Wafer corrosion device

A technology for etching devices and wafers, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as uneven temperature, large consumption of chemical liquid, and differences in uniformity of wafer surface corrosion, so as to improve the utilization rate , Mention the uniformity and ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

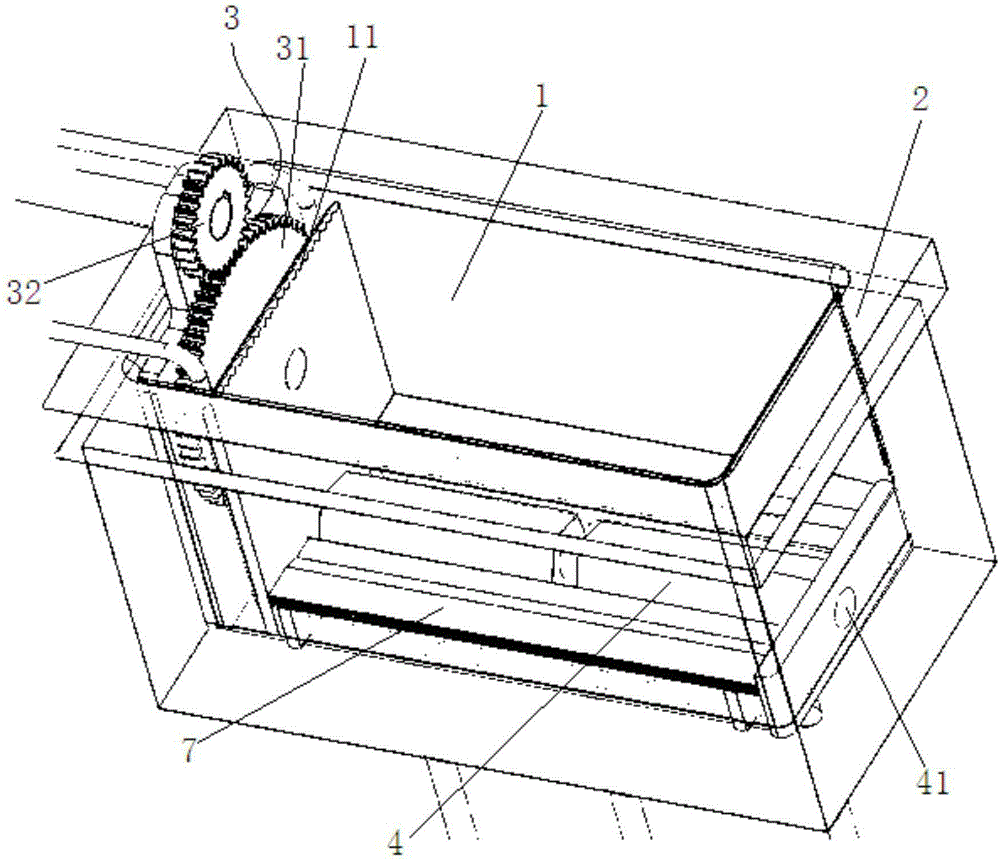

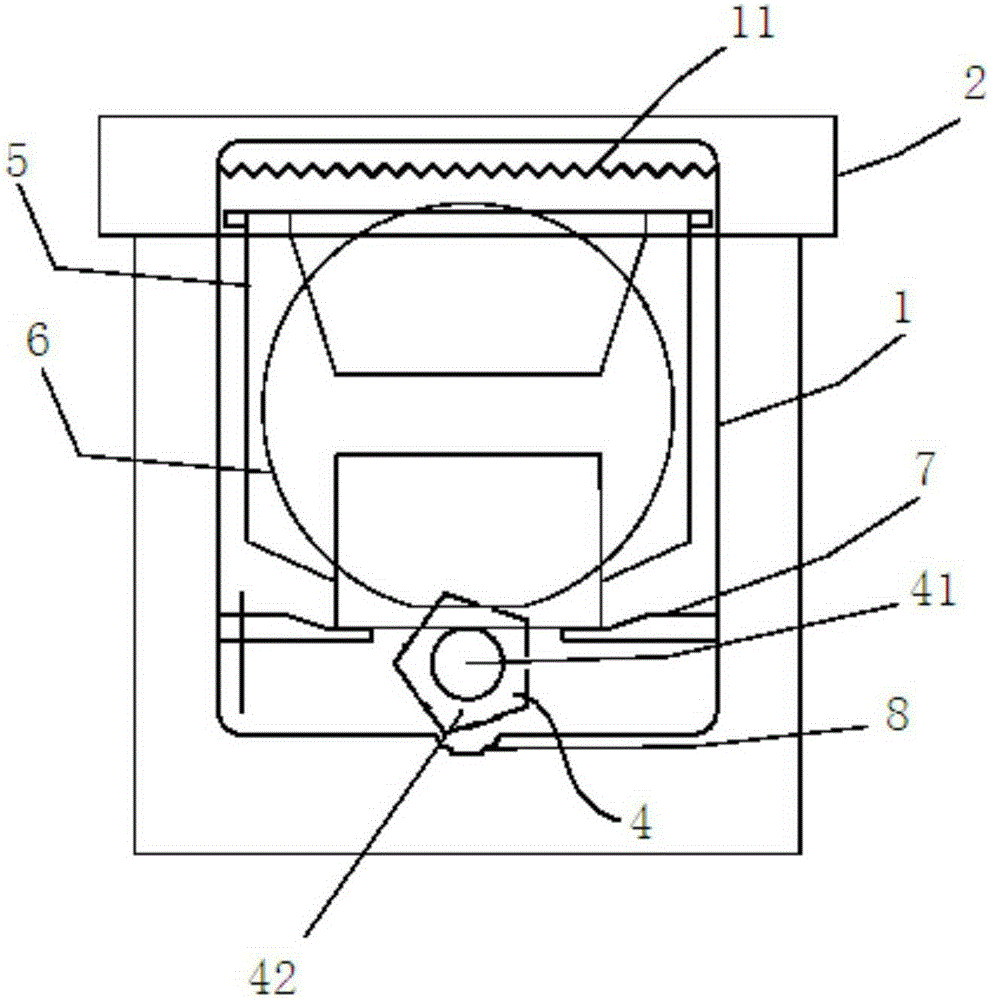

[0045] Embodiment 1, the corrosion of wafer surface removal oxide layer

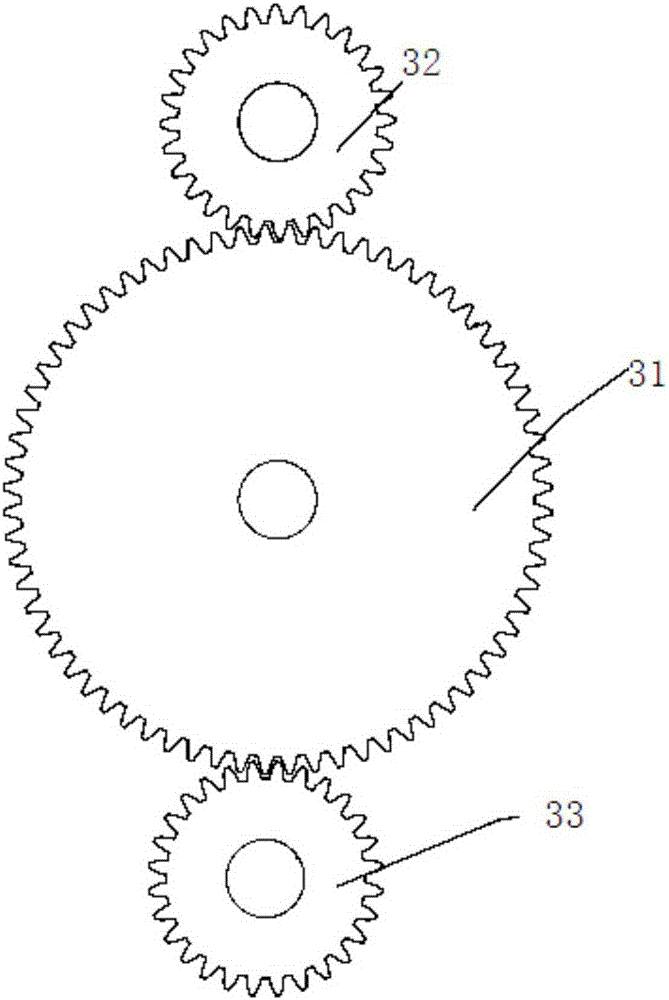

[0046] In this embodiment, the corrosion solution used is %49HF (hydrofluoric acid), and the inner box body 1 and the outer box body 2 are formed by thermal welding of PVDF material. The drive unit adopts a frequency conversion motor, the polygonal rotating column adopts a regular pentagonal rotating column, the metal shaft of the regular pentagonal rotating column is made of metal titanium, and the regular pentagonal hollow column is made of PTFE material.

[0047] Put the wafer cassette 5 into the inner box 1, inject %49HF (hydrofluoric acid) into the inner box 1, drive the frequency conversion motor to rotate, the polygonal rotating column follows the transmission gear and rotate forward, the prism between the wafer and the regular pentagonal rotating column contact, the wafer 6 is rotated, and the overflow pump is started at the same time, so that the %49HF (hydrofluoric acid) throws the wafer up and...

Embodiment 2

[0048] Embodiment 2: Corrosion of wafer 6 surface stripping surface photoresist

[0049] In this embodiment, the etching solution used is EKC (synthetic organic chemical solution). The inner box 1 and the outer box 2 are welded by 316 stainless steel, the transmission mechanism is made of 316 stainless steel, the transmission mechanism is connected to the frequency conversion motor, the polygonal rotating column adopts the regular pentagonal rotating column, and the regular pentagonal rotating column The metal shaft is made of titanium, and the regular pentagonal hollow column is made of 316 stainless steel. The stainless steel material can resist the corrosion of EKC chemical liquid. At the same time, the outer box 2 is equipped with a film heater to heat the EKC chemical liquid to make the EKC chemical liquid reach 90°C, because the degumming effect is best when the EKC chemical liquid is at 90°C.

[0050] After the wafer cassette 5 is put into the inner box 1, EKC chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com