High-temperature corrosion inhibitor for H2S-HCl-H2O system and preparation method of high-temperature corrosion inhibitor

A high-temperature corrosion inhibitor, h2s-hcl-h2o technology, applied in the field of anticorrosion of materials in the petrochemical field, can solve the problems of inability to protect equipment for a long time, endanger the health of operators, increase operating costs, etc., and achieve a wide range of operating temperatures, Less environmental pollution and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

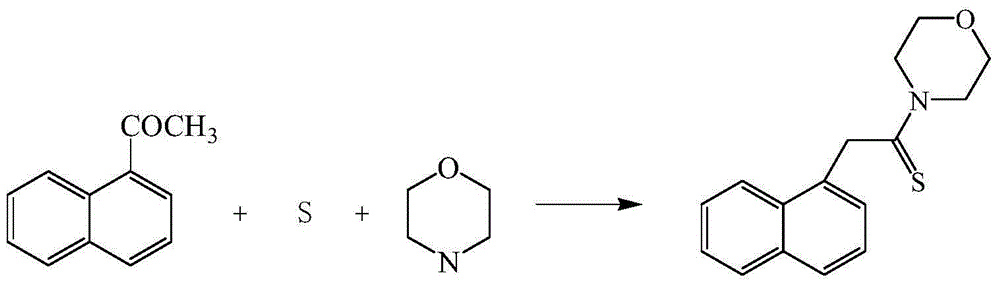

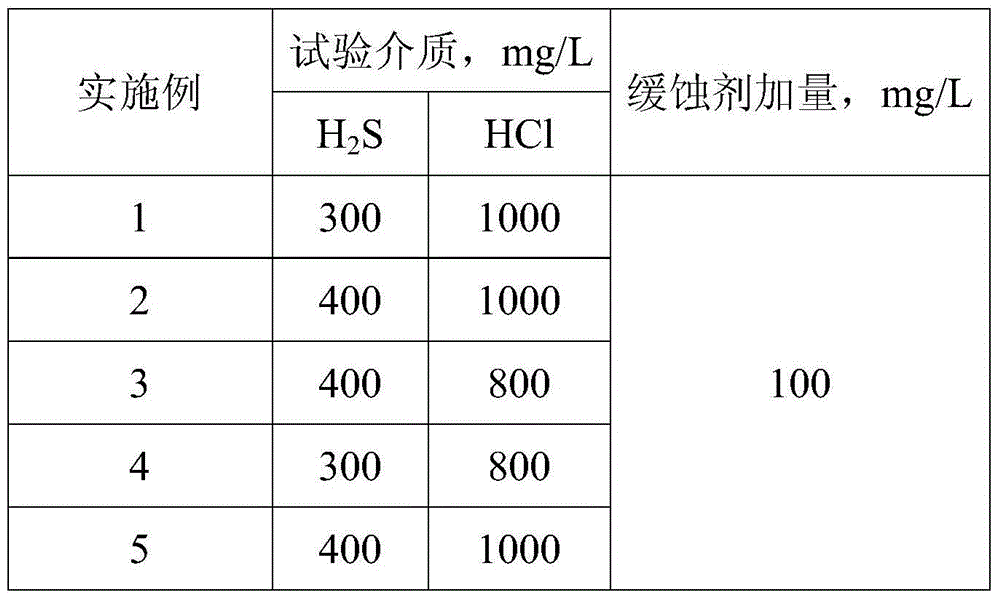

[0028] Add 34g (0.2mol) of methyl-α-naphthyl ketone, 69.6g (0.8mol) of morpholine, and 35.2g (0.26mol) of sulfur into a three-necked flask, and react 9 at the reflux temperature of morpholine (128°C). hour; Then filter and remove the unreacted sulfur to obtain naphthaleneethylthiomorpholine, then naphthylethylthiomorpholine 30g, cetylpyridine 5g, diethanolamine 10g, potassium molybdate 2g, water 5g and 33g of N,N'-dimethylformamide were mixed, stirred evenly to obtain H 2 S-HCl-H 2 High temperature corrosion inhibitor for O system.

Embodiment 2

[0030] Add 17g (0.1mol) of methyl-α-naphthyl ketone, 52g (0.6mol) of morpholine, and 17.6g (0.13mol) of sulfur into a three-necked flask, and react for 6 hours at the reflux temperature of morpholine (128°C) ; Then remove the unreacted sulfur by filtration to obtain naphthylethylthiomorpholine. Mix 50g of naphthylethylthiomorpholine, 10g of cetylpyridine, 15g of diethanolamine, 3g of potassium molybdate, 7g of water and 40g of N,N'-dimethylformamide, and stir evenly to obtain H 2 S-HCl-H 2 High temperature corrosion inhibitor for O system.

Embodiment 3

[0032] Add 34g (0.2mol) of methyl-α-naphthyl ketone, 34.8g (0.4mol) of morpholine, and 35.2g (0.26mol) of sulfur into a three-necked flask, and react 8 at the reflux temperature of morpholine (128°C). Hours; then filter to remove unreacted sulfur, that is, to obtain naphthyl ethyl thiomorpholine. Mix 35g of naphthylethylthiomorpholine, 15g of cetylpyridine, 10g of triethanolamine, 1g of potassium tungstate, 5g of water and 34g of N,N'-dimethylformamide, and stir evenly to obtain H 2 S-HCl-H 2 High temperature corrosion inhibitor for O system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com