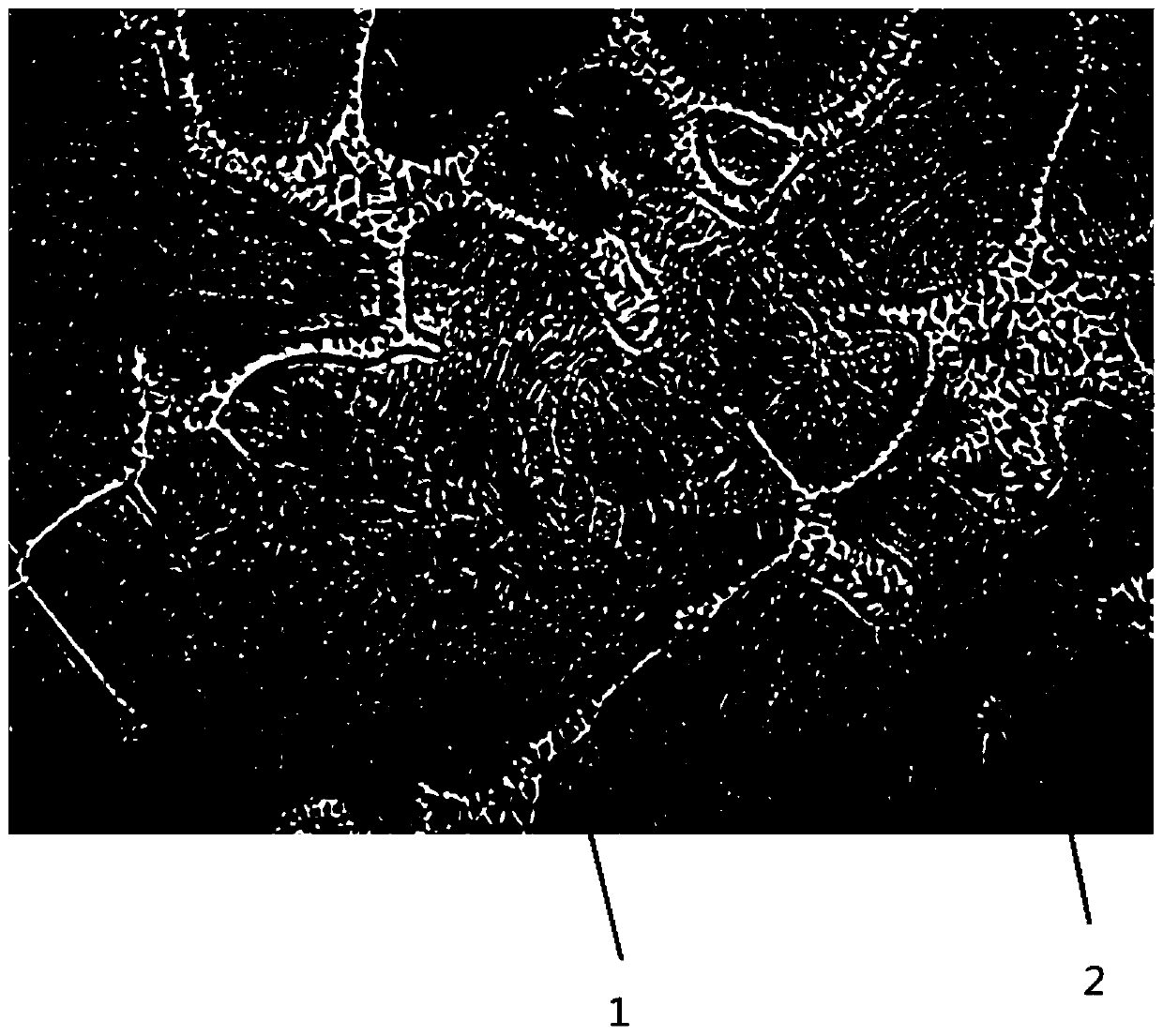

ActiveCN106745303AUniform shape and sizeEvenly dispersedMaterial nanotechnologyIron compoundsLanthanumMethyl thioglycolate

The invention discloses three-dimensional flower-ball-shaped lanthanum bismuth ferrite powder and a preparation method thereof. The preparation method comprises the steps of using Bi(NO3)3 5H2O, La(NO3)3 6H2O and Fe(NO3)3 9H2O as raw materials, preparing square-shaped Bi0.9La0.1FeO3 powder through a hydrothermal method, then processing the Bi0.9La0.1FeO3 powder through a one-step etching method, using N,N-dimethyl formamide as solvent and using reducing agent of hydrazine hydrate and complexing agent of methyl thioglycolate at the same time to prepare the three-dimensional flower-ball-shaped lanthanum bismuth ferrite powder. The specific surface area of the flower-ball-shaped Bi0.9La0.1FeO3 powder prepared through the preparation method disclosed by the invention is enlarged; meanwhile, the preparation method is simple, short in period, high in etching efficiency and free of environmental pollution; in addition, reaction is easy to control.

Owner:SHAANXI UNIV OF SCI & TECH

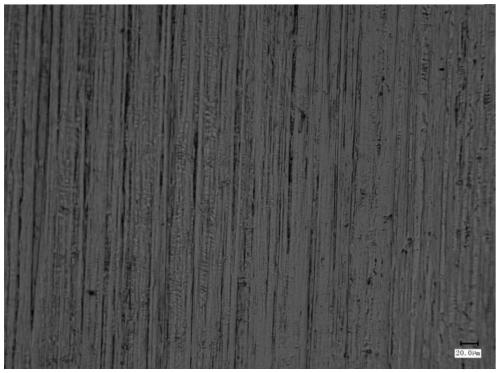

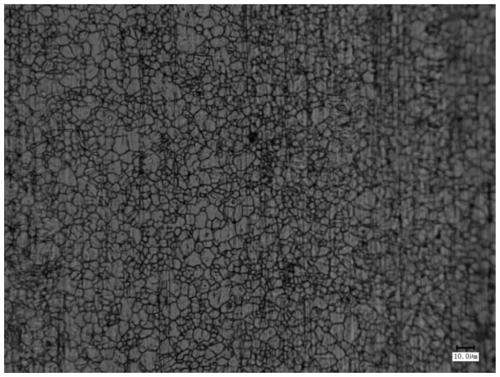

Metallographic corrosive of stainless steel high temperature quenched structure and corrosion method thereof

InactiveCN110608937AImprove display efficiencySimple configurationPreparing sample for investigationCorrosionCitric acid

The invention relates to a metallographic corrosive of a stainless steel high temperature quenched structure and a corrosion method thereof. The corrosive is made from a first corrosive and a second corrosive, wherein the first corrosive is prepared by mixing nitric acid with concentration of 68% and absolute ethyl alcohol, and the second corrosive is prepared by mixing hydrochloric acid with concentration of 37%, citric acid and absolute ethyl alcohol. The corrosive provided in the invention is easy to prepare, and the corrosion method is simple to conduct and can deliver a clear metallographic structure.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

