Patents

Literature

167results about "Lithography/patterning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

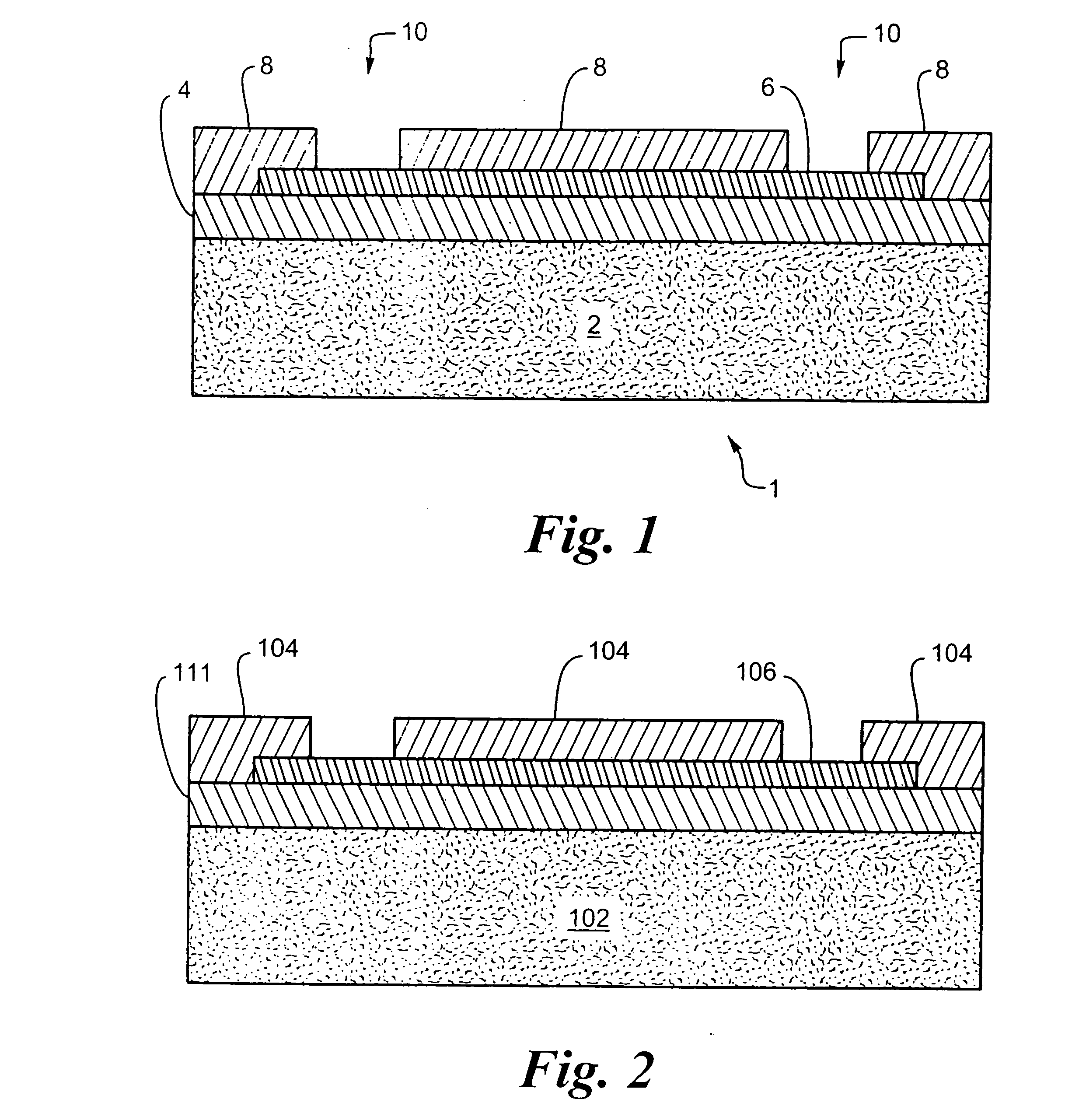

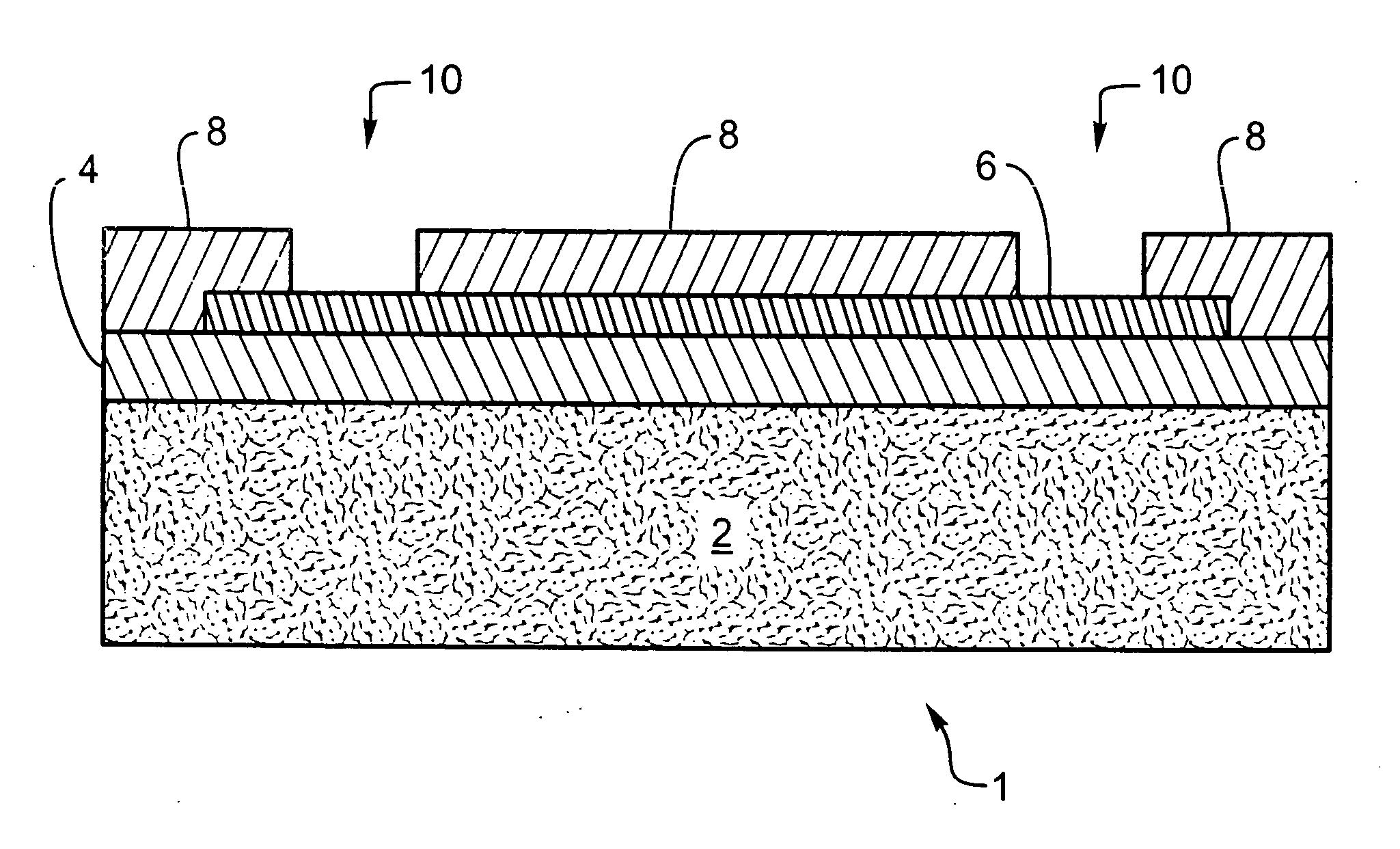

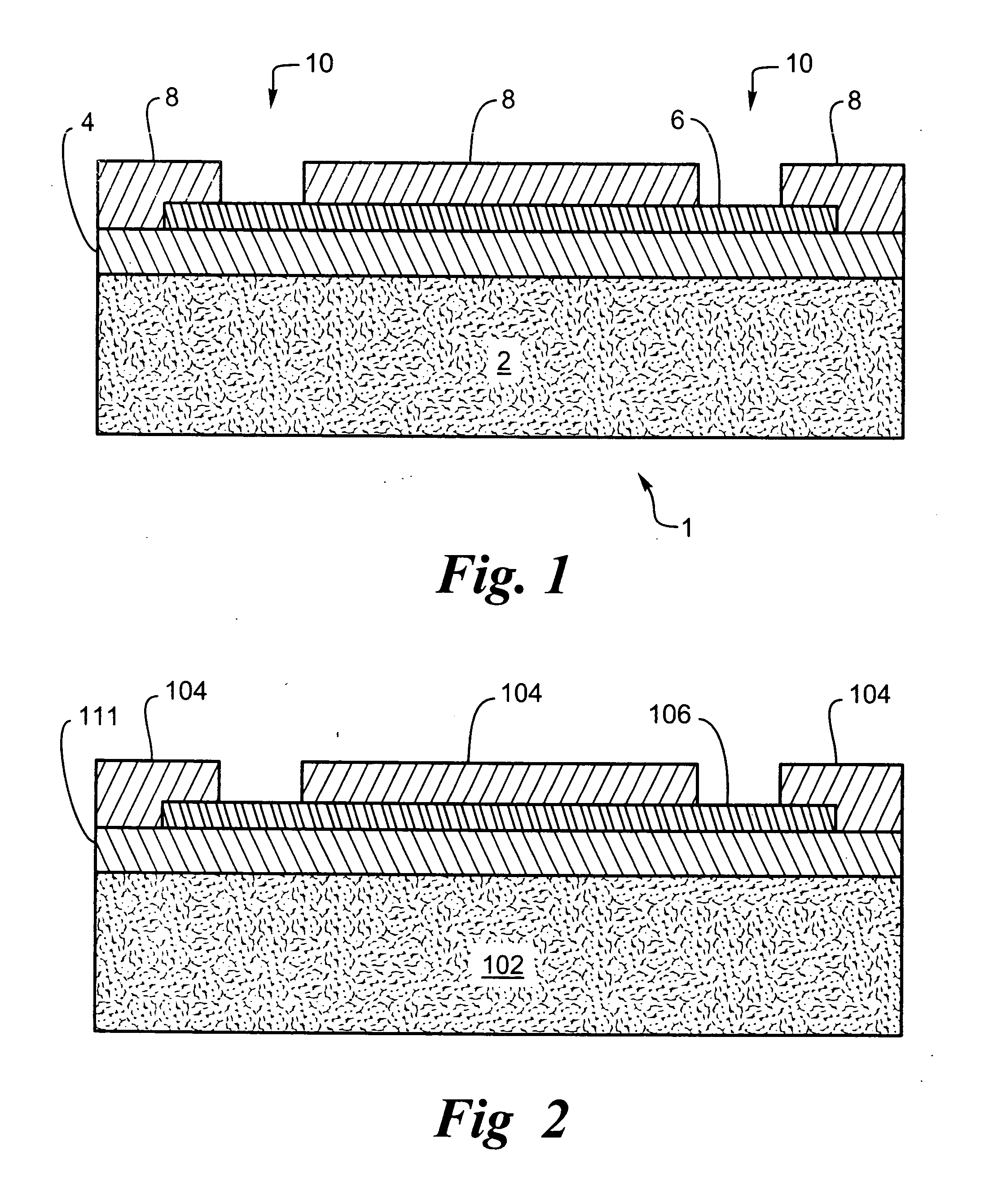

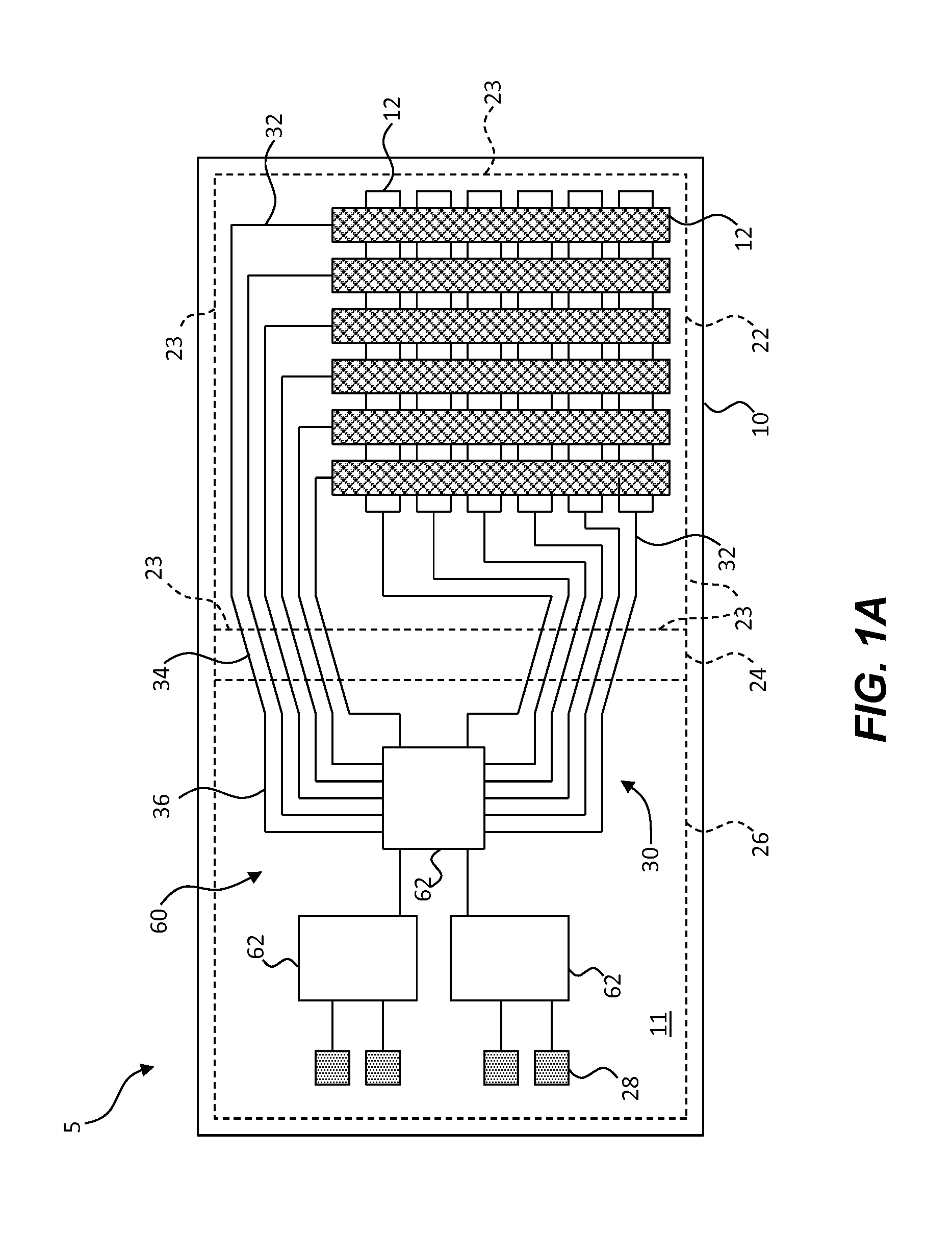

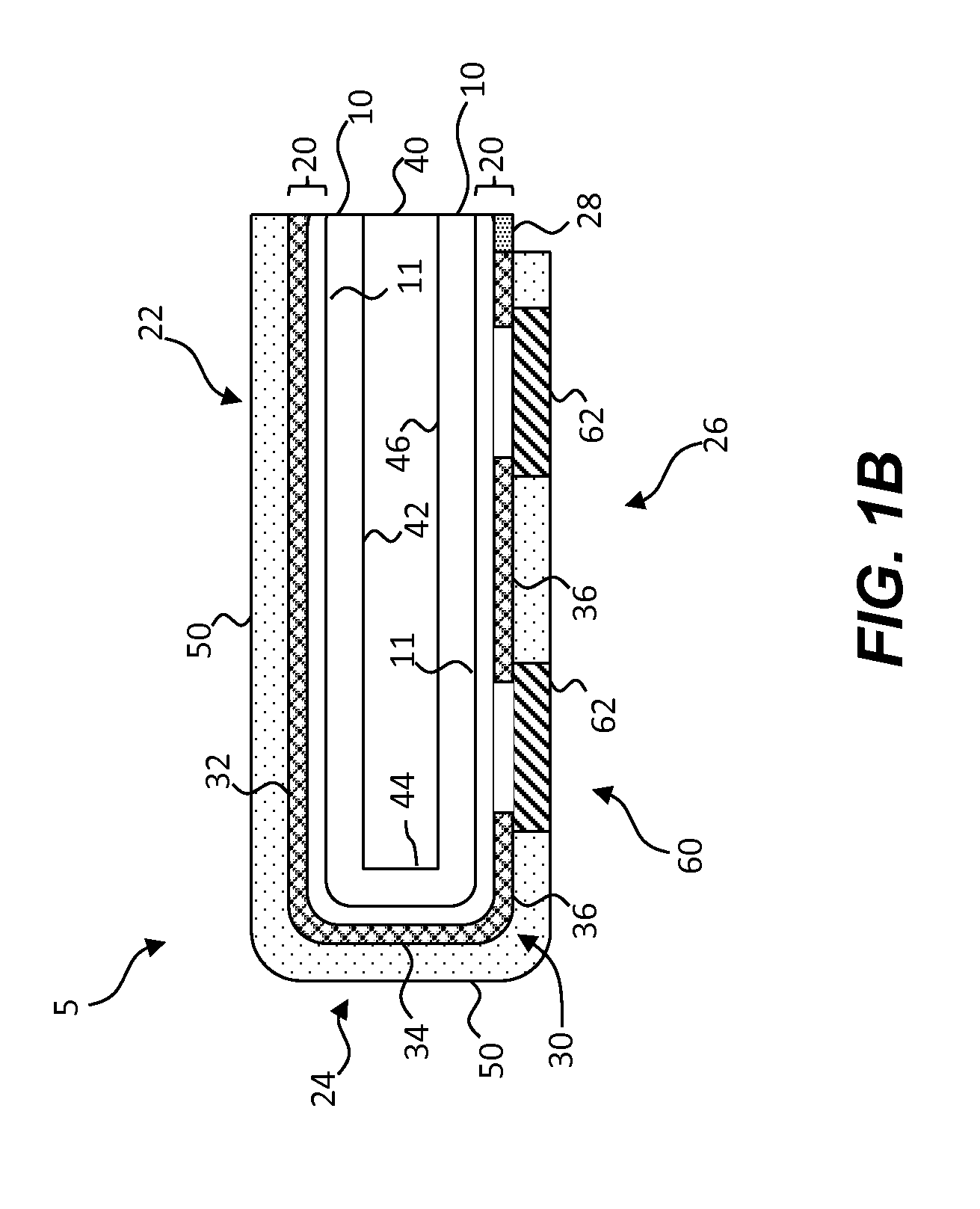

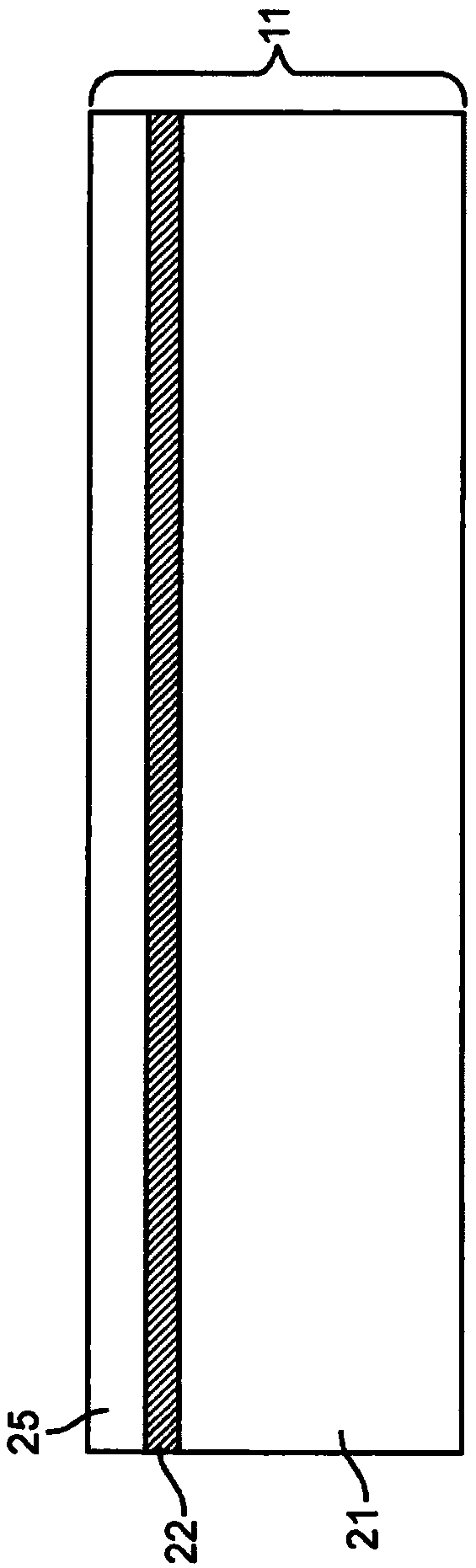

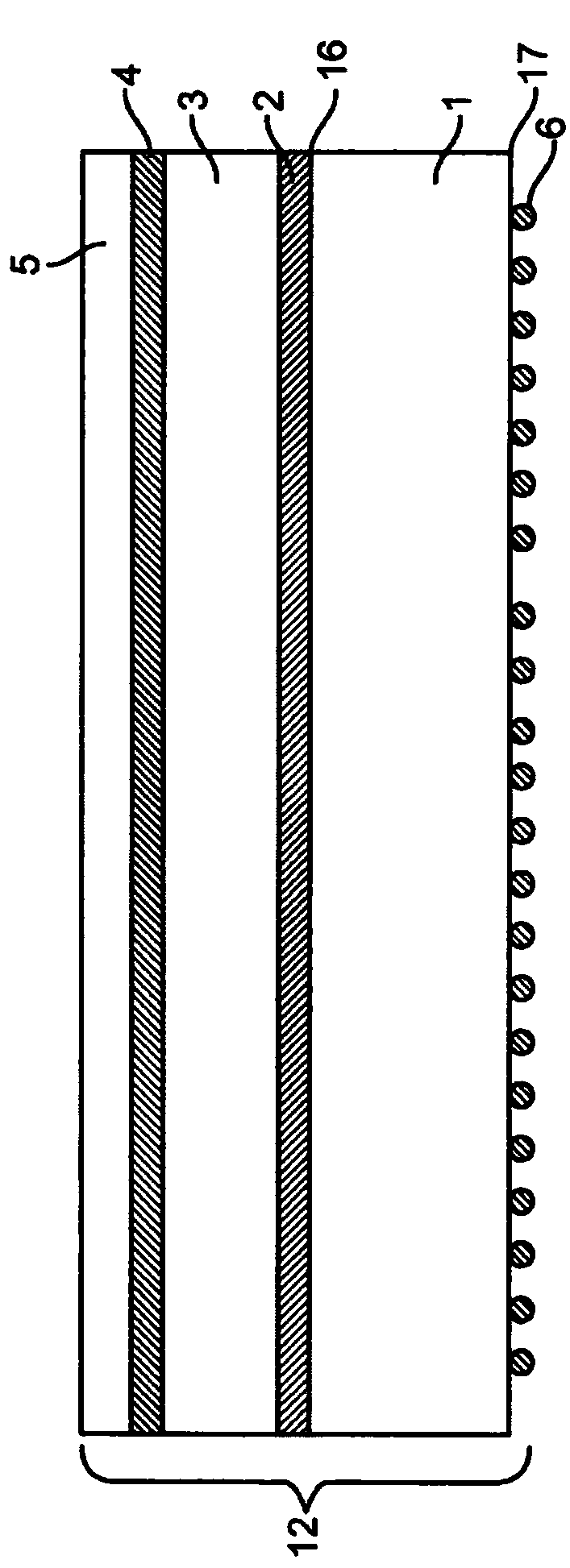

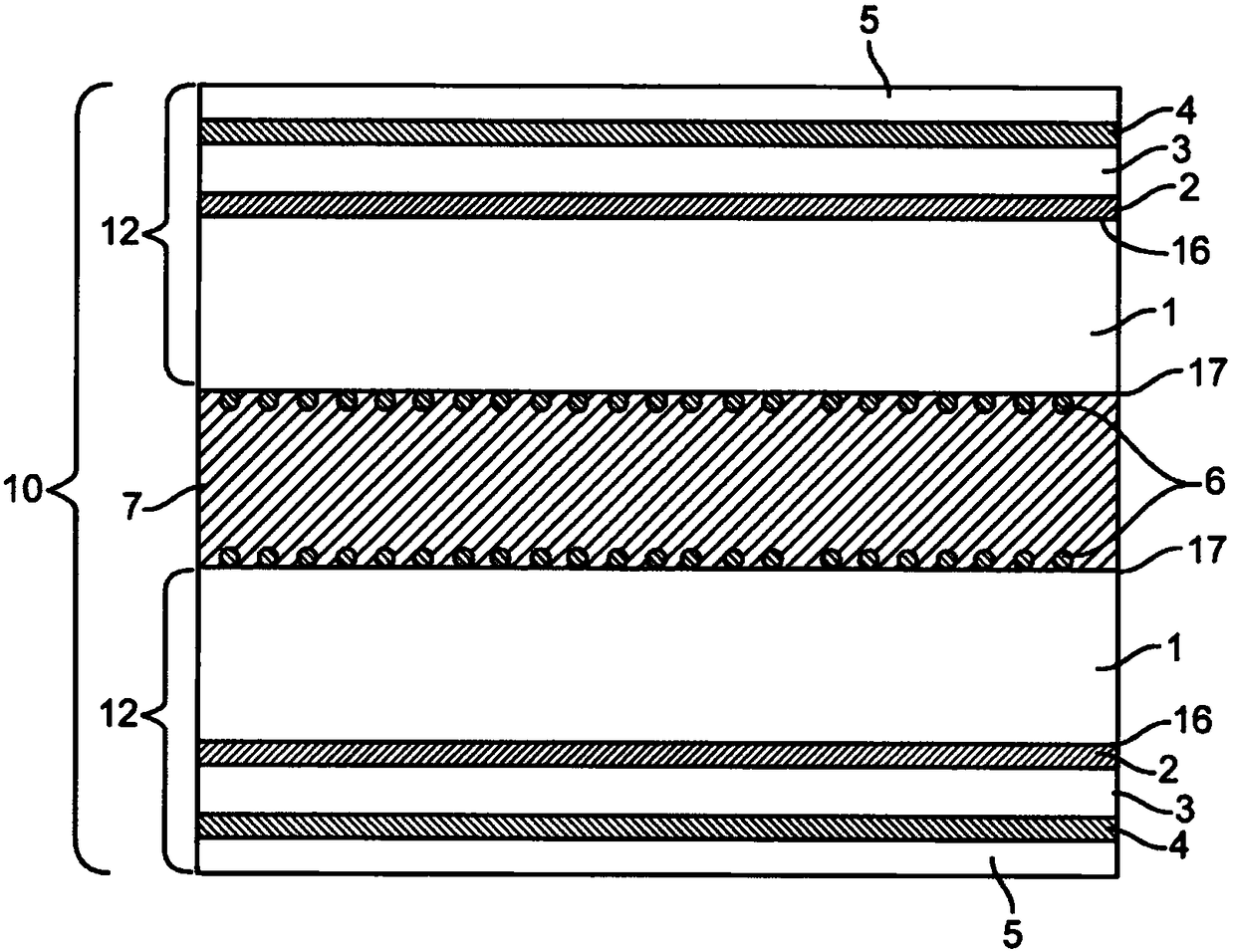

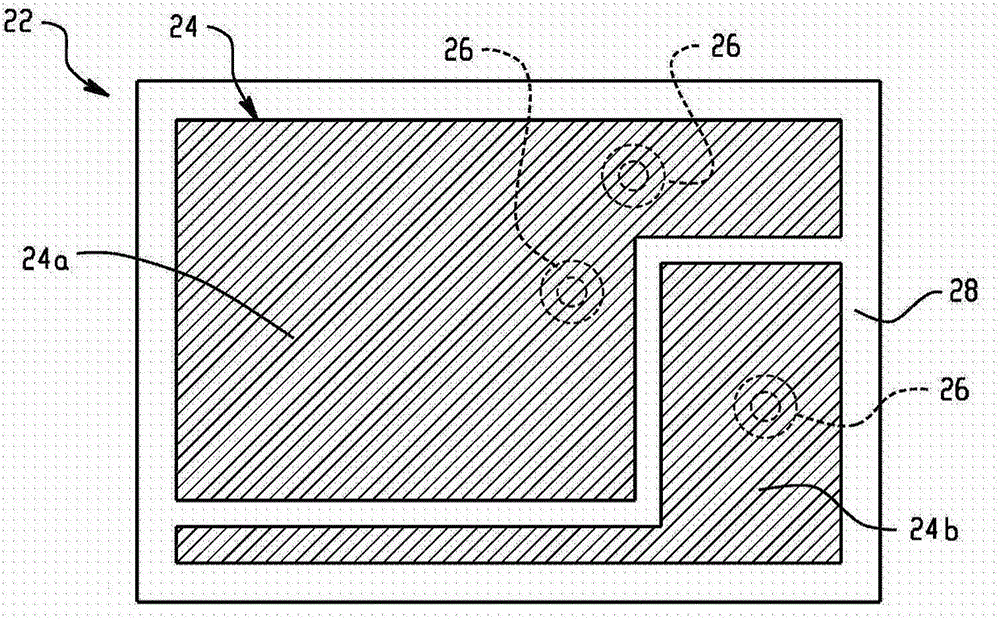

Insulated implantable electrical circuit

The invention is directed to an implantable insulated electrical circuit that utilizes polyparaxylylene, preferably as Parylene, a known polymer that has excellent living tissue implant characteristics, to provide for chronic implantation of conductive electrical devices, such as stimulators and sensors. The device is thin, flexible, electrically insulated, and stable after long exposure to living tissue. Layers of Parylene may be combined with layers of a polymer, such as polyimide, to yield greater design flexibility in the circuit. Multiple electrical conduction layers may be stacked in the circuit to increase packing density.

