Automatic PCB board corrosion chamber

A technology of PCB board and corrosion box, which is applied in the field of PCB circuit board corrosion equipment, can solve the problems of hindering water flow, low corrosion efficiency, long corrosion time, etc., and achieve the effect of reducing resource waste and improving corrosion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0039]The circuit features of this fully automatic PCB board corrosion box include: central control module, frequency modulation vibration module, mechanical transmission module, temperature detection and feedback module, heating module, liquid level sensor module, stroke control module, alarm prompt module, OLED liquid crystal Display module, key module, drive module, power module.

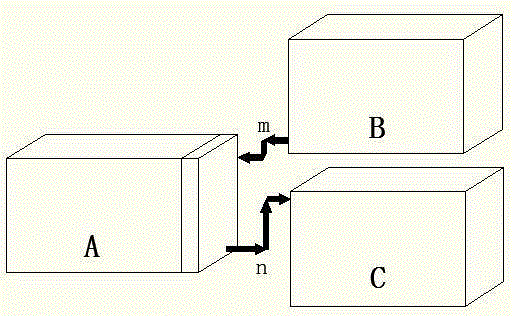

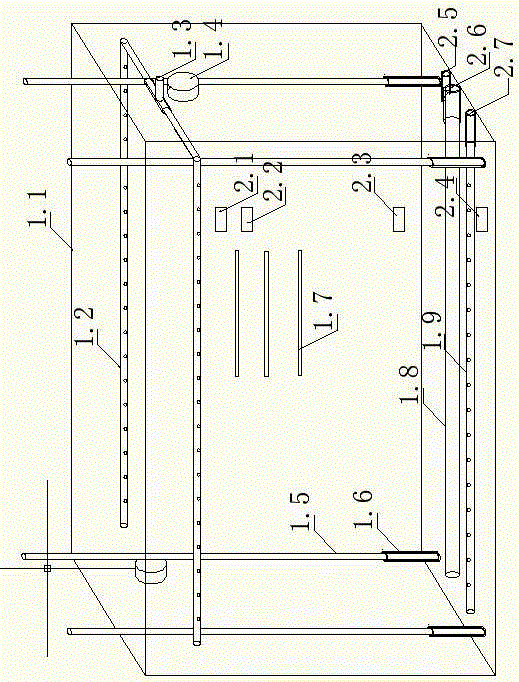

[0040] see figure 1 — Figure 4 : Its structural features:

[0041] It includes a rectangular corrosion box 1.1 made of transparent corrosion-resistant materials. There are three water level marks 1.7 on the front of the outside of the box, corresponding to PCB circuit boards of different sizes; there are three sensors and an infrared tube switch on the front of the outside of the box. 2.2, the three sensors from top to bottom are the upper liquid level sensor 2.1, the temperature sensor 2.3, and the lower liquid level sensor 2.4. The sensing parts of the three sensors are located inside the b...

no. 2 example

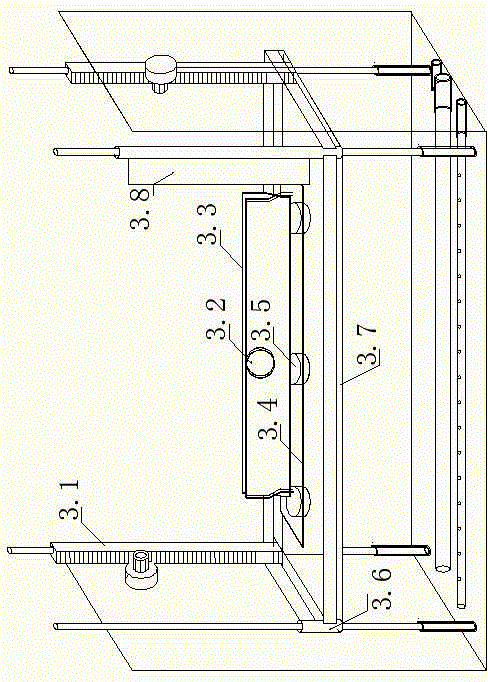

[0044] see image 3 : FM vibration module:

[0045] The solubility of the gas is related to the temperature. When the temperature rises, the solubility of the gas in the corrosion solution decreases, and part of the gas will escape from the heat on the PCB board to form gas bubbles attached to the PCB board, thereby hindering the contact between the PCB board and the corrosion solution. , thus greatly reducing the corrosion efficiency, so the gas bubbles on the PCB board must be removed every once in a while. Control the PWM input terminal driven by the vibration motor through the main control chip, and change the PWM input value every once in a while, thereby changing the vibration frequency and vibration amplitude of the vibration motor 3.2, and clearing the gas bubbles on the PCB board, so that The corrosive liquid is in full contact with the PCB board, thereby accelerating the corrosion rate. The vibration of the vibration motor 3.2 drives the PCB board to vibrate, which...

specific Embodiment 3

[0072] see figure 1 — Figure 4 : Specific operation steps:

[0073] According to the three water level marks 1.7 on the corrosion box, the corrosion personnel judge which size of circuit board their PCB board belongs to. After selecting the water level mark 1.7, the corrosion personnel fix the PCB circuit board on the strip clip 3.3, and then Pour an appropriate amount of corrosive agent into the transmission frame 3.7 for the area required to be corroded by your own board, and click the button to confirm the corrosion. At this time, the water inlet pump pumps clean water from the clean water tank B into the corrosion tank A. At this time, the 220V heating rod 1.8 starts Work; when the water level in the corrosion tank A reaches the selected water level mark 1.7 line, the water inlet pump stops working. At this time, the transmission frame 3.7 begins to descend. When the transmission frame 3.7 descends into the tank, the vibration motor 3.2 starts to work. , the air pump s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com