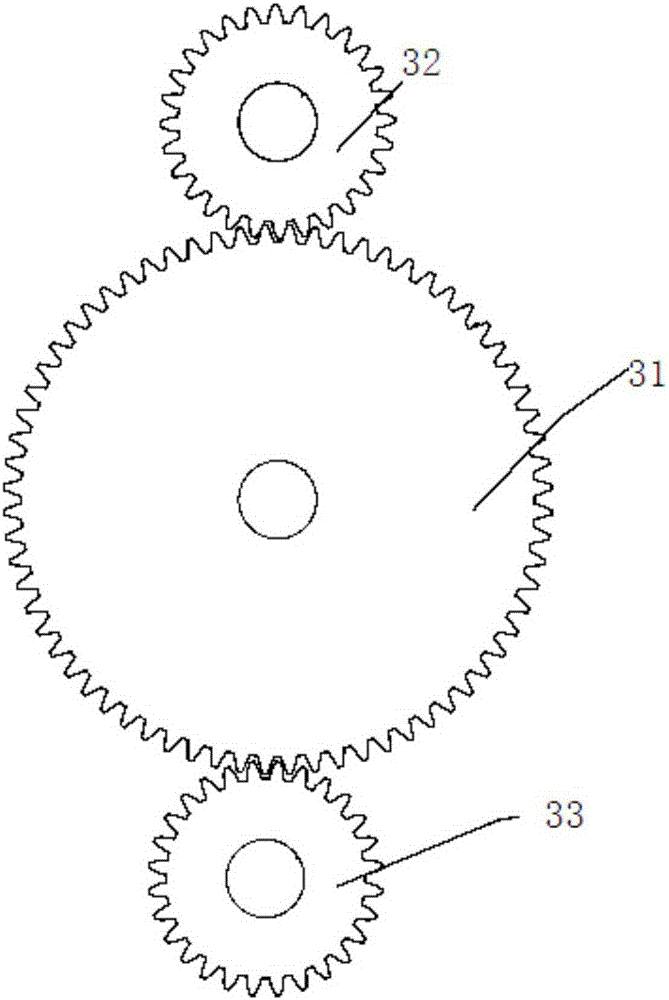

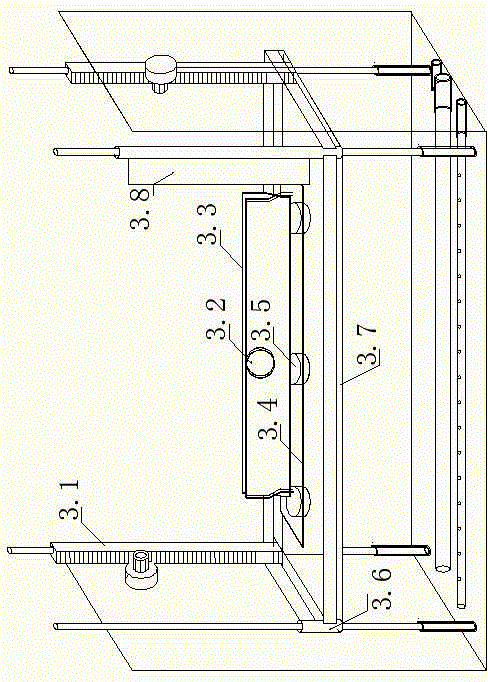

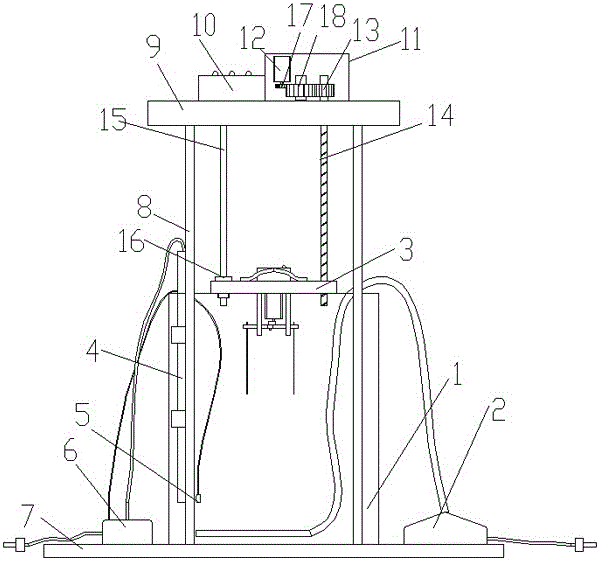

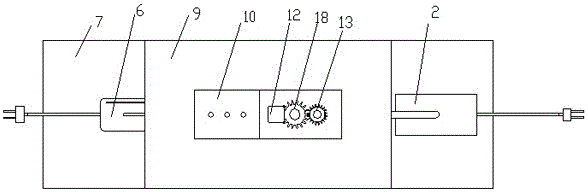

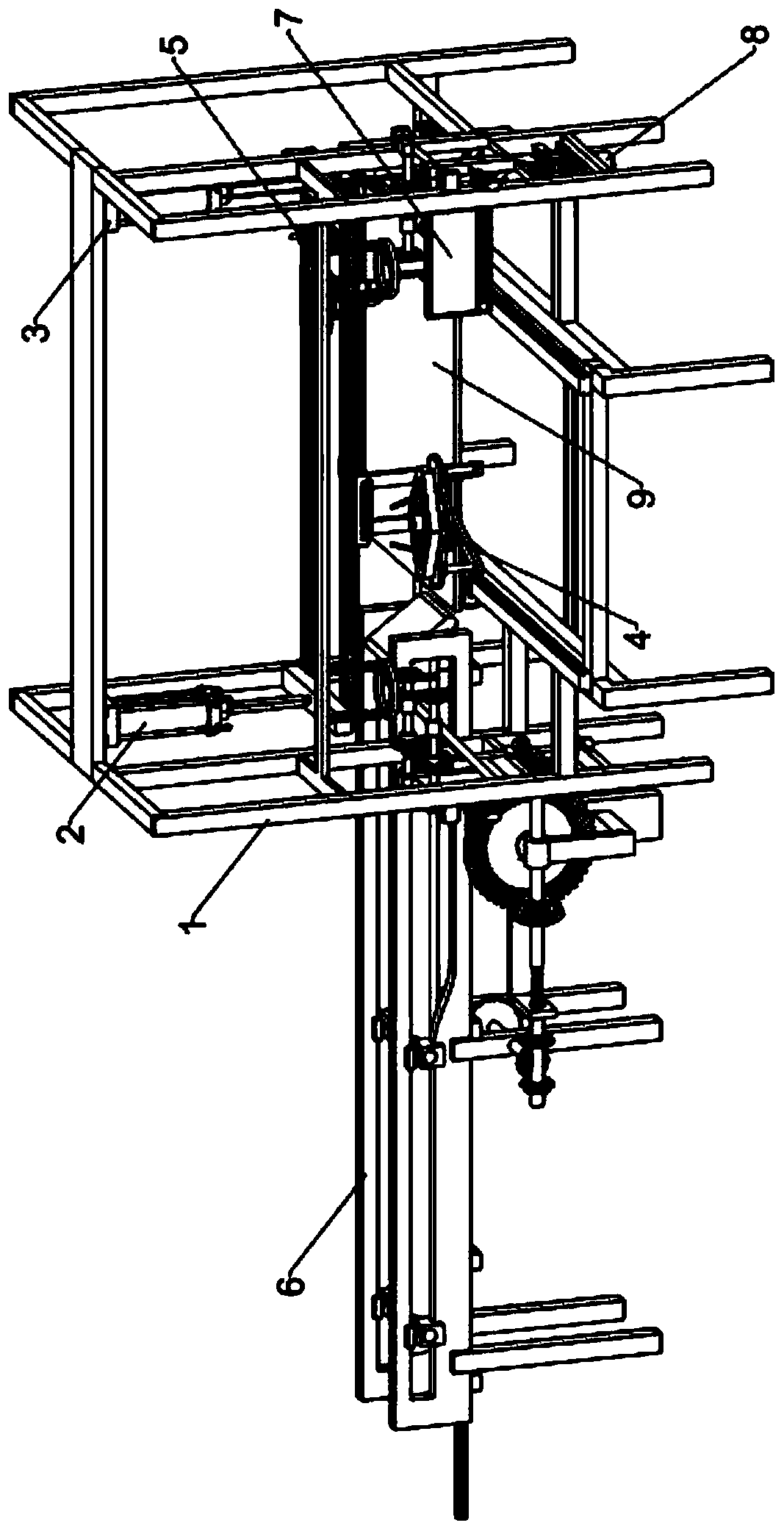

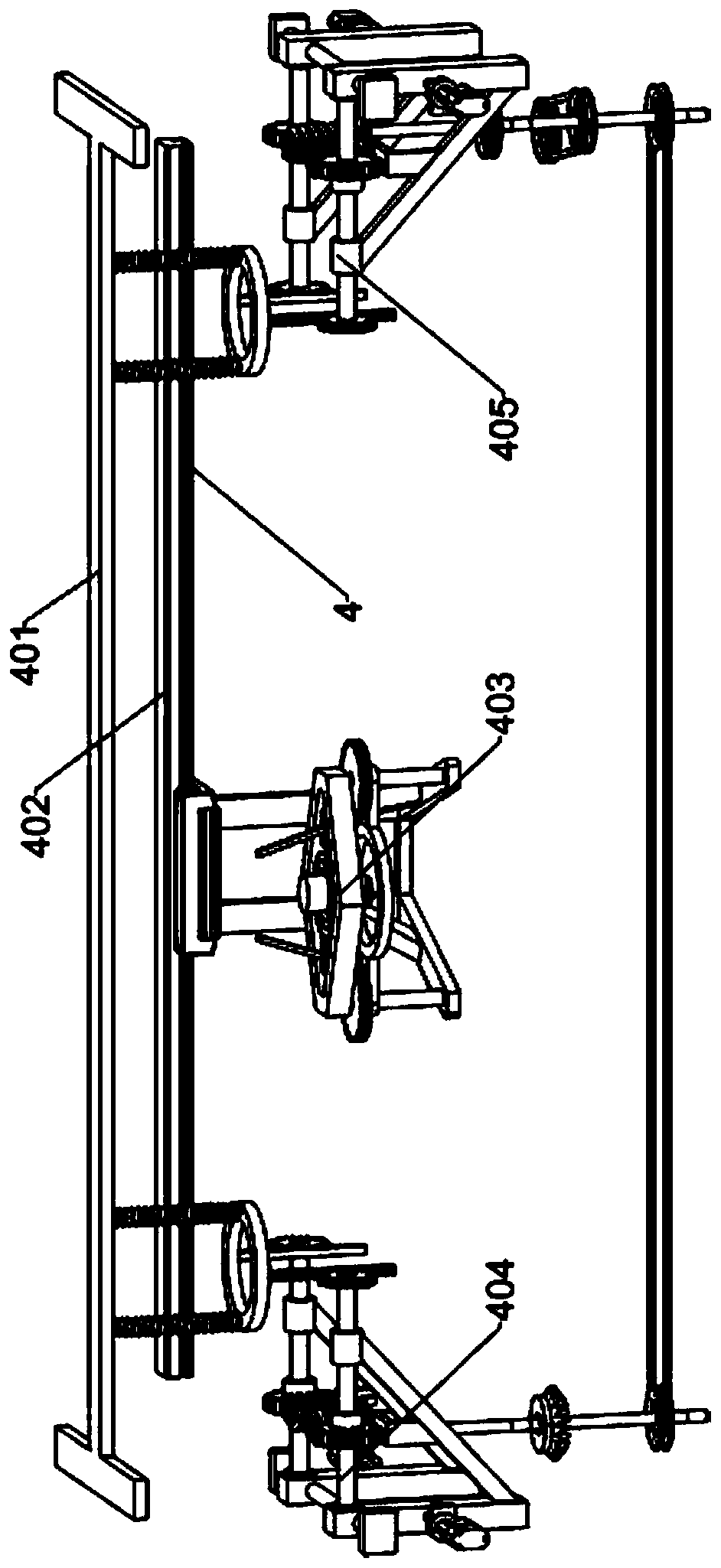

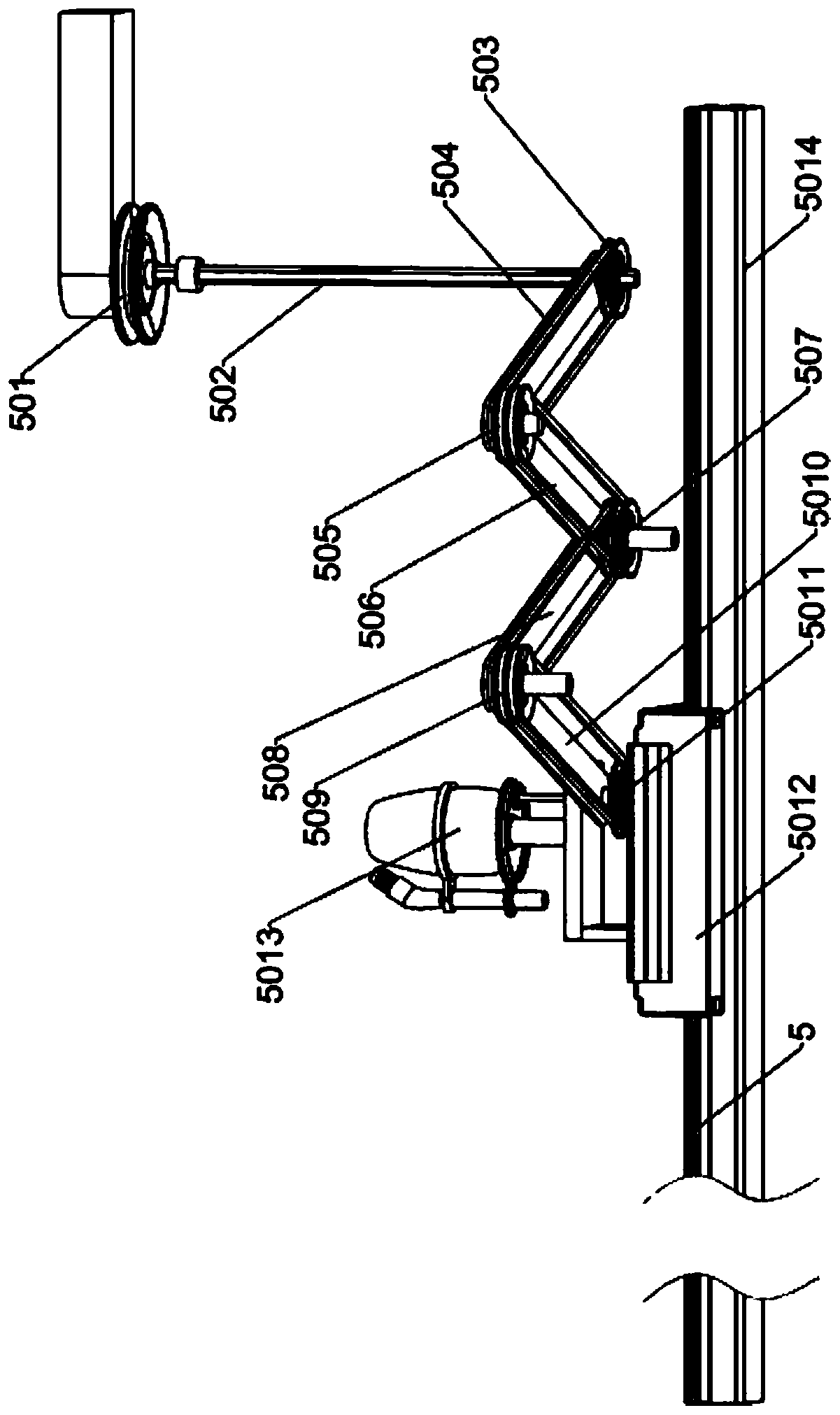

PCB (Printed Circuit Board) lift etching machine and using method thereof

PendingCN106455348ASimple structureEasy to operateConductive material chemical/electrolytical removalEngineeringMechanical engineering

The invention relates to a PCB (Printed Circuit Board) lift etching machine and a using method thereof. The lift etching machine comprises a base, wherein an etching tank, a bubble generator and a heating temperature control device are arranged on the base; the bubble generator is communicated with the etching tank through an air pipe; an upper cover is arranged on the etching tank, a lifting device is arranged above the upper cover, and a vibration device is arranged on the upper cover; the lifting device comprises a top plate, a lift control box and a transmission device; a supporting column is arranged on the base and is used for supporting the top plate; the transmission device comprises a lifting motor, a driving gear, a transmission gear, an output gear, a guide rod and a screw rod; the upper end of the screw rod penetrates through the lower end of the top plate and the upper cover, and the lower end of the screw rod is connected with the upper cover in a threaded manner; the upper end of the guide rod is fixed on the lower surface of the top plate, and the lower end of the guide rod runs through a guide sleeve; the guide sleeve is arranged on the upper cover in a penetrating manner; the driving gear is arranged on the output shaft of the lifting motor; the output gear is arranged at the upper end of the screw rod; and the transmission gear is in meshed transmission with the driving gear and the output gear. The PCB lift etching machine has the advantages of simple structure, convenience in operation and popularization and high etching efficiency.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for manufacturing GaP rough surface of GaAs-based LED wafer

ActiveCN112397624AUniformly roughened surfaceEasy to controlSemiconductor devicesRough surfaceWafering

The invention discloses a method for manufacturing a GaP rough surface of a GaAs-based LED wafer, and the method comprises the steps: preparing a wafer epitaxial layer, carrying out the roughening corrosion of a GaP window layer of the epitaxial layer, dissolving photoresist and roughening corrosion liquid together through a surfactant, forming corrosion sol with a roughening corrosion effect, coating the surface of the GaP window layer with the corrosion sol, baking at a constant temperature of 40-60 DEG C, removing a corrosion film layer and a silicon dioxide layer by using solvents such asacetone and the like, and continuously preparing to obtain an independent tube core; the process method designed by the invention is simple and easy to operate, does not need to introduce special equipment, is lower in cost, is more uniform in coarsening corrosion of the surface of the epitaxial layer, is higher in corrosion controllability, is good in coarsening effect, and solves the problems that the coarsening corrosion is more difficult to control and the coarsening brightness is not improved greatly when a solution is used at present. When the method provided by the invention is used forcoarsening, the light extraction efficiency can be improved by 25-30 percent, and the method has higher practicability.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

