Manufacturing method of LED heat radiating substrate and LED module with substrate

A technology of a heat dissipation substrate and a manufacturing method, which is applied to the removal of conductive materials by chemical/electrolytic methods, circuit thermal devices, and printed circuit manufacturing, etc. Small and other problems, to achieve the effect of small thickness, conducive to heat conduction and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

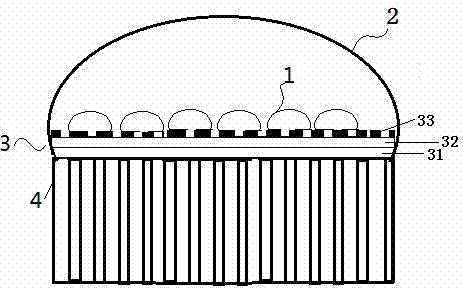

[0021] Such as figure 1 As shown, the LED cooling module described in this embodiment includes an LED lamp bead 1 , a lens 2 , a circuit board 3 and a heat sink 4 . A plurality of LED lamp beads 1 are welded on one side of the circuit board 3, and the LED lamp beads are covered with a lens 2; the heat sink 4 is arranged on the other side of the circuit board, and is closely combined with this side of the circuit board to realize heat dissipation.

[0022] In this embodiment, the circuit board is mainly used to quickly conduct the heat generated when the LED emits light to the heat sink, and then dissipate it through the heat sink, so as to reduce the junction temperature of the LED as quickly as possible and prolong its service life. The production of the circuit board adopts a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com