Owner:SECOND SIGHT MEDICAL PRODS

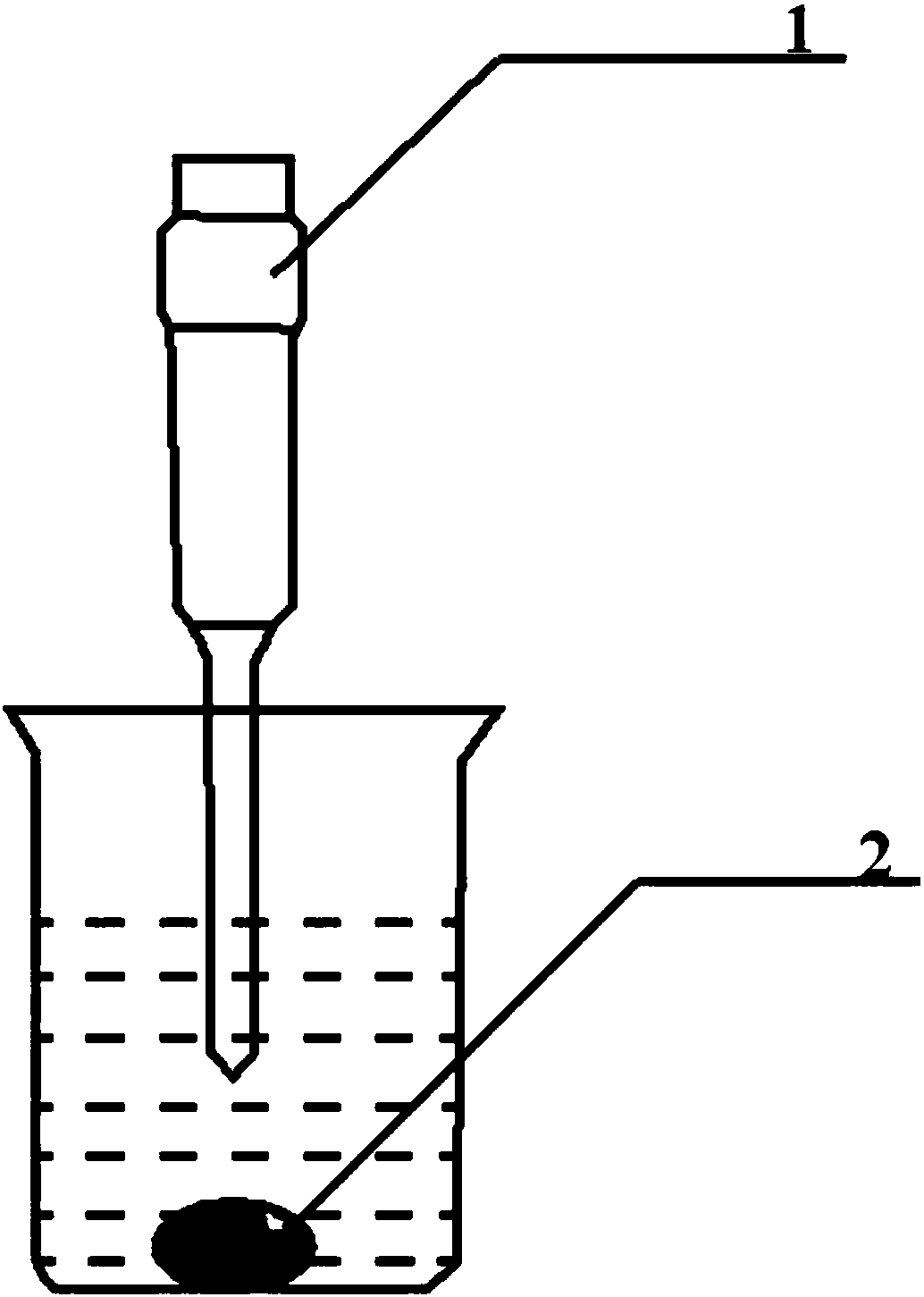

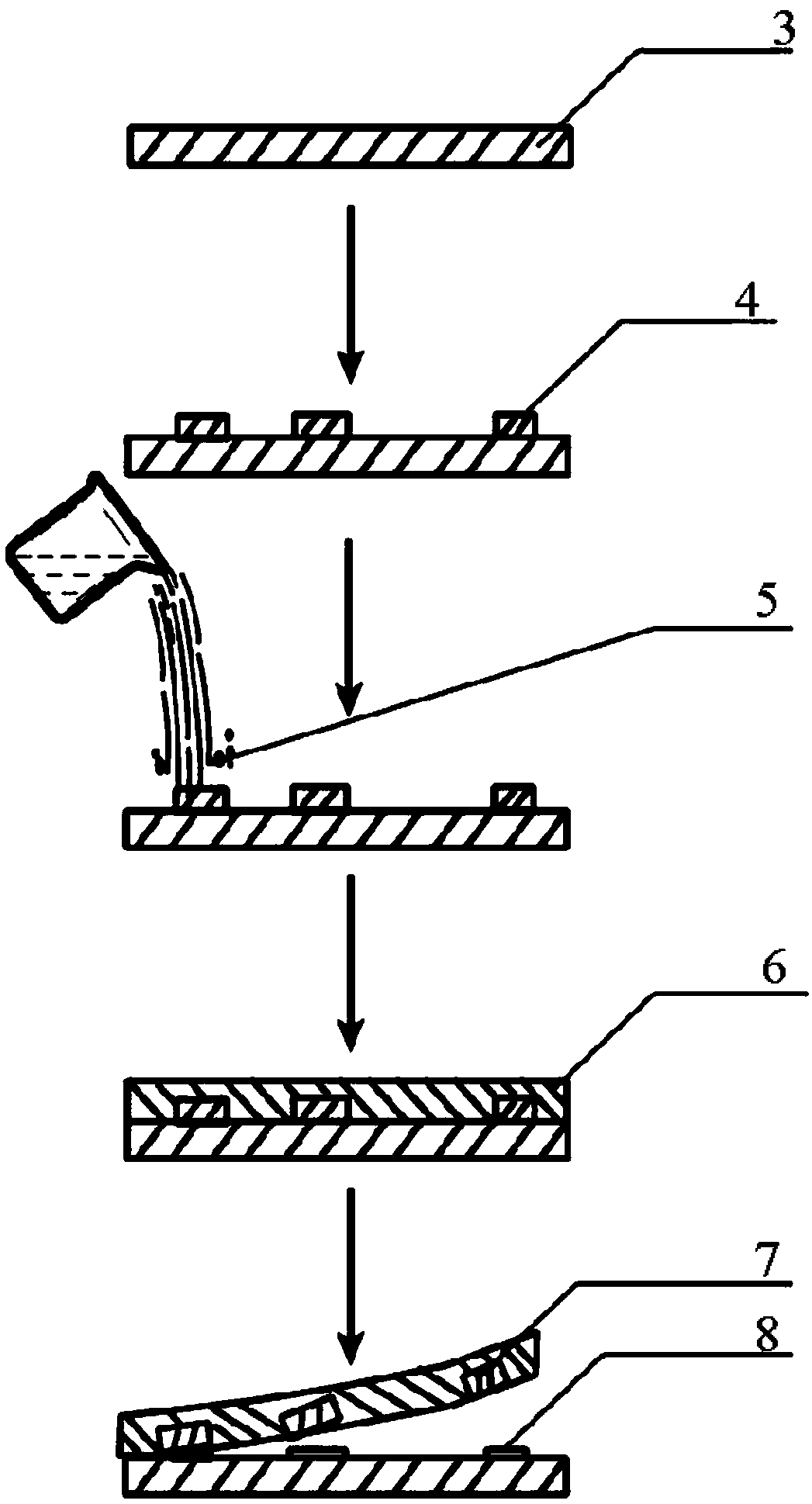

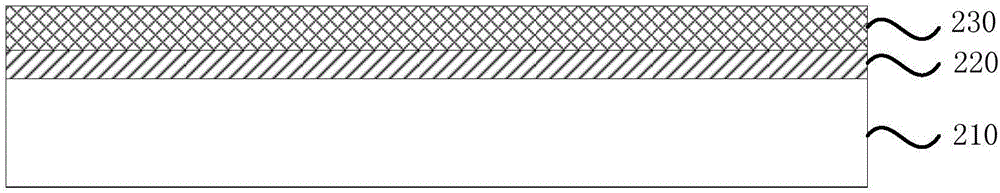

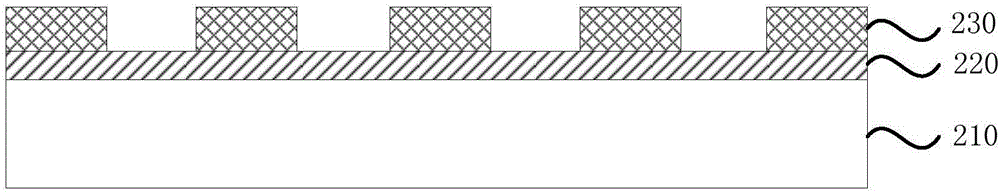

Flexible stretchable conductive circuit and preparation method and use thereof

InactiveCN108668431AReduce dosageAchieve mass productionLithography/patterningConductive pattern formationWire widthImage resolution

The invention provides a flexible stretchable conductive circuit, a preparation method and use thereof. The invention also provides double-sided wiring, multilayer board, flexible display, flexible electronics, and / or sensor comprising the flexible stretchable circuit described above. The method for preparing flexible stretchable conductive circuit provided by the invention is simple and rapid, and is generally applicable to various substrate materials, the liquid metal is used in a small amount, does not require additional external force, and the pattern does not generate cracks, the wire width is controllable, has a high resolution and it's very suitable for mass production.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

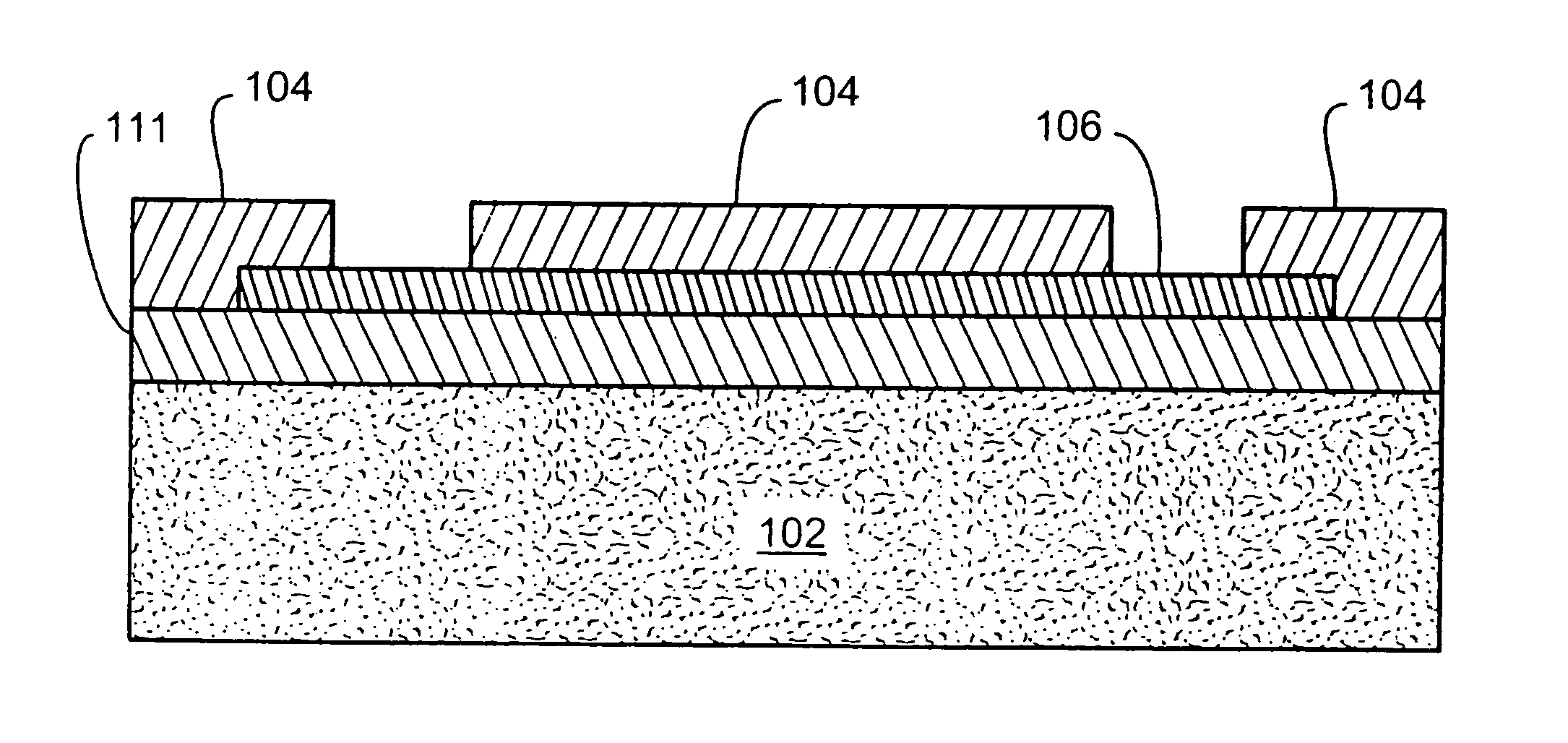

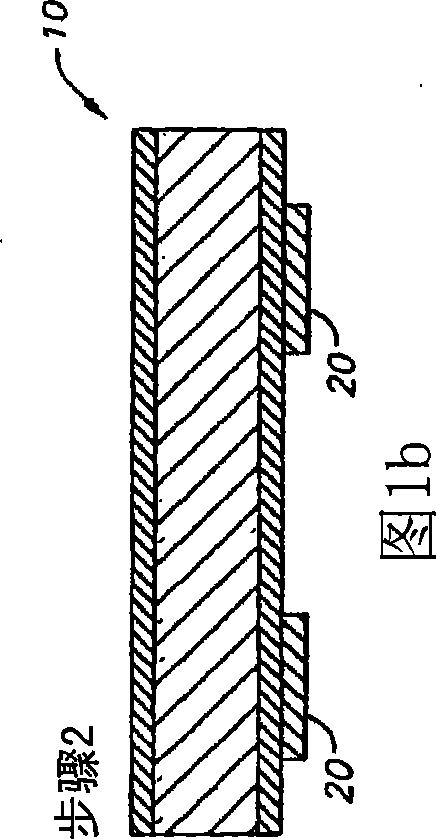

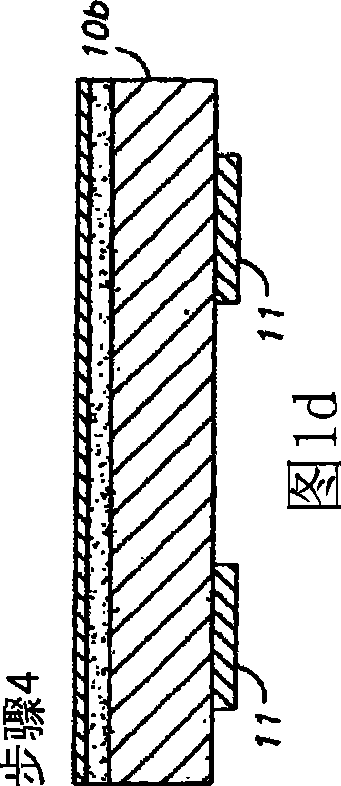

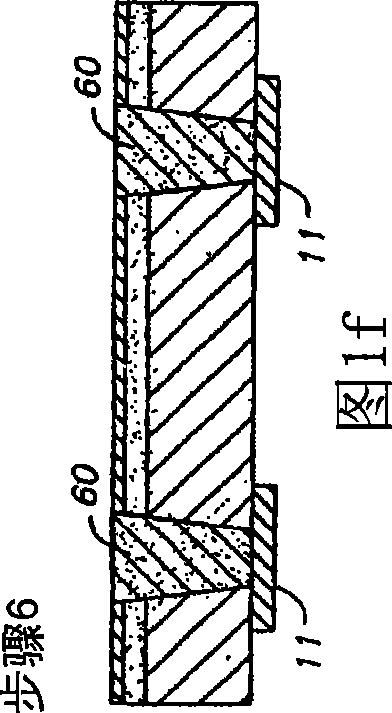

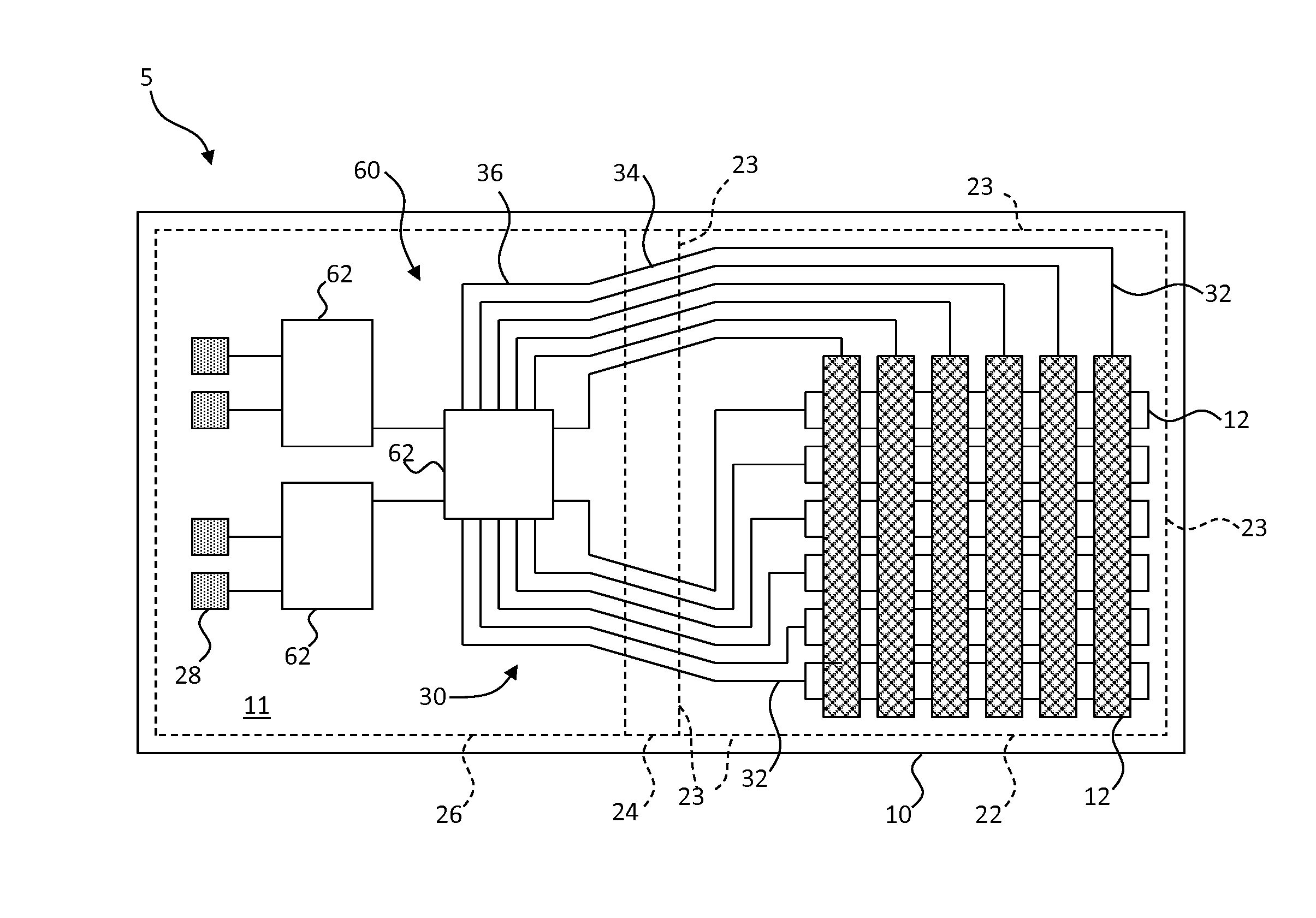

Insulated implantable electrical circuit

The invention is directed to an implant able insulated electrical circuit that utilizes polyparaxylylene, preferably as Parylene, a known polymer that has excellent living tissue implant characteristics, to provide for chronic implantation of conductive electrical devices, such as stimulators and sensors. The device is thin, flexible, electrically insulated, and stable after long exposure to living tissue. Layers of Parylene may be combined with layers of a polymer, such as polyimide, to yield greater design flexibility in the circuit. Multiple electrical conduction layers may be stacked in the circuit to increase packing density.

