Metallographic corrosive of stainless steel high temperature quenched structure and corrosion method thereof

A technology of high-temperature quenching and corrosive agents, applied in the field of heat treatment, can solve the problems of not obtaining solid-liquid two-phase structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

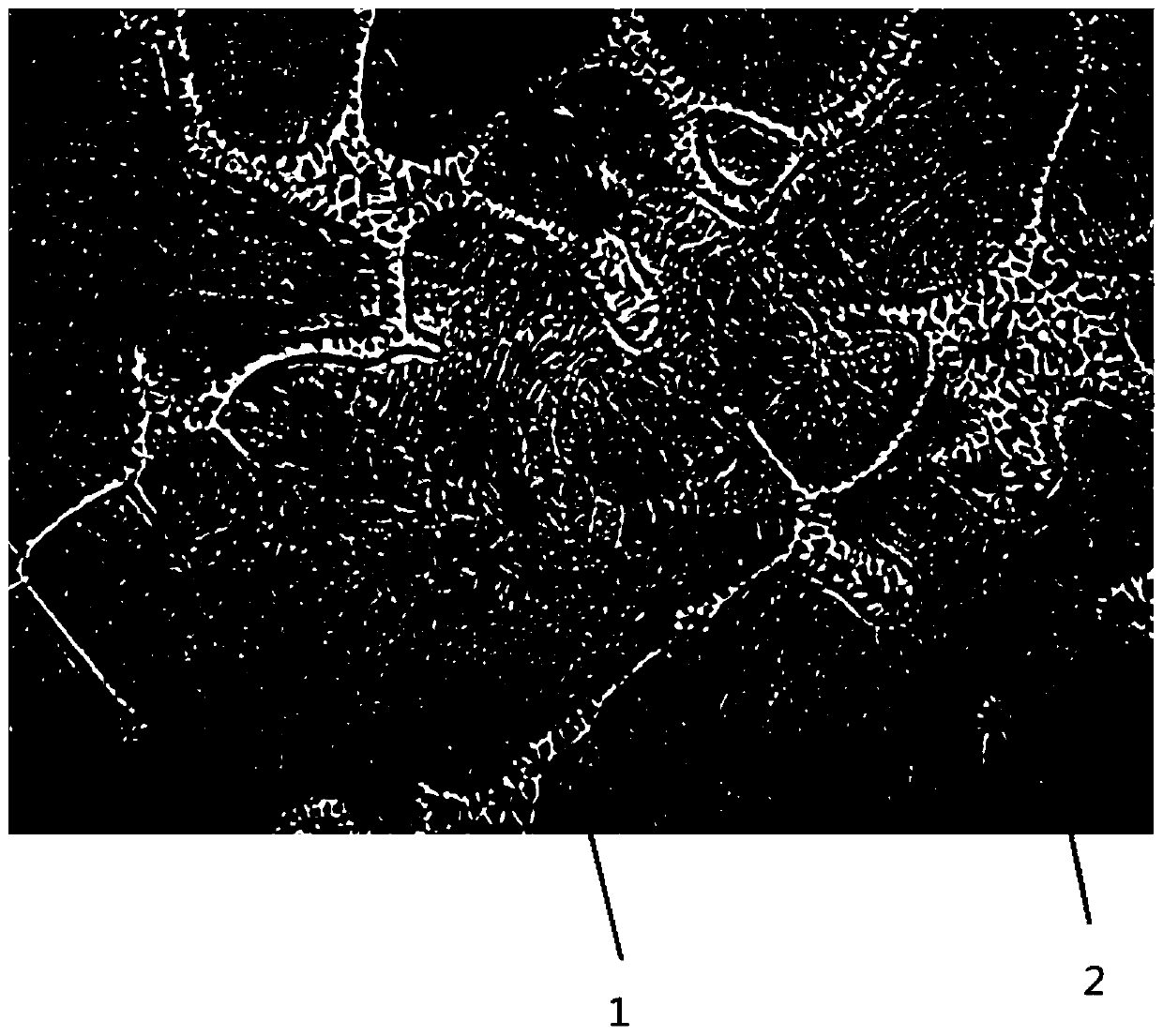

[0025] Slowly add 5ml of nitric acid with a concentration of 68% into 30ml of absolute ethanol and stir evenly to prepare the first corrosion agent; add 1g of citric acid to 30ml of absolute ethanol and keep stirring, and slowly add 10ml of hydrochloric acid with a concentration of 37% , stir and mix evenly, and prepare a liquid. Put clean water at room temperature into the ultrasonic cleaning machine, put the beakers containing the first and second corrosive agents into the ultrasonic cleaning machine, turn on the ultrasonic cleaning machine, soak the ground sample in the first corrosive agent for 10 seconds, and take out the test sample. Samples were cleaned with absolute ethanol, dried, and then soaked in the second corrosive agent for 20s, and the samples were taken out, cleaned with absolute ethanol and dried. The prepared sample was observed at 50 times magnification under a metallographic microscope, and the following results were obtained: figure 1 legend shown. The ...