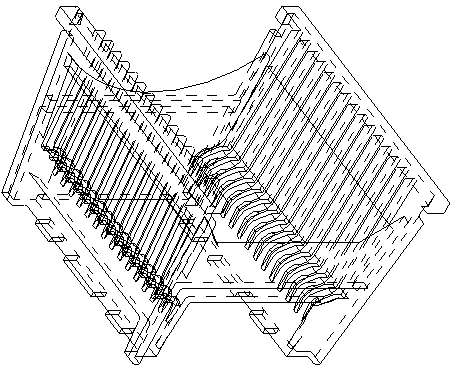

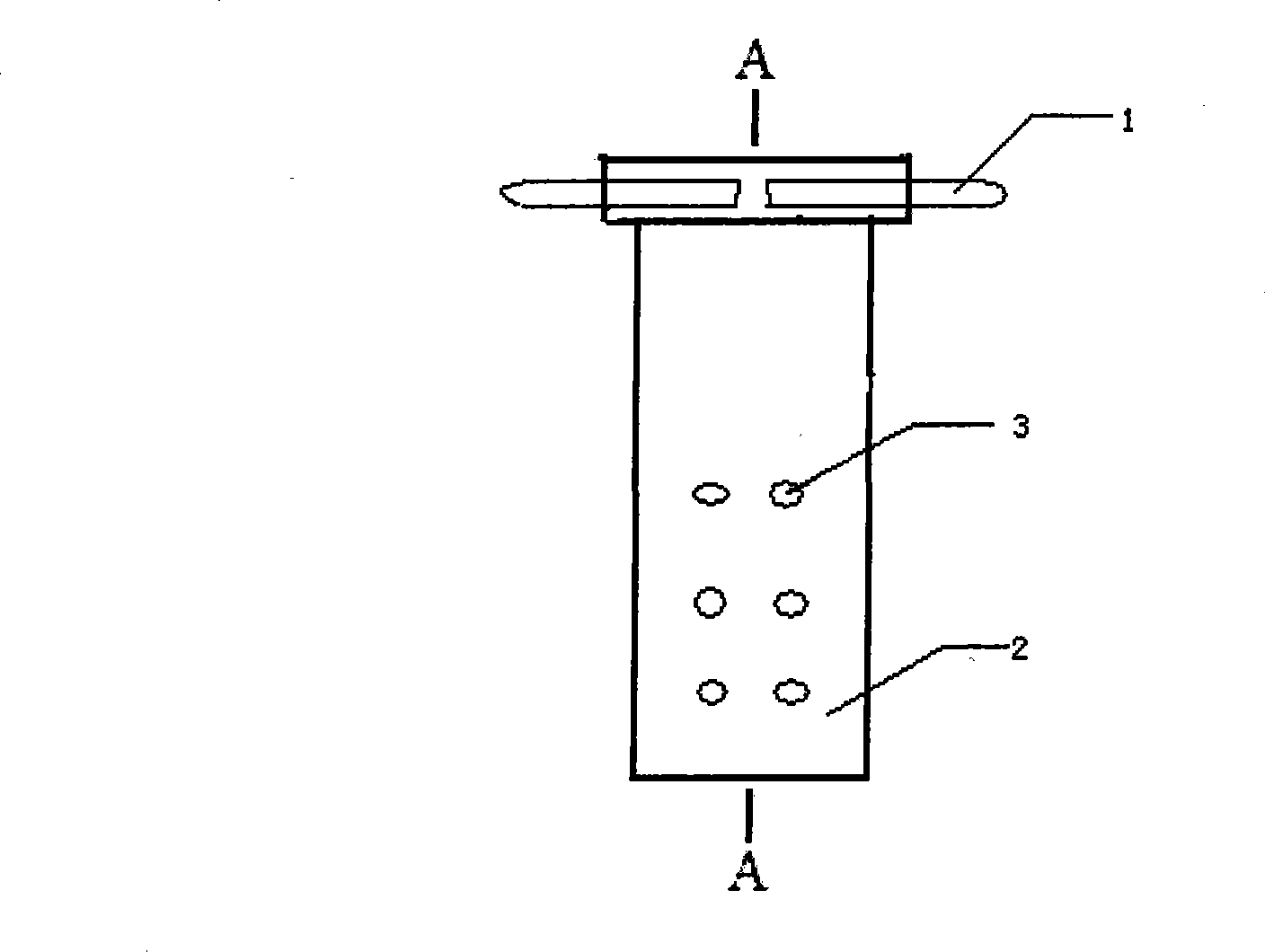

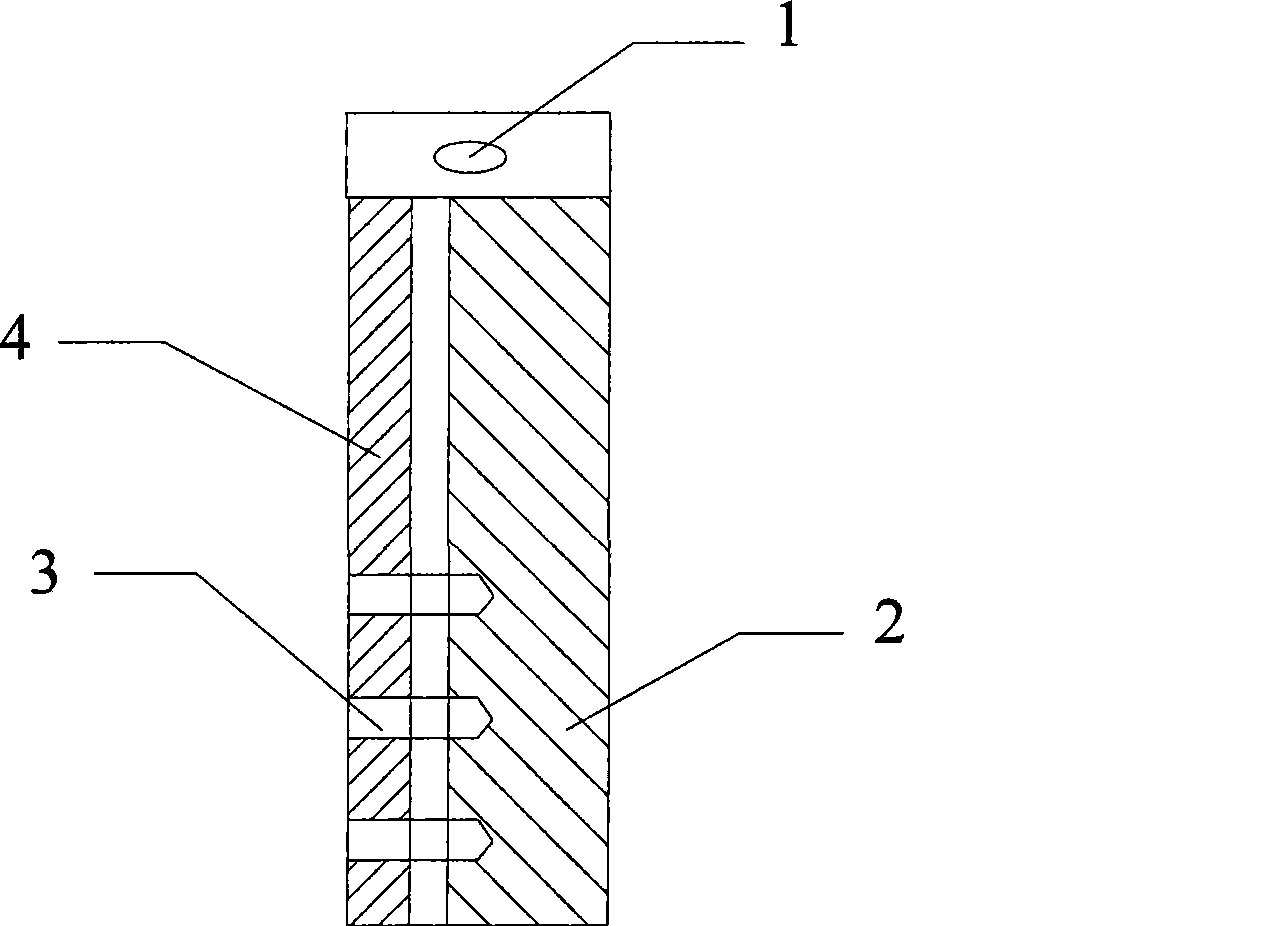

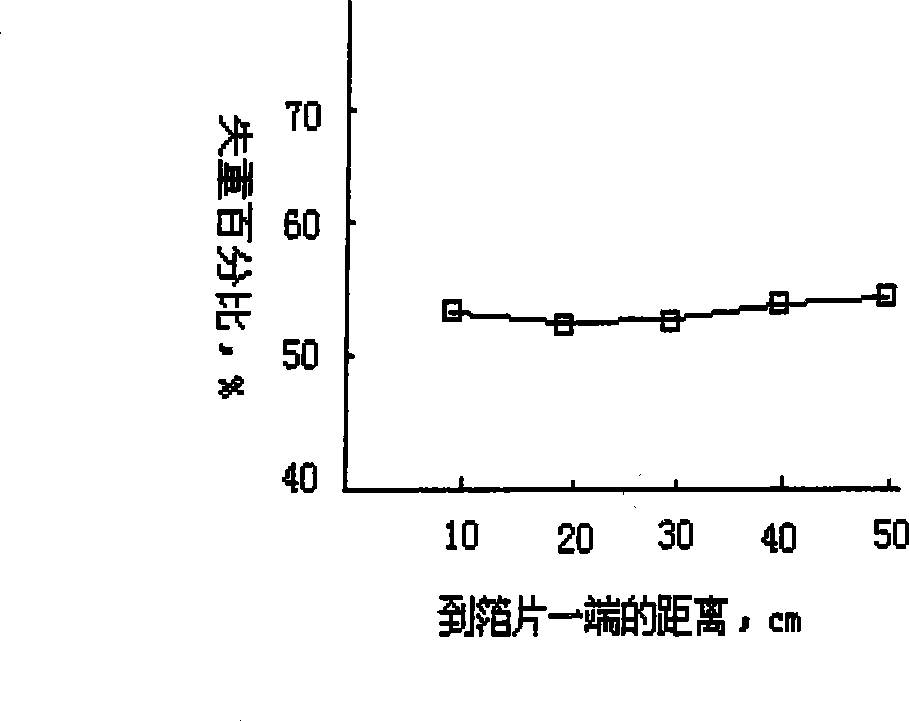

Novel graphite resistor rod for aluminum foil corrosion of capacitor

InactiveCN101423954AImprove lateral current distribution uniformityImprove the uniformity of capacitance distributionElectrolytic capacitorsElectrodesGraphiteCopper

The invention belongs to the technical field of graphite electrodes, in particular to a graphite electrode used by an aluminum electrolytic capacitor for electrochemical corrosion. The graphite electrode consists of a graphite polar plate, an insulated baffle plate and two copper bars. One end of each copper bar is inserted into the graphite polar plate and the other end of each cooper plate is connected with a power wire. The insulated baffle plate is fixed with the graphite polar plate through a graphite bolt and a non-through screw hole. Compared with the graphite electrode in the prior art, the graphite electrode has the advantages that the current in the electrode is uniformly distributed, lateral deviation of electrode foil is obviously lowered, and the self-corrosion of the electrode foil can not become more serious due to prevention of production of other metal elements that can pollute liquid in an etch bath.

