Manufacturing method of fine circuit of printed-circuit board

A technology for printed circuit boards and fine lines, applied in the fields of printed circuit manufacturing, printed circuits, electrical components, etc. Line grooves and other problems, to achieve the effect of regular shape, line width matching, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] A method for manufacturing fine lines of a printed circuit board, comprising the following steps:

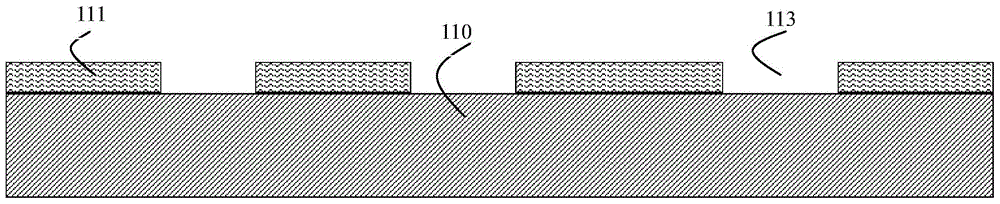

[0032] Step 1: paste the first dry film 111 on the surface of the copper-free substrate 110, and then perform exposure and development to obtain fine circuit grooves 113, such as figure 1 shown;

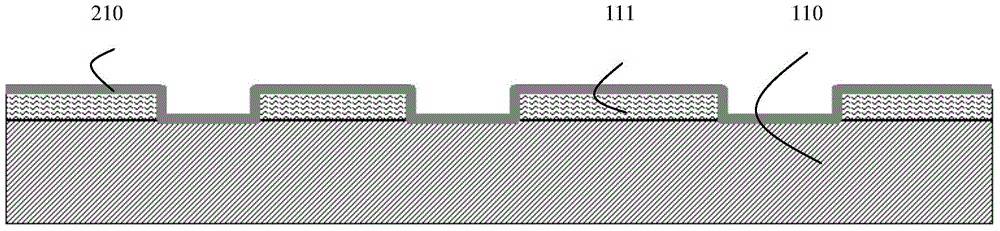

[0033] Step 2: Copper plating is performed on the surface of the base material treated in step 1, so that the upper surface of the first dry film 111 and the inner surface of the fine line groove 113 form a copper seed layer 210, such as figure 2 shown;

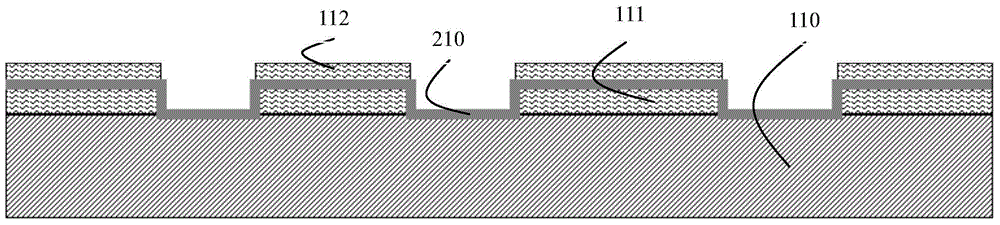

[0034] Step 3: Paste the second dry film 112 on the surface of the copper seed layer obtained after the treatment in step 2, and then perform exposure and development treatments to expose the fine line groove 113, such as image 3 shown;

[0035] Step 4: Carry out electroplating and copper filling treatment on the base material treated in step 3, and fill the fine line groove 113, such as Figure 4 shown;

[0036] Step 5:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com