Embodiment 2

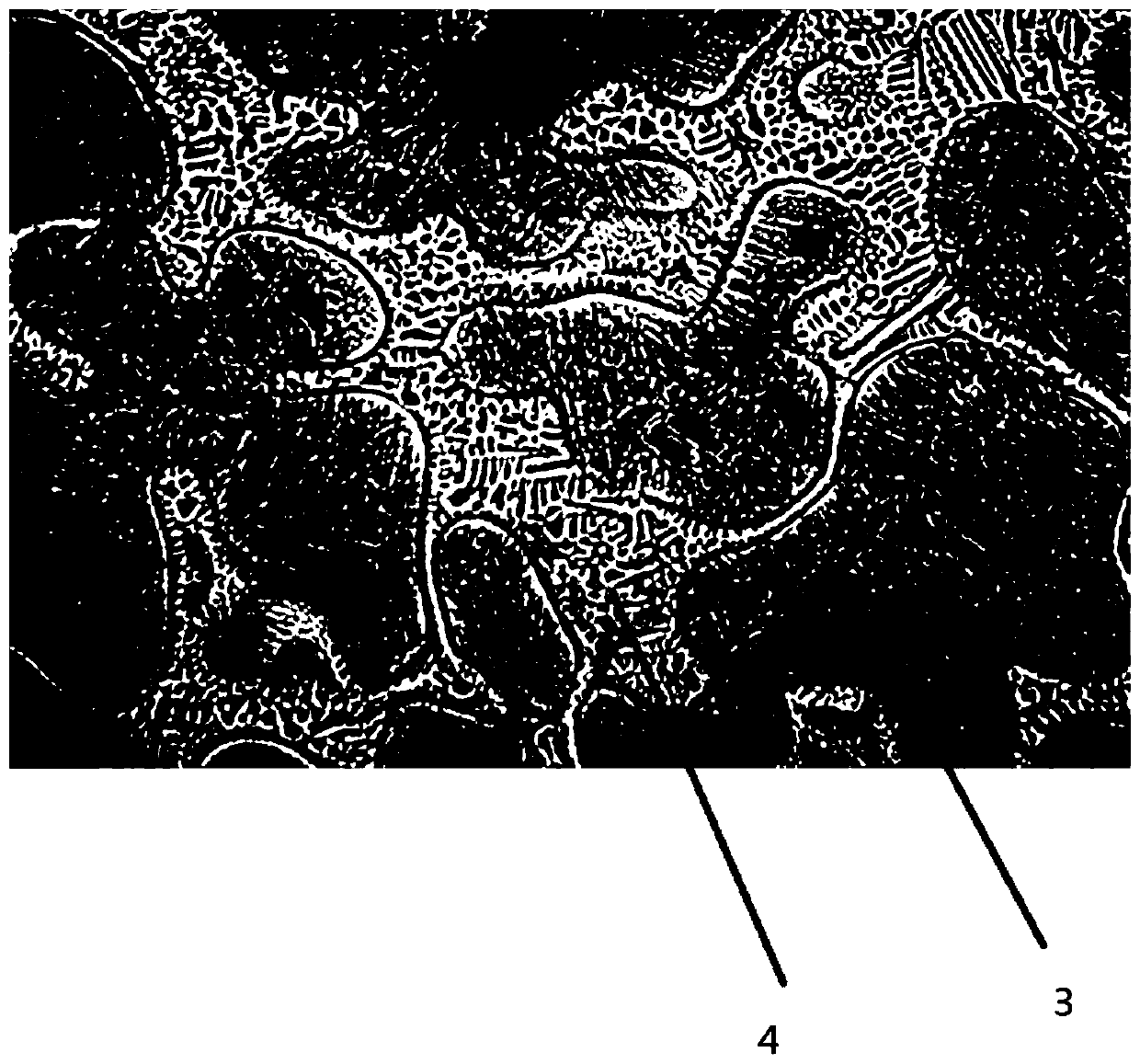

[0027] Slowly add 5ml of nitric acid with a concentration of 68% into 50ml of absolute ethanol and stir evenly to prepare the first corrosion agent; add 2g of citric acid to 50ml of absolute ethanol and stir continuously, and slowly add 12ml of hydrochloric acid with a concentration of 37% , stir and mix evenly, and prepare the second corrosive agent. Put clean water at room temperature into the ultrasonic cleaning machine, put the beakers containing the first and second corrosive agents into the ultrasonic cleaning machine, turn on the ultrasonic cleaning machine, soak the ground sample in the first corrosive agent for 15 seconds, and take out the test sample. The sample was cleaned with absolute ethanol, dried, and then soaked in the second corrosive agent for 25s, and the sample was taken out, washed with absolute ethanol and dried. The prepared sample was observed at 50 times magnification under a metallographic microscope, and the following results were obtained: figure...

