Afforest additive for vegetation concrete and preparation method thereof

A technology of greening additives and vegetation concrete, applied in fertilizer mixture, sustainable waste treatment, solid waste management, etc., can solve the problems of complex process, lifeless substrate, yellowing of vegetation, etc., achieve a good growth environment and reduce damage The effect of action and high corrosion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

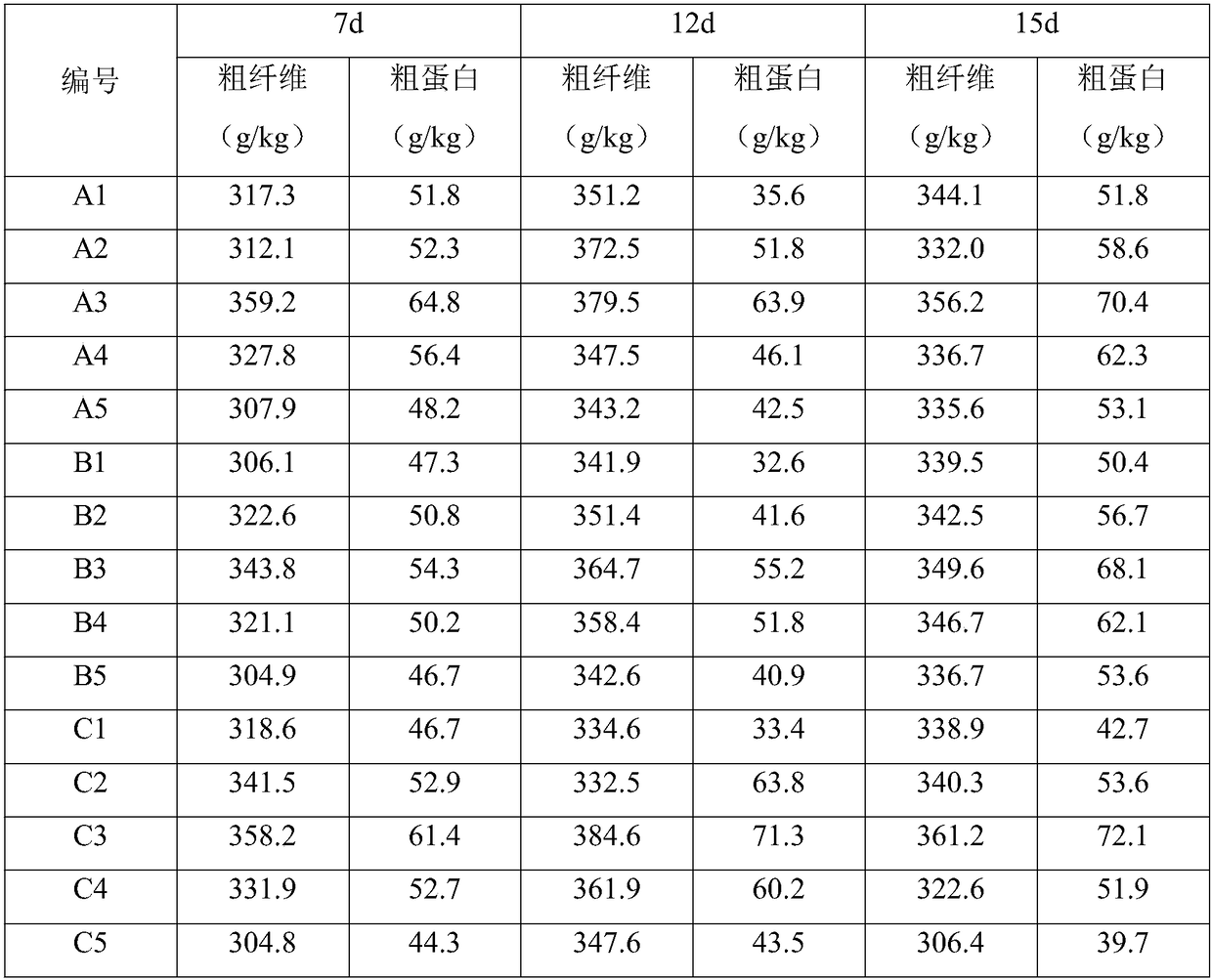

Examples

Embodiment 1

[0039] A greening additive for vegetation concrete, comprising the following components by weight: straw organic matter 22%, white rot mycelia 4%, fly ash 38%, plant ash 36%.

[0040] The preparation method of above-mentioned vegetation concrete greening additive comprises the following steps:

[0041] 1) Step 1, prepare organic additives:

[0042] Water with a specific gravity of 1.54 kg was added to a straw organic substrate weighing 2.2 kg, and after storage for 12 hours, the organic substrate was sterilized in a steam environment at 130° C. for 30 minutes to obtain a culture medium;

[0043] Adjust the pH of the above medium to make the initial pH value 4;

[0044] Mix white rot fungus with a specific gravity of 2.4g into a medium with a pH of 4, and ferment for 10 days at 30°C under dark conditions to obtain an organic additive;

[0045] 2) Step 2, preparation of inorganic additives:

[0046] The fly ash with a weight of 3.8kg and the plant ash of 3.6kg are uniformly m...

Embodiment 2

[0050] A greening additive for vegetation concrete, comprising the following components by weight: straw organic matter 22%, brown rot mycelium 0.6%, fly ash 37.4%, plant ash 40%.

[0051] The preparation method of above-mentioned vegetation concrete greening additive comprises the following steps:

[0052] 1) Step 1, prepare organic additives:

[0053] Water with a specific gravity of 1.54 kg was added to a straw organic substrate weighing 2.2 kg, and after storage for 12 hours, the organic substrate was sterilized in a steam environment at 130° C. for 30 minutes to obtain a culture medium;

[0054] Adjust the pH of the above medium to make the initial pH value 4;

[0055] Mix brown rot fungi with a specific gravity of 0.8g into a medium with a pH of 4, and ferment for 11 days at 30°C under dark conditions to obtain an organic additive;

[0056] 2) Step 2, preparation of inorganic additives:

[0057] The fly ash with a weight of 3.74kg and the plant ash of 4kg are evenly m...

Embodiment 3

[0061] A greening additive for vegetation concrete, comprising the following components by weight: 16% of sawdust organic matter, 8% of soft rot fungus hyphae, 36% of fly ash, and 40% of plant ash.

[0062] The preparation method of above-mentioned vegetation concrete greening additive comprises the following steps:

[0063] 1) Step 1, prepare organic additives:

[0064] Water with a specific gravity of 1.12 kg was added to a sawdust organic substrate weighing 1.6 kg, and after storage for 12 hours, the organic substrate was sterilized in a steam environment at 150° C. for 30 minutes to obtain a culture medium;

[0065] Adjust the pH of the above medium to make the initial pH value 4;

[0066] Mix soft rot fungus with a specific gravity of 1.0g into a medium with a pH of 4, and ferment for 7 days at 30°C under dark conditions to obtain an organic additive;

[0067] 2) Step 2, preparation of inorganic additives:

[0068] The fly ash with a weight of 3.6kg and the plant ash o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com