Owner:DONGGUAN HEC CONDENSER CO LTD

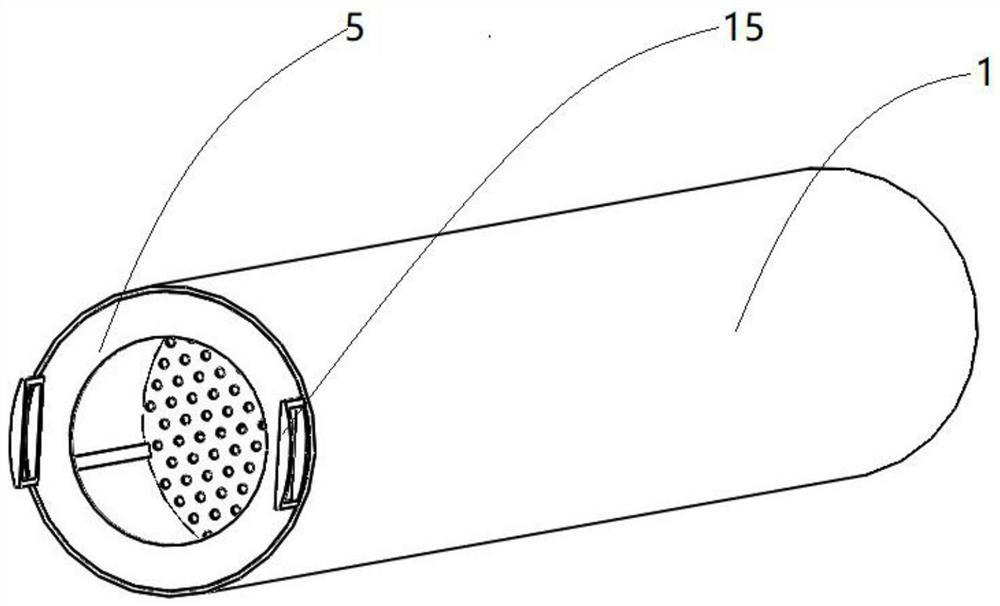

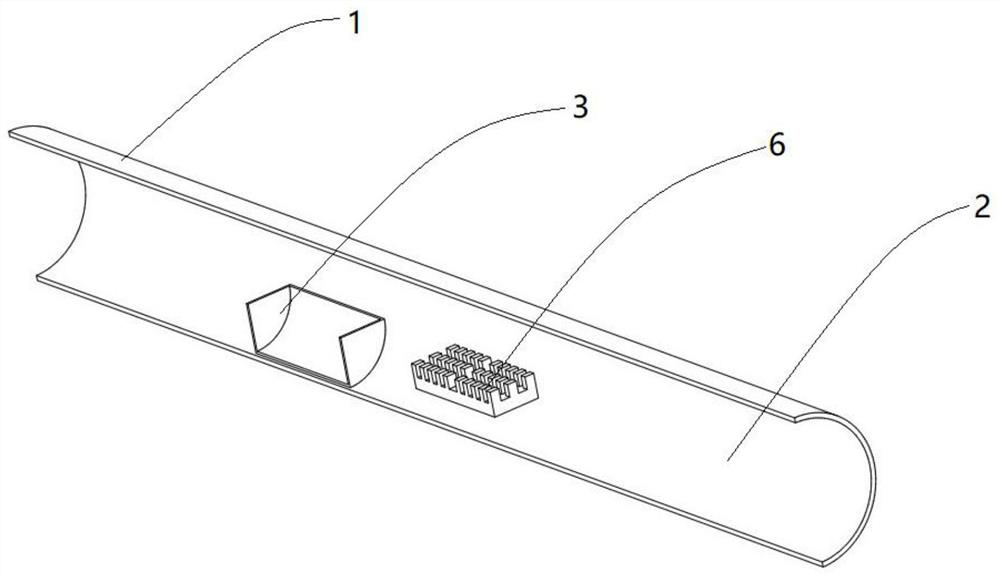

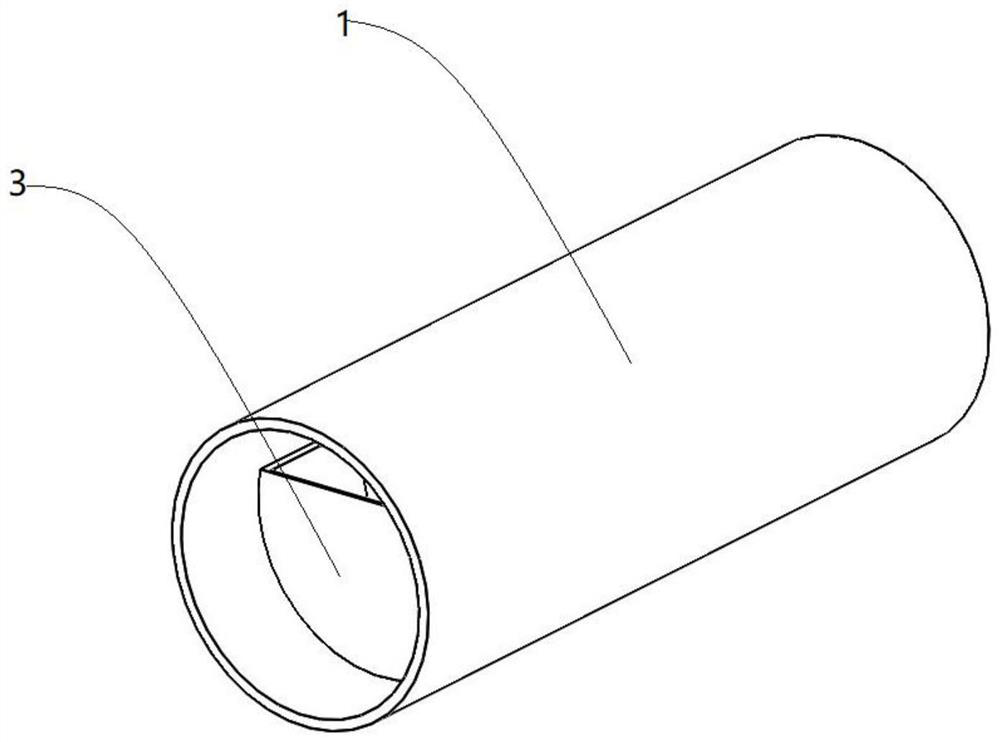

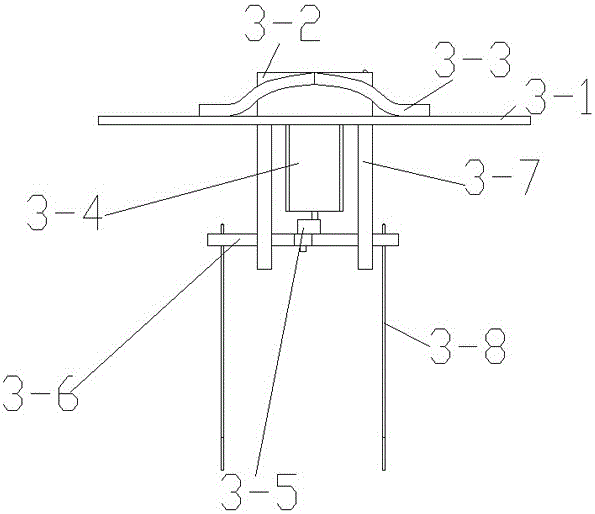

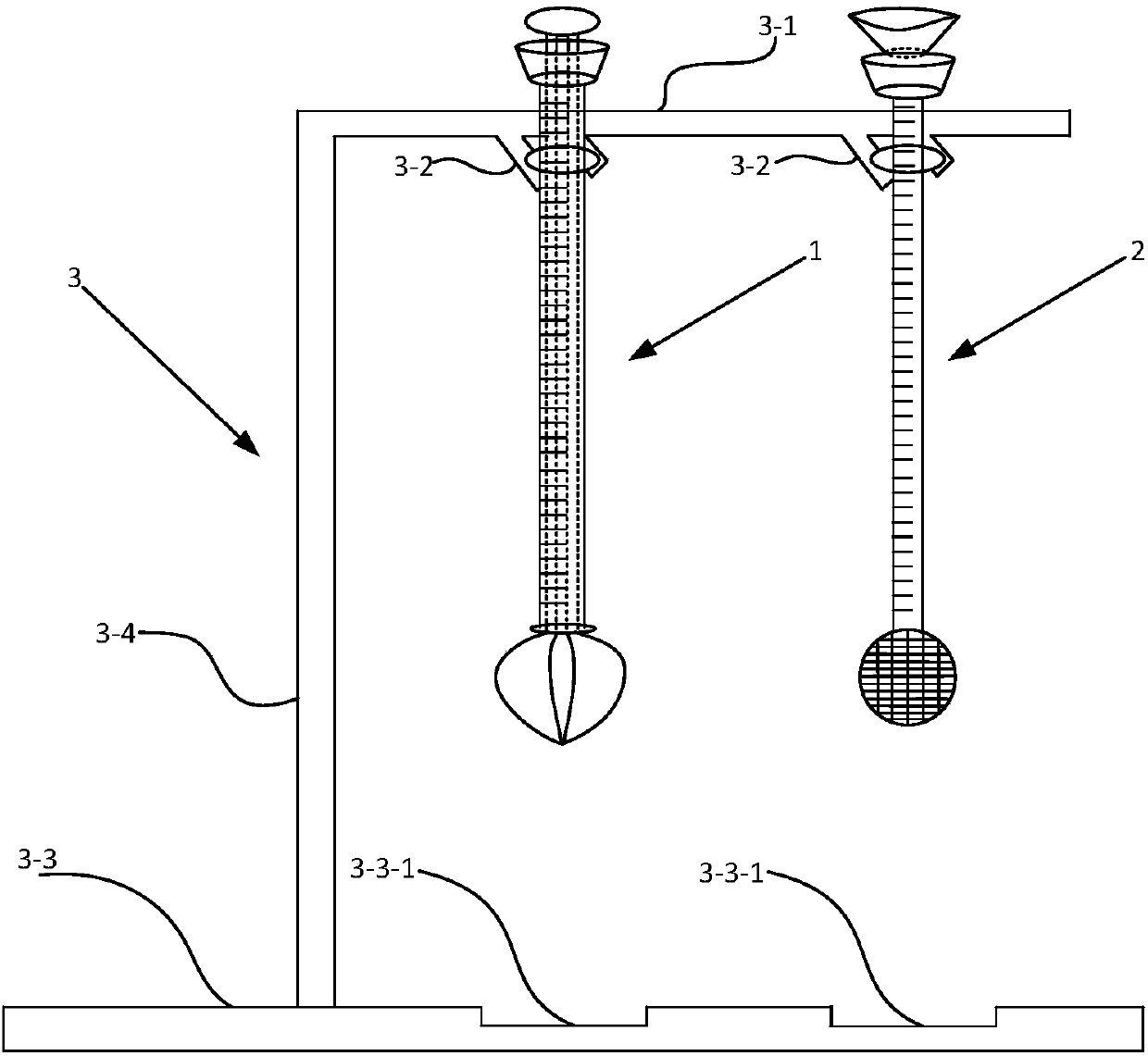