Embodiment 3

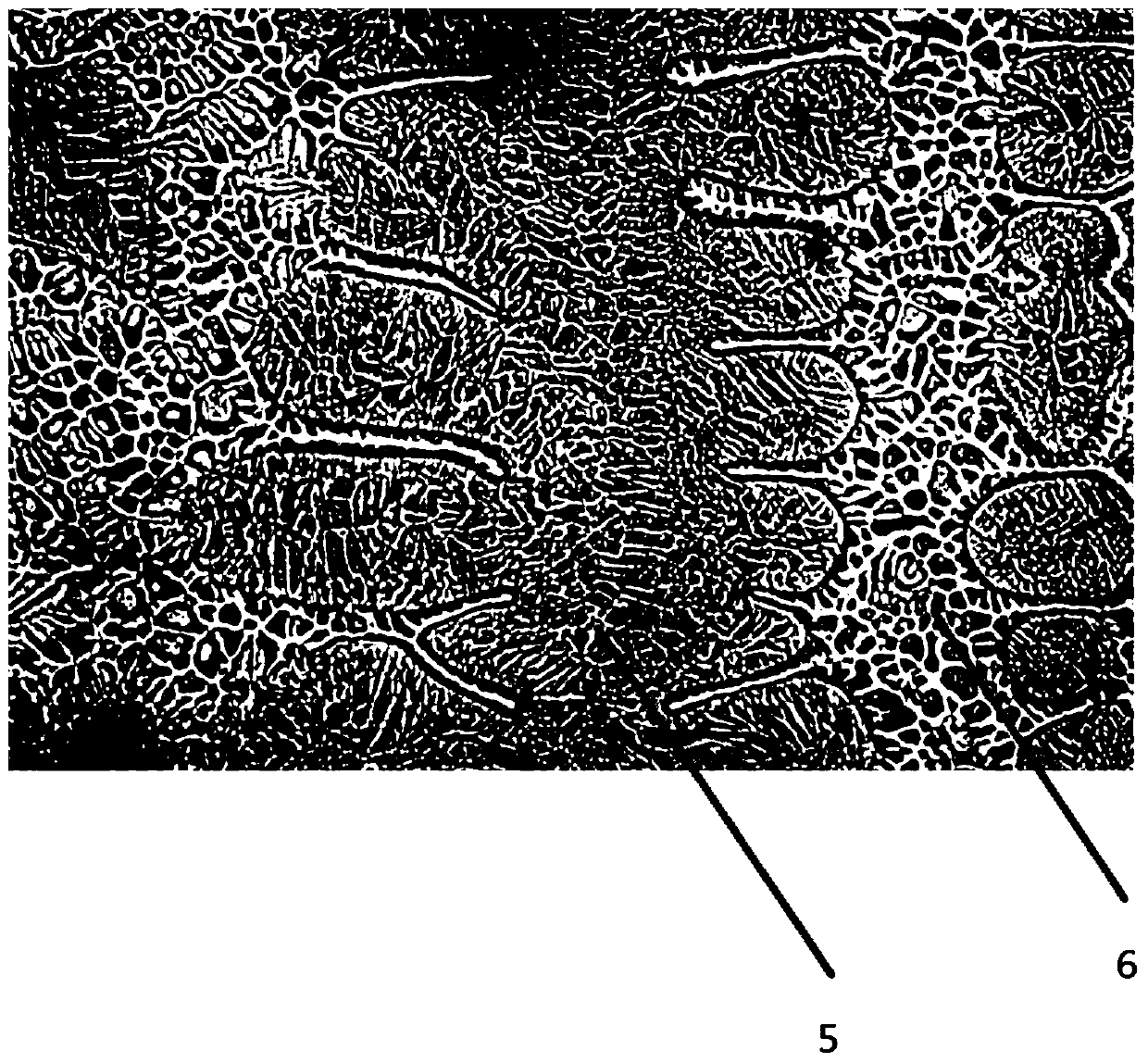

[0029] Slowly add 7ml of nitric acid with a concentration of 68% into 40ml of absolute ethanol and stir evenly to prepare the first corrosion agent; add 3g of citric acid to 40ml of absolute ethanol and stir continuously, and slowly add 12ml of hydrochloric acid with a concentration of 37% , stir and mix evenly, and prepare the second etchant solution. Put clean water at room temperature into the ultrasonic cleaning machine, put the beakers containing the first and second corrosive agents into the ultrasonic cleaning machine, turn on the ultrasonic cleaning machine, soak the ground sample in the first corrosive agent for 20 seconds, and take out the test sample. The samples were cleaned with absolute ethanol, dried, and then soaked in the second corrosive agent for 30s, and the samples were taken out, washed with absolute ethanol and dried. The prepared sample was observed at 50 times magnification under a metallographic microscope, and the following results were obtained: i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com