Chemical corrosion method for removing hard phases on surface of hard alloys

A cemented carbide and chemical corrosion technology, applied in the field of cemented carbide, can solve the problems of easy-to-corrosion WC corrosion binder phase, difficult control of electrolytic parameters, quantitative measurement errors, etc., to achieve convenient preparation, easy popularization and application, and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

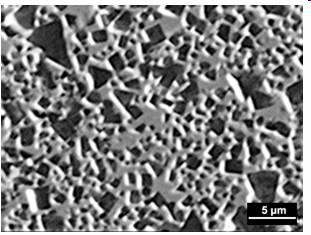

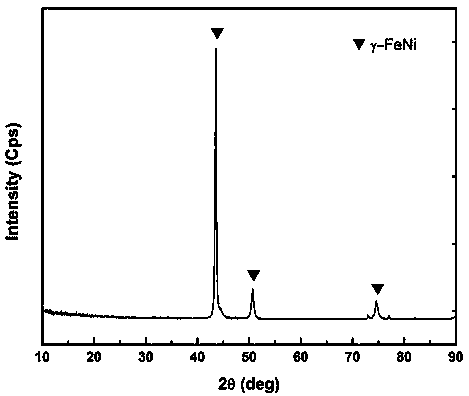

[0036] A chemical corrosion method for removing the hard phase on the surface of the cemented carbide. In this embodiment, a WC-Fe-Ni cemented carbide with a binder phase content of 10 wt.% is selected, and the steps are as follows:

[0037] (1) Use 180#, 400#, 800#, 1000#, 2000# diamond grinding discs to polish on the polishing machine, and then use 0.5μm diamond polishing paste to polish the cemented carbide surface into a mirror surface, and then clean it with water , Blow dry;

[0038] (2) Dissolve 1.0 g potassium ferricyanide and 15.2 g sodium hydroxide per 100 mL of distilled water, mix and stir to prepare the corrosive solution, ready to use; put the polished cemented carbide into the corroded Immediately proceed to the next step in the liquid;

[0039] (3) Ultrasonic vibration treatment for 20 minutes;

[0040] (4) Turn off the ultrasound and let it stand for 130min at room temperature in a shading environment;

[0041] (5) Repeat steps (3) and (4) 4 times;

[0042] (6) Remove ...

Embodiment 2

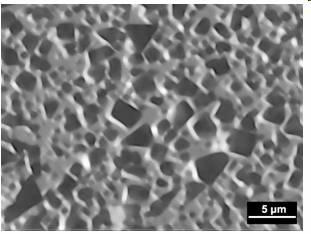

[0045] A chemical corrosion method for removing the hard phase on the surface of cemented carbide. In this embodiment, a WC-Fe-Ni cemented carbide with a binder phase content of 20 wt.% is selected, and the steps are as follows:

[0046] (1) Use 180#, 400#, 800#, 1000#, 2000# diamond grinding discs to polish on the polishing machine, and then use 0.5μm diamond polishing paste to polish the cemented carbide surface into a mirror surface, and then clean it with water , Blow dry;

[0047] (2) Dissolve 0.8 g potassium ferricyanide and 10.2 g sodium hydroxide per 100 mL of distilled water, mix and stir to prepare the corrosive solution, ready to use; put the polished cemented carbide into the corroded Immediately proceed to the next step in the liquid;

[0048] (3) Ultrasonic vibration treatment for 15 minutes;

[0049] (4) Turn off the ultrasound and let it stand for 105min at room temperature in a shading environment;

[0050] (5) Repeat steps (3) and (4) 4 times;

[0051] (6) Remove the ...

Embodiment 3

[0054] A chemical corrosion method for removing the hard phase on the surface of the cemented carbide. In this embodiment, a WC-Fe-Ni cemented carbide with a binder phase content of 30wt.% is selected, and the steps are as follows:

[0055] (1) Use 180#, 400#, 800#, 1000#, 2000# diamond grinding discs to polish on the polishing machine, and then use 0.5μm diamond polishing paste to polish the cemented carbide surface into a mirror surface, and then clean it with water , Blow dry;

[0056] (2) Dissolve 0.4g potassium ferricyanide and 9.2g sodium hydroxide per 100 mL of distilled water, mix and stir to prepare the corrosive solution, ready to use; put the polished cemented carbide into the corrosion Immediately proceed to the next step in the liquid;

[0057] (3) Ultrasonic vibration treatment for 10 minutes;

[0058] (4) Turn off the ultrasound and let it stand for 90 minutes at room temperature in a shading environment;

[0059] (5) Repeat steps (3) and (4) 3 times;

[0060] (6) Remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com