Owner:SECOND SIGHT MEDICAL PRODS

Manufacturing method of fine circuit of printed-circuit board

InactiveCN104411106AReduce line widthReduce line spacingLithography/patterningConductive pattern formationFine lineEtching

The invention provides a manufacturing method of a fine circuit of a printed-circuit board, and belongs to the field of the manufacture of the printed-circuit board. The method comprises the steps of forming a fine line slot by dry film pasting and exposure and development, and obtaining the fine line by carrying out deposition on a copper seed layer, dry film pasting, electroplating and copper filling, defilming, quick etching and the like. According to the method provided by the invention, the line width and line spacing of the circuit can be greatly reduced, and the lateral erosion problem generated when the copper seed layer is removed can be effectively prevented. The method provided by the invention is convenient to operate and low in cost, and expensive and complicate equipments can be prevented; furthermore, the slot of the fine line formed by the method is regular in shape, the problem that the shape of the slot formed by laser ablation is irregular can be overcome to obtain a complete line shape, and the shape of the line is matched with the designed line width to meet an impedance requirement.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

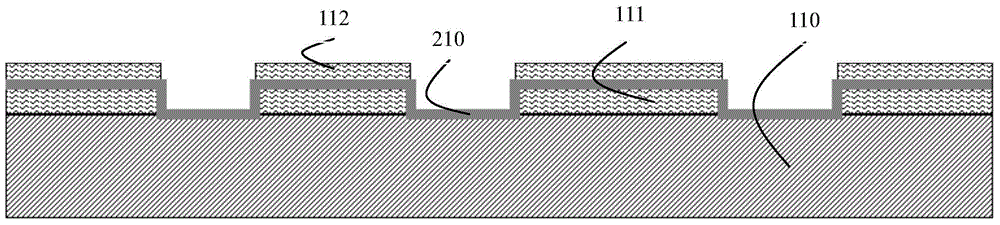

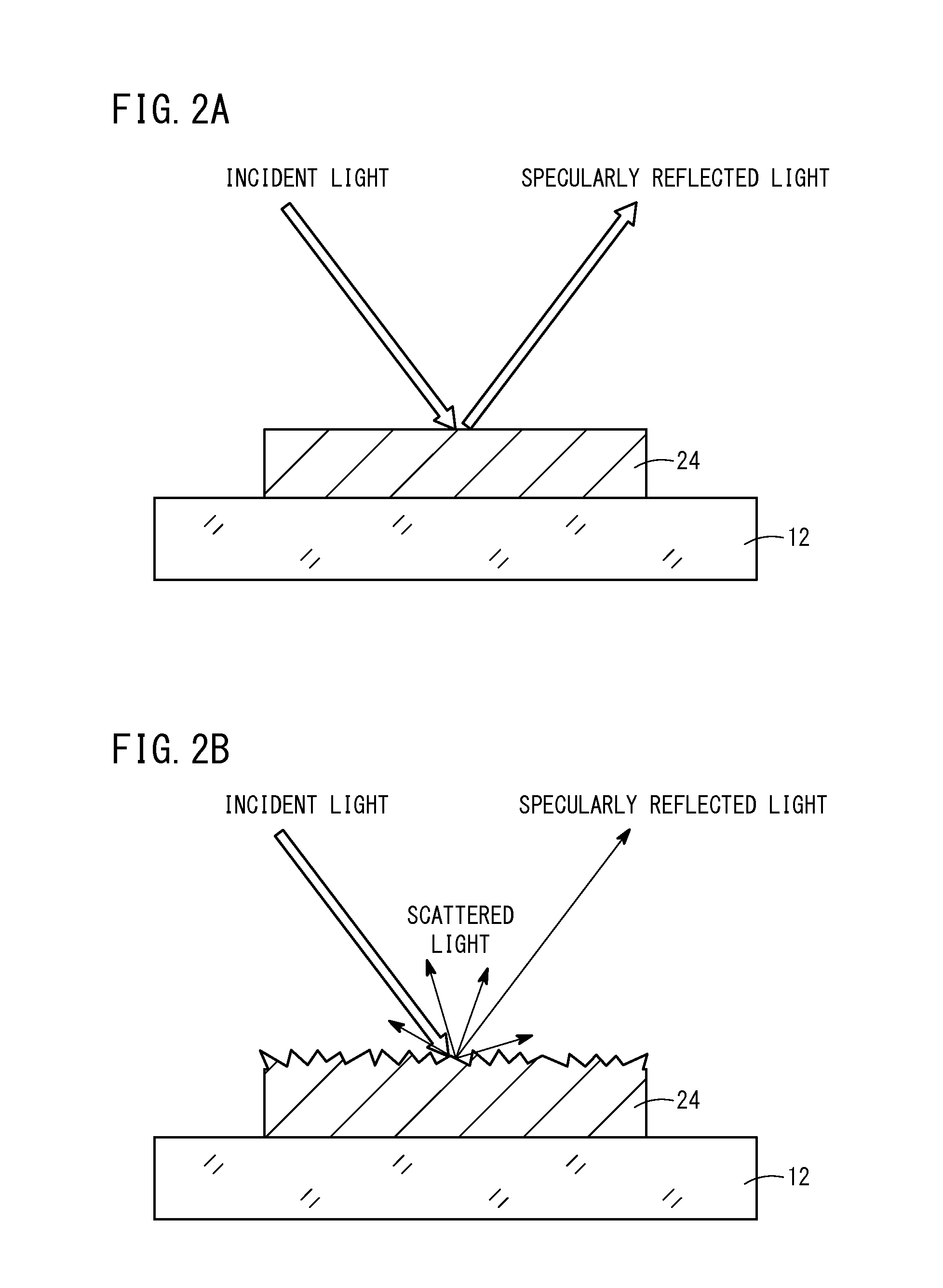

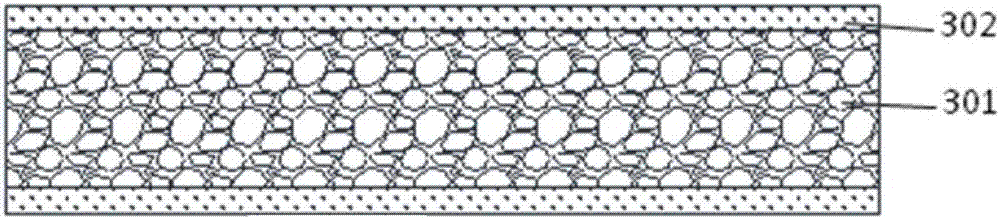

Transparent conductive film and method for producing transparent conductive film

ActiveUS20160081184A1Lower resistanceExcellent wiring adhesionLithography/patterningPrinted circuit aspectsMetallurgyMicrometer

A transparent conductive film comprises a transparent substrate and a metal wiring portion formed thereon. A thin metal wire contained in an electrode portion in the metal wiring portion has a surface shape satisfying the condition of Ra2 / Sm>0.01 μm and has a metal volume content of 35% or more. Ra represents an arithmetic average roughness in micrometers and is equal to or smaller than the thickness of a metal wiring located in a position where the surface roughness is measured. Sm represents an average distance between convex portions and is 0.01 μm or more.

Owner:FUJIFILM CORP

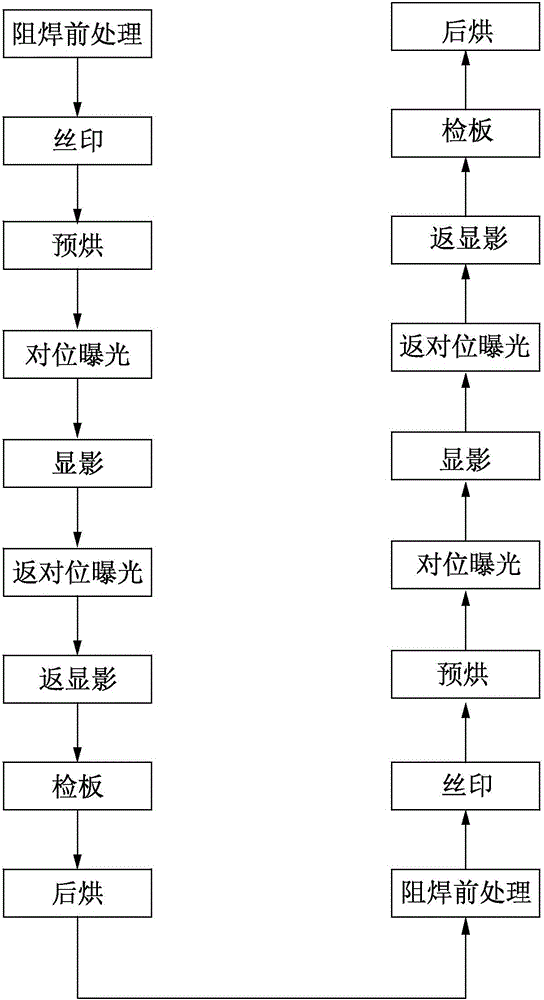

PCB manufacturing method capable of preventing green oil hole plugging

ActiveCN105916302ACoverage is precise and comprehensiveImprove pass rateLithography/patterningResistScreen printing

Provided is a PCB (Printed Circuit Board) manufacturing method capable of preventing green oil hole plugging, comprising the steps of: (1) pre-welding treatment; (2) screen printing: forming a layer of solder resist ink on a copper layer; (3) preliminary baking: performing preheating; (4) counterpoint exposure: performing selective ultraviolet exposure on the solder resist ink covering the area needing solder resist to form a solder resist layer; (5) developing; (6) secondary counterpoint exposure: performing secondary ultraviolet exposure on the area except the function hole of a PCB; (7) secondary developing: employing chemical liquid medicine to perform secondary developing on solder resist ink in the function hole so as to thoroughly remove solder resist ink left in the function hole; (8) board checking; (9) postbaking; and (10) performing pre-welding treatment, screen printing, preliminary baking, counterpoint exposure, developing, secondary counterpoint exposure, secondary developing, board checking and postbaking again on the PCB. The method introduces secondary counterpoint exposure and secondary developing, and effectively solves the problem of hole plugging.

Owner:DONGGUAN MEADVILLE CIRCUITS

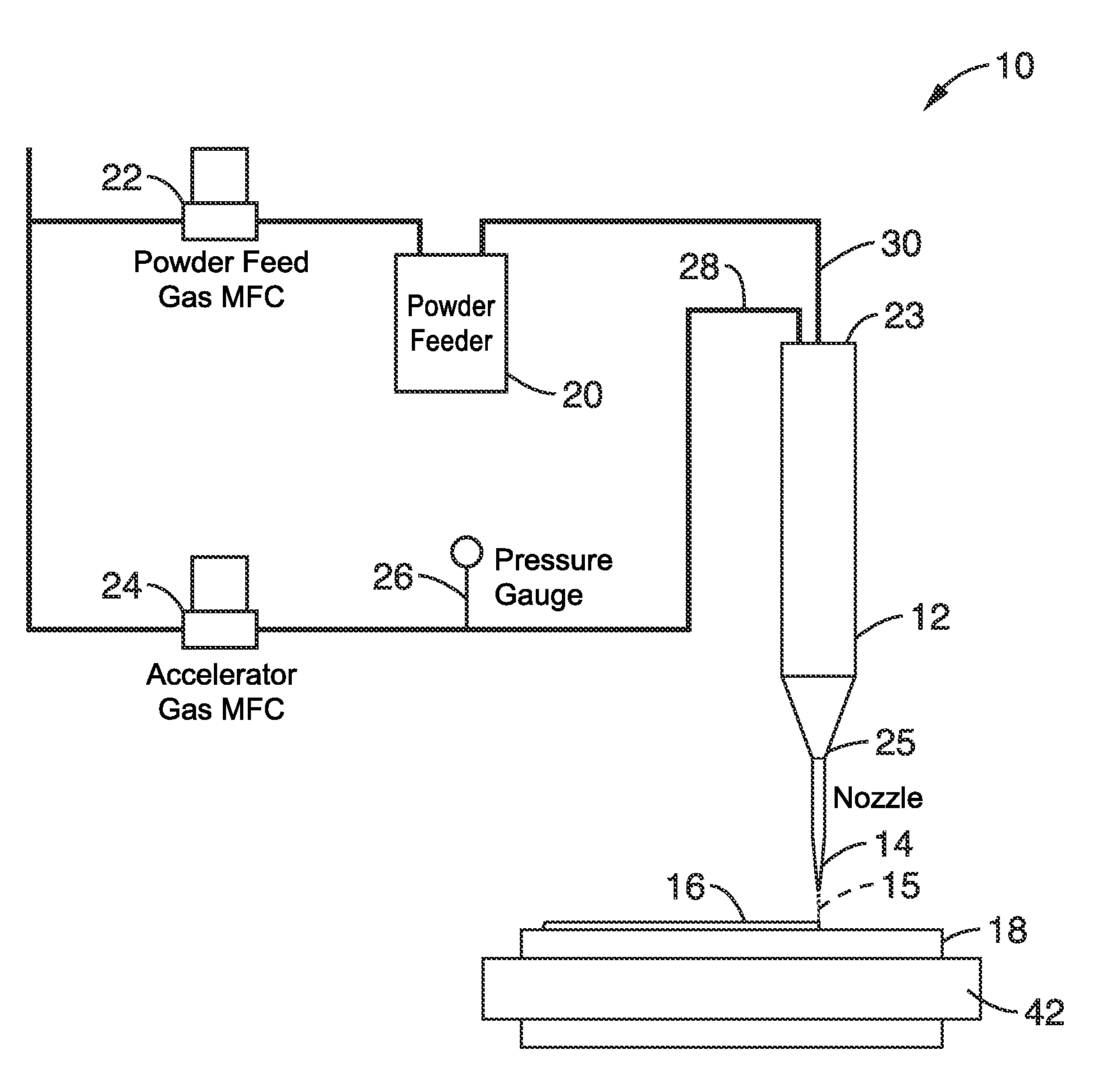

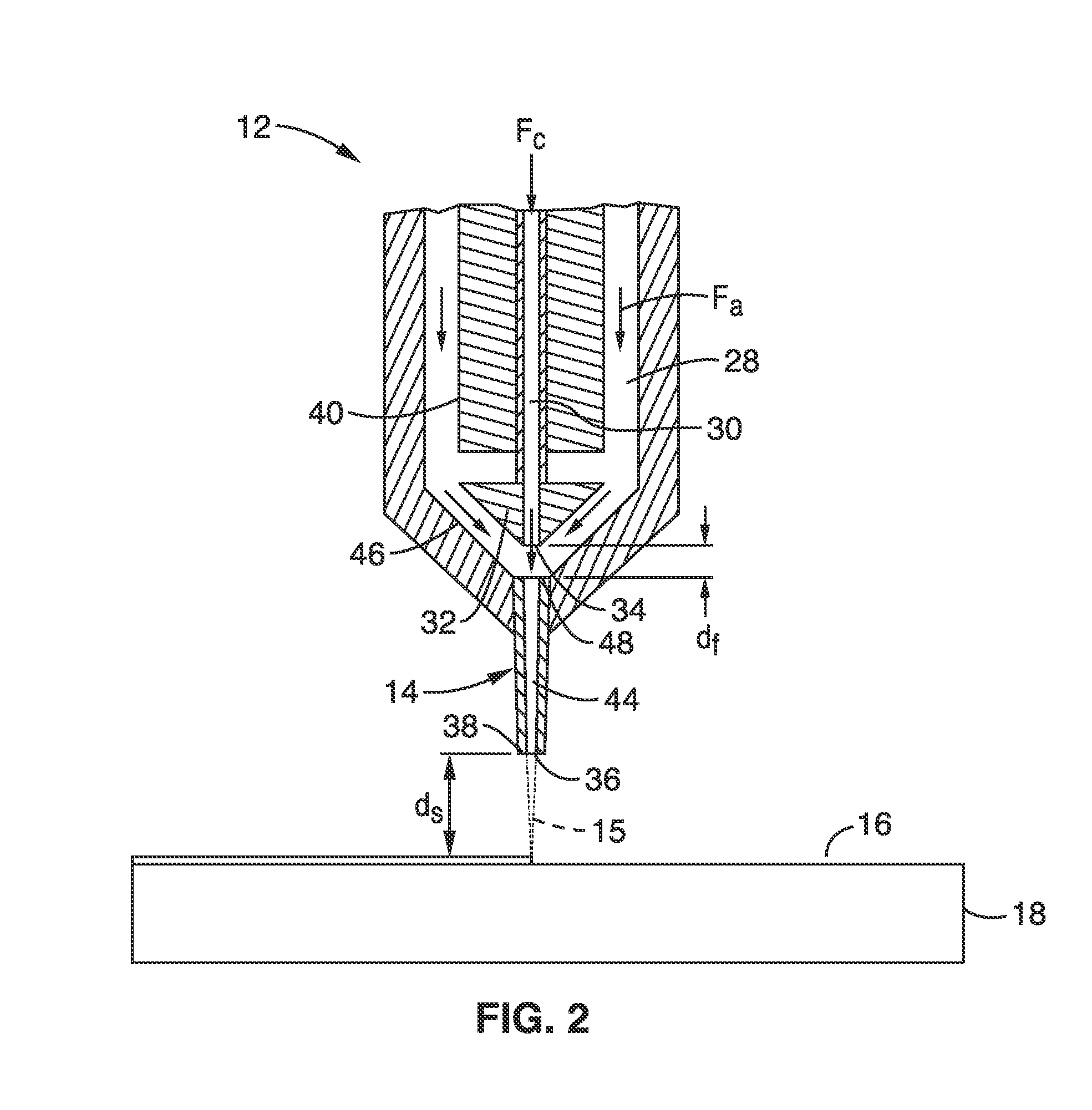

Micro cold spray direct write systems and methods for printed micro electronics

InactiveUS20140370203A1Minimal sizeFunction increaseLiquid surface applicatorsMolten spray coatingSolid particleEngineering

A system and method for depositing an aerosolized powder of solid particles on a substrate for printed circuit applications is disclosed and comprises cold spraying the aerosolized powder onto the substrate to form a finite feature, wherein at least one of the dimensions of length and width of the finite feature measures 500 microns or less.

Owner:NORTH DAKOTA STATE UNIV RES FOUND

Printed circuit boards with stacked micros vias

ActiveCN101449630ALithography/patterningPrinted electric component incorporationConductive pasteConductive materials

The present invention provides printed circuit boards having circuit layers laminated with stacked (or staggered) micro via(s) and methods of manufacturing the same. Aspects of embodiments of the present invention are directed to a printed circuit board with Z-axis interconnect(s) or micro via(s) that can eliminate a need for plating micro vias and / or eliminate a need for planarizing plated bumps of a surface, that can be fabricated with one or two lamination cycles, and / or that can have carrier-to-carrier (or substrate-to-substrate) attachments with conductive vias, each filled with a conductive material (e.g., with a conductive paste) in the Z-axis. In one embodiment, a printed circuit board having a plurality of circuit layers with at least one z-axis interconnect can be fabricated using a single lamination cycle.

Owner:DYNAMIC DETAILS

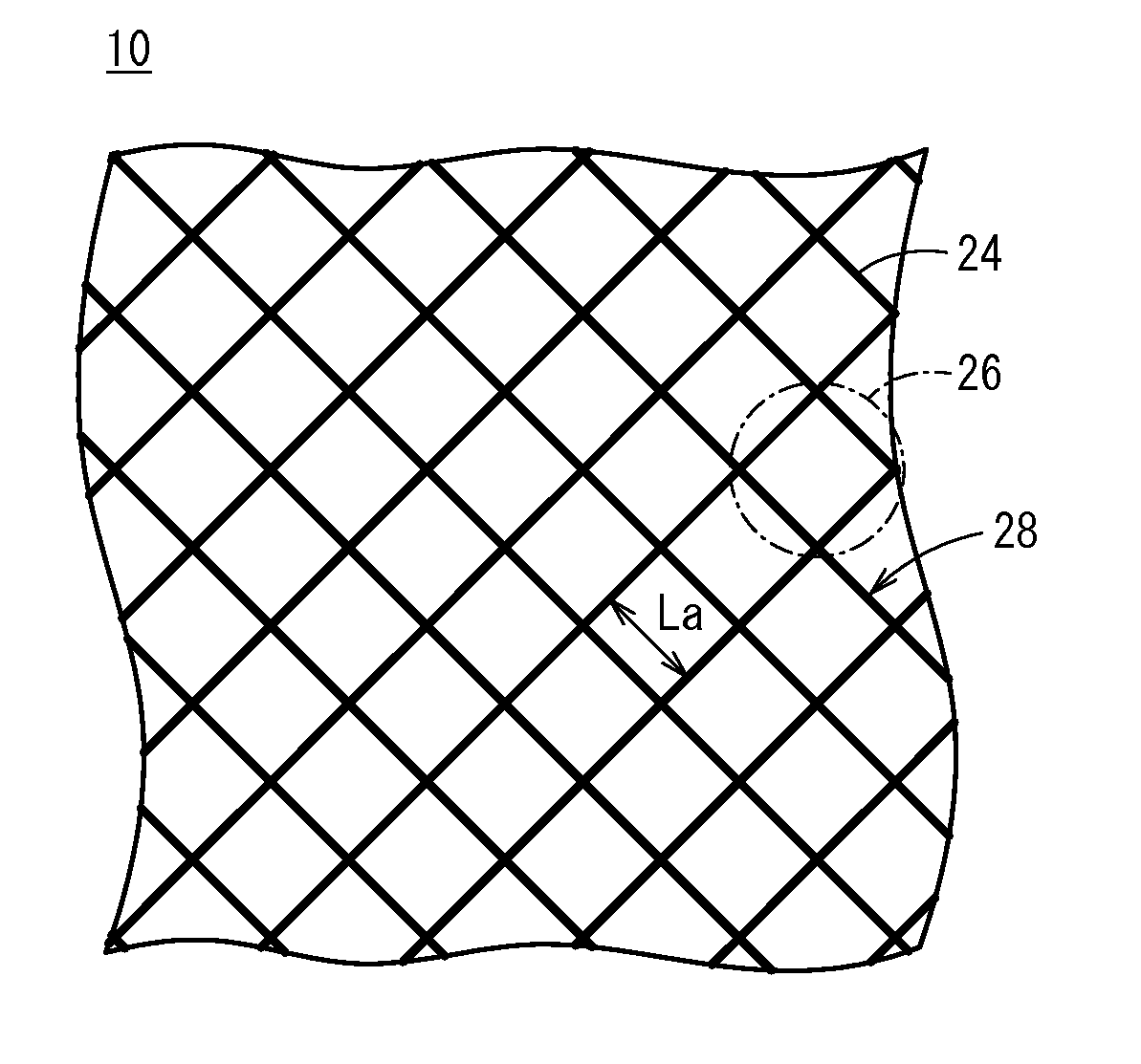

Wrap-around micro-wire circuit method

InactiveUS20150305138A1Low costHighly integratedLithography/patterningCircuit optical detailsElectricityDisplay device

A method of making a micro-wire circuit structure adapted for wrapping includes providing a display and a flexible substrate. The flexible substrate includes a plurality of electrically conductive micro-wires on, in, or adjacent to a common side of the flexible substrate and forming micro-wire electrodes in a touch portion of the flexible substrate. One or more electrical circuits is located on or in a circuit portion of the flexible substrate and one or more micro-wires electrically connects the one or more electrical circuits to corresponding micro-wire electrodes. The flexible substrate is located in relation to the display with the touch portion located adjacent to a display viewing side, the circuit portion located adjacent to a display back side, and an edge portion of the flexible substrate wrapping around a display edge from the display viewing side to the display back side.

