Patents

Literature

77results about How to "Reduce line spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

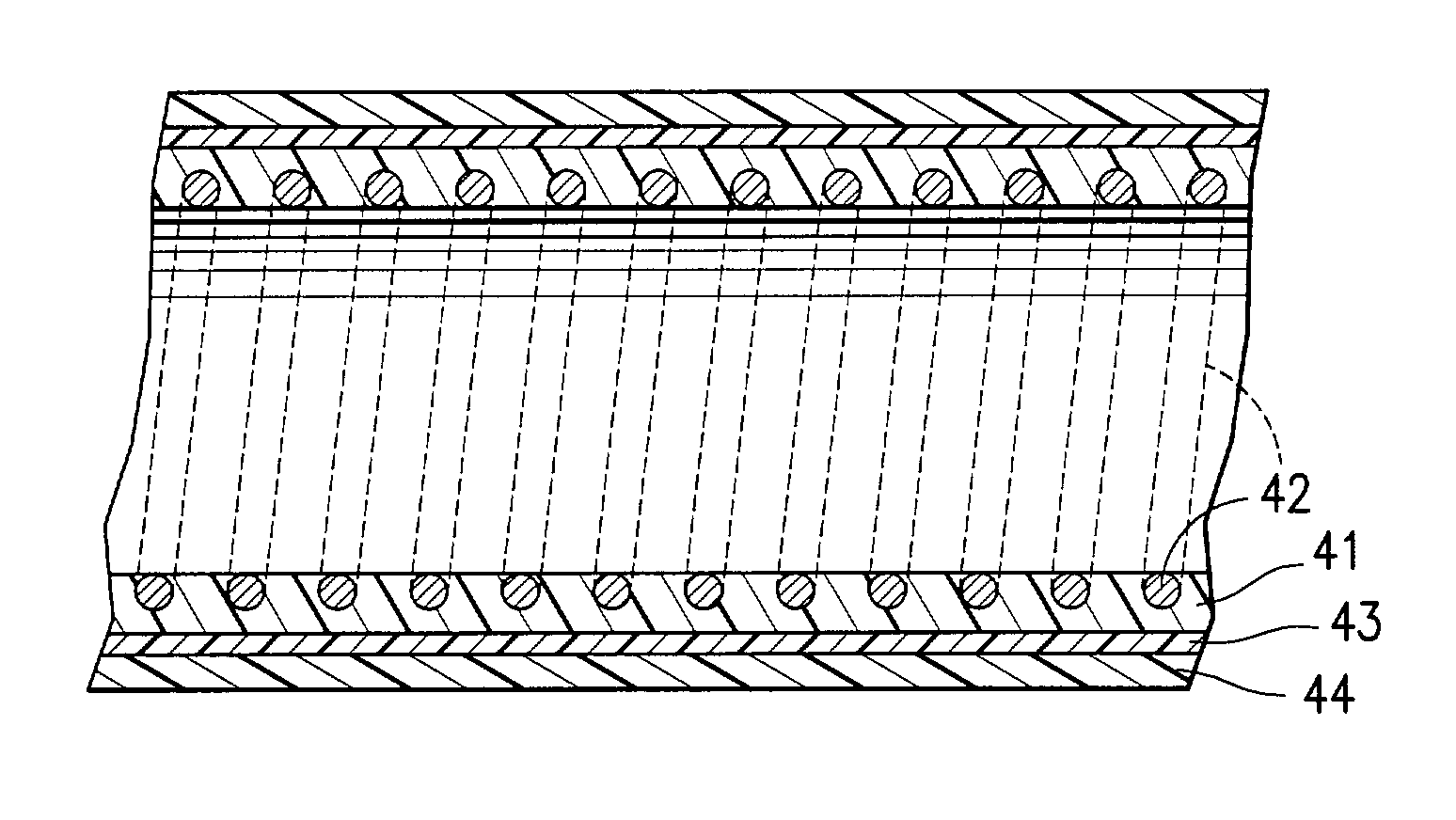

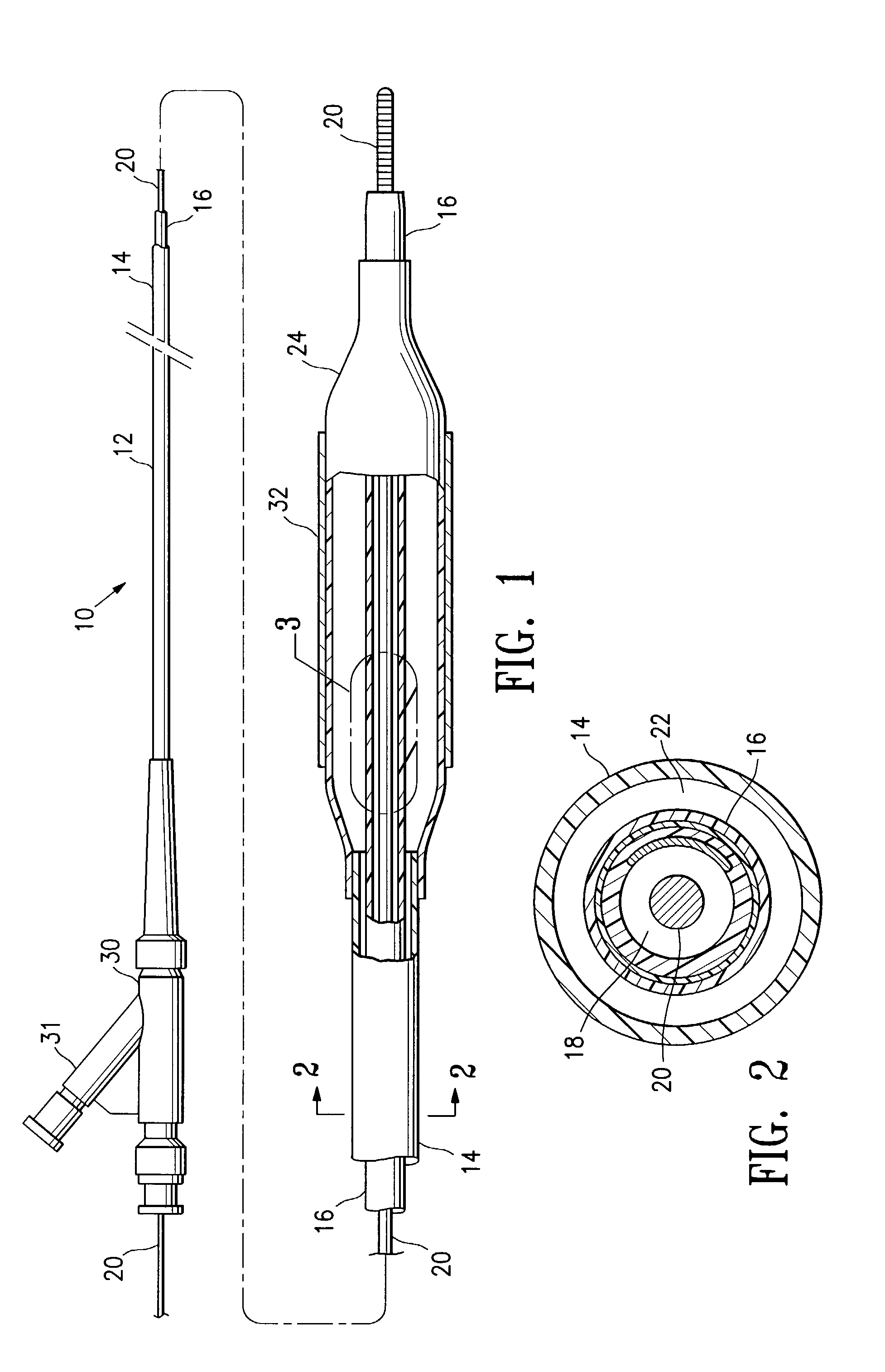

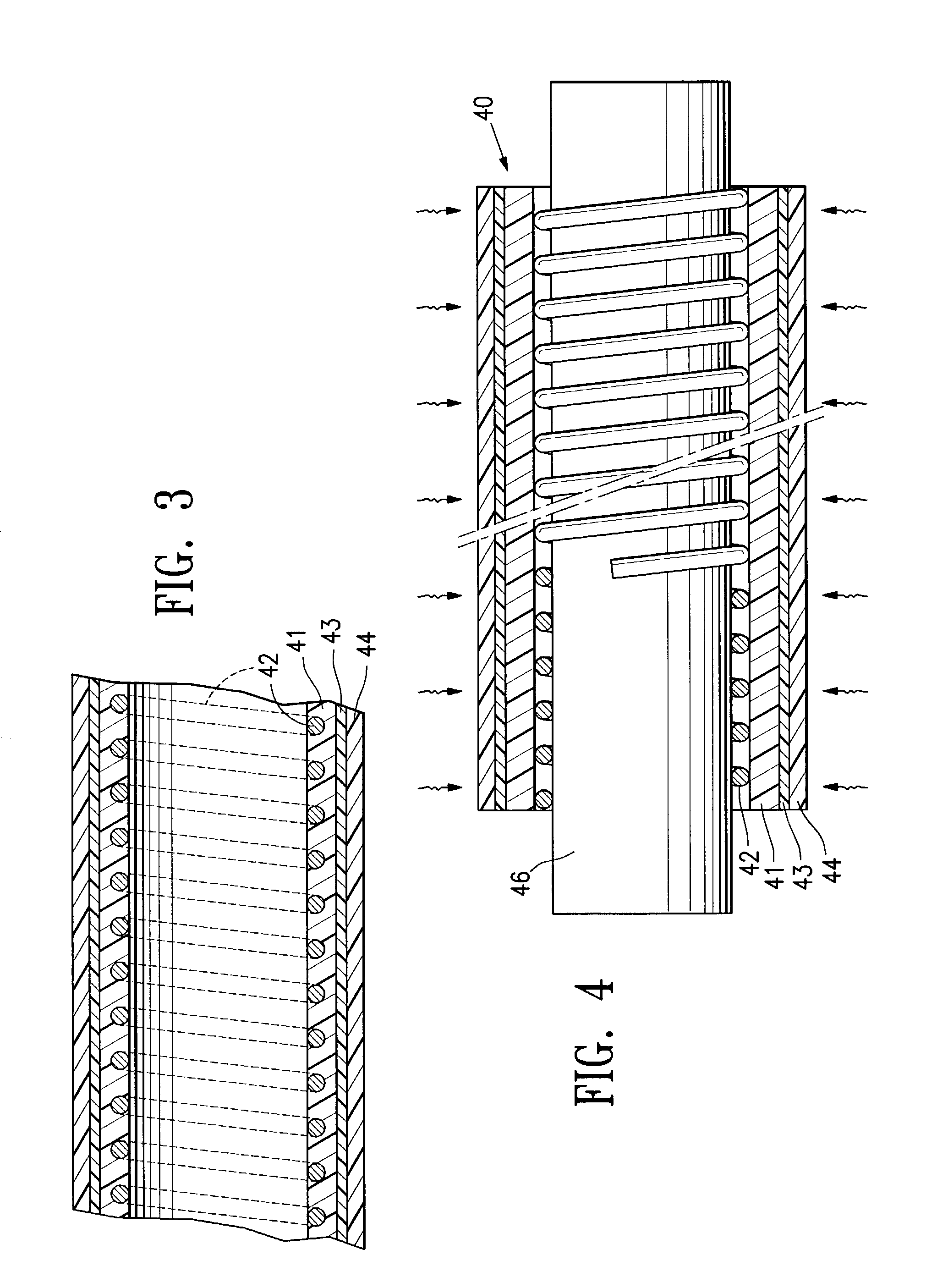

Coil reinforced multilayered inner tubular member for a balloon catheter

A catheter having an elongated shaft formed of a polymeric tubular member with at least a section having a lubricious inner layer defining the guidewire lumen, a coiled support member at least partially embedded in the lubricious inner layer, and an outer layer on an outer surface of at least a distal portion of the lubricious inner layer. In a presently preferred embodiment, the coil supported polymeric tubular member forms an inner tubular member of a balloon catheter.

