Showing and quantitative evaluation methods of gamma' phase in nickel-based superalloy

A technology of nickel-based superalloy and corrosive agent, which is applied in the preparation of test samples, instruments, scanning probe technology, etc. High and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

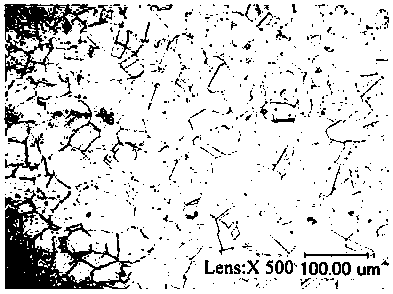

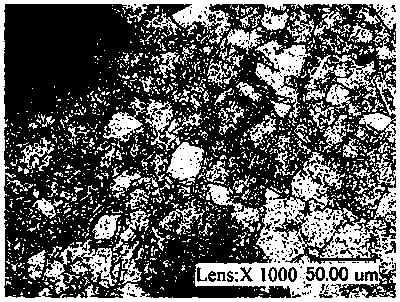

Embodiment 1

[0046] The invention provides a set of schemes for quantitatively evaluating the γ' phase content aiming at the shortcomings of the existing nickel-base superalloy metallographic quantitative evaluation. The scheme includes: 1. providing a corrosion agent with good corrosion effect and capable of displaying the γ' form of the nickel-based superalloy strengthening phase and its preparation method, and at the same time providing a corrosion method for the corrosion agent to corrode the nickel-base superalloy. The morphology of the strengthening phase γ' of the nickel-base superalloy is clearly displayed, which is beneficial to the observation and measurement of the strengthening phase γ' of the processed surface of the nickel-base superalloy. Second, on this basis, use the drawing analysis software to process the obtained microscope γ' phase pictures to obtain the volume fraction of the nickel-based superalloy γ' phase.

[0047] The whole operation flow of the present invention ...

Embodiment 2

[0065] Nickel-based superalloy GH4169 corroded by the formula of "40 milliliters of hydrochloric acid, 20 milliliters of hydrofluoric acid, 40 milliliters of ethanol, and 2 grams of copper chloride", and other processing steps are the same as in Example 1 to obtain the volume of the γ' phase in GH4169 The score is 29.82%.

[0066] G 0 (γ') is 27.53%,

[0067] The error of the amount of γ' phase obtained by comparing the formula C of this etchant with the above calculation formula is 8.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com