Owner:EASTMAN KODAK CO

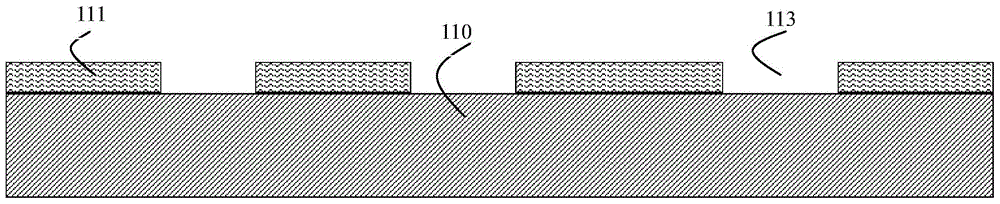

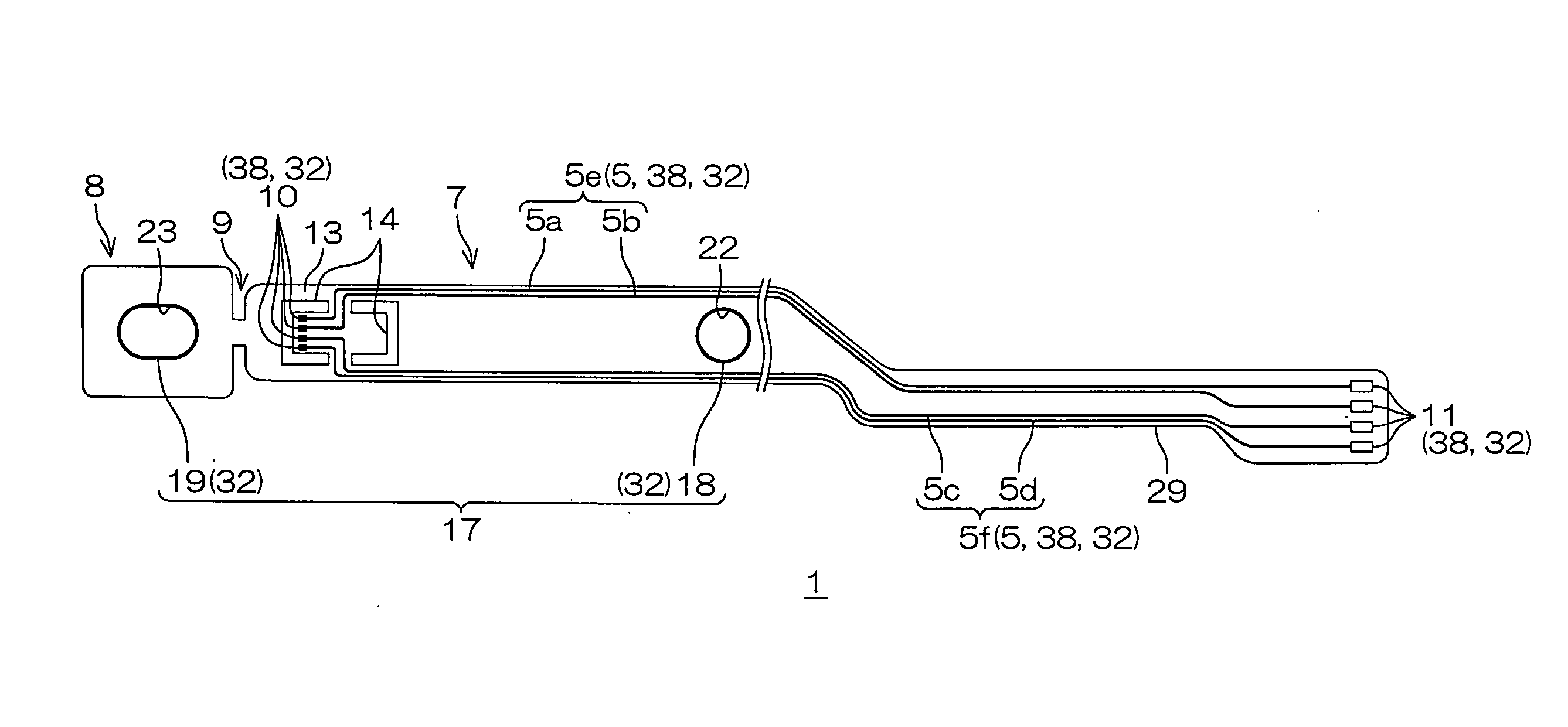

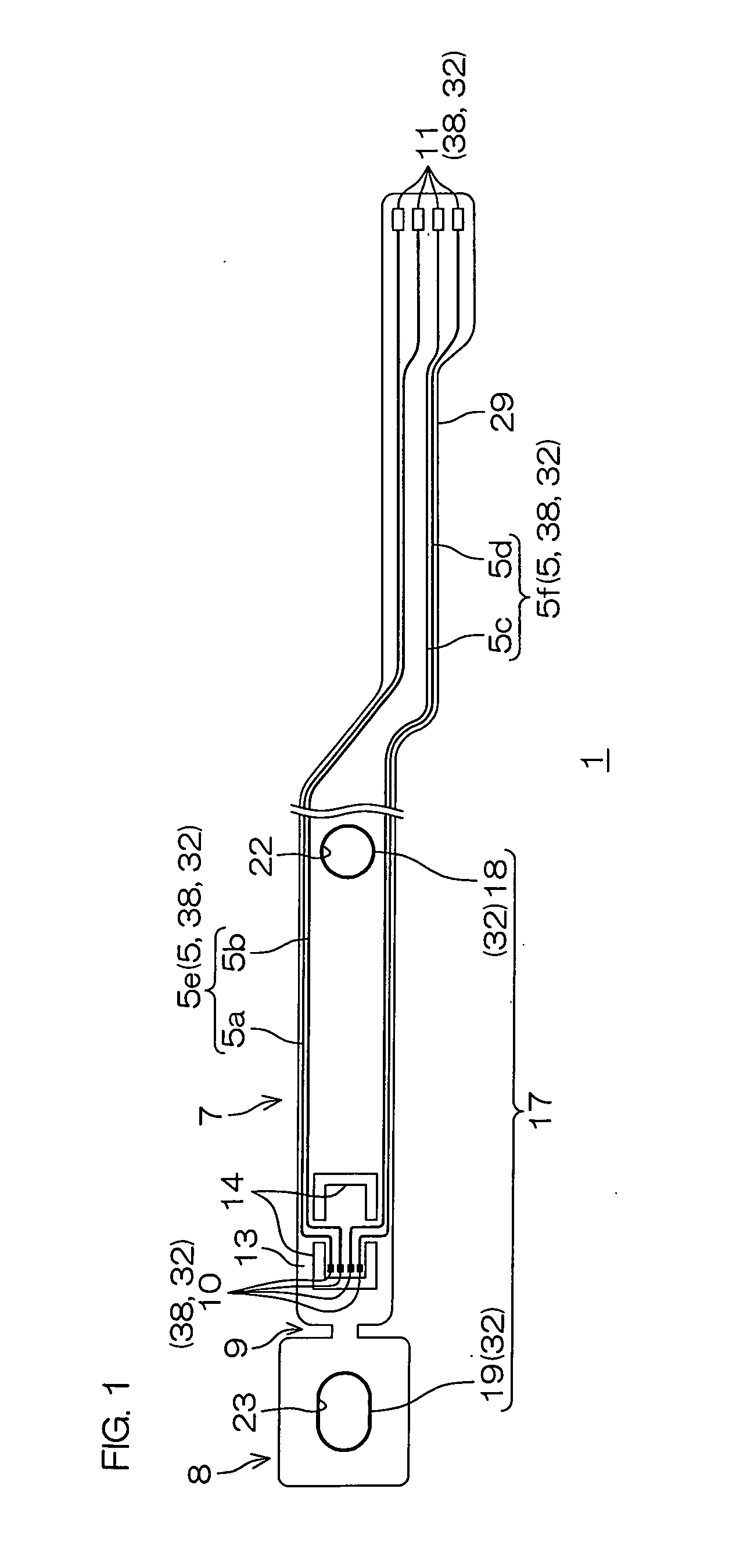

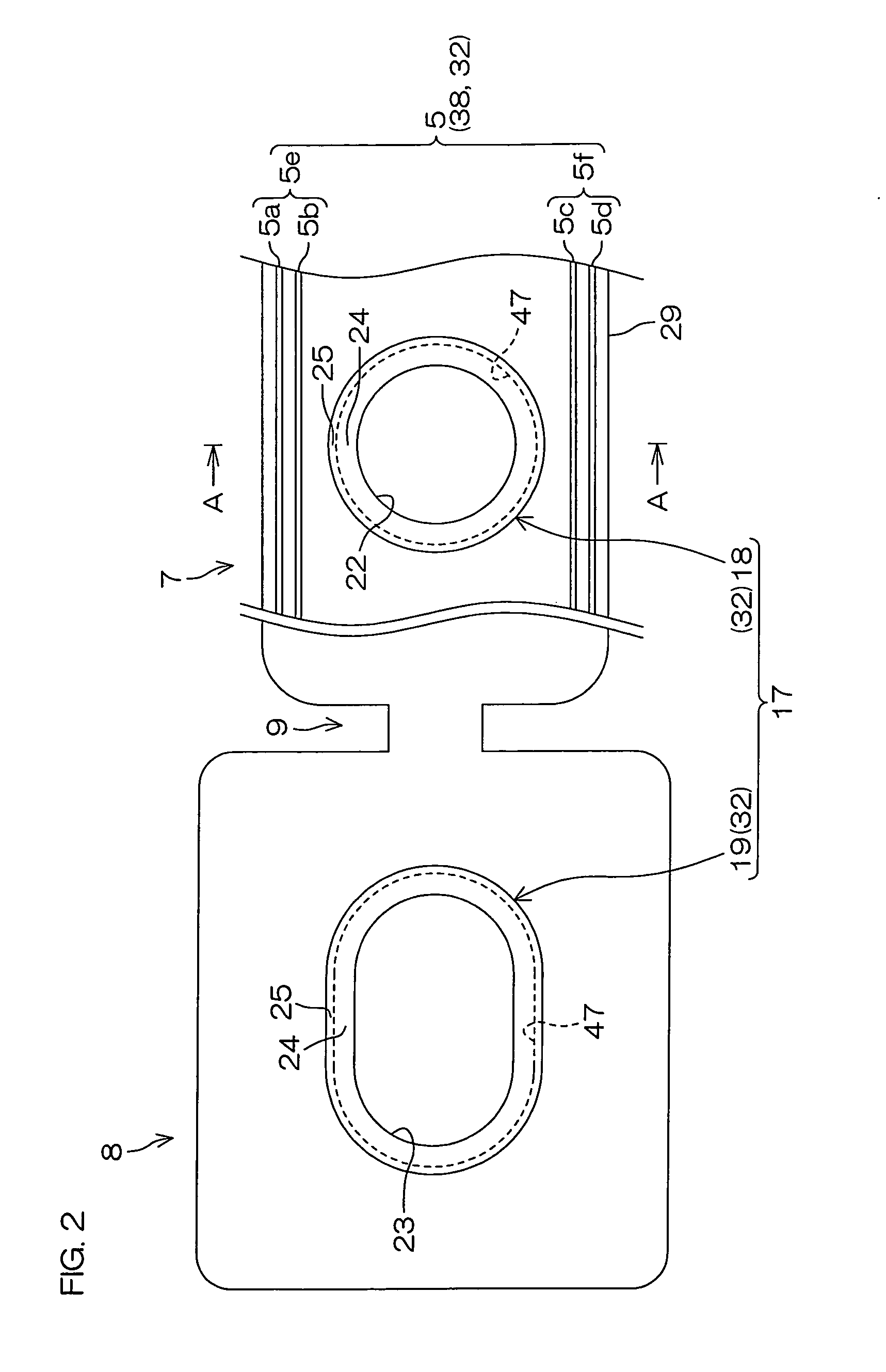

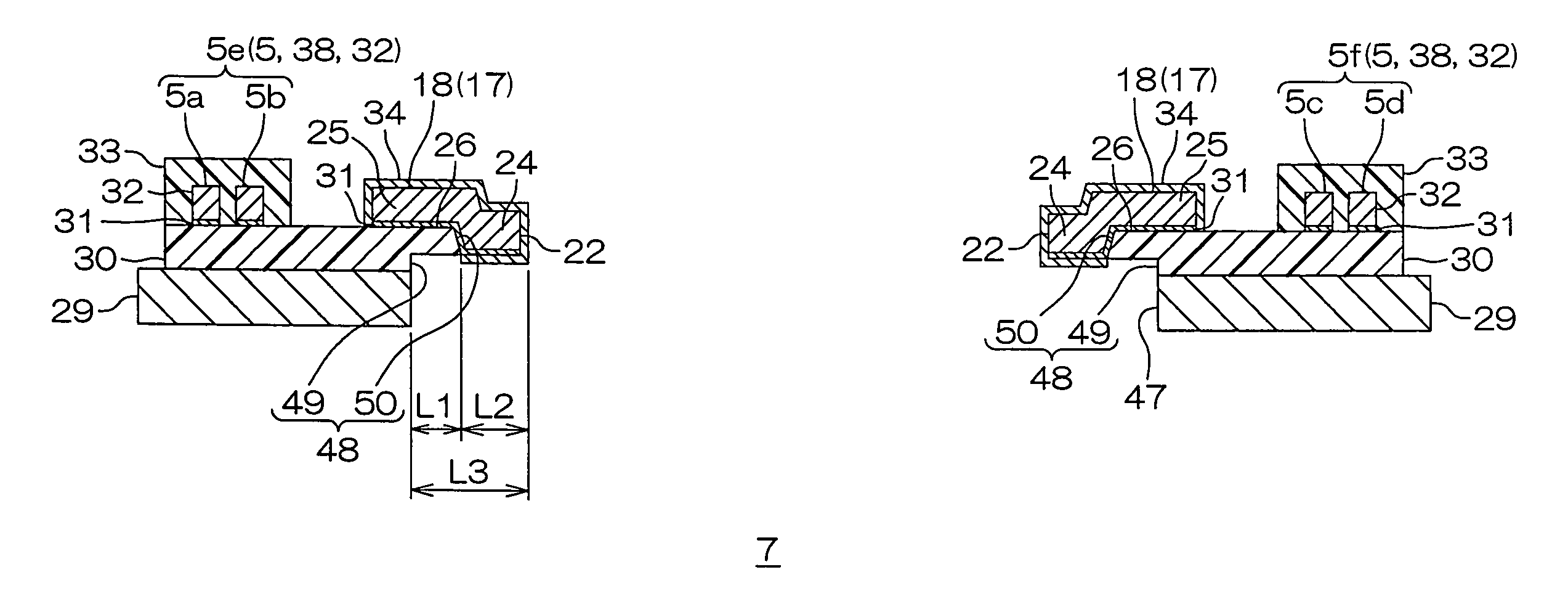

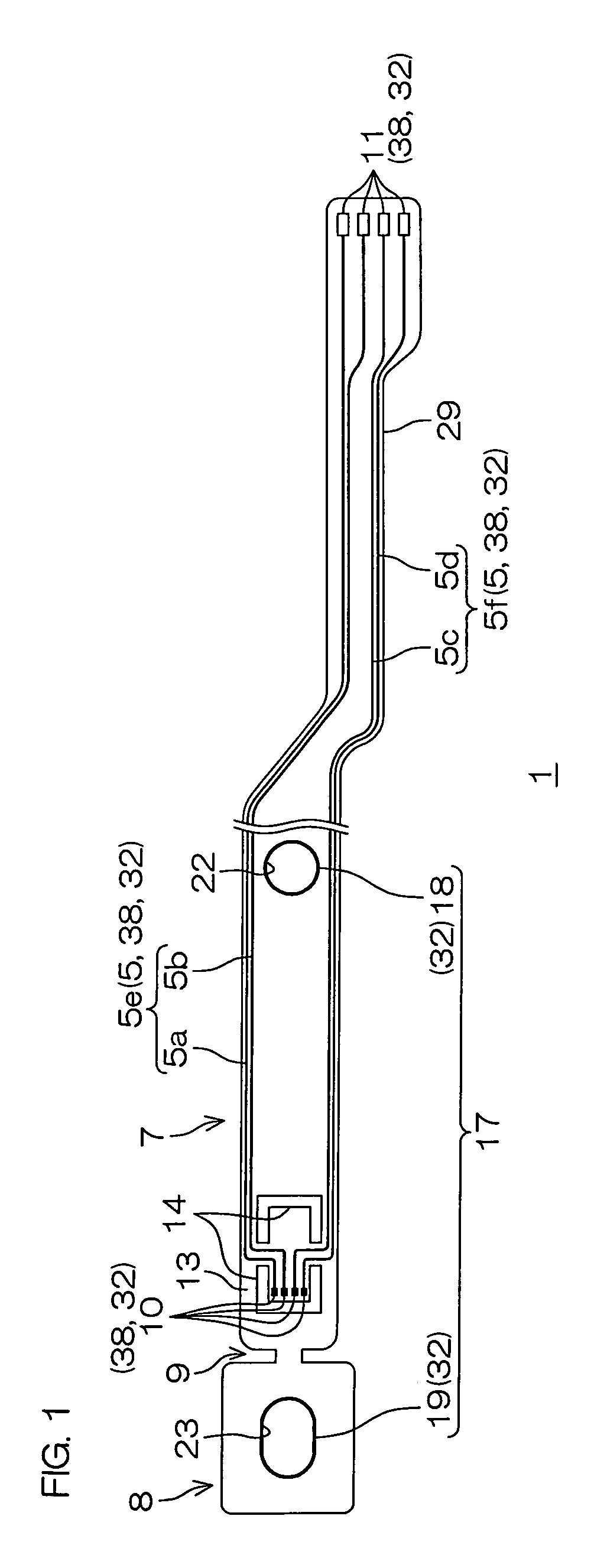

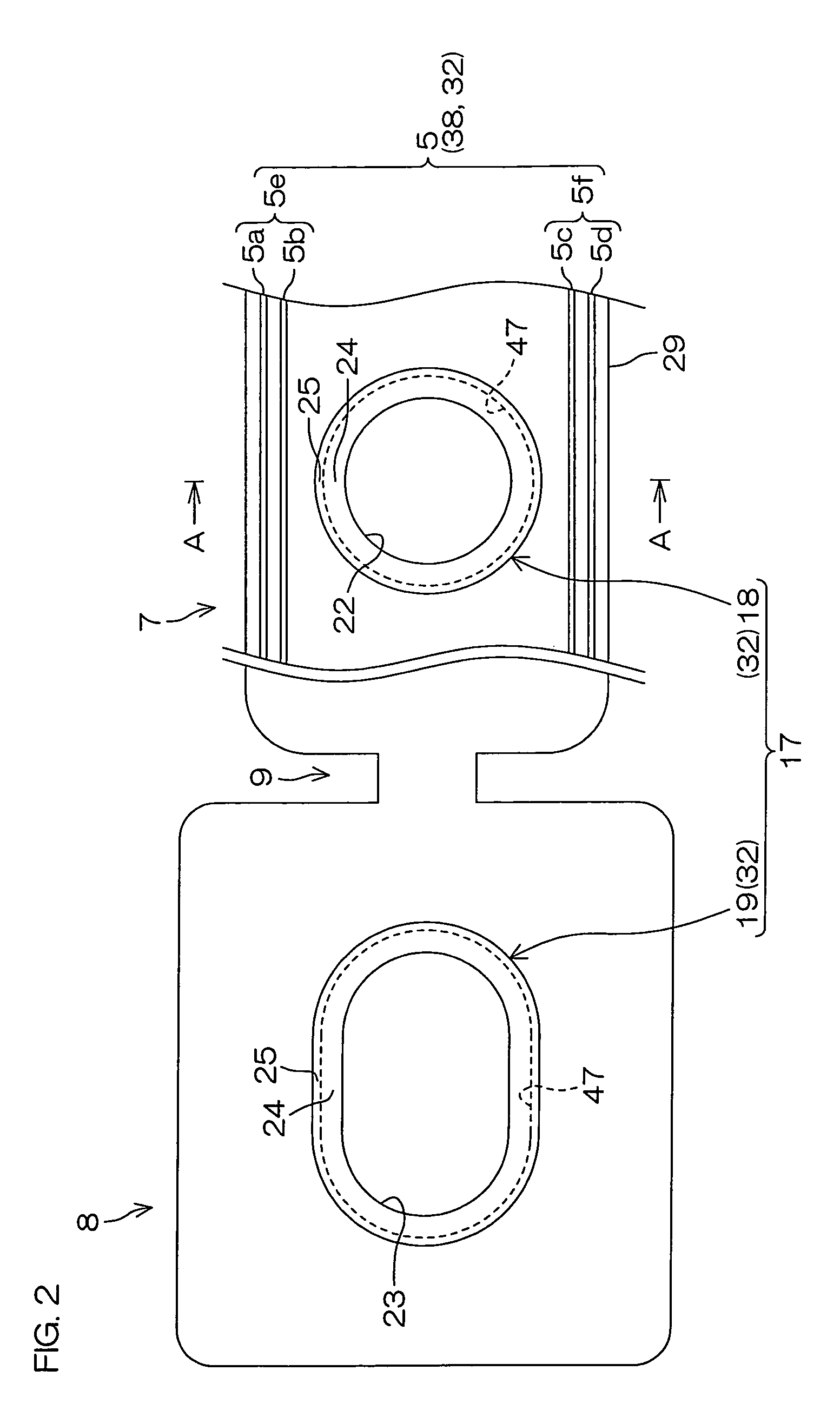

Suspension board with circuit, producing method thereof, and positioning method of suspension board with circuit

ActiveUS20100032201A1High positioning accuracyPrecise positioningElectrical connection between head and armLithography/patterningMetalElectrical and Electronics engineering

A suspension board with circuit includes a metal supporting board, a conductive layer laminated on the metal supporting board, and a via layer interposed between the metal supporting board and the conductive layer. The conductive layer includes a conductive pattern, and a reference portion serving as a positioning reference for placing the suspension board with circuit on a load beam.

Owner:NITTO DENKO CORP

Method for high-accuracy ink printed flexible circuit

InactiveCN108337813AReduce line widthLimited spreadLithography/patterningConductive pattern formationPolyethylene terephthalate glycolPolyvinyl alcohol

The invention discloses a method for high-accuracy ink printed flexible circuit. The method comprises process parameter optimization and substrate surface modification and processing and comprises thefollowing steps of coating a layer of high-hydrophobicity material polydimethylsiloxane PDMS on a flexible substrate such as polyethylene terephthalate PET, polyethylene naphthalate PEN, polyimide PI, polyvinyl alcohol PVA, polyurethane acrylate PUA and a hydrogenated styrene-butadiene segmented copolymer SEBS, performing oxygen plasma or ultraviolet ozone (UVO) processing, rising a temperature of the processed substrate to 30-65 DEG C, and controlling an ink printing circuit within a point distance range of 20-65 micrometers. The patterned circuit fabricated by the method has the characteristics of high circuit accuracy, small line width and high resolution, and high conductivity and high flexibility are shown.

Owner:NANJING UNIV OF POSTS & TELECOMM

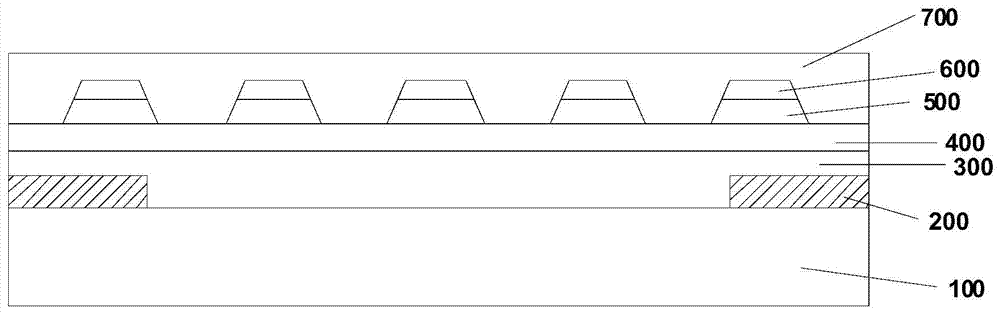

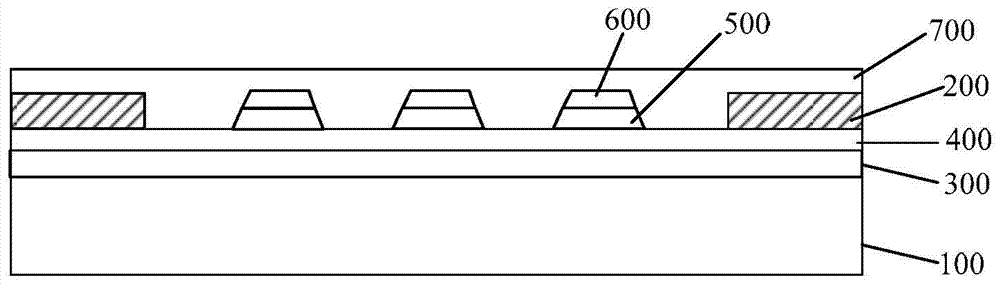

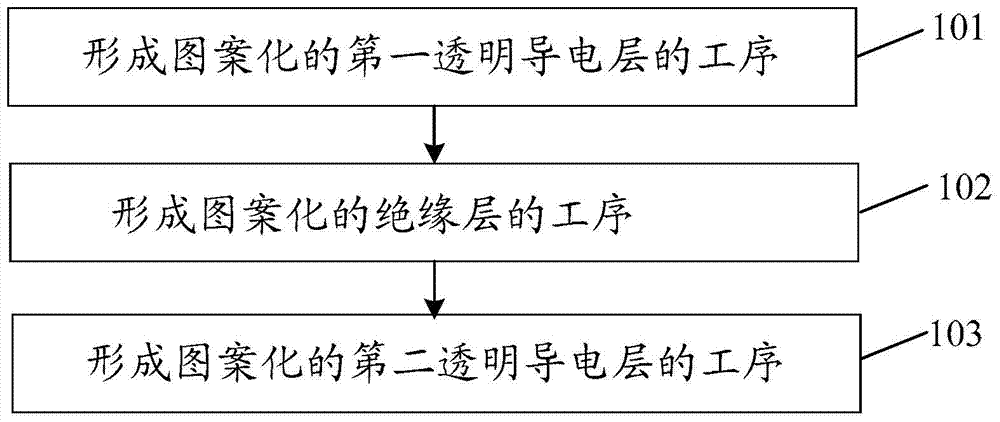

Touch screen and production thereof and touch display device

InactiveCN104267859AImprove transmittanceHigh mass production yieldLithography/patterningTransparent dielectricsTransmittanceDisplay device

An embodiment of the invention discloses a touch screen and a production thereof and a touch display device and relates to the display field. The bridging is not required, the transmittance is high, the technological process is simple, the production cost can be reduced, and the yield of mass production is high. The touch screen comprises a transparent substrate, a first transparent conductive layer, an insulating layer and a second transparent conductive layer; the patterned first transparent conductive layer, the patterned insulating layer and the patterned second transparent conductive layer are formed on the transparent substrate in turn; a plurality of driving wires are formed in one of the first transparent conductive layer and the second transparent conductive layer and a plurality of sensing wires are formed in the other conductive layer; patterns of the insulating layer are as same as those of the first transparent conductive layer or the second transparent conductive layer.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

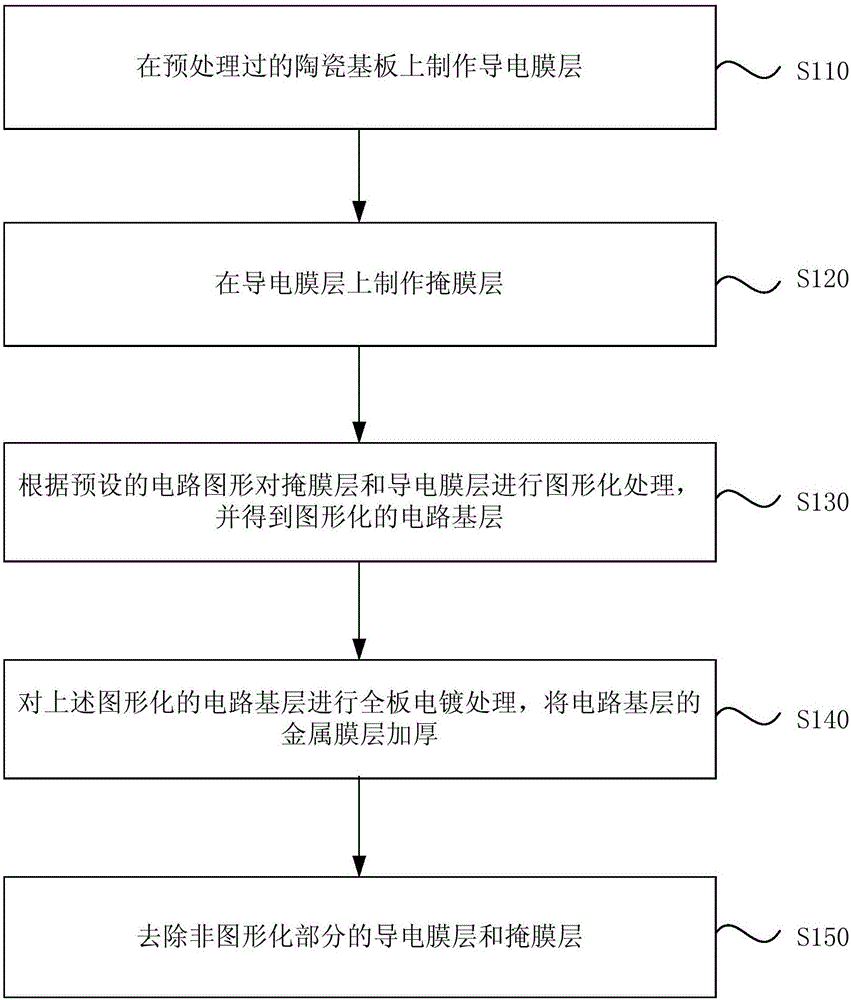

Ceramic package substrate manufacturing method and ceramic package substrate

InactiveCN106793529ASimplify the process flowShorten the production cycleLithography/patterningConductive material chemical/electrolytical removalOptoelectronicsPre treatment

The embodiments of the invention disclose a ceramic package substrate manufacturing method and a ceramic package substrate. The method comprises the following steps: making a conductive film layer on a pretreated ceramic substrate; making a mask layer on the conductive film layer; patterning the mask layer and the conductive film layer according to a preset circuit pattern to get a patterned circuit base layer; panel-plating the patterned circuit base layer, and thickening the metal film layer of the circuit base layer; and removing the non-patterned parts of the conductive film layer and the mask layer. The ceramic package substrate manufacturing process is more optimized, the procedures are simpler, and the cost input is lower.

Owner:江苏华功第三代半导体产业技术研究院有限公司

Multilayer carrier foil

The present disclosure relates to a multilayer carrier foil, a core structure formed using the multilayer carrier foil, printed circuit boards, and electronic devices. The multilayer carrier foil comprises: (a) a copper carrier layer having a release side and a laminate side, wherein the laminate side of carrier layer optionally has nodules; (b) a chromium release layer applied to the copper carrier layer (a); (c) an intermediate copper layer applied to the chromium release layer (b); (d) an anti-migration layer applied to the intermediate copper layer (c); and (e) an ultra-thin copper layer applied to the anti-migration layer of (d). The disclosure further relates to methods of making the multi-layer carrier foil, the core structure, and printed circuit boards.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

Suspension board with circuit, producing method thereof, and positioning method of suspension board with circuit

InactiveUS9072207B2Precise positioningHigh positioning accuracyElectrical connection between head and armLithography/patterningEngineeringMetal

A suspension board with circuit includes a metal supporting board, a conductive layer laminated on the metal supporting board, and a via layer interposed between the metal supporting board and the conductive layer. The conductive layer includes a conductive pattern, and a reference portion serving as a positioning reference for placing the suspension board with circuit on a load beam.