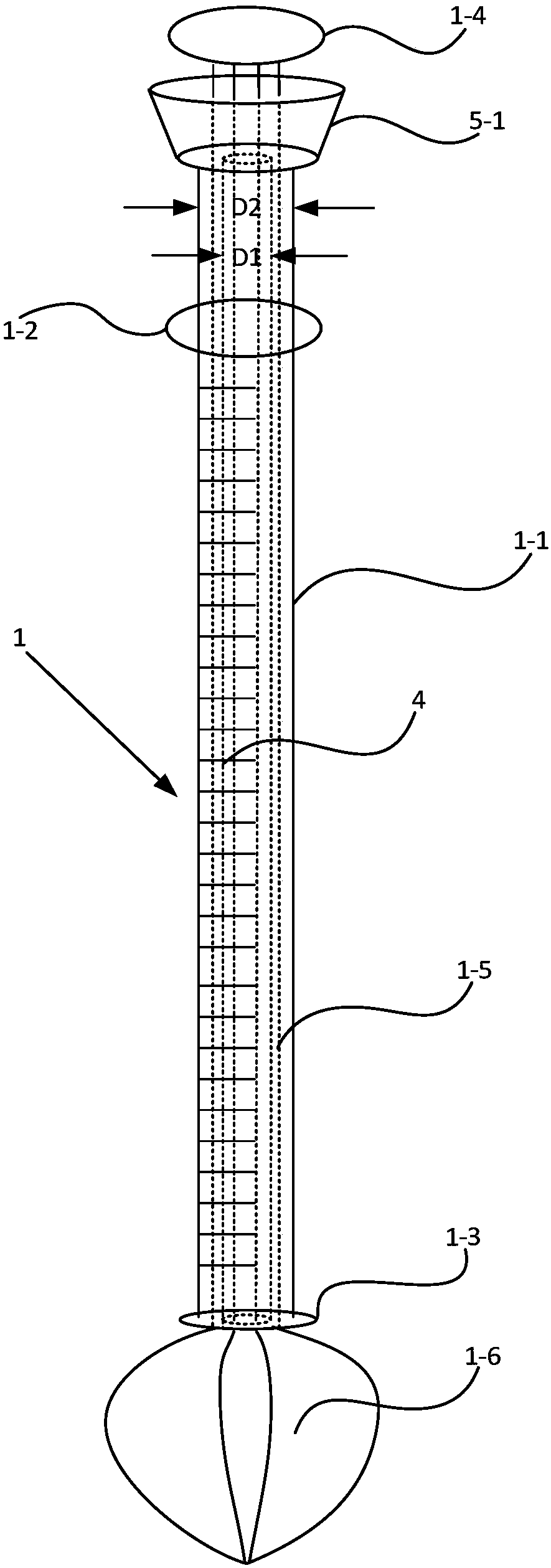

Support set for metal detection corrosive container

PendingCN107941685AImprove corrosion efficiencyImprove practicalityWeather/light/corrosion resistanceInsertion stentArchitectural engineering

