Solar cell optical corrosion device

A solar cell and optical corrosion technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as inability to achieve solar cell efficiency, ineffective solar curing, poor anti-reflection effect of anti-reflection coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

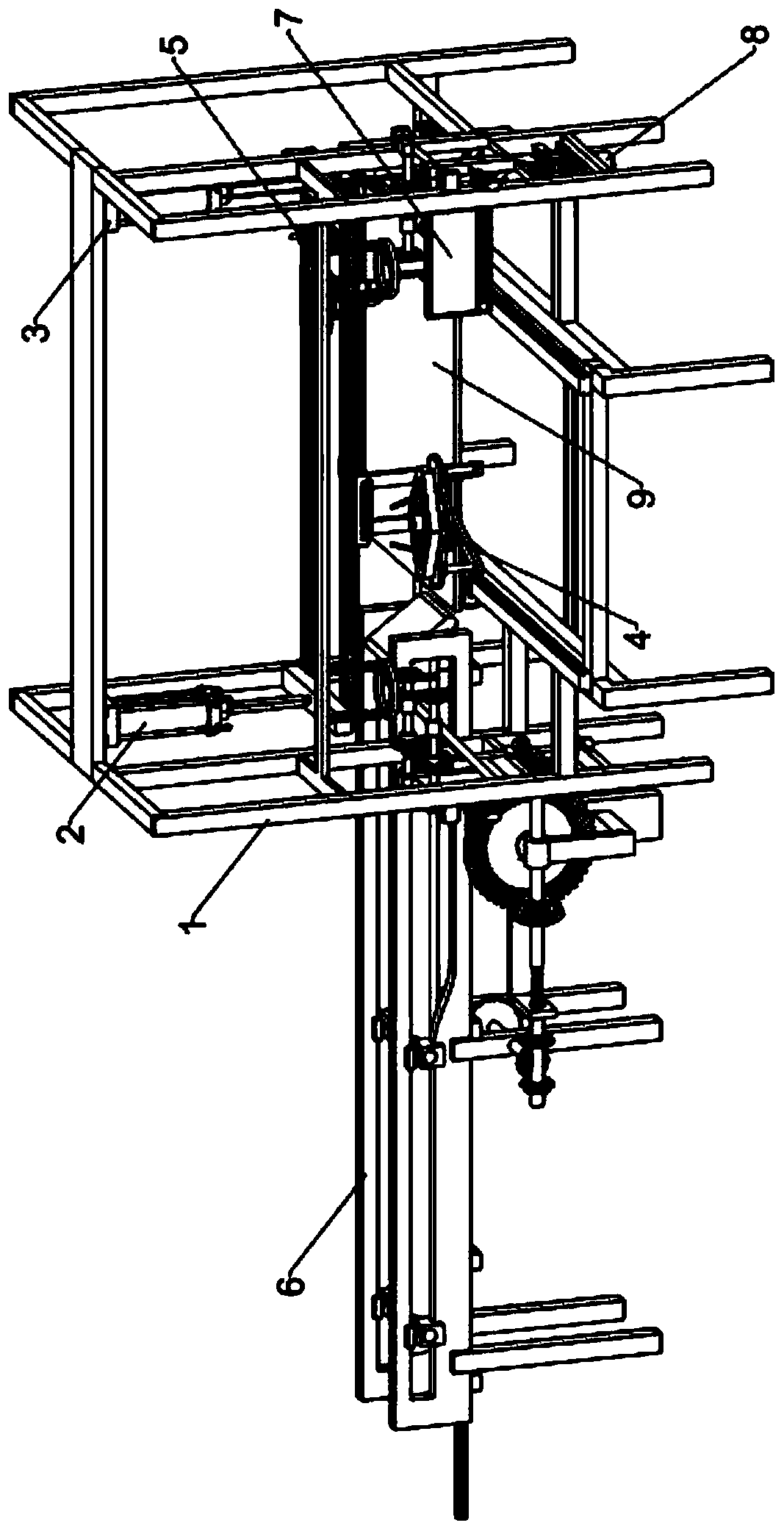

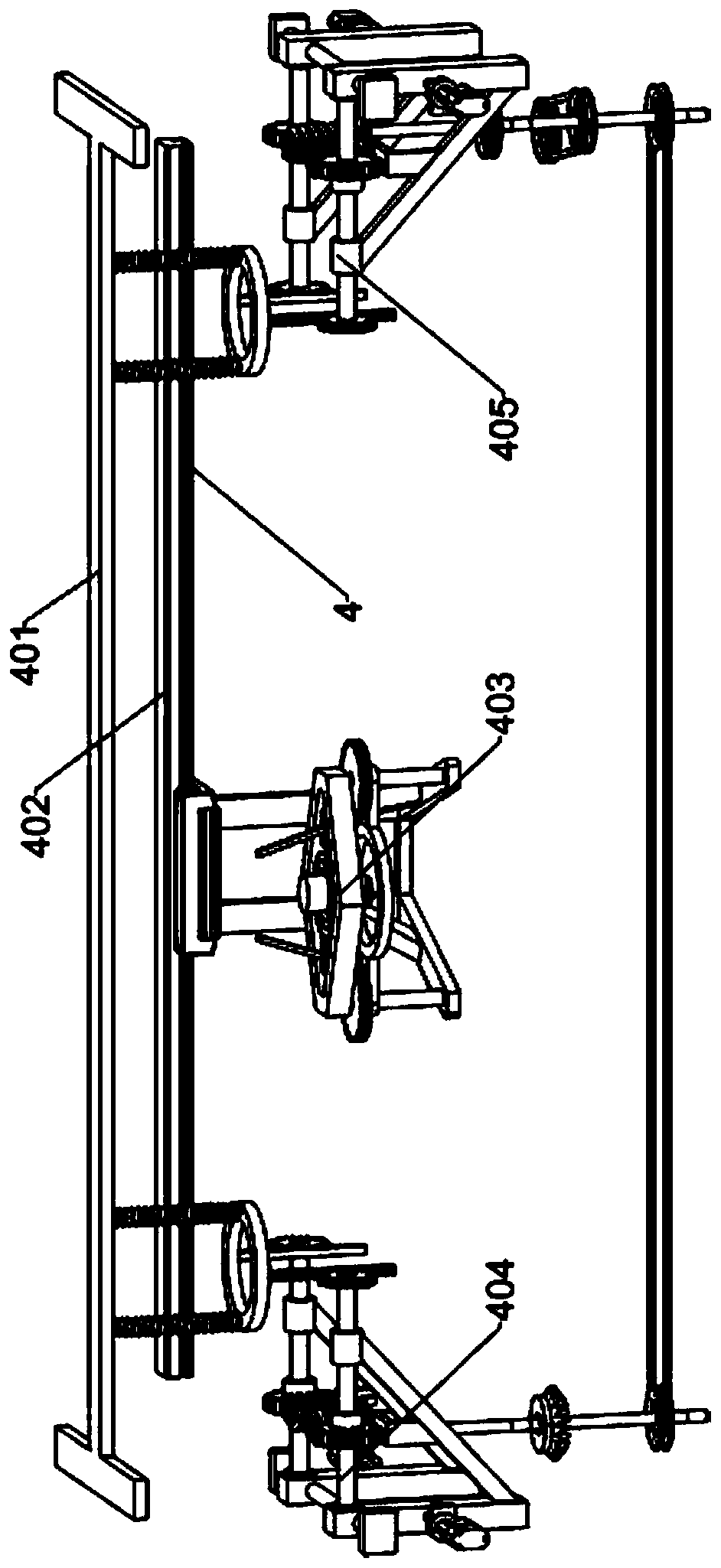

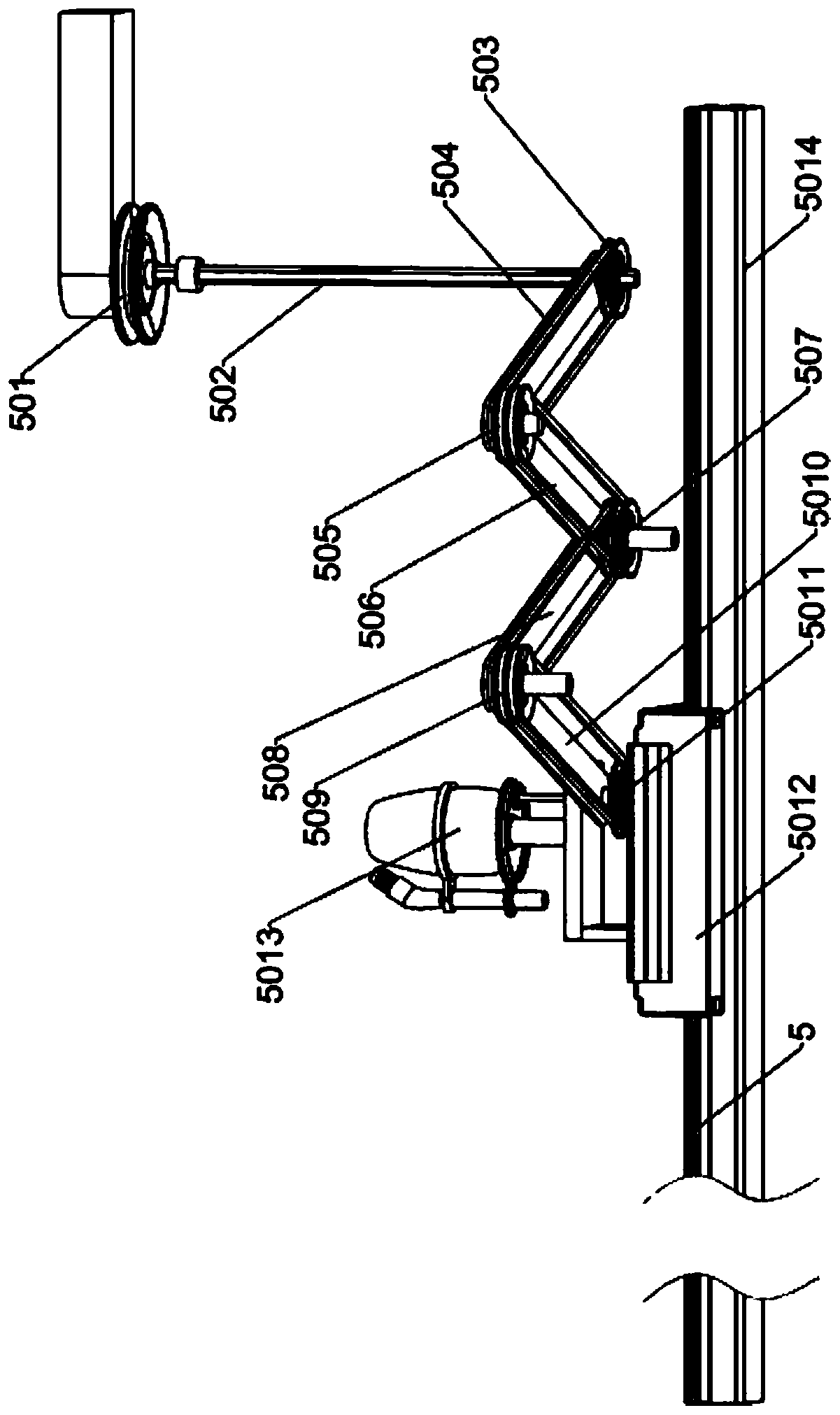

[0031] A solar cell optical etching device, such as Figure 1-9 As shown, it includes the installation frame 1, the first hydraulic cylinder fixing frame 2, the second hydraulic cylinder fixing frame 3, the laser planing mechanism 4, the hot air corrosion mechanism 5, the liquid level equalizing mechanism 6, the control display 7, the motor 8 and the depth Carry plate 9; the middle part of the inner top of the mounting frame 1 is bolted to the first hydraulic cylinder fixing frame 2; the right side of the inner top of the mounting frame 1 is bolted to the second hydraulic cylinder fixing frame 3; the right side of the front middle part of the mounting frame 1 A laser grooving mechanism 4 is provided, and the left rear side of the top of the laser grooving mechanism 4 is connected to the first hydraulic cylinder fixing frame 2, and the right rear side of the top of the laser grooving mechanism 4 is connected to the second hydraulic cylinder fixing frame 3; The right middle part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com