Owner:ABBOTT CARDIOVASCULAR

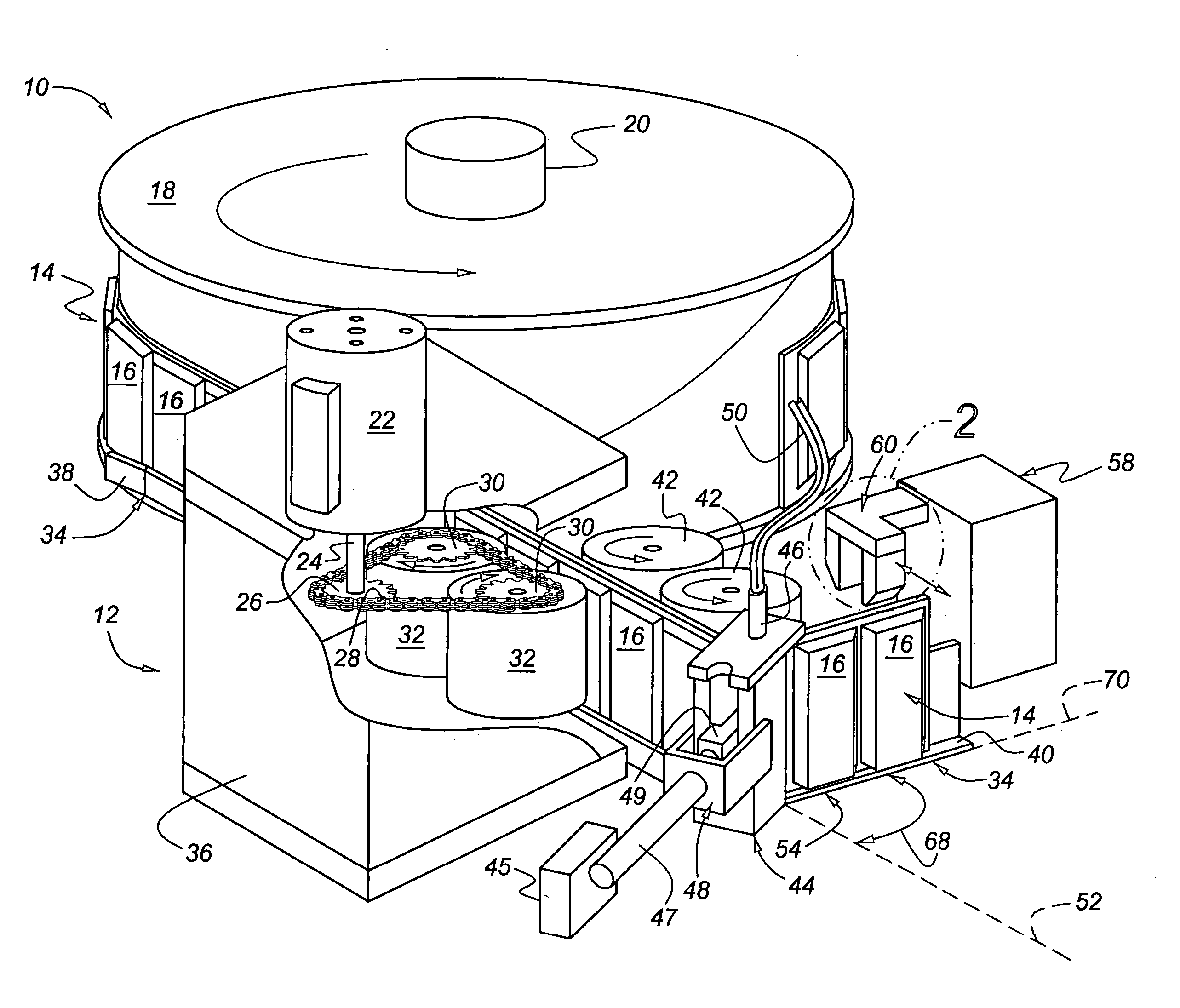

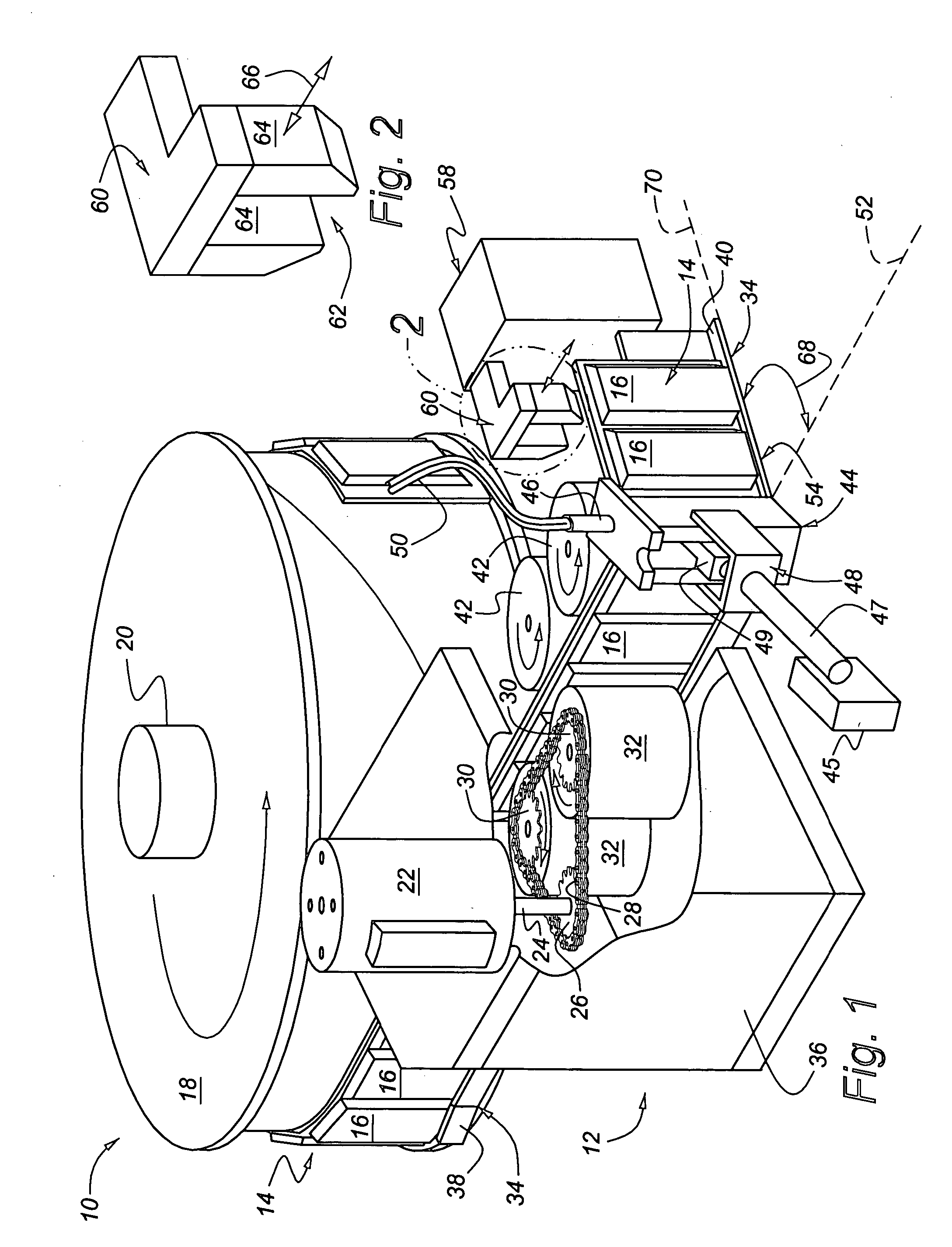

