Metallographic corrosive and metallographic structure display method of copper and copper alloy

A metallographic structure display and copper alloy technology, applied in the field of metallographic structure display of copper and copper alloys, and metallographic etchant, can solve the problems of cumbersome display methods and steps, poor effect, and difficult to control the degree of corrosion, etc., to achieve improved Corrosion efficiency and the effect of surface metallographic microstructure display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the present invention, the technical solutions of the present invention will be described in detail below in conjunction with specific examples. The display method includes the following steps:

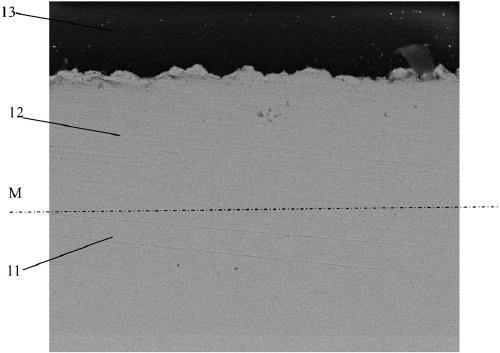

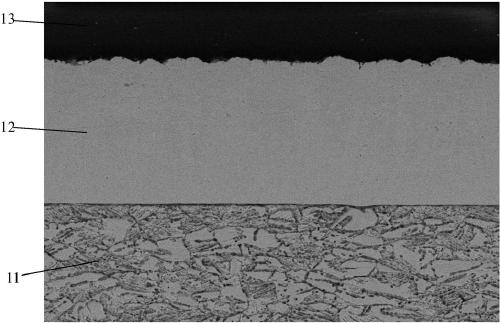

[0020] The first step is to provide copper and copper alloy metallographic samples, such as figure 1 As shown, the metallographic sample includes a copper layer 11 and a copper alloy layer 12 plated on the copper layer 11, and the dotted line M is the dividing line between the two layers, and the dividing line is not obvious in the real object;

[0021] In the second step, a container (not shown) is provided, the metallographic sample is fixed into the container with a fixture, and liquid polyflor resin is injected, and the metallographic sample is put into the polyflor resin for 4h to 6h cold embedding, the effect after cold embedding is as follows figure 1 As shown, the Polyflor resin layer 13 is surrounded on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com