Owner:NITTO DENKO CORP

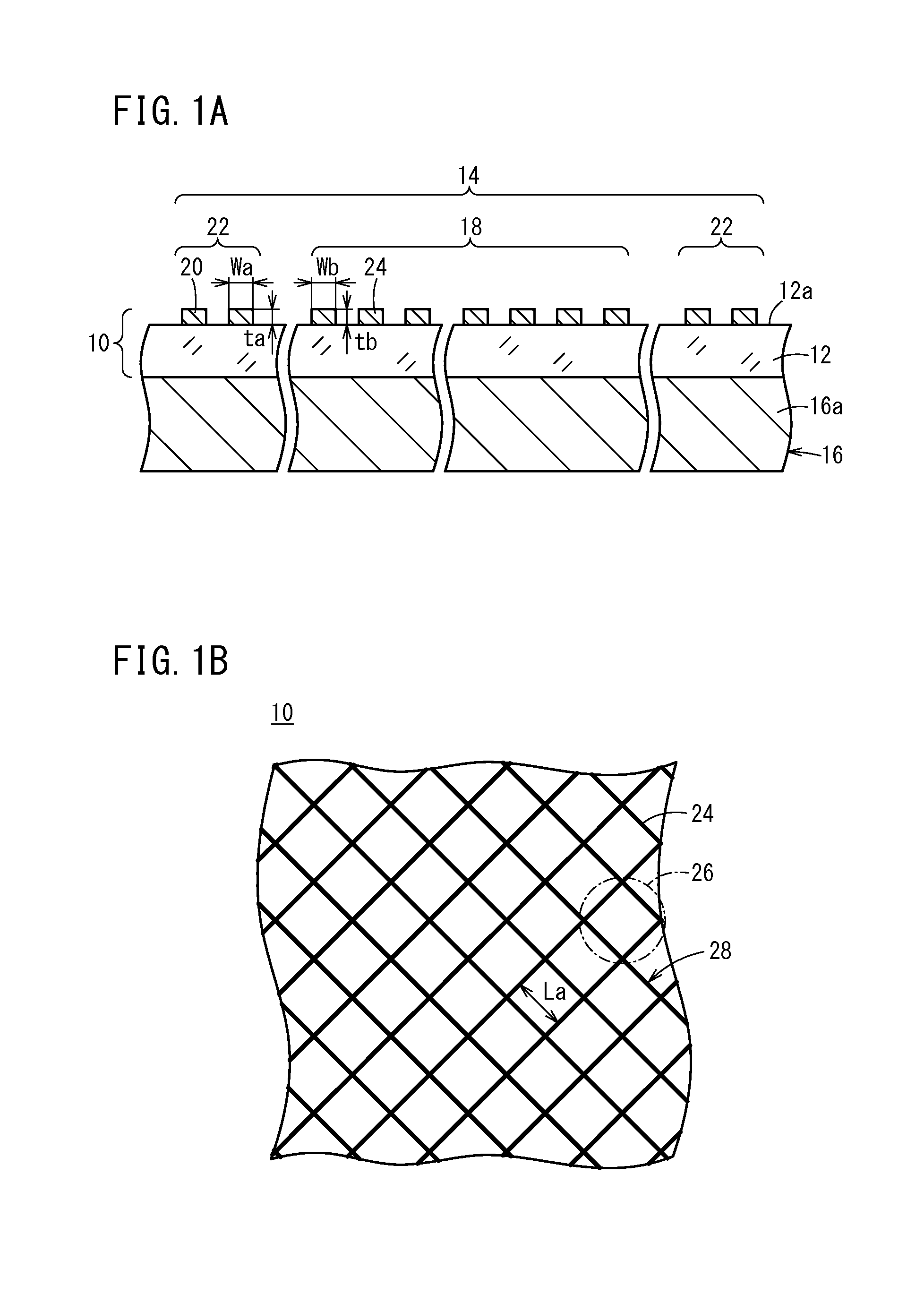

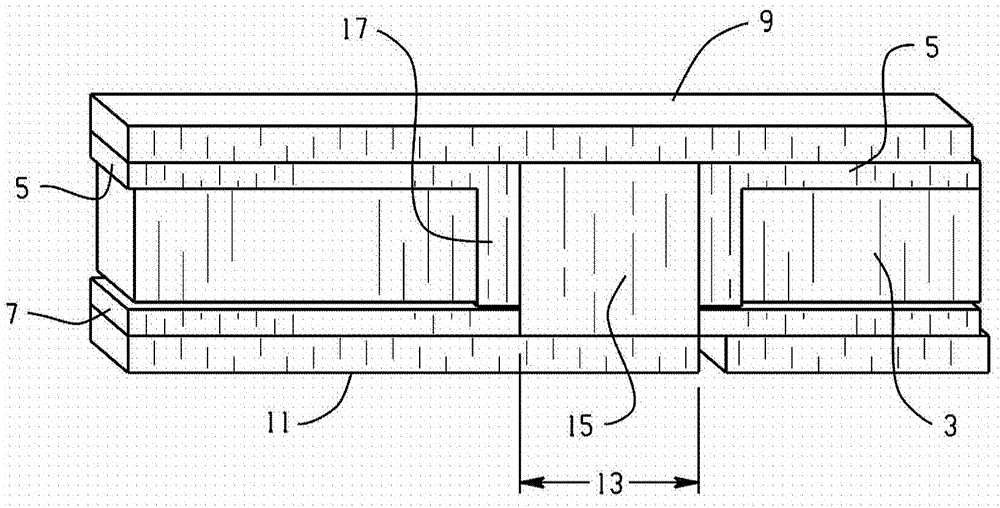

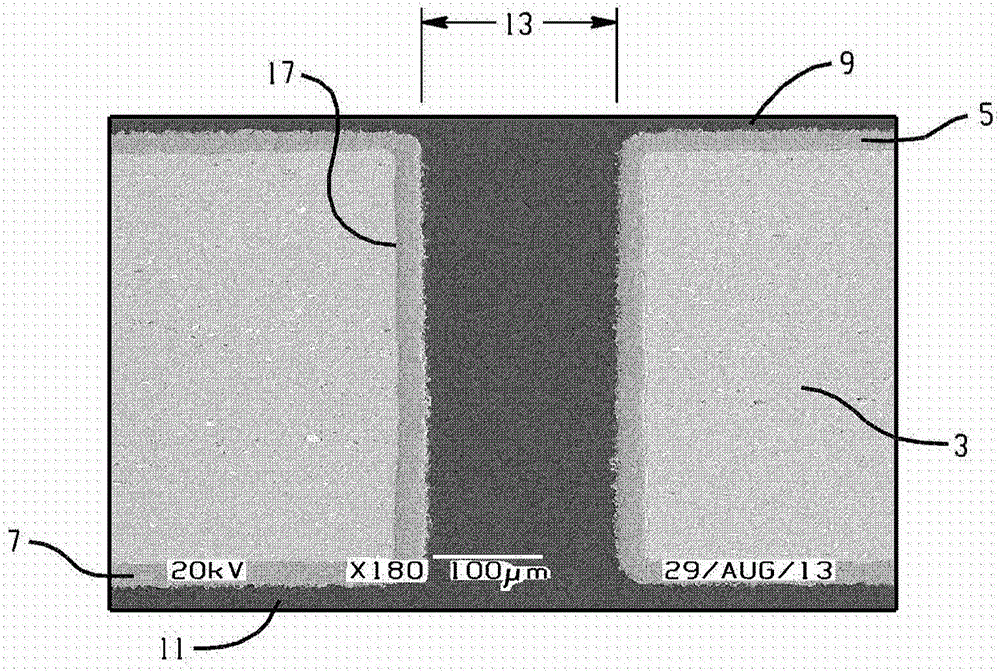

Laminate For Printed Wiring Board, Method Of Manufacturing Printed Wiring Board, And Method Of Manufacturing Electronic Device

ActiveUS20170231101A1Favorable bending enduranceFavorable circuit formabilityLithography/patterningFlexible printed circuitsEngineeringArea ratio

A laminate for printed wiring board is used in a method of manufacturing printed wiring boards that includes a process of forming a circuit by any one of a semi-additive method, a partly additive method, a modified semi-additive method, and an embedding method. The laminate includes an insulating resin substrate, a metal layer 1 and a metal layer 2 in this order. When a cross section that is parallel to the thickness direction of the laminate is processed by means of ion milling and the cross sections of the metal layer 1 and the metal layer 2 were observed with EBSD, each of the metal layer 1 and the metal layer 2 has one or plural crystal grain(s) at the processed cross section, and an area ratio of the total area of crystal grains of which a difference in angle of the <100> crystal direction from a perpendicular of the processed cross section is 15° or less from among the one or plural crystal grains to the total area of the plural crystal grains was 15% or higher but less than 97% in the metal layer 1 and the metal layer 2.

Owner:JX NIPPON MINING& METALS CORP

Thermal management circuit materials, method of manufacture thereof, and articles formed therefrom

InactiveCN105706231ASemiconductor/solid-state device detailsSolid-state devicesDielectric layerElectron

The invention provides thermal management circuit materials, a method of manufacture thereof, and articles formed therefrom. According to one embodiment, the thermal management circuit material comprises a thermally conductive metallic core substrate, metal oxide dielectric layers on both sides of the metallic core substrate, electrically conductive metal layers on the metal oxide metal oxide dielectric layers, and at least one through-hole via filled with an electrically conductive metal-containing core element connecting at least a portion of each of the electrically conductive metal layers, wherein the containing walls of the through-hole via are covered by a metal oxide dielectric layer connecting at least a portion of the metal oxide dielectric layers on opposite sides of the metallic core substrate. Also disclosed are methods of making such circuit materials, comprising forming metal oxide dielectric layers by oxidative conversion of a surface portion of the metallic core substrate. Articles having a heat-generating electronic device such as an HBLED mounted in the circuit material are also disclosed.

Owner:ROGERS CORP

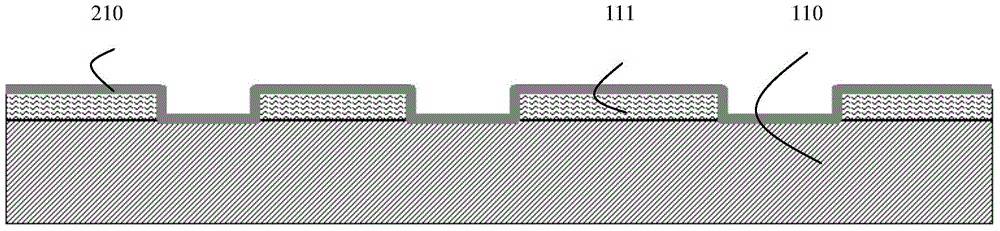

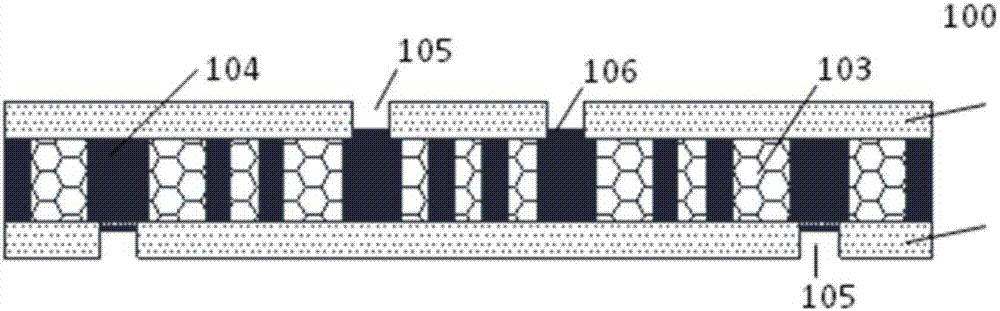

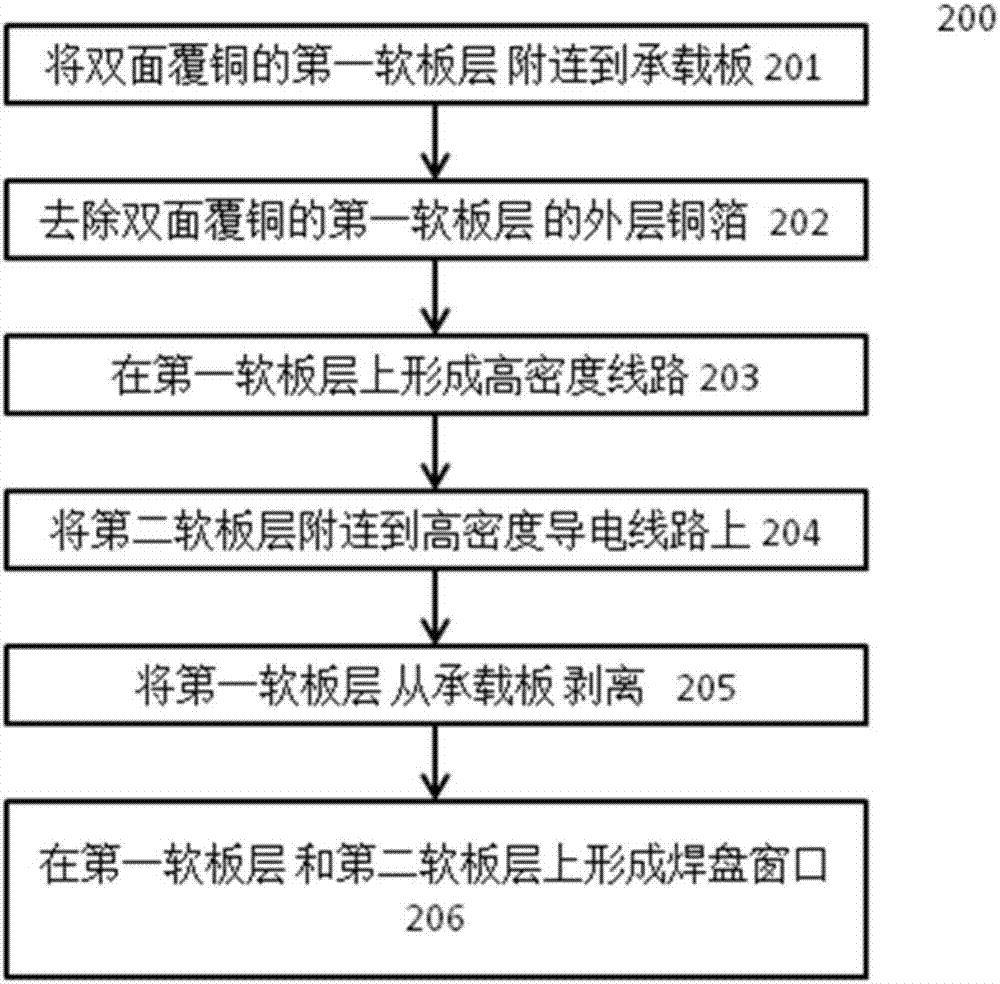

High density flexible substrate manufacturing method

ActiveCN107041078AHigh impedanceCurrent transfer capability limitationLithography/patterningFlexible printed circuitsHigh densityCopper foil

The invention provides a high density flexible substrate manufacturing method. The high density flexible substrate manufacturing method comprises steps that a first copper foil layer of a double-sided copper-clad first flexible printed circuit board layer is removed, and the first surface of the first flexible printed circuit board layer is exposed; a conductive line is formed on the first surface of the first flexible printed circuit board layer; a second flexible printed circuit board layer is connected with the conductive line in an attached manner; the second copper foil layer of the first flexible printed circuit board is removed; and at least one bonding pad window is formed in the first flexible printed circuit board layer and the second flexible printed circuit board layer to expose a bonding pad.

Owner:NAT CENT FOR ADVANCED PACKAGING

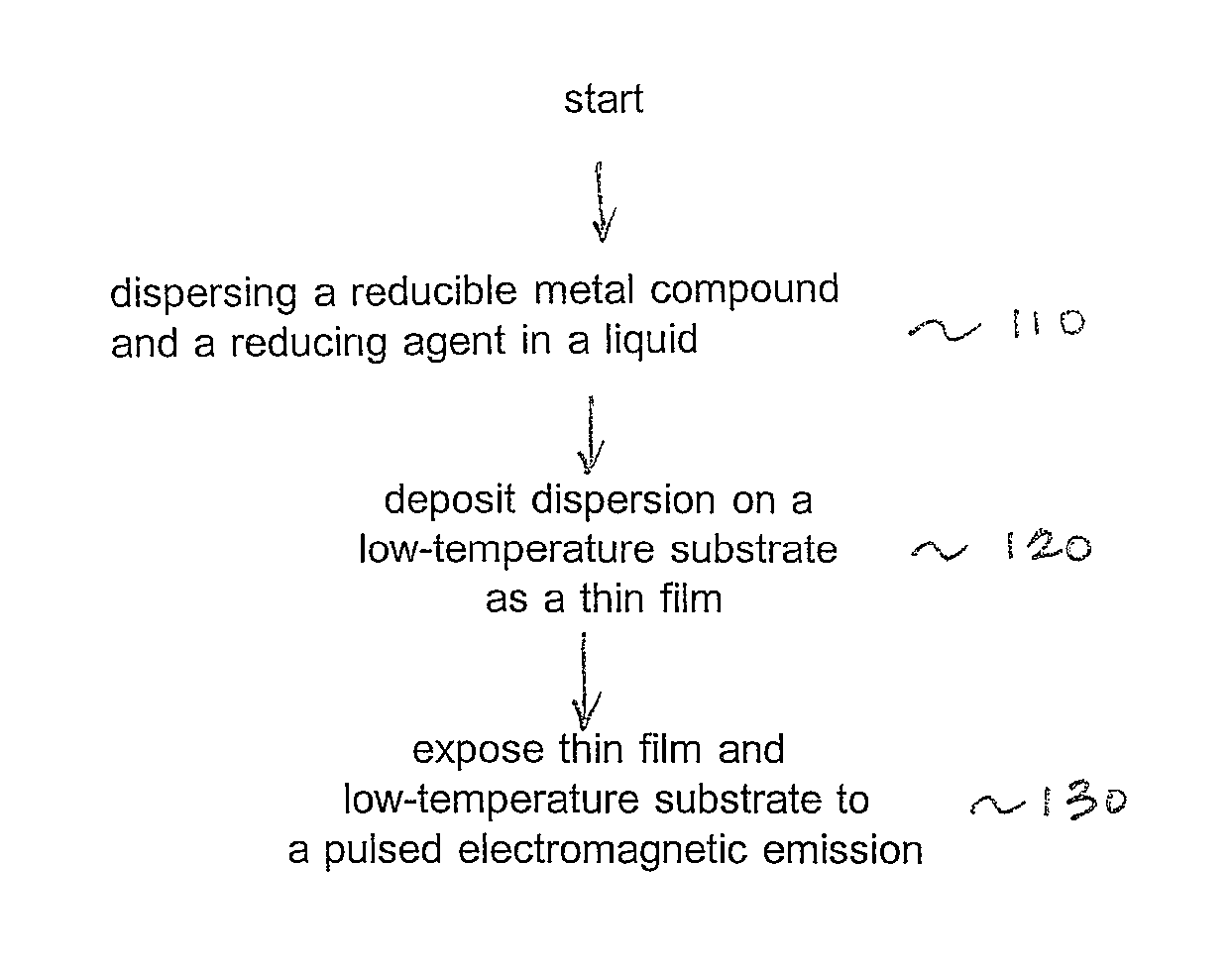

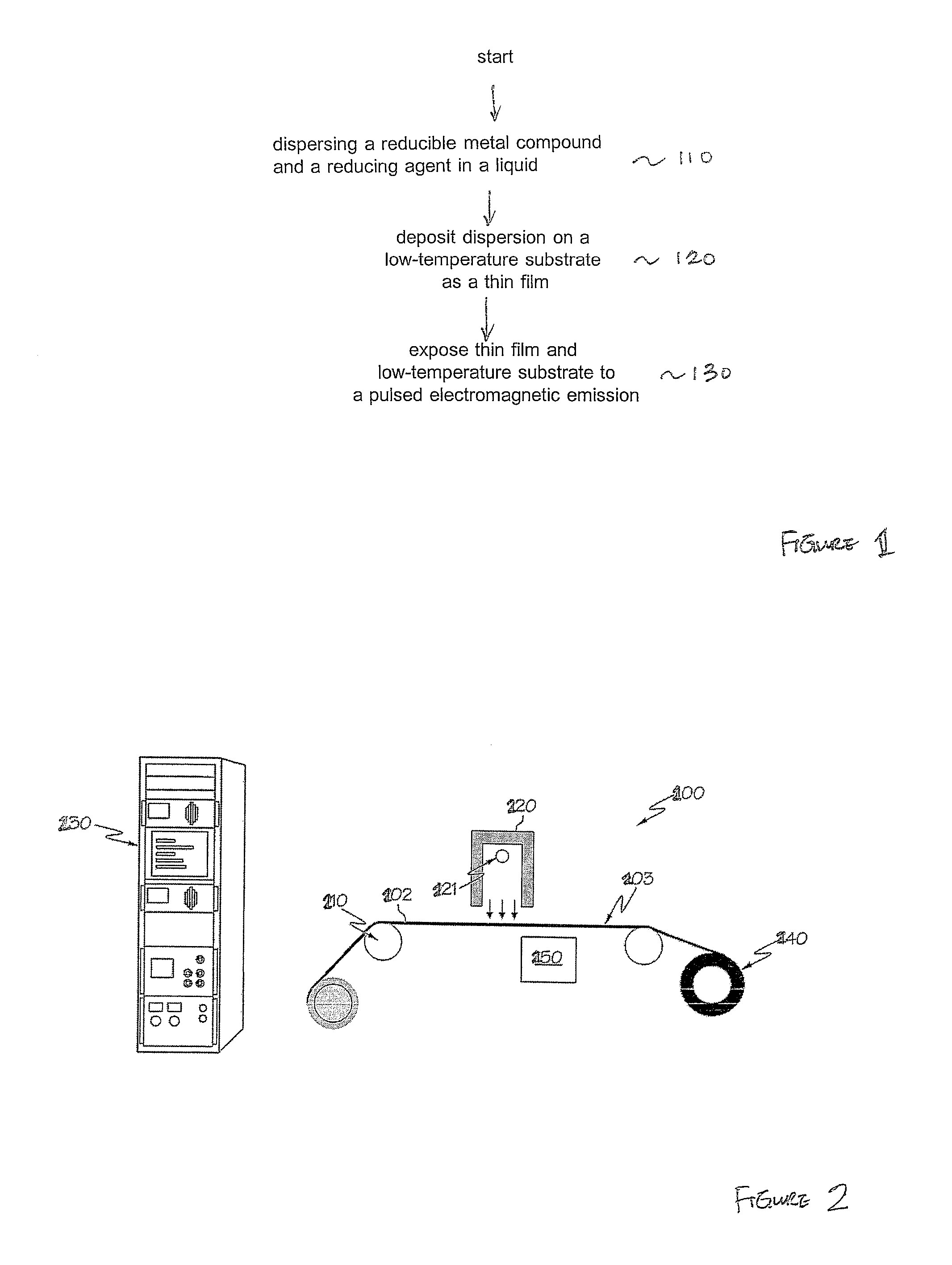

Method for reducing thin films on low temperature substrates

ActiveUS8945686B2Lithography/patterningAlkali metal silicate coatingsMaterials scienceReducing agent

Owner:NCC NANO LLC

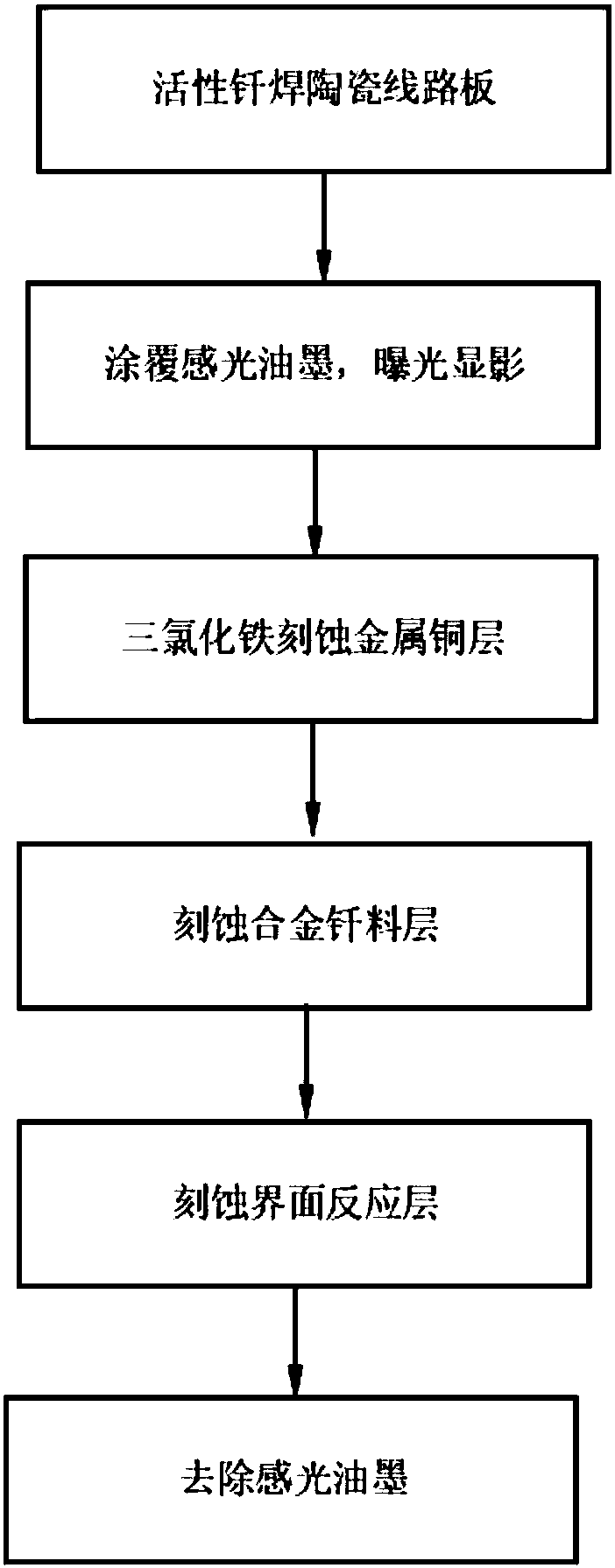

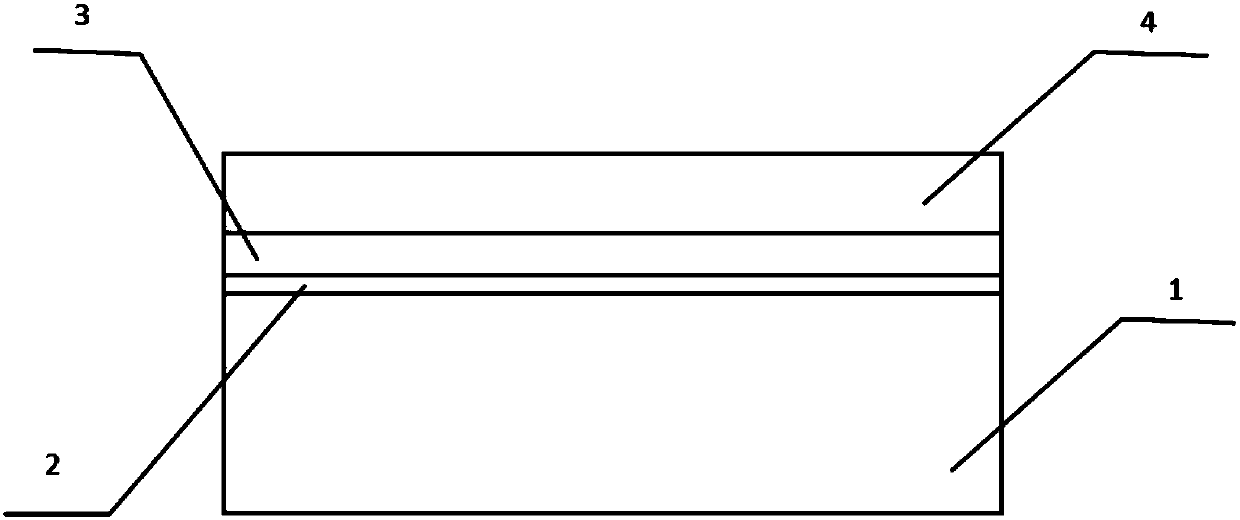

Aluminum nitride ceramic substrate line etching method

ActiveCN108040435AGuaranteed accuracyGuaranteed uniformityLithography/patterningConductive material chemical/electrolytical removalFiller metalNitride

The invention relates to an aluminum nitride ceramic substrate line etching method. The aluminum nitride ceramic substrate is an active brazing ceramic substrate, the etching is carried out in two steps, the alloy brazing filler metal layer is etched in the first step, and the interface reaction layer of the brazing filler metal and the ceramic is etched in the second step. In the first step, theetching solution is composed of nitric acid and hydrogen peroxide, wherein the volume ratio of nitric acid to hydrogen peroxide is 0.3-2: 0.8-1.5, the mass concentration of the nitric acid is 65%-70%, and the mass concentration of the hydrogen peroxide is 20%-40%. In the second step, the etching solution is composed of sulfuric acid, hydrogen peroxide and water, wherein the volume ratio of sulfuric acid to hydrogen peroxide is 0.5-2: 0.3-1.5:0.1, the mass concentration of the sulfuric acid is 98%, and the mass concentration of the hydrogen peroxide is 20%-40%. According to the invention, a novel formula etching solution is adopted, the brazing layer and the interface reaction layer of the active brazing heat dissipation substrate can be selectively removed, the etching rate is high, and high-precision and efficient etching of the ceramic substrate is realized.