The invention discloses a support set for a metal detection corrosive container. The support set comprises a first support and a second support, wherein the first support is provided with a first pipesection; a first baffle plate is arranged along the circumferential direction of the upper end of the first pipe section, and a second baffle plate is arranged along the circumferential direction ofthe lower end of the first pipe section; the first pipe section is internally provided with two turn-back filaments, the upper ends of the turn-back filaments are fixed on a driving part, and the lower ends of the turn-back filaments are fixed in a crossed way so as to form a first mesh cage; the second support is provided with a second pipe section; a funnel provided with an upward opening is arranged at the upper end of the second pipe section, a second mesh cage is arranged at the lower end of the second pipe section, and a third baffle plate is arranged along the circumferential directionof the second pipe section; the tail ends of the first pipe section and the second pipe section are separately provided with a tapered fixed plug which is inserted into the neck of the corrosive container; the support set also comprises a storage rack; the upper end and lower end of the storage rack are respectively provided with a cross beam and a base; the cross beam is provided with buckles; asupport rod is arranged between the base and the cross beam. The support set provided by the invention can be used for carrying bulk solid metal and particulate metal so as to enable the metal to be sufficiently corroded, and is wide in application scope and high in practicality.

Owner:JIANGSU SCIENCE TEST TECHNOLOGY SERVICE CO LTD

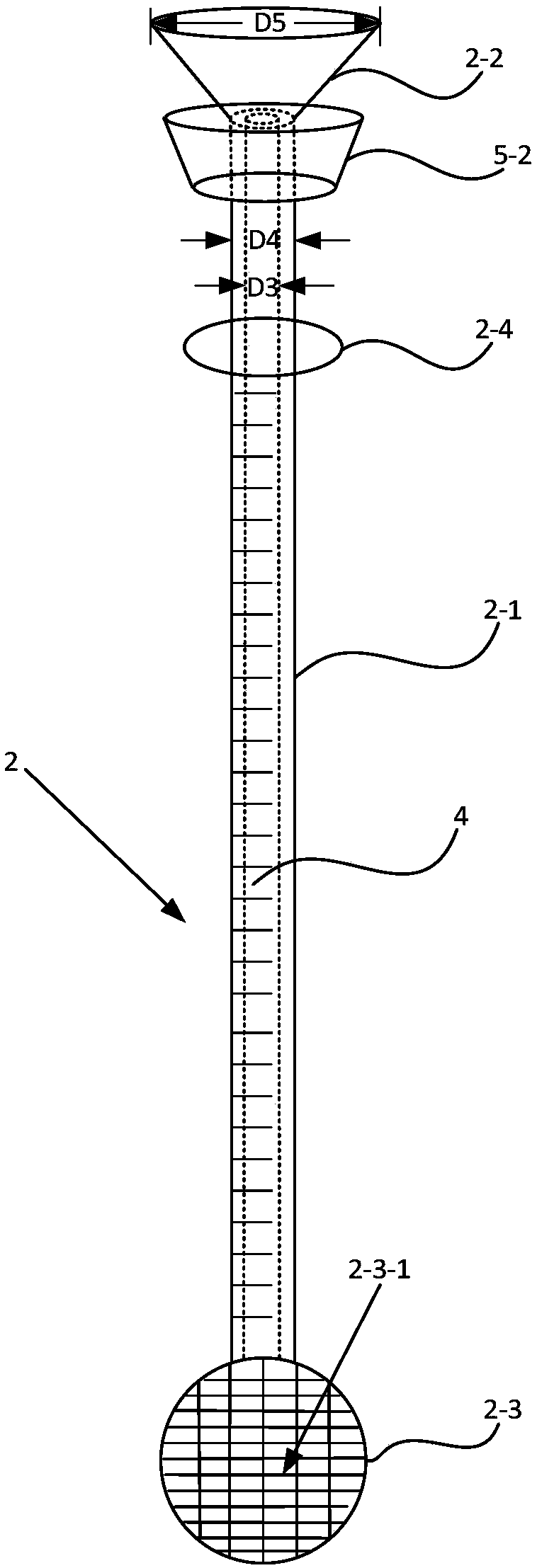

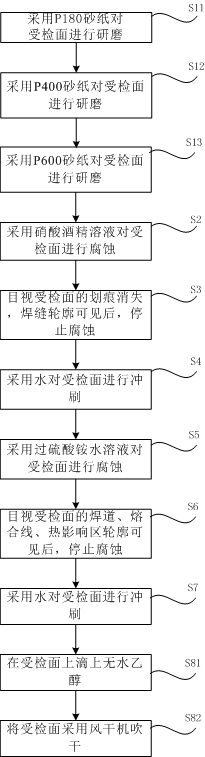

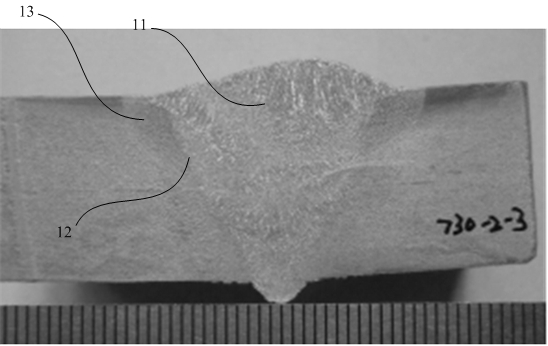

Weld joint metallographic corrosion method

PendingCN113945441AImprove efficiencyAvoid affecting back staining phenomenonPreparing sample for investigationHeat-affected zoneAqueous solution

The invention discloses a weld joint metallographic corrosion method. The method comprises the following steps of: S1, grinding a detected surface of a metallographic sample; S2, corroding the detected surface by adopting a nitric acid alcohol solution; S3, after scratches on the detected surface disappear visually and the contour of a welding seam is visible, stopping corrosion; S4, washing the detected surface with water; S5, corroding the detected surface by adopting an ammonium persulfate aqueous solution; S6, after a second welding bead, a second fusion line and a second heat affected zone outline of the detected surface are visible, stopping corrosion; S7, washing the detected surface with water; and S8, blow-drying the detected surface. According to the weld joint metallographic corrosion method, the weld bead, the fusion line and the heat affected zone in the weld seam can be clearer and distinguishable, a back stain phenomenon affecting weld seam defect display is effectively avoided, inspection work of welding quality is facilitated, the efficiency of weld seam macroscopic metallographic inspection work can be improved, and the technical problem to be solved urgently is solved.

Owner:青岛中车四方轨道车辆有限公司

Afforest additive for vegetation concrete and preparation method thereof

InactiveCN108503249AFull of corruptionImprove corrosion efficiencySolid waste managementOrganic fertilisersFood additiveFermentation

The invention provides an afforest additive for vegetation concrete. The afforest additive comprises the following components in percentage by weight: 14-26% of organic matter, 0.6-8% of wood-destroying fungi mycelium, 30-38% of fly ash and 32-40% of plant ash. The afforest additive provided by the invention comprises a certain amount of the organic matter and the wood-destroying fungi mycelium, the production cost is low, the preparation technology is simple, the stability and durability of slope vegetation concrete can be improved, and the sprouting rate and the survival rate of seeds of slope vegetation can also be increased. The invention further provides a preparation method of the afforest additive for vegetation concrete. The preparation method comprises the following steps: preparing an organic additive: adding water of which the proportion is 65-75%a to an organic matrix of which the weight is a, and after storing for 12 hours, performing sterilization to obtain a culture medium; regulating the PH of the culture medium so that the initial PH value is 4; and adding wood-destroying fungi of which the proportion is 0.02-0.06a to the culture medium of which the PH is 4, and performing fermentation in a manner of being away from light for 7-12 days to obtain the organic additive.

