Novel graphite resistor rod for aluminum foil corrosion of capacitor

A capacitor aluminum foil, graphite electrode technology, applied in capacitors, electrolytic capacitors, electrodes and other directions, can solve the problems of uneven lateral distribution of corrosion current density, deviation of corrosion current density, affecting the quality of anode aluminum foil, etc., to improve the uniformity of lateral current distribution , avoid the increase, improve the effect of the uniformity of capacitance distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in more detail below in conjunction with accompanying drawing:

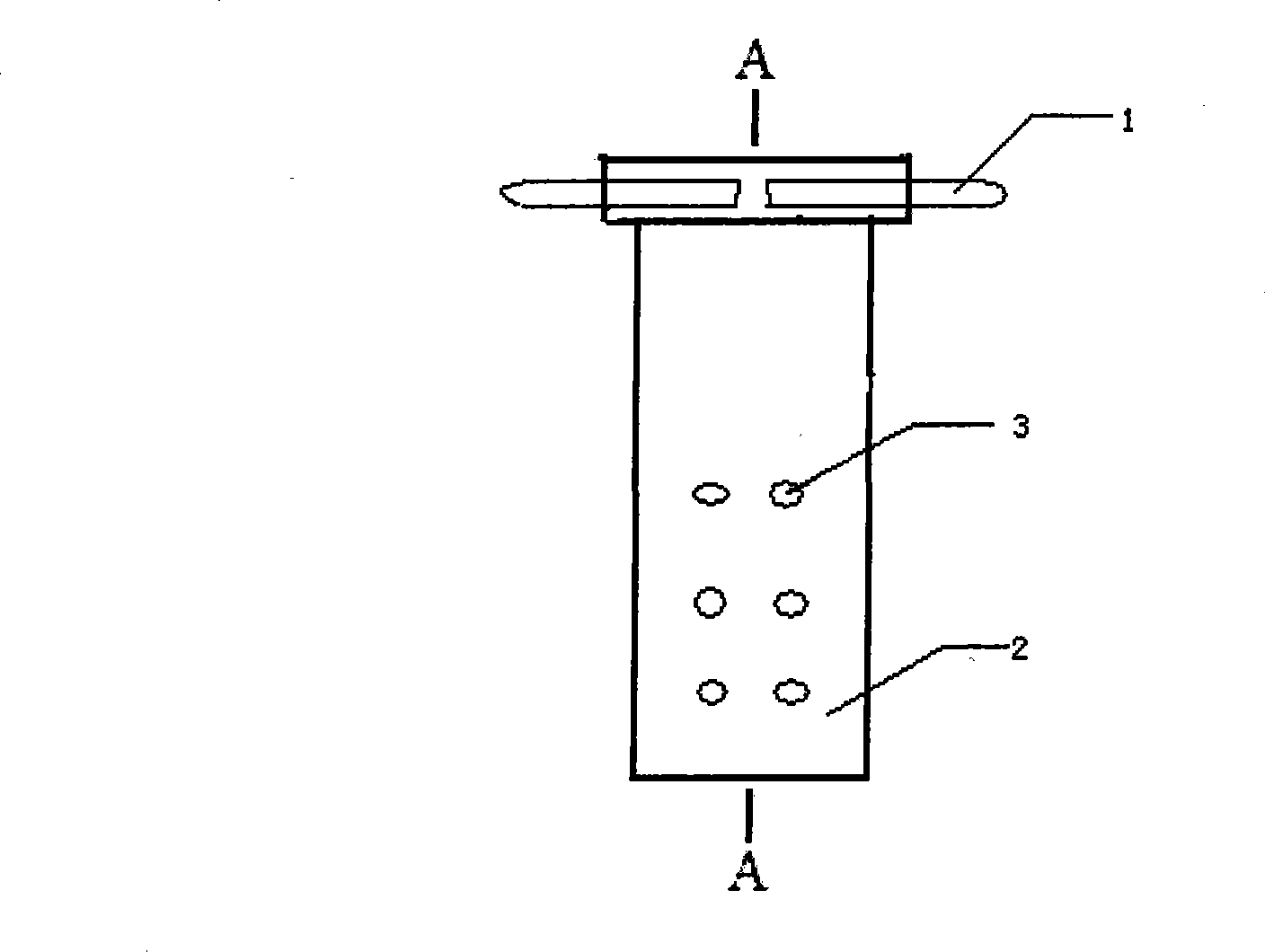

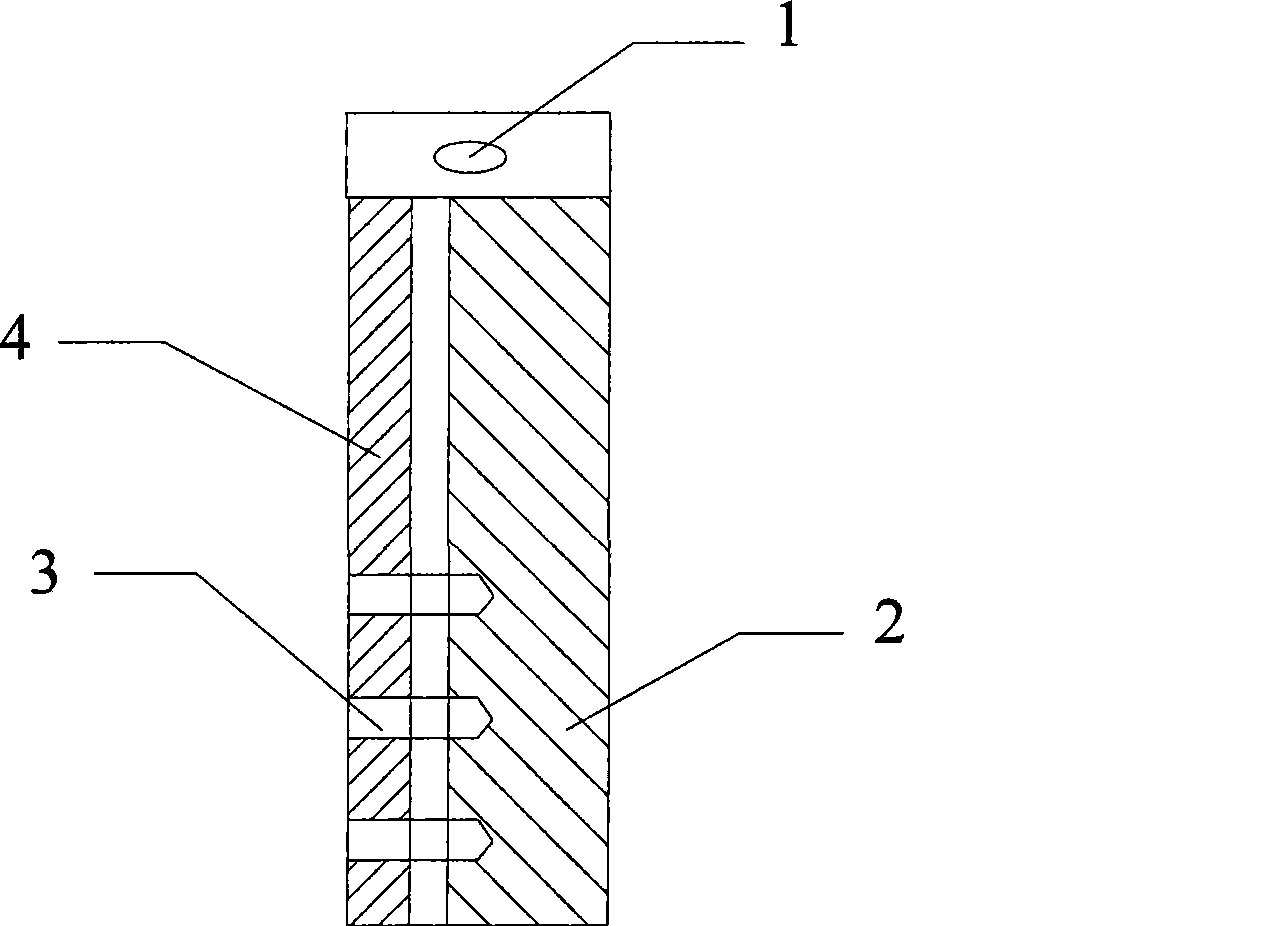

