Preparation method of special graphene master batch for automobile engineering plastic

A technology of automotive engineering and graphene, which is applied in the field of preparation of graphene masterbatch for automotive engineering plastics, can solve problems such as poor fluidity and difficulty in graphene dispersion, solve dispersion problems, easily realize large-scale industrial production, and good processing The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

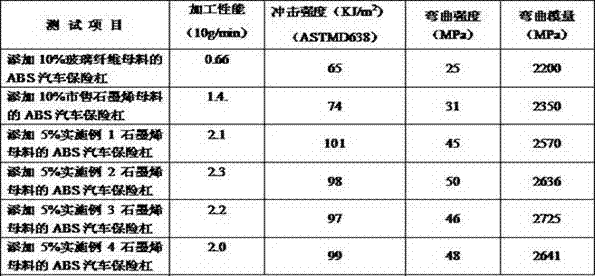

Examples

Embodiment 1

[0035] (1) Blend and shake 10 parts by weight of calcium carbonate microspheres with a particle size of 5 μm, a pore size of 250 nm, and a sphericity greater than 0.85 and 0.3 parts by weight of polyamide wax, and set the vibration frequency to 10 Hz, and then modify the surface The porous calcium carbonate microspheres are subjected to conventional centrifugation screening, the centrifugal speed is 300 rpm, the microspheres broken by vibration are removed, and the surface-modified calcium carbonate microspheres with a sphericity greater than 0.85 are obtained;

[0036](2) Add surface-modified calcium carbonate microspheres into the pressure vessel, add 50 parts by weight of graphene slurry, the solvent is water, the mass concentration is 10%, and the solute graphene is single-layer graphene and Multi-layer graphene mixed powder, the particle size of the powder is 100nm, the thickness is less than 1.6nm, stir evenly, let stand for 10-30 min, add static pressure 20 MPa to the li...

Embodiment 2

[0041] (1) Blend and shake 15 parts by weight of barium sulfate microspheres with a particle size of 10 μm and a pore size of 250 nm and a sphericity greater than 0.85 and 0.5 parts by weight of polyamide wax evenly, set the vibration frequency to 35 Hz, and then modify the surface The porous microspheres are conventionally screened by centrifugation at a rotational speed of 130 rpm to remove the broken microspheres and obtain intact surface-modified barium sulfate microspheres;

[0042] (2) Add surface-modified barium sulfate microspheres into the pressure vessel, add graphene slurry with a weight part of 60, the solvent is water, and the graphene slurry with a solute mass concentration of 15%, wherein the solute graphene is Reduced graphene oxide powder, the particle size of the powder is less than or equal to 100nm, the thickness is 0.4nm, stir evenly, let it stand for 30 minutes, apply a static pressure of 10 MPa to the liquid at a pressurization speed of 0.05 MPa / min, and ...

Embodiment 3

[0047] (1) Blend and shake 12 parts by weight of silica microspheres with a particle size of 5 μm, a pore size of 200 nm, and a sphericity greater than 0.9 and 1 part by weight of phthalate, and set the vibration frequency to 35 Hz. Then carry out conventional centrifugation screening on the surface-modified silica porous microspheres, the centrifugation speed is 250 rpm, remove the microspheres broken by vibration, and obtain intact surface-modified silica microspheres;

[0048] (2) Add surface-modified silica microspheres into the pressure vessel, add 70 parts by weight of graphene slurry, the solvent is water, and the graphene slurry with a mass concentration of 18%, wherein the solute graphene is graphite Graphene nanoribbon and graphene nanosheet mixed powder, the particle size of the powder is less than or equal to 100nm, the thickness is 1.0nm, stir evenly, let it stand for 25 minutes, and apply a static pressure of 10 MPa to the liquid at a pressurization speed of 0.05M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| sphericity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com