Owner:北京漠石科技有限公司

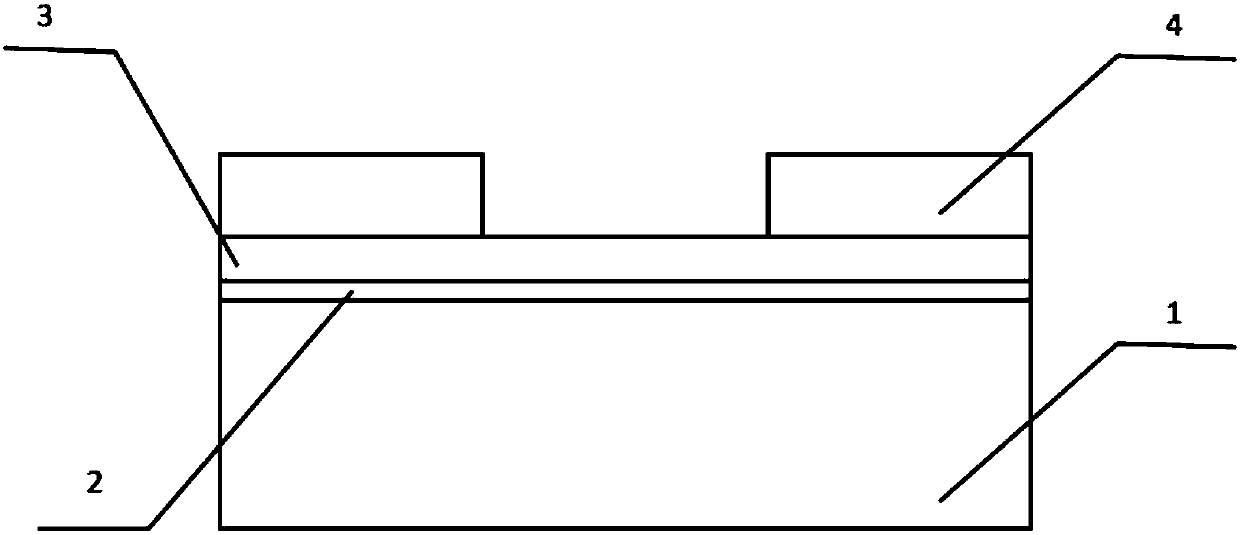

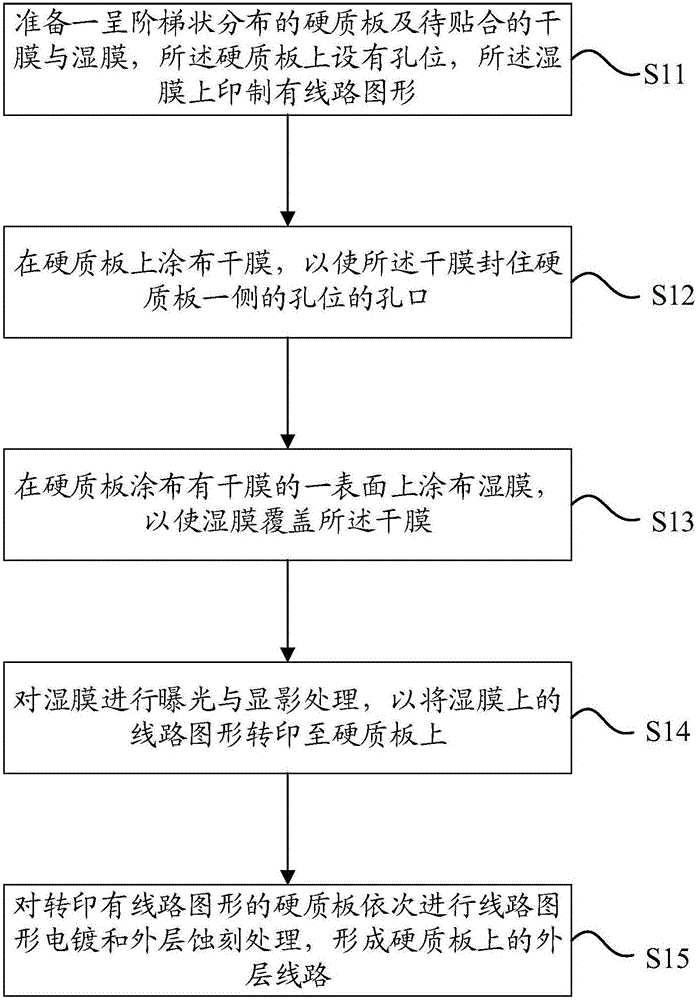

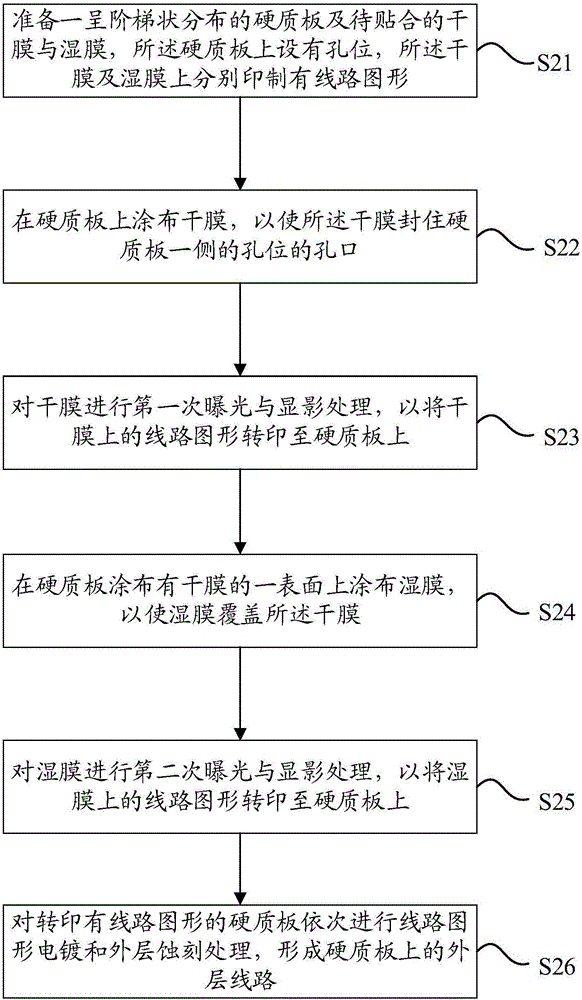

Method for manufacturing outer-layer line by using hard board with large drop

The invention discloses a method for manufacturing outer-layer line by using a hard board with large drop. The method comprises the following steps: preparing a ladder-like hard board and a dry film and a wet film to be bonded, wherein the hard board is provided with hole sites, and a line pattern is printed on the wet film; coating the dry film on the hard board so that the dry film seals orifices at the hole sites at one side of the hard board; coating the wet film on one surface coated with the dry film of the hard board so that the wet film covers the dry film; exposing and developing the wet film to transfer the line pattern on the wet film to the hard plate; sequentially carrying out line pattern electroplating and outer-layer etching treatment on the hard board transferred with the line pattern to form the outer-layer line on the hard board. The technical scheme provided by the invention can improve the yield of the hard board outer-layer line.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

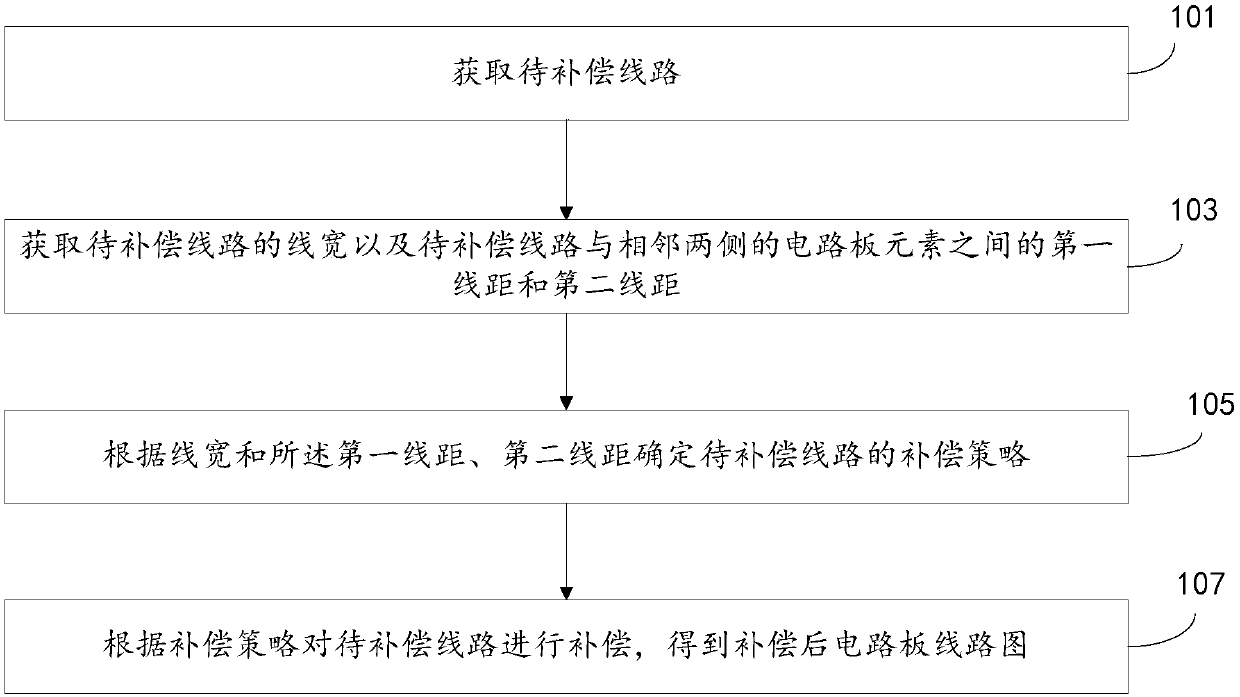

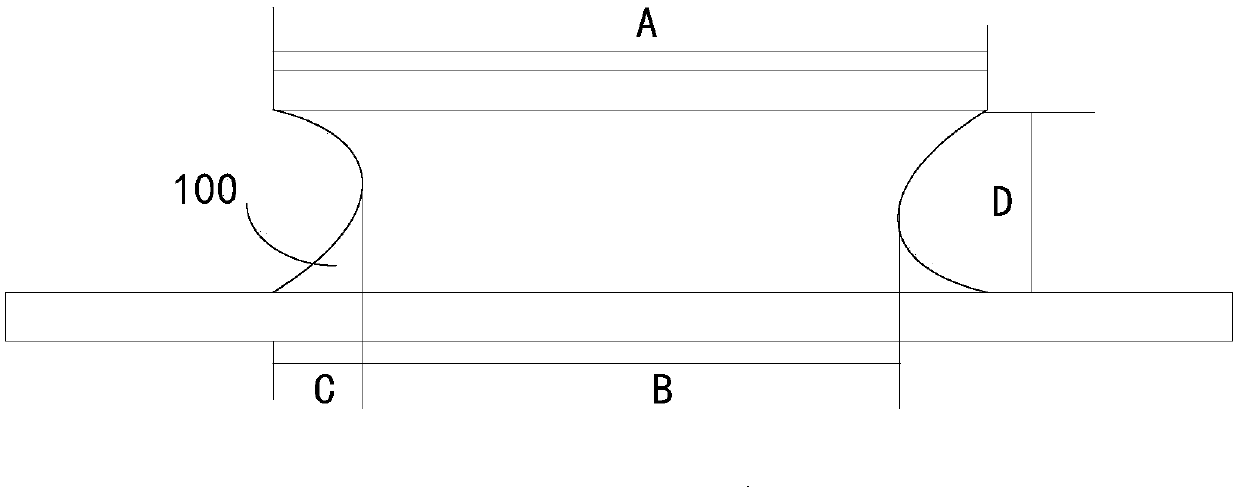

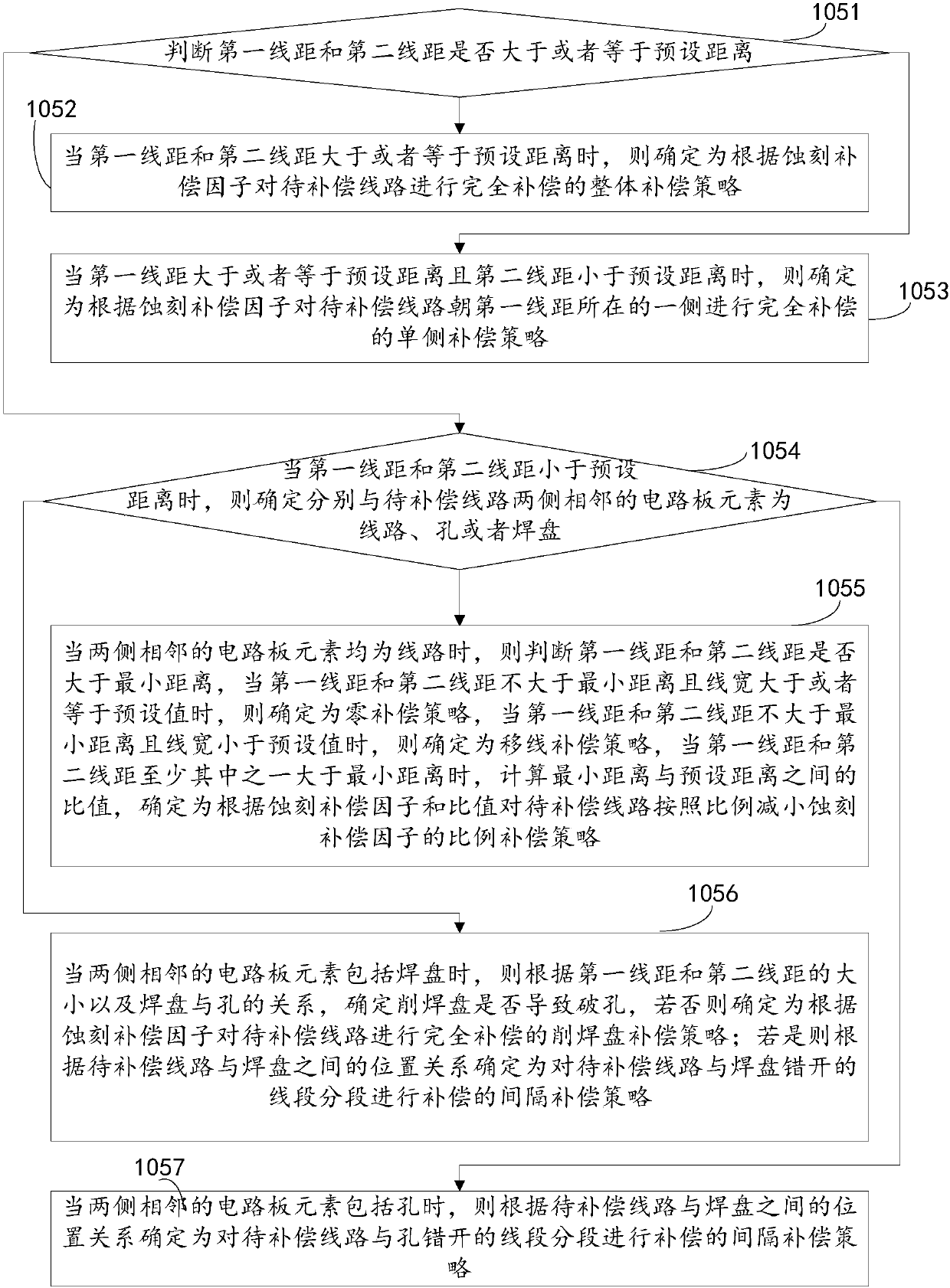

Circuit board line compensation method and device

ActiveCN107787122AImprove manufacturing yieldGuaranteed qualityLithography/patterningConductive material chemical/electrolytical removalEngineeringCompensation strategy

The invention relates to a circuit board line compensation method. A to-be-compensated line is acquired; a line width of the to-be-compensated line and a first line distance and a second line distancebetween the to-be-compensated line and circuit board elements at two adjacent sides are acquired; the compensation strategy of the to-be-compensated line is determined according to the line width, the first line distance and the second line distance; the to-be-compensated line is compensated according to the compensation strategy to acquire a compensated circuit board line diagram. The inventionfurther provides a circuit board circuit line compensation device. Through acquiring the line width and the line distances of the to-be-compensated line, the compensation strategy suitable for the to-be-compensated line is determined, the compensated circuit board line diagram is formed, so that the manufacturing process of circuit boards can be controlled according to design parameters of the compensated circuit board line diagram.

Owner:深圳嘉立创科技集团股份有限公司

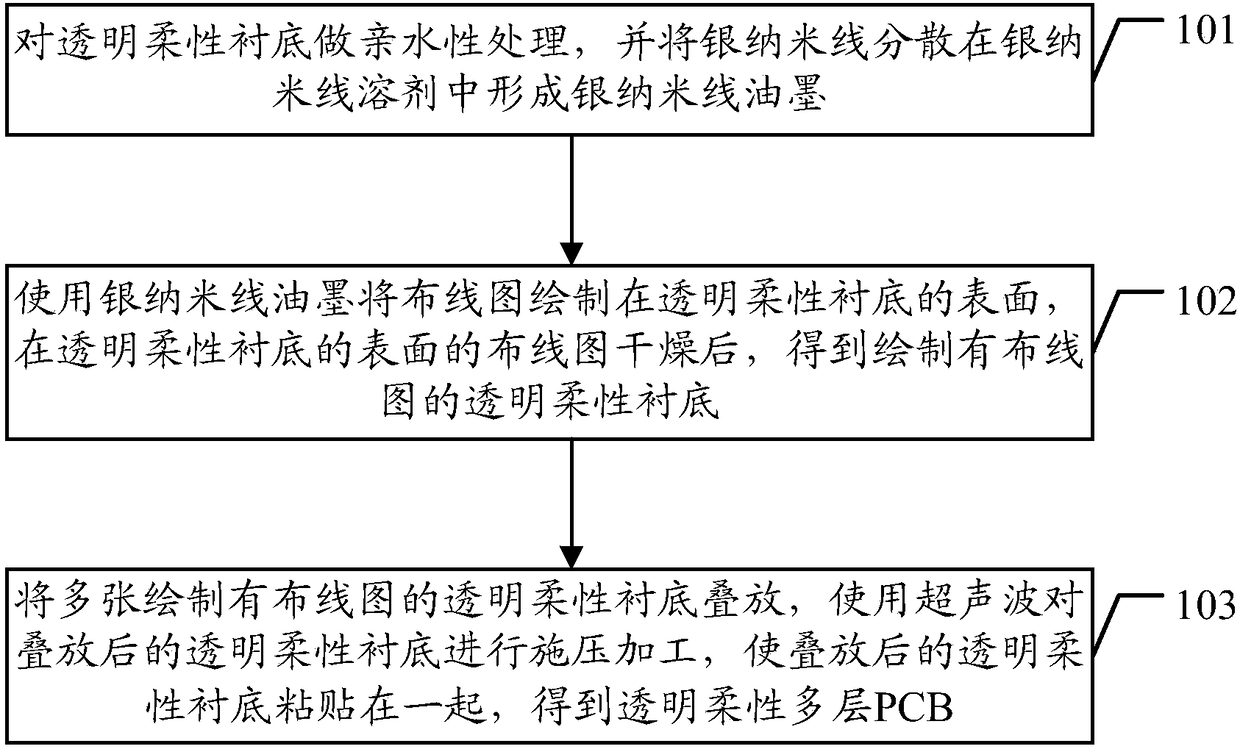

Method for manufacturing transparent flexible multilayer PCB

The invention discloses a method for manufacturing a transparent flexible multilayer PCB. The method comprises steps of: subjecting a transparent flexible substrate to hydrophilic treatment, dispersing silver nanowires in a silver nanowire solvent to form silver nanowire ink, drawing a wiring pattern on the surface of the transparent flexible substrate by using the silver nanowire ink, drying thewiring pattern, stacking a plurality of transparent flexible substrates on which wiring patterns are drawn, applying pressure to the stacked transparent flexible substrates by using ultrasonic, and pasting the stacked transparent flexible substrates together to obtain the transparent and flexible multilayer PCB. Since the transparent flexible substrate is transparent and flexible, the transparentflexible multilayer PCB is transparent, less likely to deform or fracture. Since the silver nanowires have low surface resistance, the PCB has low square resistance. The manufacturing method is simple, can easily use a roll-to-roll industrialized continuous production method, improves the production efficiency and facilitates transportation.

Owner:SHENZHEN UNIV

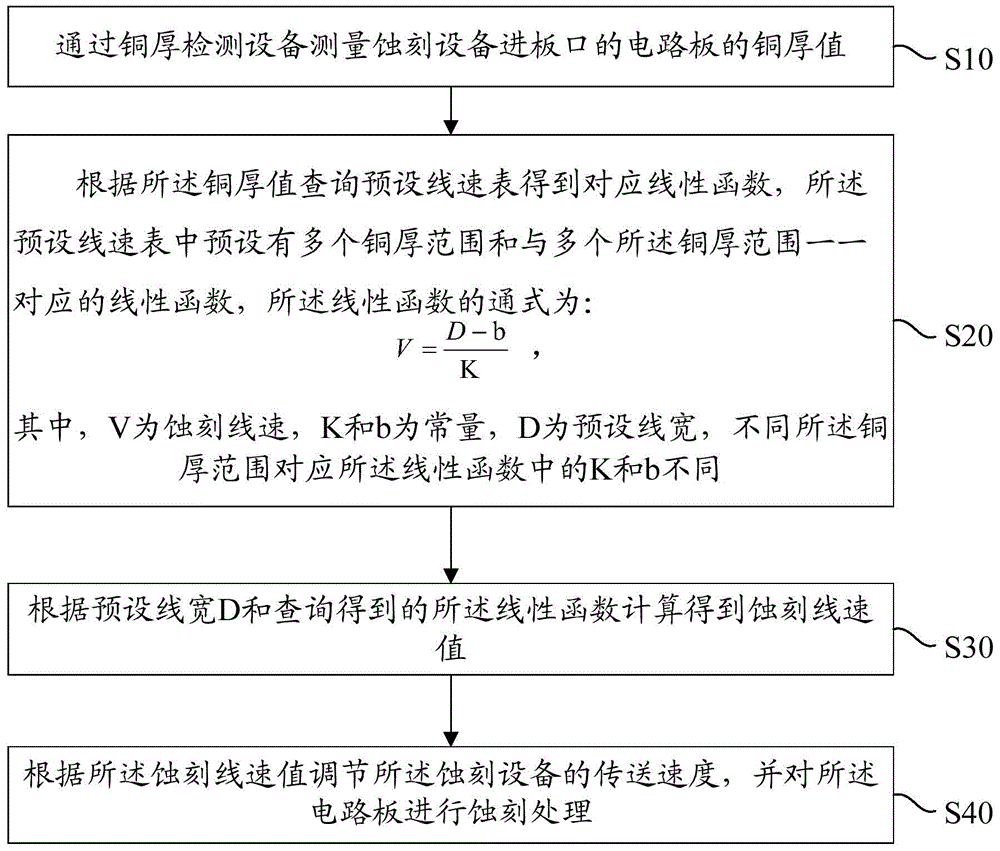

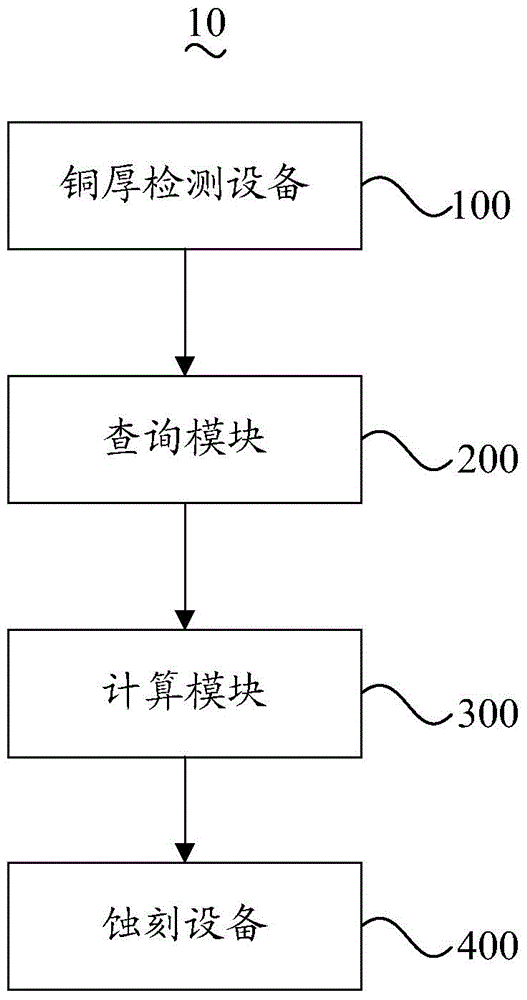

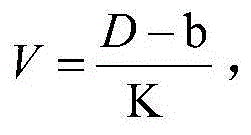

Method and system for automatically regulating etching line speed

ActiveCN104582294AImprove Linewidth AccuracyImprove regulation efficiencyLithography/patterningConductive material chemical/electrolytical removalHemt circuitsMechanical engineering

The invention discloses a method and a system for automatically regulating an etching line speed. The method comprises the following steps: measuring a copper thickness value of a circuit board at a board inlet of etching equipment by copper thickness detection equipment; according to the copper thickness value, inquiring a preset line speed table to obtain a corresponding linear function, wherein a plurality of copper thickness ranges and linear functions corresponding to the copper thickness ranges are preset in the preset line speed table; according to a preset line width D and the linear function, calculating to obtain an etching line speed value; according to the etching line speed value, regulating a transmission speed of the etching equipment and carrying out etching processing on the circuit board. According to the method for automatically regulating the etching line speed, the preset line speed table can be inquired according to the copper thickness value to obtain the corresponding linear function and then calculation is carried out by the preset line width D and the linear function obtained by inquiry to obtain the etching line speed so as to correspondingly regulate the transmission speed of the etching equipment to enable the line width to accord with the requirement of the preset line width D after etching, and thus, line width accuracy of the etched circuit board can be improved. Moreover, the regulating efficiency is also high.

