Lightweight composite organic heat preservation and sound insulation prefabricated board for fabricated buildings and preparation method

A technology for thermal insulation, sound insulation, and construction. It is applied in thermal insulation, sound insulation, building components, etc., and can solve the problems of heavy unit mass, difficult molding, and heavy mass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

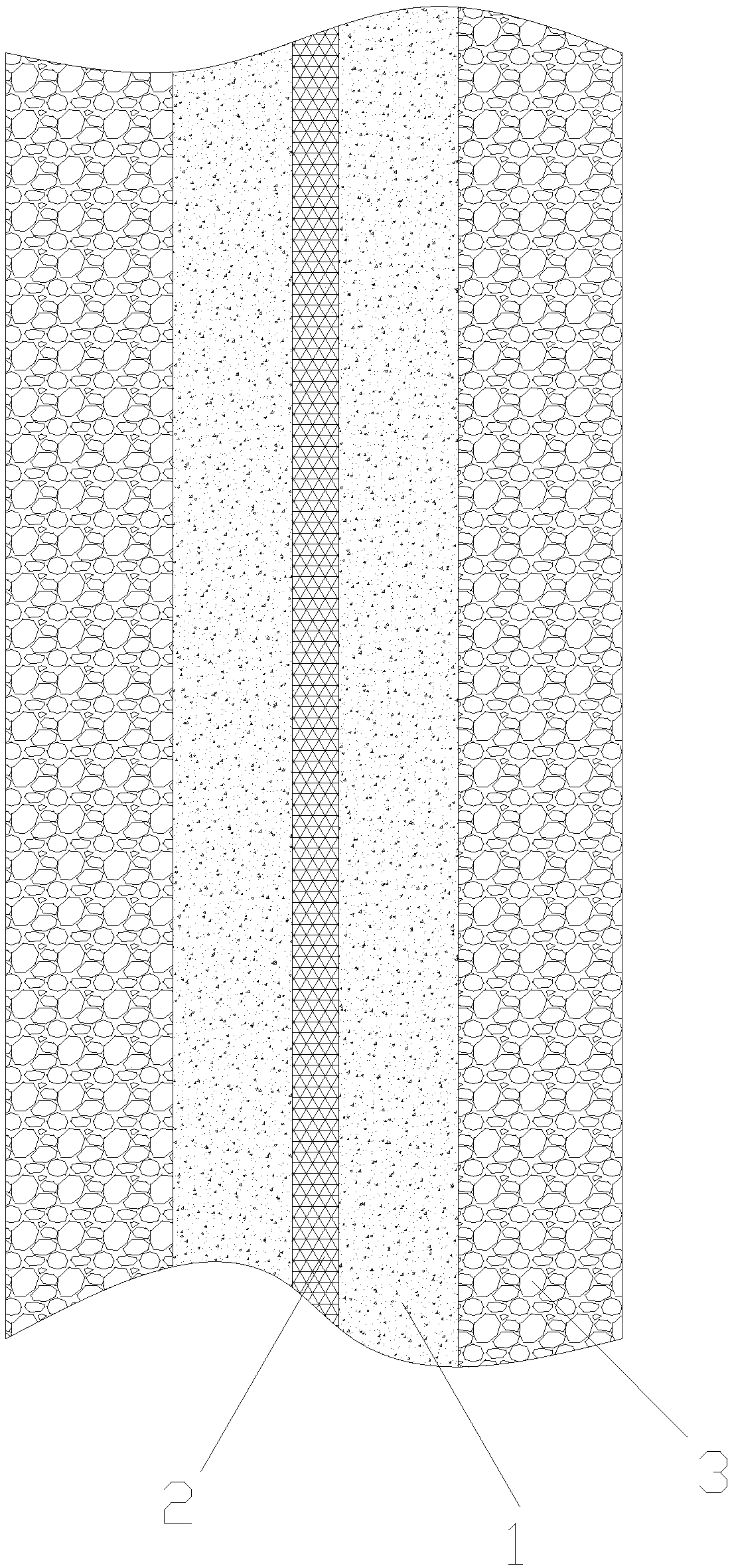

[0042] Such as figure 1 As shown, a prefabricated lightweight composite organic thermal insulation and sound insulation prefabricated panel for prefabricated buildings, including:

[0043] Two organic sound-absorbing panels 1, which are made of 80 parts by weight of wood organic matter, 6 parts of white rot fungus mycelia, and 12 parts of foaming agent;

[0044] Damping silicone rubber layer 2, which is arranged between the two organic sound-absorbing panels, for connecting the organic sound-absorbing panels and blocking the transmission of sound waves;

[0045] Two fiber cement pressure boards 3 are arranged on the outside of the organic sound-absorbing board 1 respectively.

