Fabrication device and fabrication method of substrate surface light trapping structure

A light-trapping structure and technology for preparing devices, which is applied in the field of solar energy, can solve the problems of limited efficiency improvement, poor light-trapping effect, and high manufacturing cost, and achieve anti-reflection, improve light utilization, and increase light-receiving area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

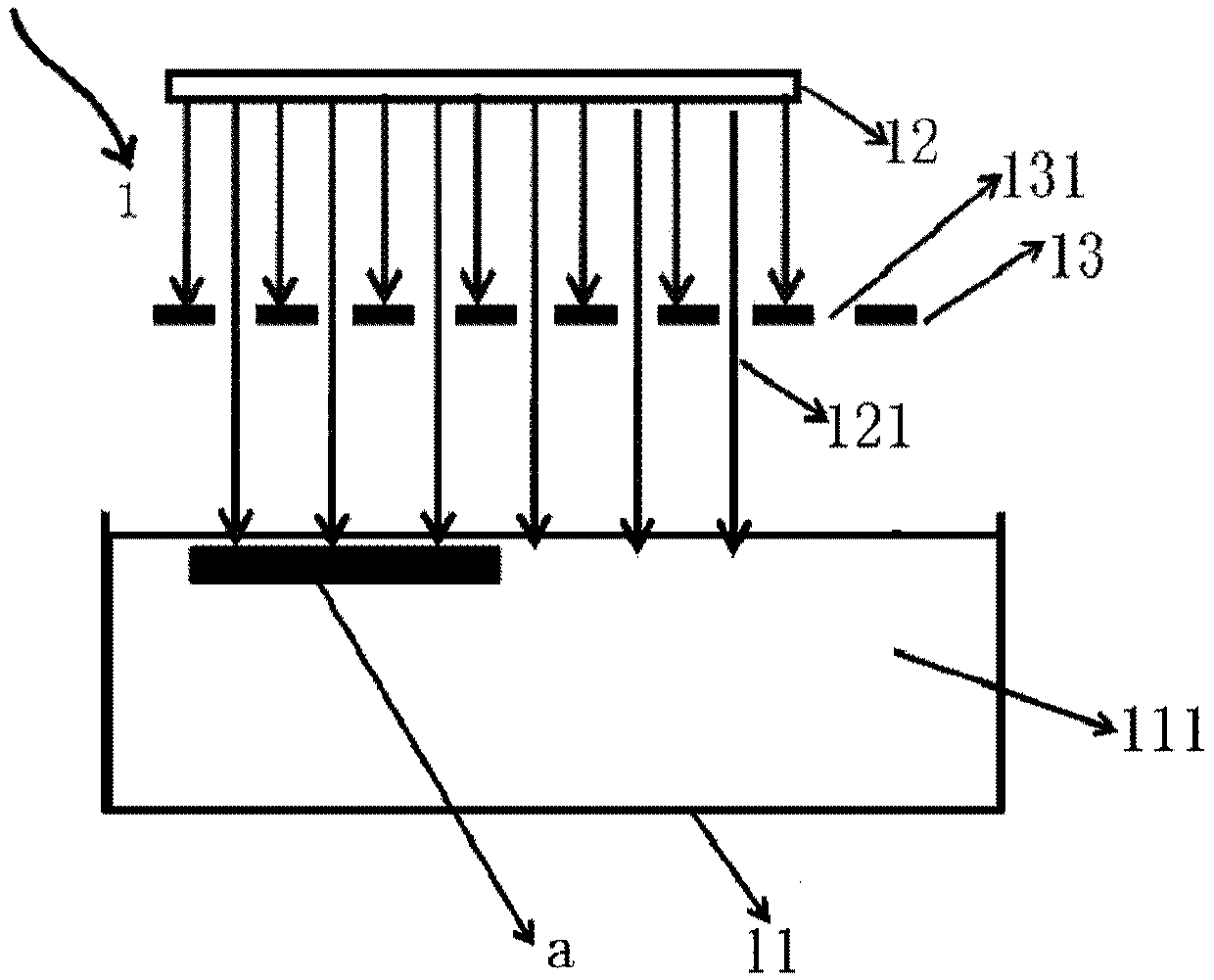

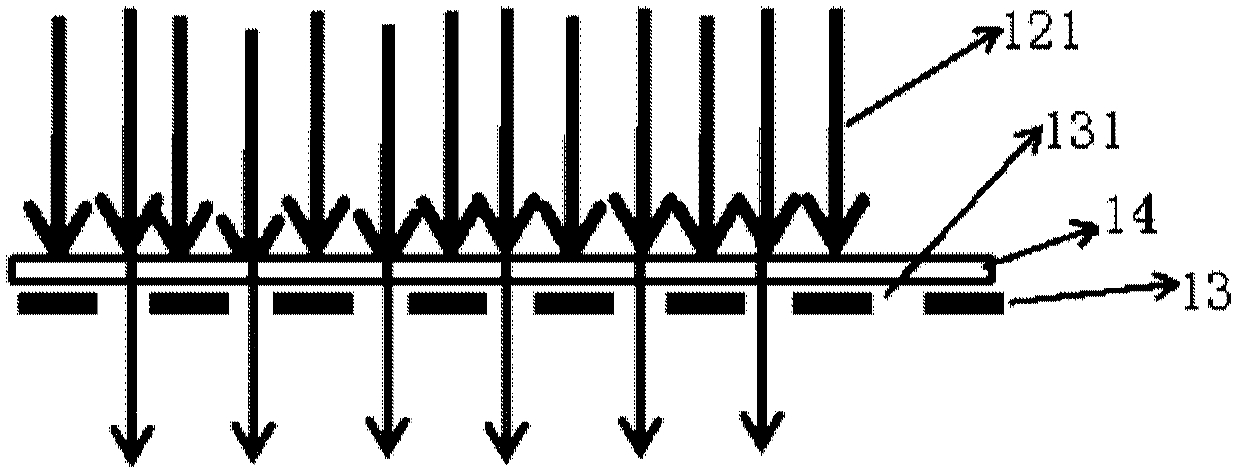

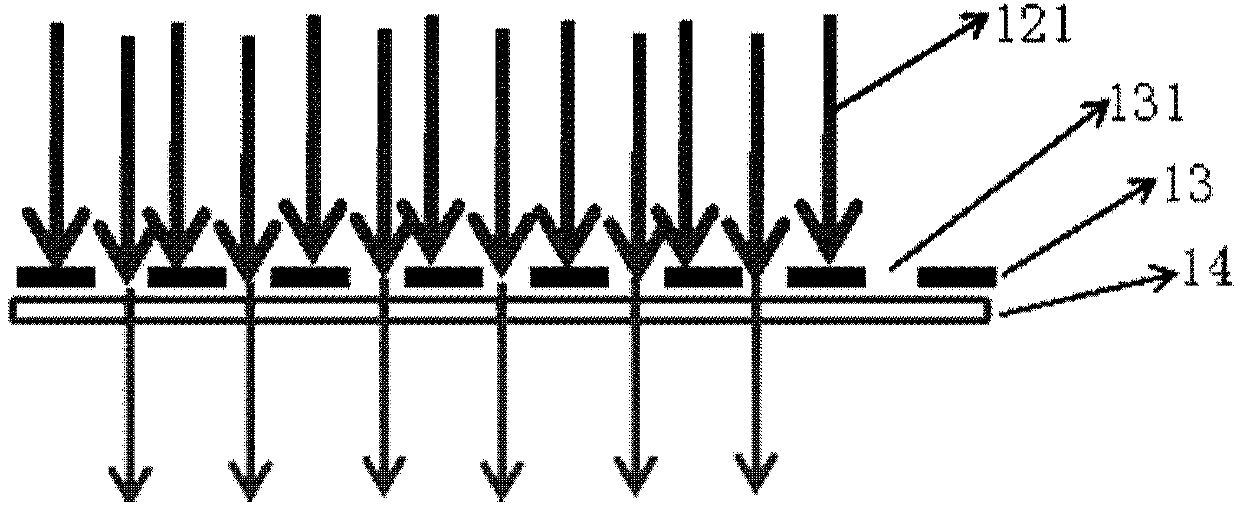

[0057] based on Figure 9 The preparation device of the light-trapping structure on the surface of the substrate, the present invention also proposes a preparation method of the light-trapping structure on the surface of the substrate, using the above-mentioned preparation device of the light-trapping structure on the surface of the substrate, comprising the following steps: Step 1. Catalytic light, the catalytic light is injected into the corrosion tank through the pores of the light-transmitting plate; step 2, the corrosion liquid in the corrosion tank, under the action of catalytic light, corrodes the substrate placed in the corrosion tank, forming Light-trapping structure; step 3, the mechanical arm cooperates with the insertion machine to move the substrate with the light-trapping structure on the surface to the acid modification tank, and the acid modification solution therein modifies the surface of the light-trapping structure; step 4, the mechanical arm cooperates with...

Embodiment

[0075] Such as Figure 11 It is a schematic diagram of the light-trapping structure manufacturing equipment and its supporting process proposed in this embodiment. This figure is a schematic diagram of chain equipment.

[0076] The manufacturing equipment of the present embodiment has six tanks: respectively chain type corrosion tank body 701 and tank type corrosion tank body 702 and 703 three corrosion tank bodies; 705 and 706). These tanks are Figure 11 Arranged in a way that constitutes the corrosion body of the entire device. Wherein above the tank body of 701, there is a surface light source 707 and a light-transmitting plate 708 (on the light-transmitting plate is a light-transmitting small hole 708a). The light passes through the small light-transmitting hole 708 a on the light-transmitting plate 708 , and shines on the battery sheet 8 in the corrosion tank 701 . The battery sheet 8 is placed on the top of the roller 701a in the tank. When the roller 701a rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com