Transferring method of edge-free vertical structure LED chip substrate

A LED chip and vertical structure technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of easy warping, high cost, high stress, etc., to prevent lateral immersion, prevent scratches, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

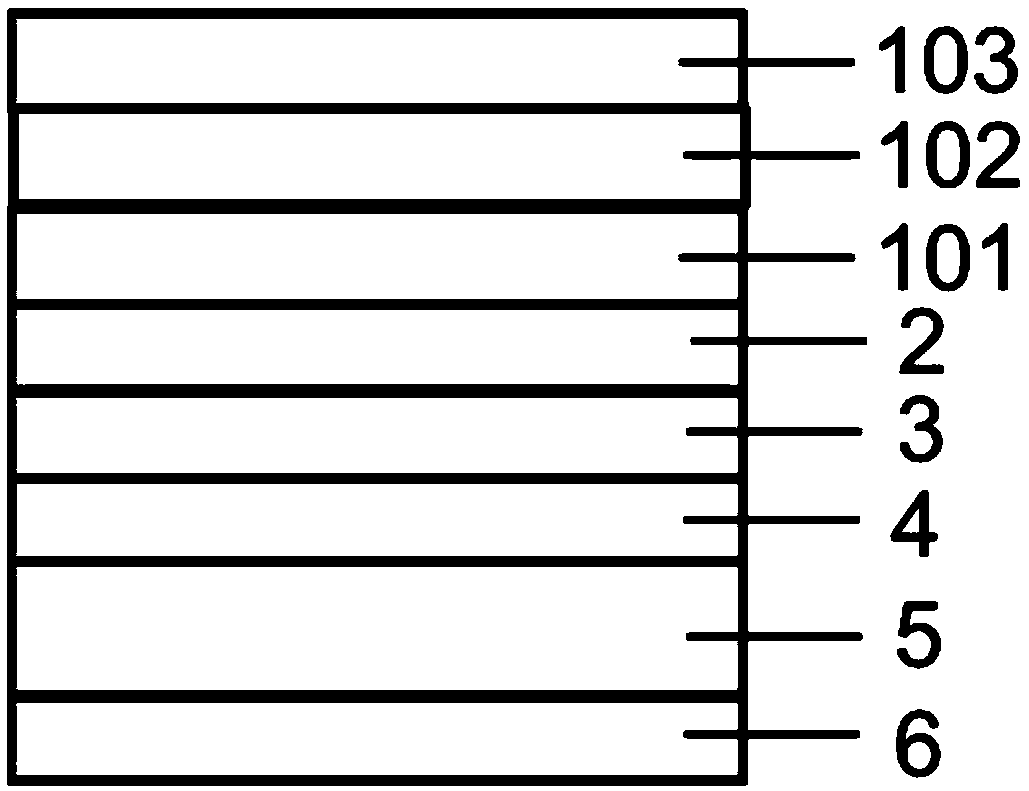

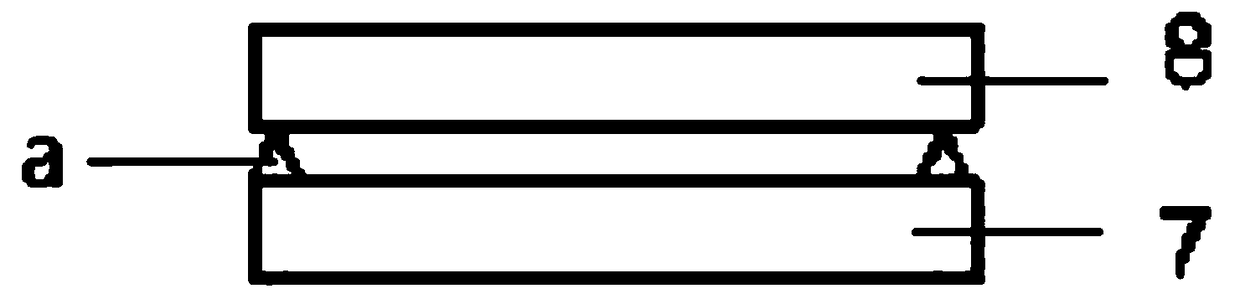

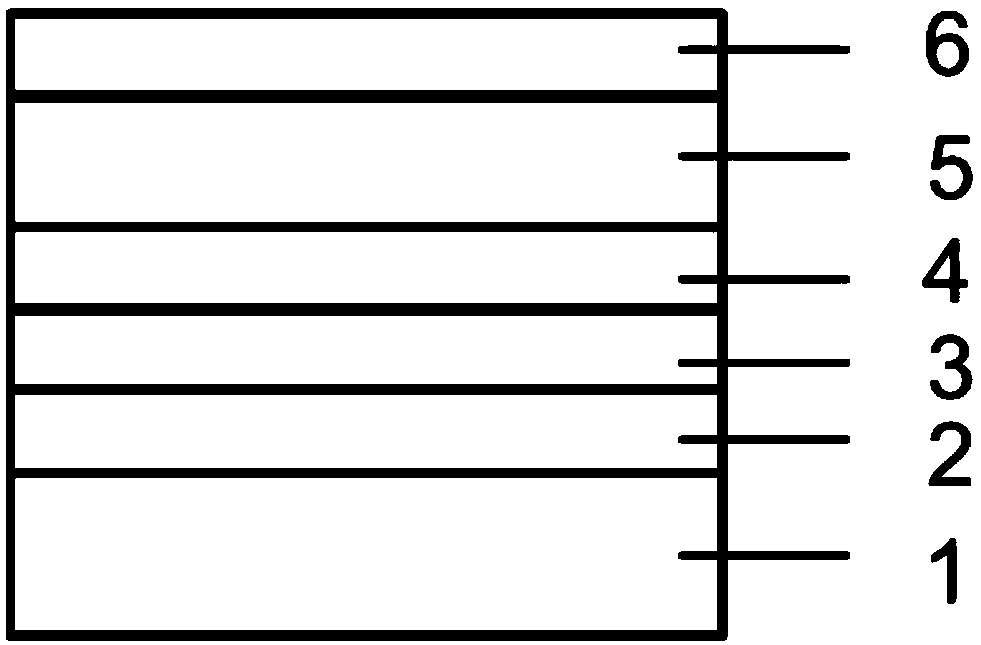

[0056] refer to Figure 1-6 , a method for transferring an edgeless vertical structure LED chip substrate, comprising,

[0057] Step of depositing metal layer: first obtain silicon-based LED epitaxial wafer 1, deposit metal layer on silicon-based LED epitaxial wafer 1, metal layer includes reflector layer 2, reflector protection layer 3 and bonding layer metal 4, reflector layer 2 E-beam is used to deposit on the surface of the silicon-based LED epitaxial wafer 1 (non-silicon substrate surface), the mirror protective layer 3 is deposited on the surface of the reflective mirror layer 2, and the bonding layer metal 4 is deposited on the surface of the reflective mirror protective layer 3 to obtain an epitaxial wafer 7. The silicon-based LED epitaxial wafer 1 includes an epitaxial layer 101, a residual silicon layer 102 removed by a wet method, and a residual silicon layer 103 removed by a dry method;

[0058] The mirror layer 2 is an Ag-based stacked mirror with a structure of ...

Embodiment 2

[0066] A method for transferring a vertical structure LED chip substrate without loss of edges, comprising,