Owner:熊远

Chemical corrosion method for removing hard phases on surface of hard alloys

ActiveCN109576710AEasy to prepareEasy to operatePreparing sample for investigationMaterial analysis using radiation diffractionPotassium ferricyanideCemented carbide

The invention belongs to the technical field of hard alloys, and discloses a chemical corrosion method for removing hard phases on the surface of hard alloys. The method comprises the following steps:(1) the hard alloys are polished, and then, are cleaned and dried; (2) corrosion liquid is prepared according to a ratio of dissolving 0.2-1.1 g potassium ferricyanide and 5-19.8 g sodium hydroxide in every 100 mL water; and the polished hard alloys are fed in the corrosion liquid for next treatment; (3) the ultrasonic oscillation is performed by 5-30 min; (4) ultrasonic waves are turned off; andthe hard alloys are stood in a light shielding environment at a normal temperature for 30-180 min; (5) the steps (3) and (4) are repeated by 3-8 times; and (6) the hard alloys are taken out from thecorrosion liquid to put in water for ultrasonic cleaning by 1-8 min; and the surfaces of the hard alloys are dried after cleaning. The corrosion process of combining chemical corrosion with ultrasonicoscillation is adopted; WC phases on the surfaces of the alloys are thoroughly corroded; no WC is remained on the surfaces of the alloys; and bonding phases cannot be oxidized.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

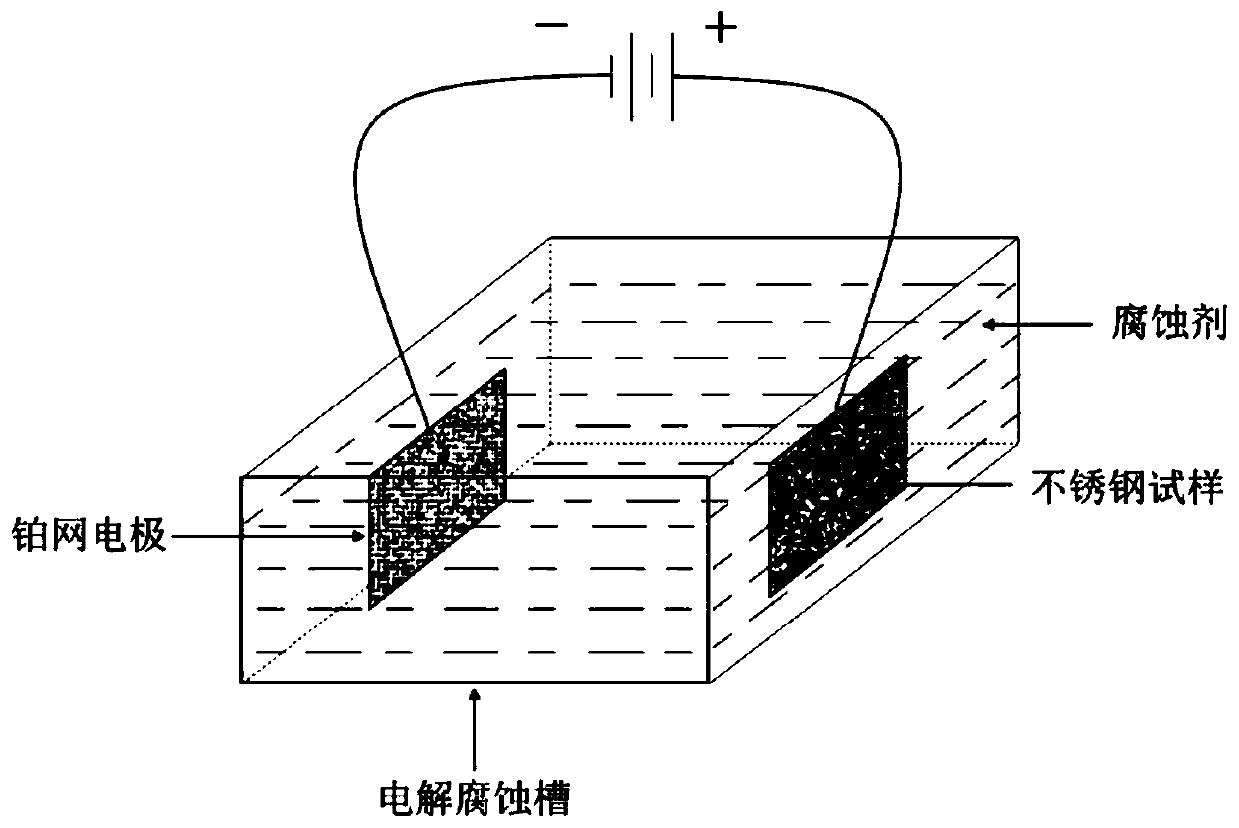

Stainless steel corrosive for fuel cell bipolar plate and metallographic phase preparation method

ActiveCN111139481ASimple componentsEasy to preparePreparing sample for investigationHydrogen SulfateFuel cells

The invention relates to a stainless steel corrosive for a fuel cell bipolar plate and a metallographic phase preparation method. The stainless steel corrosive comprises the following components in percentage by volume: 1.0-5.0% of concentrated sulfuric acid, equal to or less than 1.0% of hydrofluoric acid and the balance of deionized water. The metallographic phase preparation method adopts the corrosive and comprises the following steps: 1, preparing a sample; 2, preheating the corrosive at the temperature of 40-90 DEG C; 3, taking the sample and corrosion resistant conductive material as the anode and the cathode separately, inserting the anode and the cathode in the preheated corrosive, applying 1.0-2.0 V of voltage at the two ends of the sample and the corrosion resistant conductive material, and carrying out corrosion for 0.5-6 minutes; and 4, taking the sample out, and washing and drying the sample. Compared with the prior art, the corrosive is simple in matching, easy to prepare, safe and environmentally-friendly; the corrosive method is easy to operate and excellent in controllability, a stainless steel metallographic phase sample can be rapidly prepared on batches, the corrosive liquid can be repeatedly used and is economical and efficient; and the metallographic structure and grain boundary are uniform and clear.

Owner:TONGJI UNIV

Solar cell optical corrosion device

InactiveCN111477725AImprove utilizationImprove absorption efficiencyPhotovoltaic energy generationLaser beam welding apparatusCell fabricationPhysical chemistry

The invention relates to the field of solar cell manufacturing, in particular to a solar cell optical corrosion device. The technical problem to be solved by the invention is to provide a solar cell optical corrosion device. A solar cell optical corrosion device comprises a laser grooving mechanism, a hot air corrosion mechanism and the like. The middle of the inner top of the mounting frame is inbolted connection with the first hydraulic cylinder fixing frame. According to the invention, irregular laser simulation disorder engraving lines are carried out on the surface of the solar cell by using a blackbody effect, solar energy absorption efficiency is improved, the liquid level is even, the agentia spreading and corrosion carving progress is unified, all parts of the carving groove arein sufficient contact with the corrosion agentia through hot air surrounding blowing, the corrosion efficiency is improved, the situation that bubbles are mixed and cannot be corroded is prevented, solar energy utilization is increased through the reflection frequency of light in the rough carving groove after corrosion, and the solar panel curing efficiency is improved.

Owner:王小娟

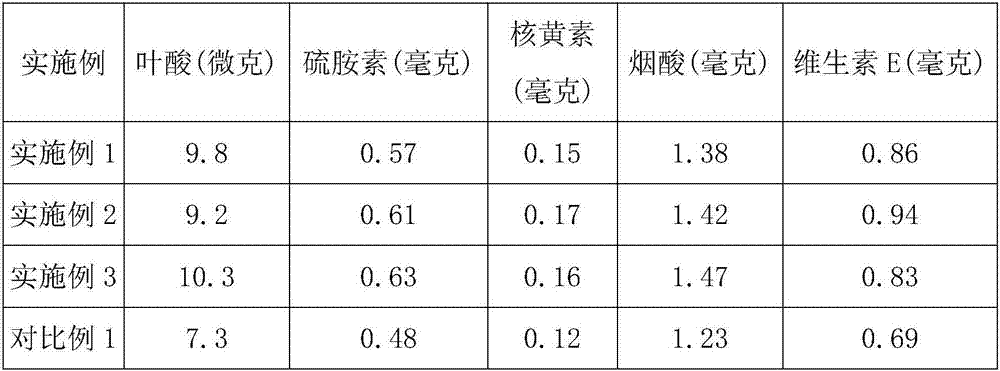

Efficient oat processing technology

InactiveCN107469896AReduce mechanical damageFully absorbedGrain treatmentsFood scienceMoistureImpurity

A high-efficiency treatment process for oats, comprising the following steps: impurity removal and drying, removing impurities and drying the oats taken out of the granary at the same time using suspension preheating technology; On oats; oats are shelled, and the oats are shelled by a bone huller to obtain oat rice; rice is rolled, and the oats are roughened and whitened by a rice mill, and water is added while rolling the rice; washing and drying, The obtained oatmeal is washed in a cleaning pool, and dried after cleaning; the moisture content is detected, sterilized, and packaged to obtain the oatmeal. The oat rice prepared by the invention is natural and pure, has clear and crystal clear color, mellow and palatable taste, and a high proportion of high-quality rice.

Owner:ANHUI KEJIE LIANGBAO STORAGE EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com