[0018] See Figure 1-2 , a new type of graphite electrode for electrochemically corroding anode aluminum foil, consisting of a graphite pole plate 2, an insulating baffle 4 and two copper rods 1, one end of the two copper rods is inserted into the graphite pole plate 2 and fixed, and the other One end of the exposed graphite plate 2 is connected to the power supply wire. The exposed parts of the copper rod are all coated with insulating glue, and the contact between the copper rod and the wire is not coated with glue. The insulating baffle 4 is passed through the non-penetrating screw hole 3 with graphite bolts It is fixed together with the graphite pole plate 2 to form a group of electrodes for electrochemically expanding the surface of the capacitor anode aluminum foil.

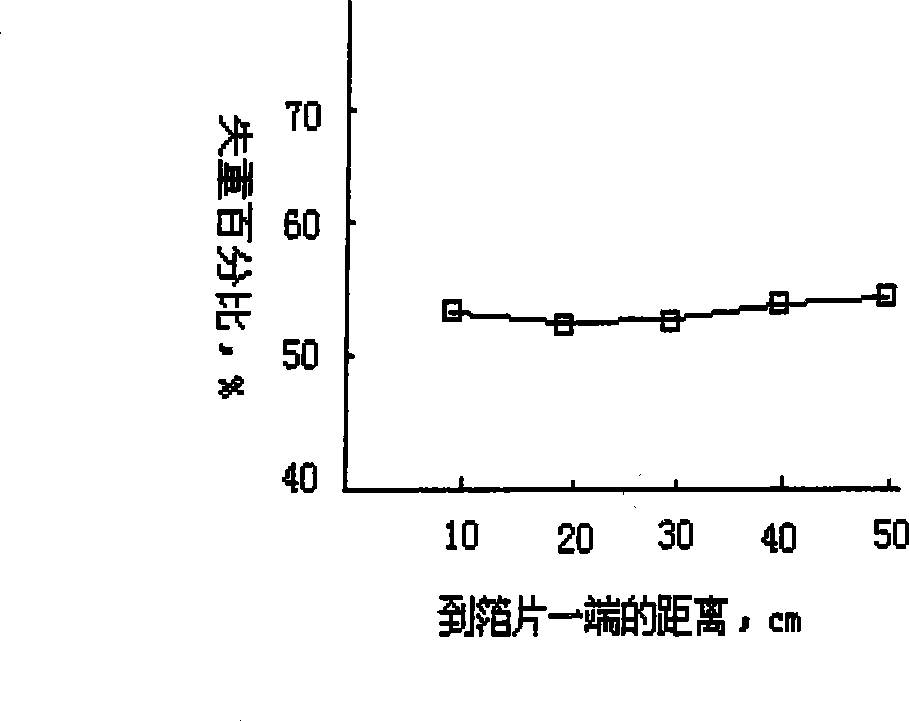

[0019] See attached image 3 And attached Figure 4 , the abscissa is the distance from one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com