Efficient oat processing technology

A treatment process, oat technology, which is applied in the field of high-efficiency oat treatment process, can solve the problems of low treatment efficiency and low quality of oat rice, and achieve the effect of high corrosion efficiency, clear and crystal color, and high proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

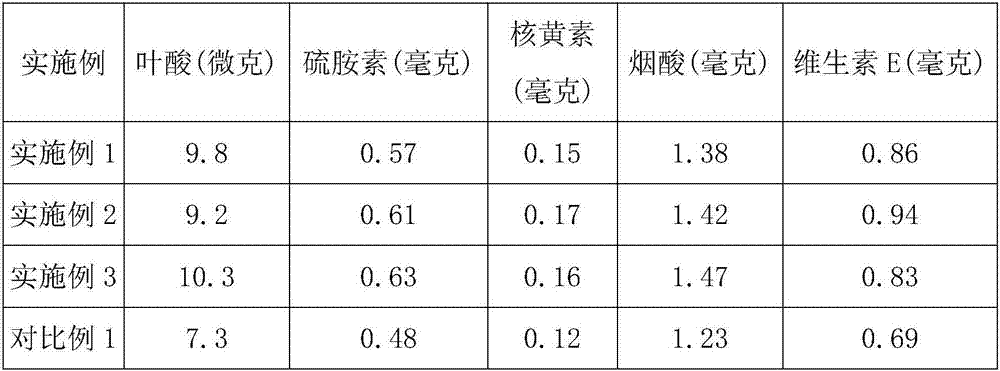

Examples

Embodiment 1

[0026] A high-efficiency treatment process for oats, comprising the following steps:

[0027] (1) Impurity removal and drying. The oats taken out of the granary are removed and dried by suspension preheating technology at the same time. When the suspension preheating technology is used to remove impurities and dry oats, the oats flow from top to bottom and hot air flows from Flow upwards, after the oats are removed and dried, the total impurity content does not exceed 0.5% of the total weight of the rice, and the water content does not exceed 4%;

[0028] (2) Spraying the septic solution, evenly spraying the septic solution on the oat after impurity removal and drying, the septic solution is composed of the following raw materials in parts by weight: 6 parts of acid-resistant cellulase, 0.3 part of glucose oxidase, tea 1 part of polyphenol, 0.2 part of nattokinase, 0.5 part of citric acid, 0.8 part of sodium phosphate, 0.3 part of hemicellulase, 2 parts of potassium borate, 1 ...

Embodiment 2

[0034] A high-efficiency treatment process for oats, comprising the following steps:

[0035] (1) Impurity removal and drying. The oats taken out of the granary are removed and dried by suspension preheating technology at the same time. When the suspension preheating technology is used to remove impurities and dry oats, the oats flow from top to bottom and hot air flows from Flow upwards, after the oats are removed and dried, the total impurity content does not exceed 0.5% of the total weight of the rice, and the water content does not exceed 4%;

[0036] (2) Spraying the septic solution, evenly spraying the septic solution on the oat after impurity removal and drying, the septic solution is composed of the following raw materials in parts by weight: 8 parts of acid-resistant cellulase, 0.4 part of glucose oxidase, tea 1.5 parts of polyphenols, 0.3 parts of nattokinase, 0.8 parts of citric acid, 1.0 parts of sodium phosphate, 0.5 parts of hemicellulase, 3 parts of potassium bo...

Embodiment 3

[0042] A high-efficiency treatment process for oats, comprising the following steps:

[0043] (1) Impurity removal and drying. The oats taken out of the granary are removed and dried by suspension preheating technology at the same time. When the suspension preheating technology is used to remove impurities and dry oats, the oats flow from top to bottom and hot air flows from Flow upwards, after the oats are removed and dried, the total impurity content does not exceed 0.5% of the total weight of the rice, and the water content does not exceed 4%;

[0044] (2) Spraying the septic solution, evenly spraying the septic solution on the oat after impurity removal and drying, the septic solution is composed of the following raw materials in parts by weight: 10 parts of acid-resistant cellulase, 0.5 part of glucose oxidase, tea 2 parts of polyphenols, 0.4 parts of nattokinase, 1.0 parts of citric acid, 1.2 parts of sodium phosphate, 0.8 parts of hemicellulase, 4 parts of potassium bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com