Owner:HUIZHOU TECHUANG ELECTRONIC TECH CO LTD

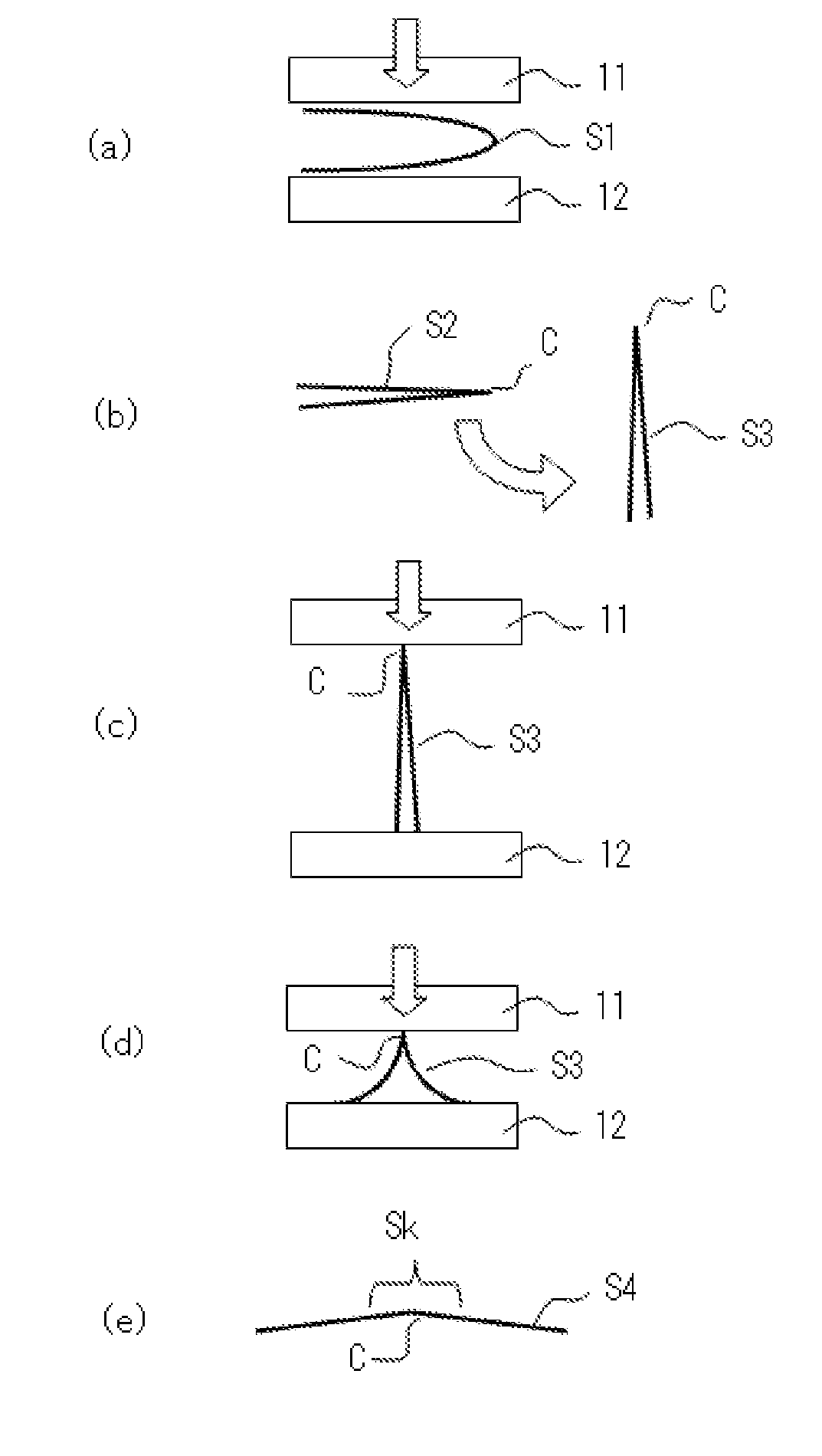

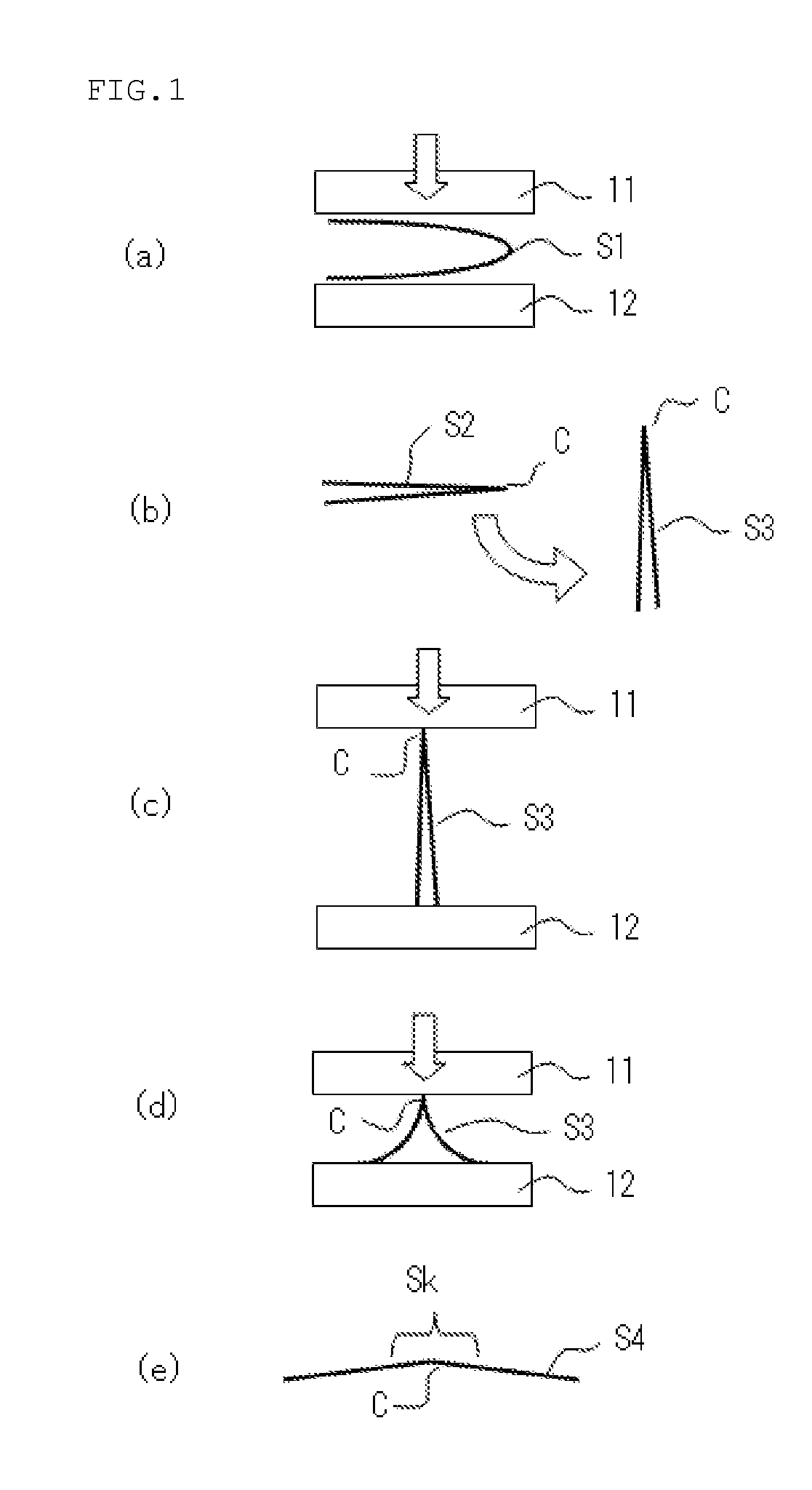

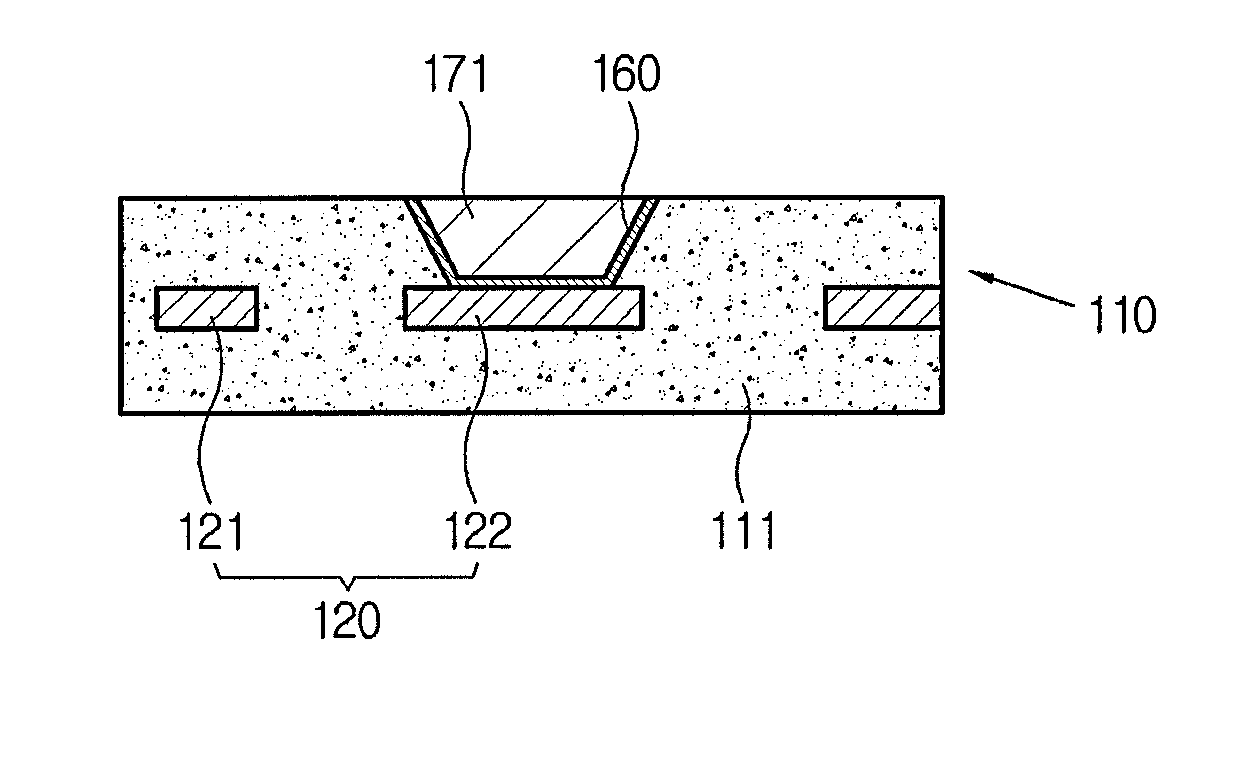

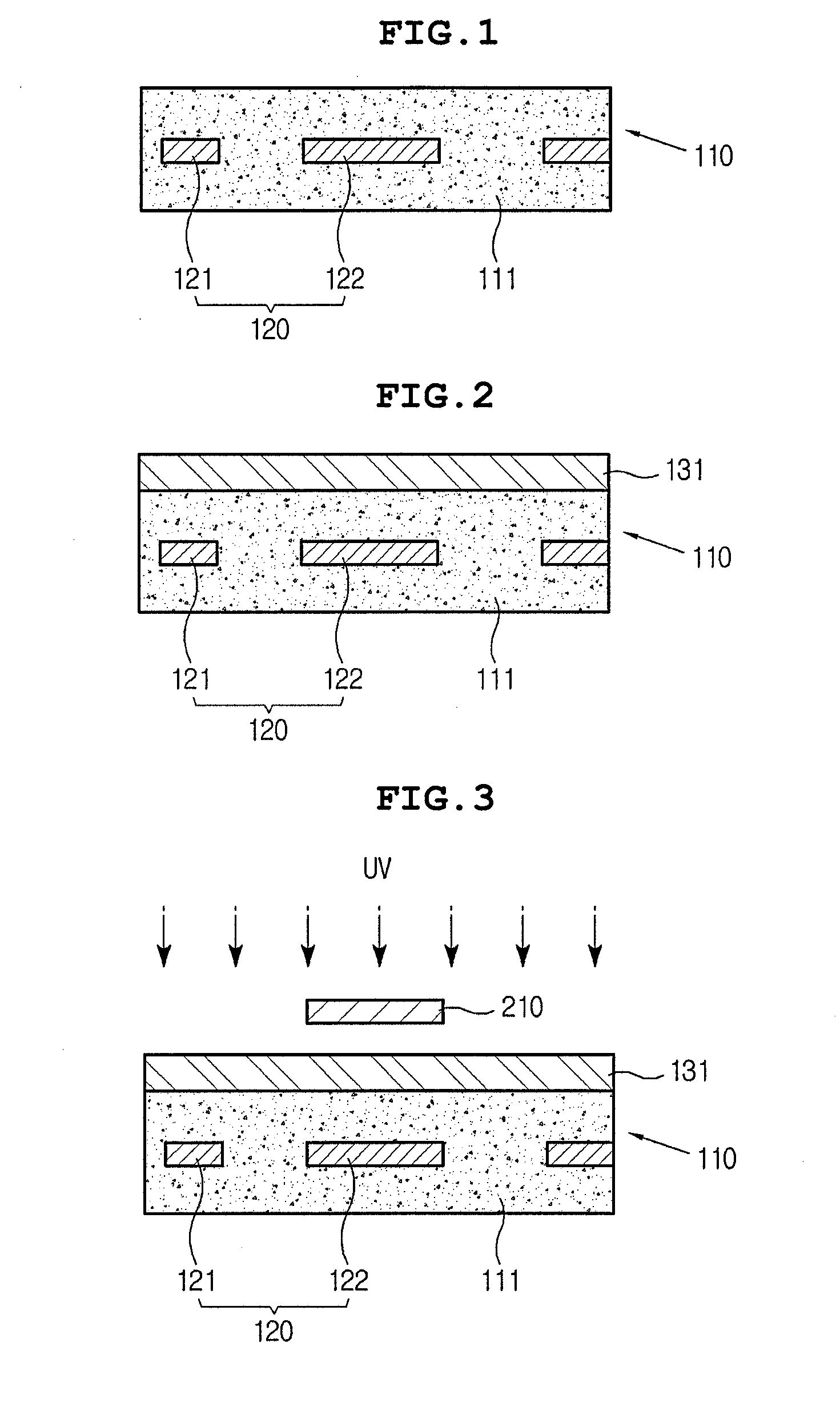

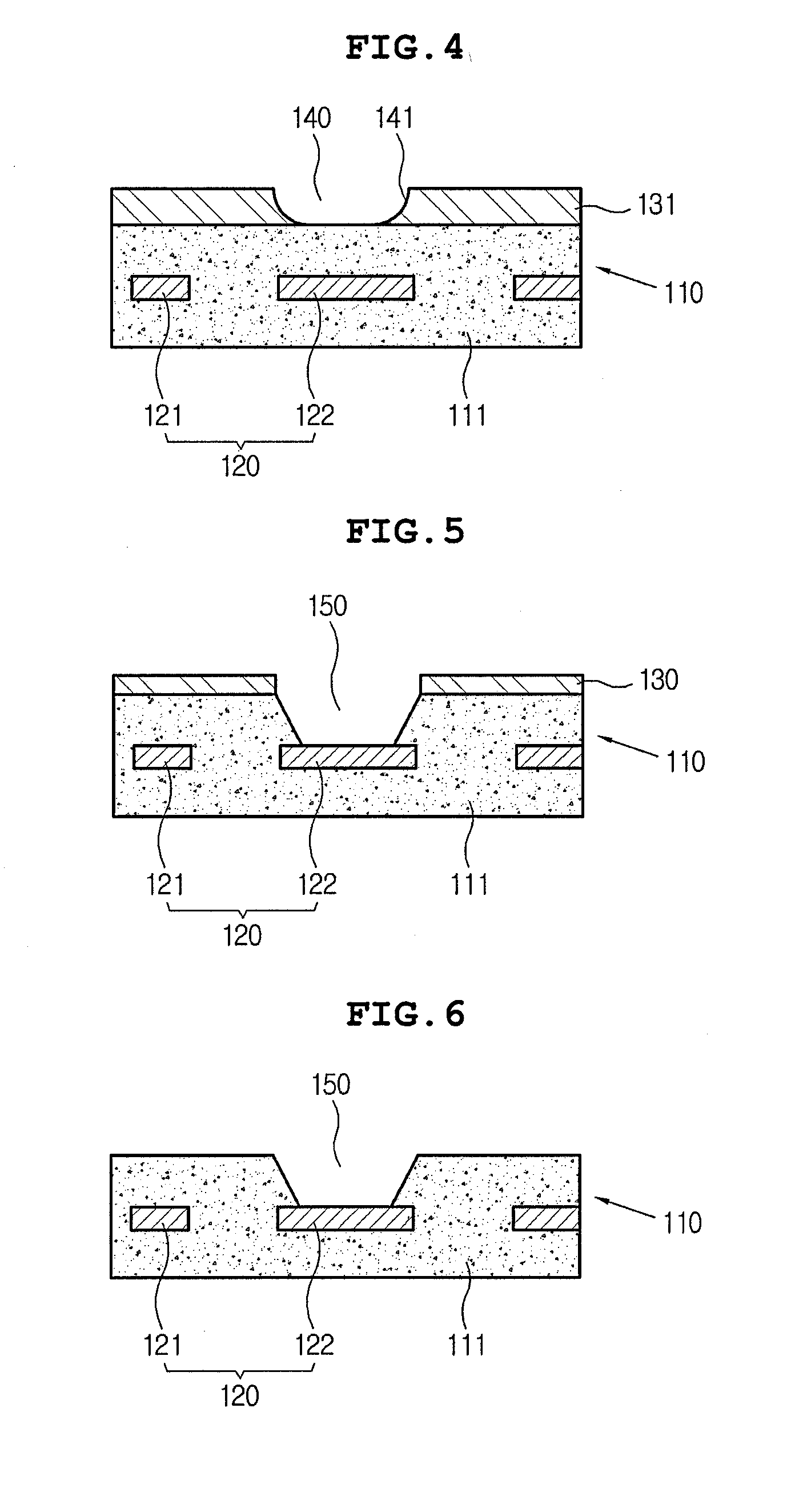

Method of manufacturing printed circuit board

Disclosed herein is a method of manufacturing a printed circuit board, the method including: preparing a base substrate having an insulating layer and a connection pad formed in the insulating layer; forming a photosensitive resist on the insulating layer; forming an opening part of which a side surface has a foot shape by patterning the photosensitive resist; forming a via hole exposing the connection pad by etching the insulating layer exposed by the opening part; and forming a via by filling the via hole.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

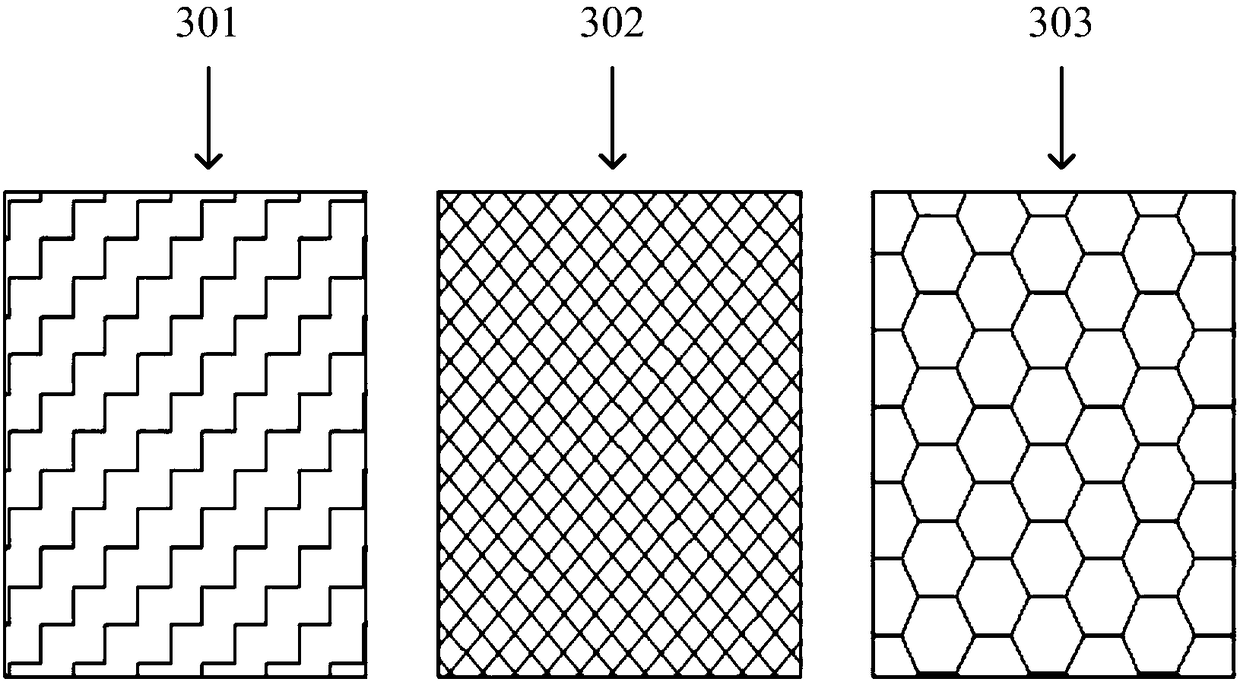

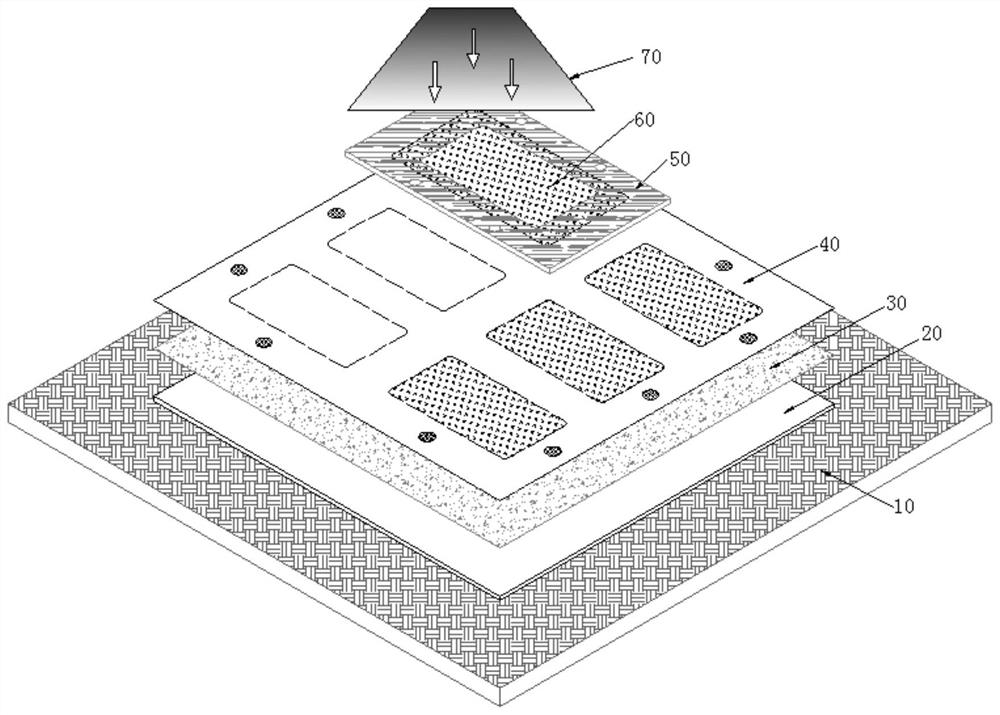

Preparation process of micro-nano texture seamless splicing texture mold

PendingCN111935910AAvoid chippingAvoid dirt and discolorationLithography/patterningRadiation-sensitive masks exposureEngineeringExposure

The invention discloses a preparation process of a micro-nano texture seamless splicing texture template. Micro-nano seamless splicing is realized by adopting film shielding and UV local exposure modes. An upper platform target and a lower platform target are grabbed and positioned through a CCD. Different row distances and column distances are set to realize multi-mode typesetting, and single films can be spliced into multiple films, so that the problems of long development period and high development cost of a texture female die are solved, and the preparation process disclosed by the invention can be used for quickly realizing multi-mode production, improving the production efficiency and reducing the development cost in a mode of splicing the single films into multiple modes.