[0067] Depositing metal layer steps: first obtain the silicon-based LED epitaxial wafer, deposit the metal layer on the silicon-based LED epitaxial wafer, the metal layer includes the reflector layer, the reflector protection layer and the bonding layer metal, and the reflector layer is deposited on the silicon-based LED epitaxial wafer surface, the mirror protective layer is deposited on the surface of the mirror layer, and the bonding layer metal is deposited on the surface of the mirror protective layer to obtain an epitaxial wafer; the mirror layer is TiO 2 / SiN x Distributed Bragg reflector, the structure of Bragg reflector is TiO 2 and SiN x Alternately arranged into a periodic structure film in the form of ABAB, prepared by DBR electron beam evaporation station, with TiO 2 and SiN x as one cycle, a total of 17 cycles, each layer of TiO 2 The thickness is 12...

Embodiment 3

[0075] A method for transferring a vertical structure LED chip substrate without loss of edges, comprising,

[0076] Deposit metal layer steps: first obtain silicon-based LED epitaxial wafer, deposit metal layer on silicon-based LED epitaxial wafer, metal layer includes mirror layer, mirror protection layer and bonding layer metal, mirror layer is deposited on silicon by E-beam Based on the surface of the LED epitaxial wafer, the mirror protective layer is deposited on the surface of the mirror layer, and the bonding layer metal is deposited on the surface of the mirror protective layer to obtain the epitaxial wafer; the mirror layer is an Ag-based laminated mirror, and its structure is Pd / Ag / W / Au, the thickness is 2 / 200 / 800 / 200nm; the mirror protective layer is TiW / Pt laminated layer, the laminated period is 5, and the thickness of one laminated period of the mirror protective layer is 300 / 200nm; The bonding layer metal is In / Sn, and the thickness of the bonding layer metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com