[0046] The preparation method of the above-mentioned lightweight composite organic thermal insulation and sound insulation prefabricated panels for prefabricated buildings includes the steps of preparing organic sound-absorbing panels:

[0047] 1) Add 56 parts of water to 80 parts of wood wool with a ...

Embodiment 2

[0054] Such as figure 1 As shown, a prefabricated lightweight composite organic thermal insulation and sound insulation prefabricated panel for prefabricated buildings, including:

[0055] Two organic sound-absorbing boards 1, which are made of 120 parts by weight of wood organic matter, 12 parts of white rot fungus mycelia, and 26 parts of foaming agent;

[0056] Damping silicone rubber layer 2, which is arranged between the two organic sound-absorbing panels 1, for connecting the organic sound-absorbing panels 1, and blocking the transmission of sound waves;

[0057] Two fiber cement pressure boards 3 are arranged on the outside of the organic sound-absorbing board 1 respectively.

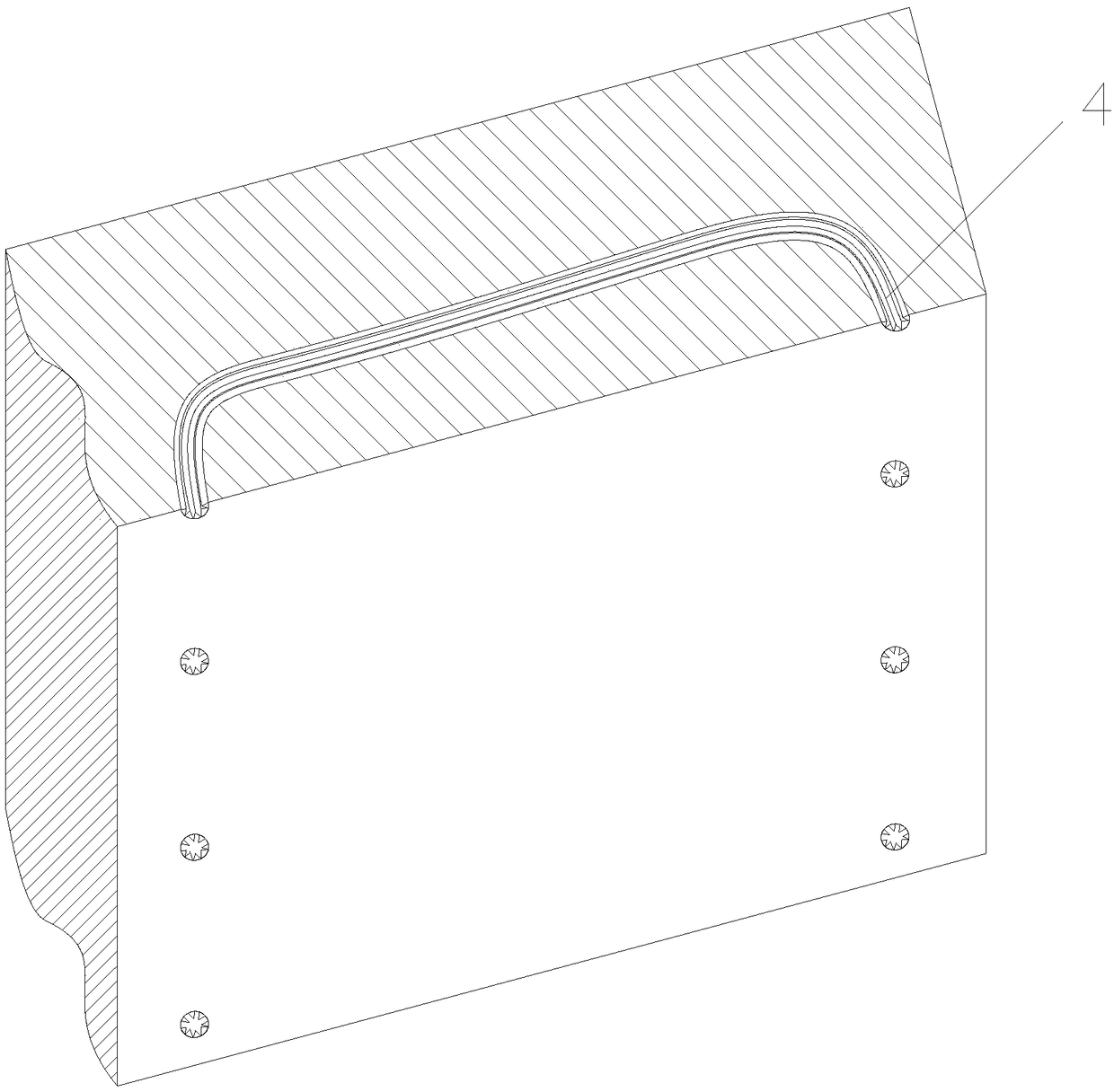

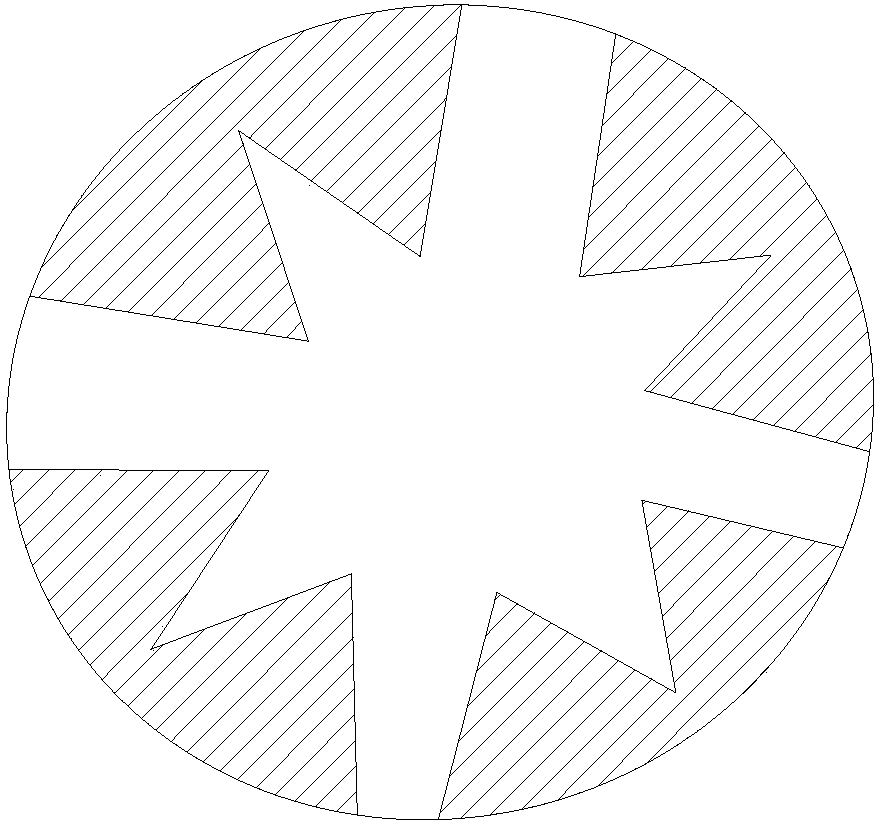

[0058] Wherein, as shown in soil 2, the fiber cement pressure plate layer 3 is provided with several mufflers 4 with both ends communicating with the outside air, and the muffler channels 4 are located in the 3 layers of the fiber cement pressure plate, and The cross section of the muffler chan...

Embodiment 3

[0067] Such as figure 1 As shown, a prefabricated lightweight composite organic thermal insulation and sound insulation prefabricated panel for prefabricated buildings, including:

[0068] Two organic sound-absorbing panels 1, which are made of 60 parts by weight of wood organic matter, 8 parts of white rot mycelia, and 18 parts of foaming agent;

[0069] Damping silicone rubber layer 2, which is arranged between the two organic sound-absorbing panels 1, for connecting the organic sound-absorbing panels 1, and blocking the transmission of sound waves;

[0070] Two fiber cement pressure boards 3 are arranged on the outside of the organic sound-absorbing board 1 respectively.

[0071] The preparation method of the above-mentioned lightweight composite organic thermal insulation and sound insulation prefabricated panels for prefabricated buildings includes the steps of preparing organic sound-absorbing panels:

[0072] 1) Add 56 parts of water to 60 parts of wood wool with a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com