Owner:伯恩创盛技术研发(惠州)有限公司

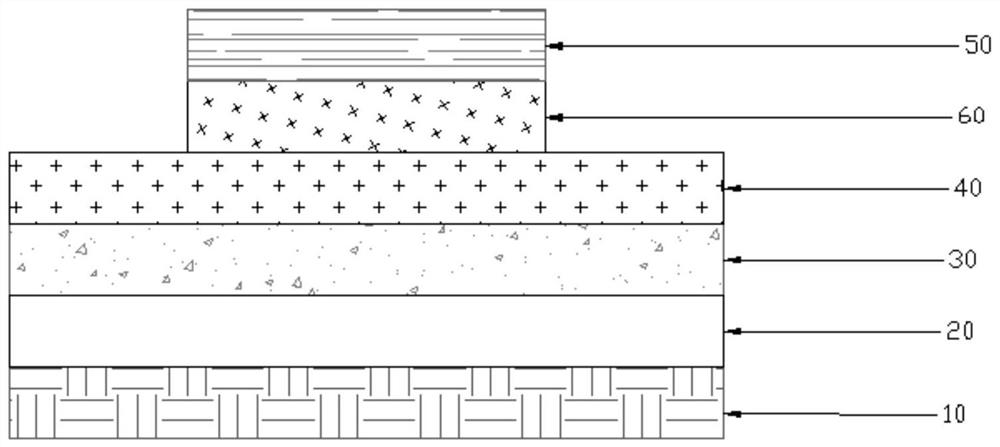

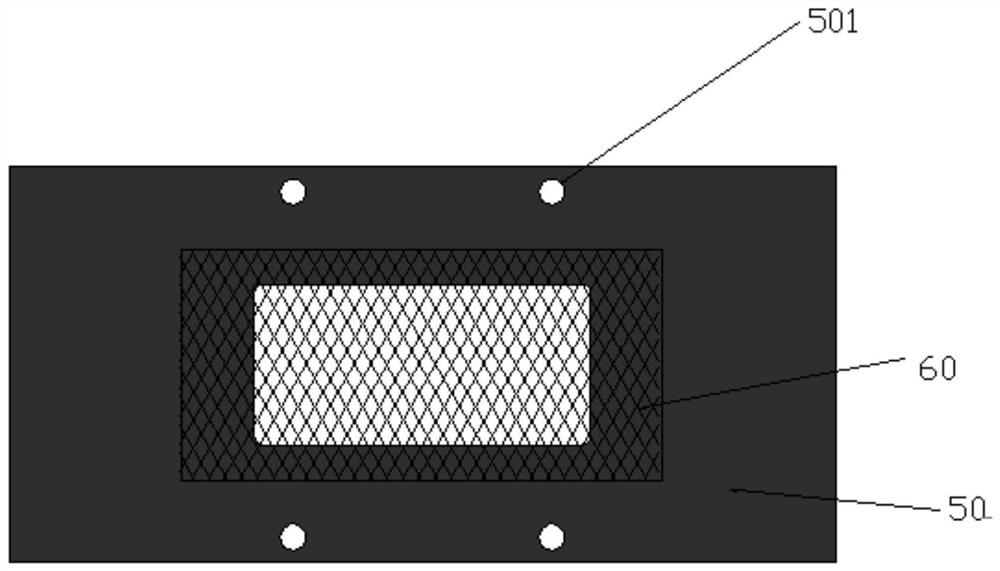

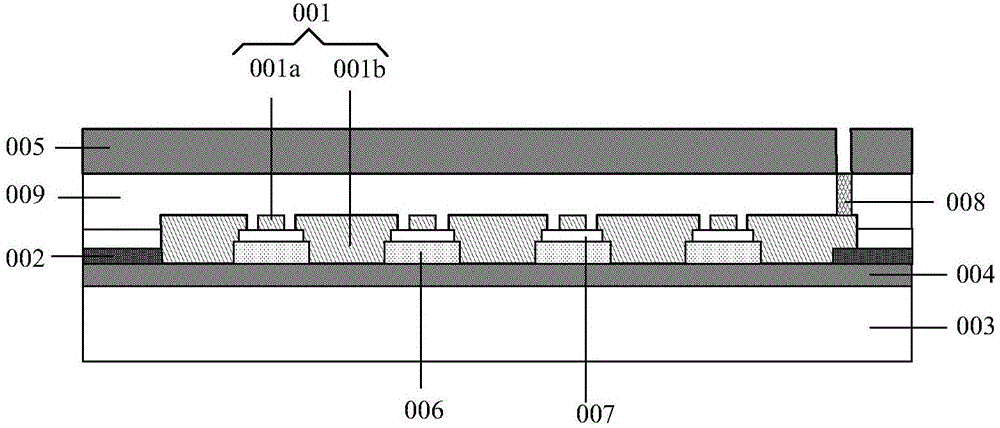

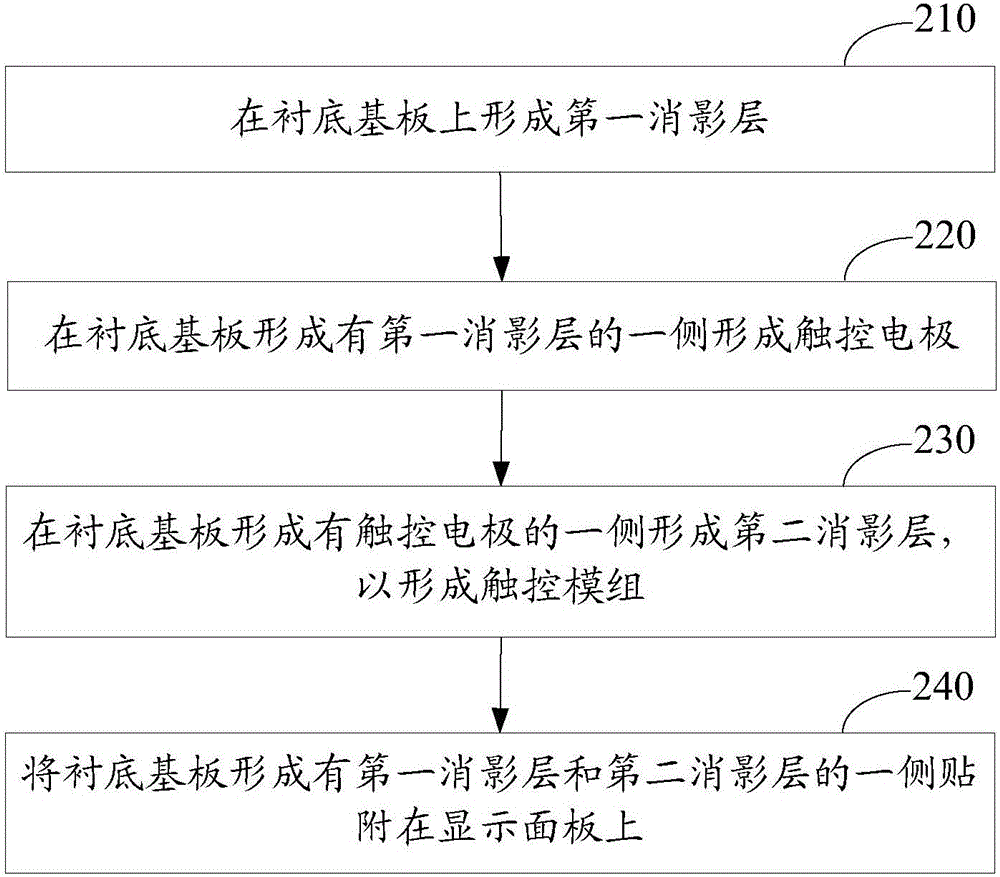

Touch display module, preparing method and display device thereof

ActiveCN106354305APlay a protective effectShadowing achievedLithography/patterningPrinted circuit aspectsDisplay deviceHuman–computer interaction

The embodiment of the invention discloses a touch display module, a preparing method and a display device thereof. The touch display module comprises a display panel and a touch display module attached on the display module, wherein the touch module is divided into areas with touch area with touch electrodes and the frame area with black matrix, the touch module comprises the substrate,on the side near to the display panel, the first shadow elimination layer and the second shadow elimination layer are included; among which: the first shadow elimination layer is located between the touch electrodes and the substrate; the second shadow elimination layer is located on the side far from the touch electrodes; the thickness of the second shadow elimination layer shall be greater than that of the first shadow elimination layer, and the thickness of the first and second shadow elimination layers shall meet the conditions: under the mode of dark state display, the color variation shall be smaller than the default value. Comparing with the existing technology, the touch display module can greatly reduce the color variation between the touch area and the frame area to improve the integrated black effect.

Owner:BOE TECH GRP CO LTD +1

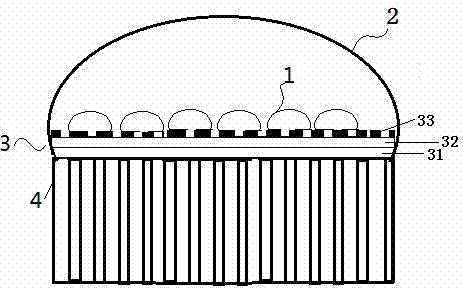

Manufacturing method of LED heat radiating substrate and LED module with substrate

InactiveCN104333981AFast heat conductionImprove cooling efficiencyLithography/patterningPoint-like light sourceScreen printingOrganic solvent

The invention relates to a manufacturing method of an LED heat radiating substrate and an LED module with the substrate. The manufacturing method of the LED heat radiating substrate comprises the following steps: (1) forming an insulating layer at the surface of an aluminum substrate through an anodic oxidation way, (2) forming a layer of ink opposite to a needed circuit diagram on the insulating layer by using screen printing technology, (3) drying the ink and then carrying out sputtering on the ink to form a metal layer, and (4) cleaning and removing the ink by using an organic solvent such that a metal layer film deposited at the surface of the ink falls and the remaining metal circuit is the needed circuit. The LED heat radiating module comprises an LED bulb, a circuit board which carries the LED bulb and a lens which covers the LED bulb. The insulating layer is in the shape of a honeycomb. According to the heat radiating module, a special heat radiating substrate is used, combined with the special structural design, the heat radiating efficiency is high, and the service life is long.

Owner:THERMAL GROUP TECH HUIZHOU +2

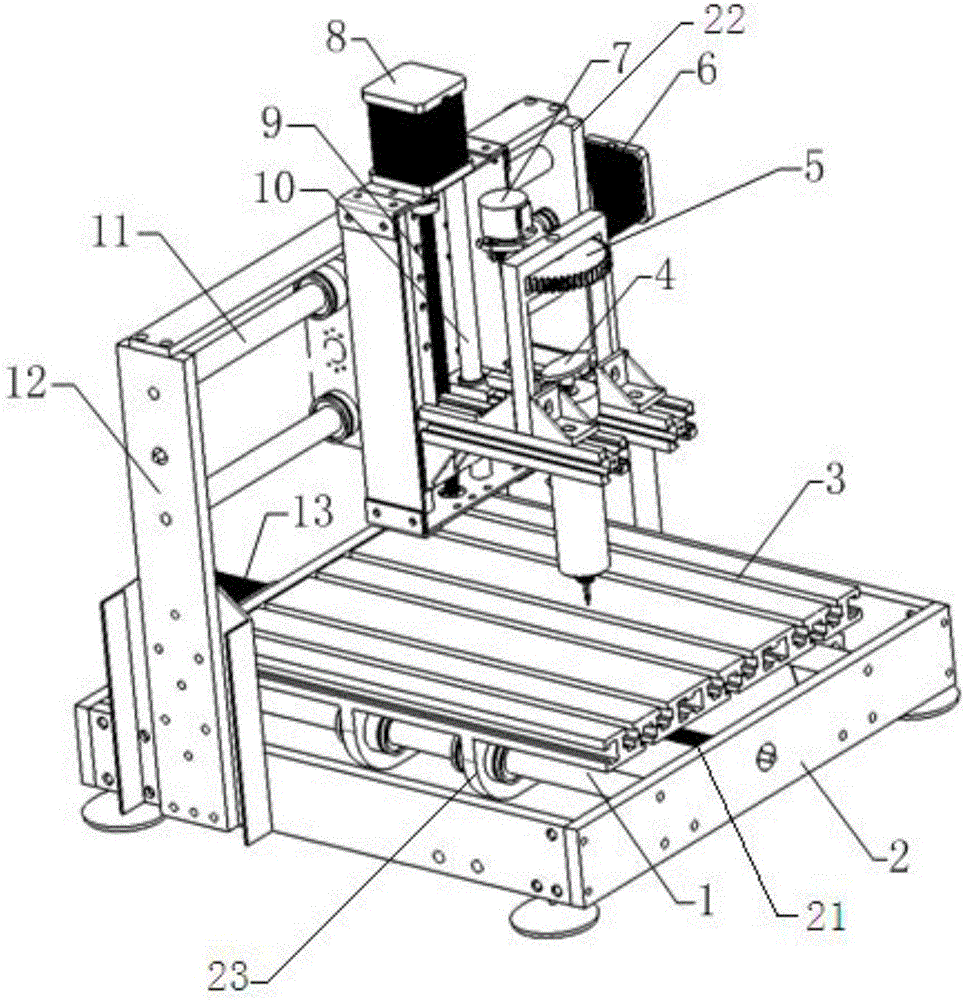

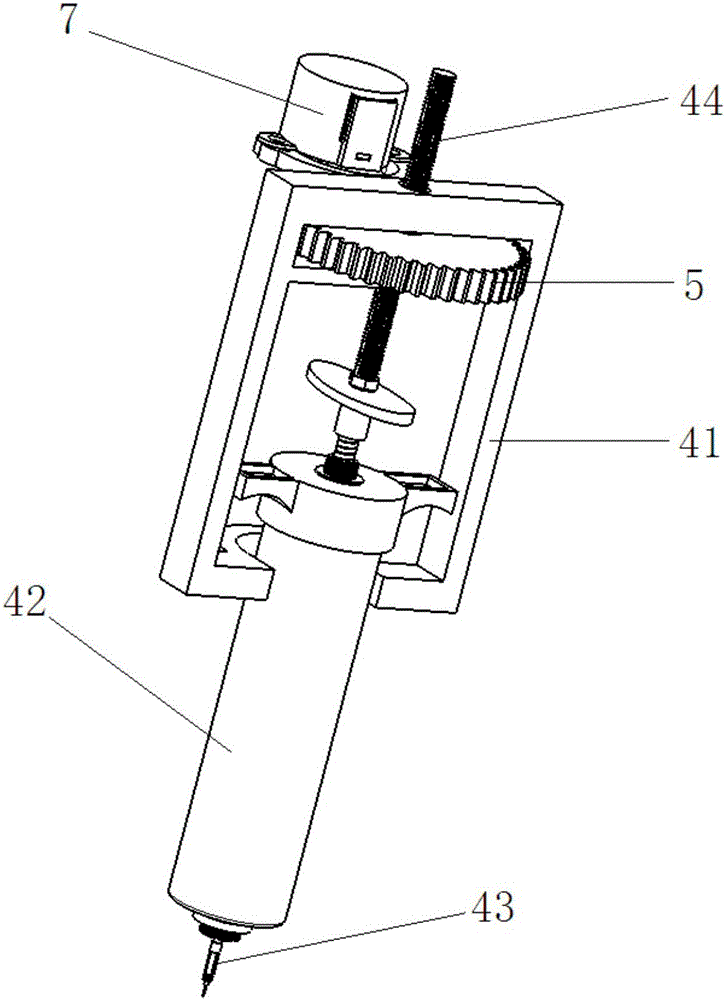

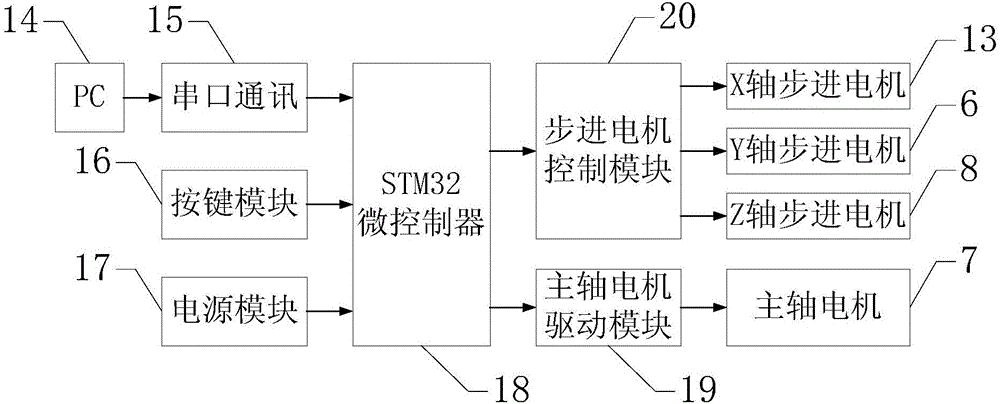

Device for drawing flexible circuit board and control method thereof

InactiveCN106658981AManufacturing process innovationSimple processLithography/patterningConductive pattern formationSilver pasteGear drive

The invention discloses a device for drawing a flexible circuit board. The device comprises a machine frame, an extrusion unit, moving parts and a control circuit, wherein the moving parts are on X, Y and Z directions; the machine frame includes a chassis, and left and right lateral plate brackets; the moving parts on the X, Y and Z directions are installed and are fixed on the machine frame; each of the three moving parts consists of a polished rod, a screw rod and a stepping motor; the extrusion unit is arranged on the Z direction; a slowdown stepping motor on the extrusion unit drives a gear, and the gear drives a bolt, thereby achieving a pushing-extruding effect; and a conductive silver paste is adopted by an extrusion material and is used for drawing the flexible circuit board on a flexible material such as paper, cloth material and the like. According to the device for drawing the flexible circuit board and the control method thereof disclosed by the invention, a printing manner is adopted to manufacture a circuit board, so the manufacturing manner of the traditional circuit board is broken through, and the device for drawing the flexible circuit board and the control method thereof are innovations of a circuit board manufacturing process; and the circuit board manufacturing process is simple, and the consumption time is short.

Owner:SOUTHWEST UNIVERSITY

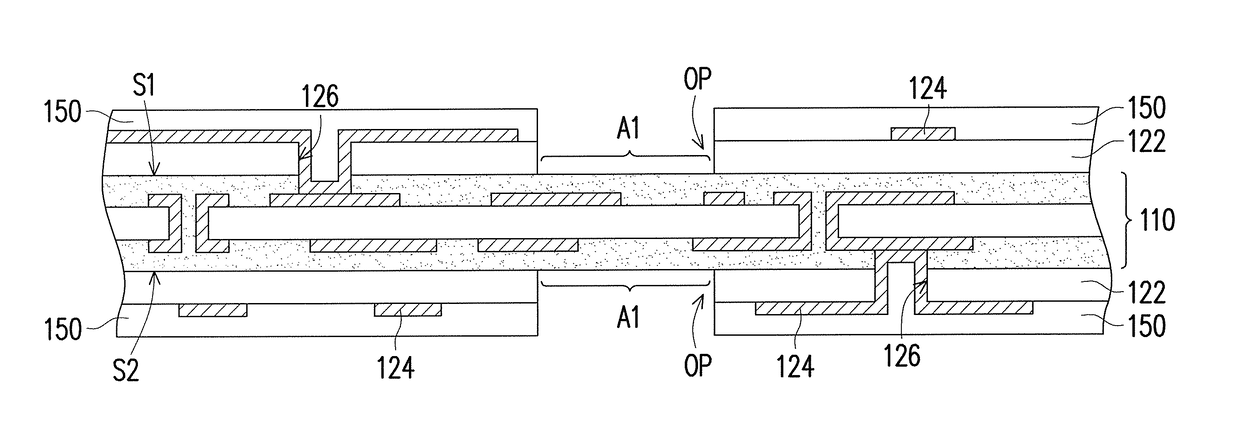

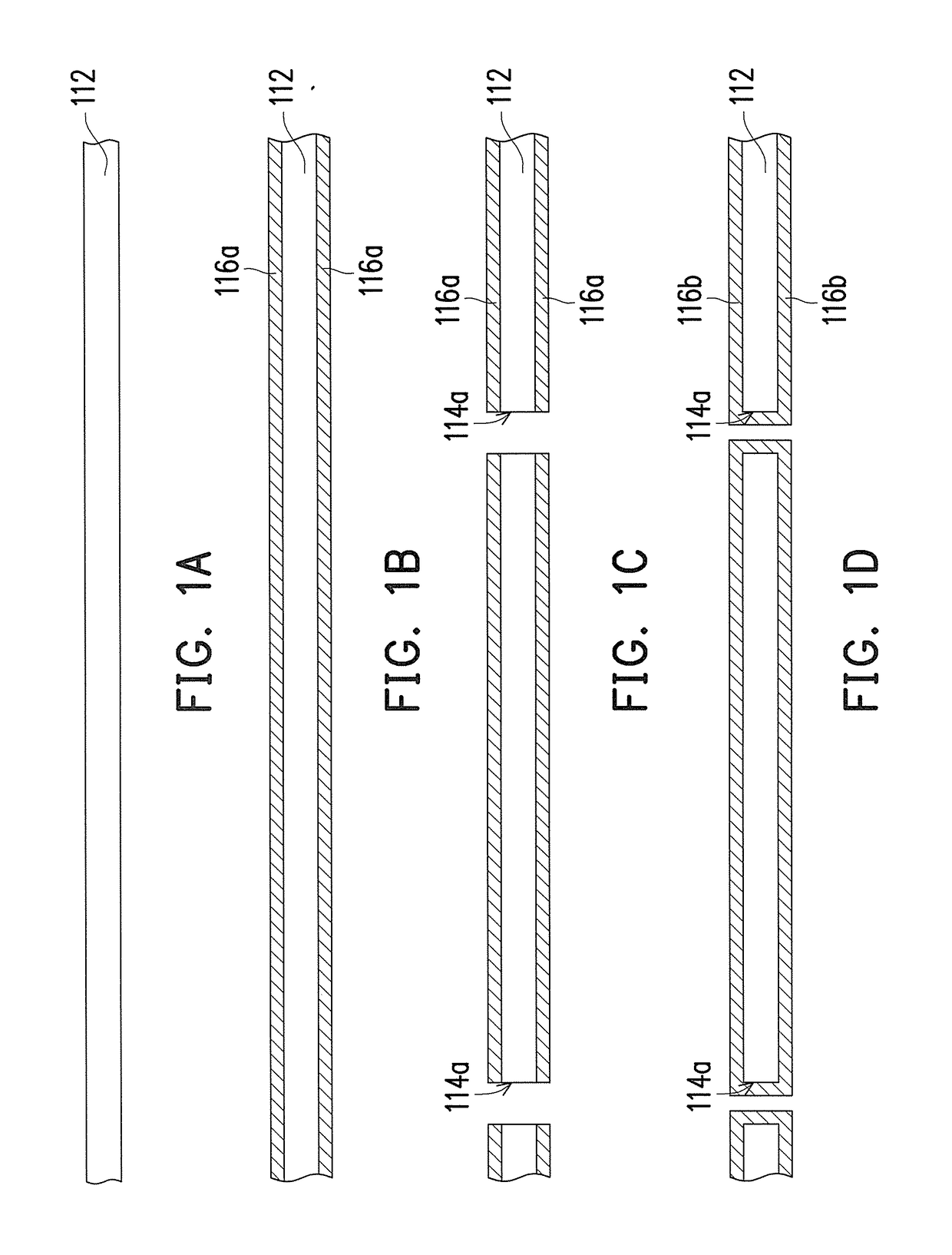

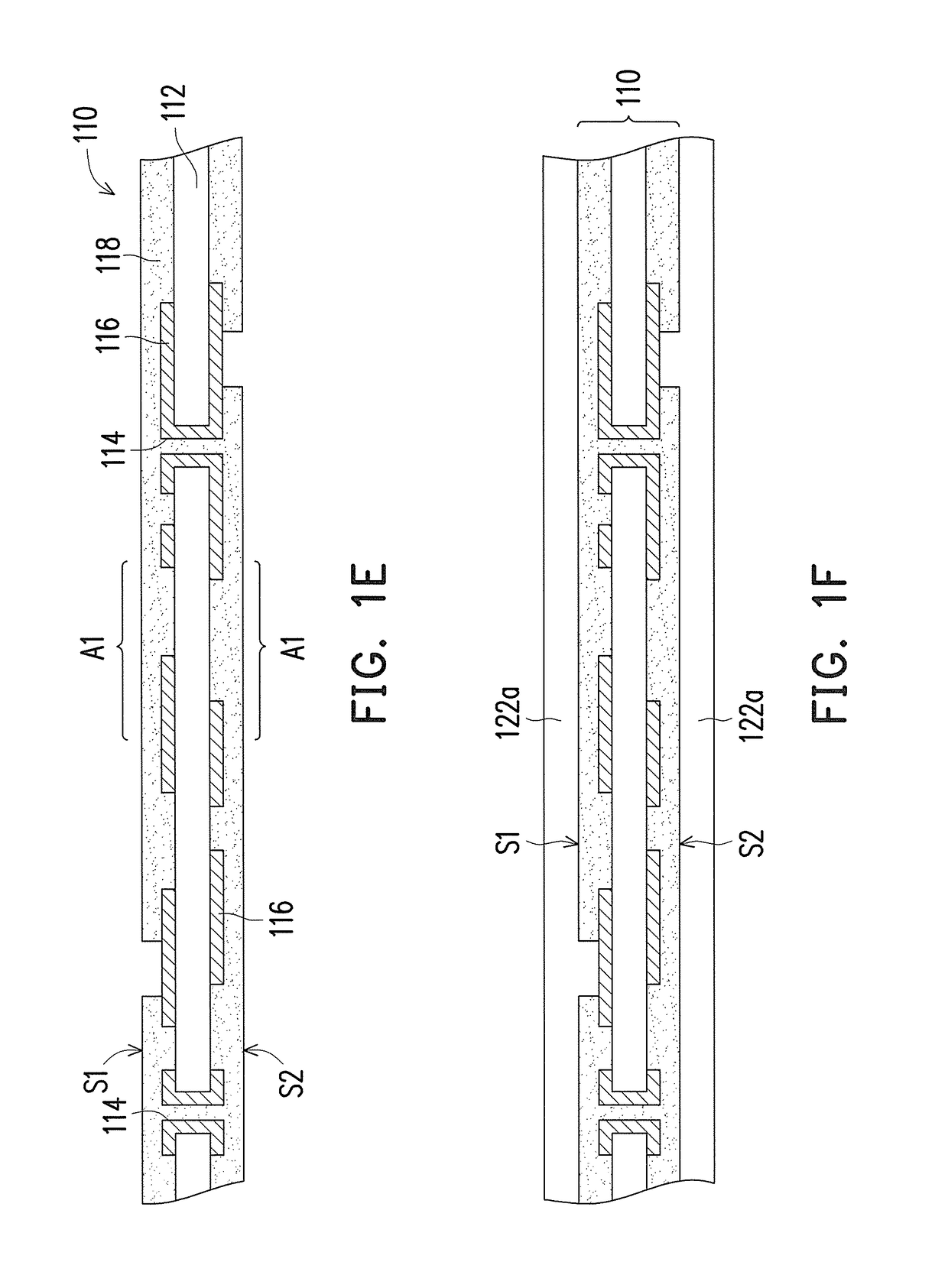

Rigid-flex circuit board and manufacturing method thereof

ActiveUS20170156205A1Improve production efficiencyAvoid damageCircuit bendability/stretchabilityLithography/patterningFlexible circuits

A rigid-flex circuit board includes a flexible circuit board, a plurality of patterned photo-imageable substrates and a plurality of patterned circuit layers. The flexible circuit board includes a plurality of exposed regions, a top surface and a bottom surface opposite to the top surface. The exposed regions are respectively located at the top surface and the bottom surface. The patterned photo-imageable substrates are disposed on the top surface and the bottom surface respectively. Each patterned photo-imageable substrate includes an opening exposing the corresponding exposed region. Each patterned photo-imageable substrate includes photo-sensitive material. The patterned circuit layers are disposed on the patterned photo-imageable substrates respectively and expose the exposed regions. A manufacturing method of the rigid-flex circuit board is also provided.

Owner:UNIFLEX TECH

Popular searches

Diagnostic recording/measuring Sensors External electrodes Chemical vapor deposition coating Circuit susbtrate materials Non-metallic protective coating application Metallic pattern materials Metal/alloy conductors Conductive material removal by irradiation Input/output processes for data processing

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com