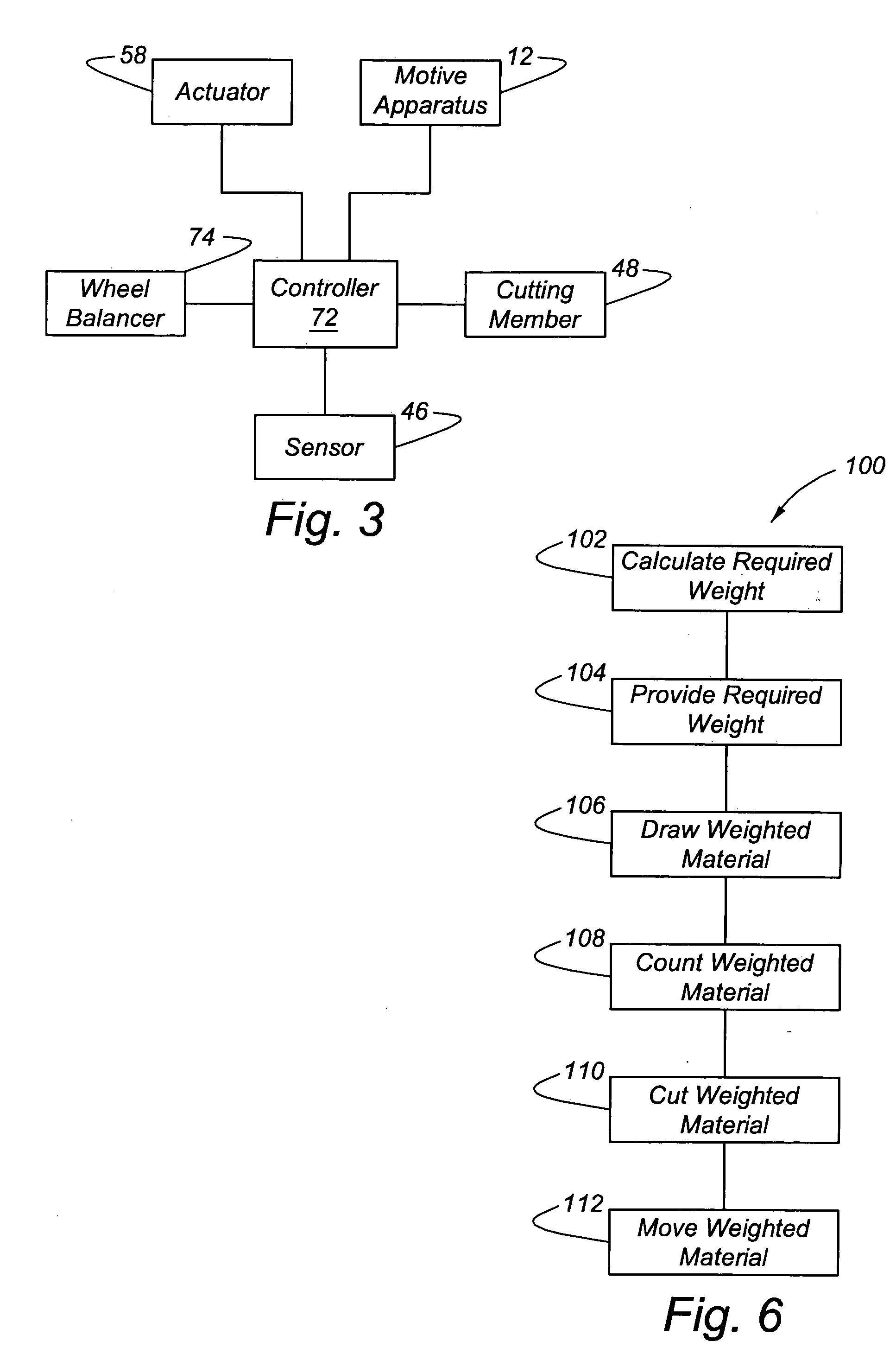

Adhesive wheel weight dispensing apparatus

InactiveUS20060016309A1Reduce potential errorReduce container spaceStatic/dynamic balance measurementGang saw millsEngineeringMechanical engineering

An apparatus for dispensing a predetermined amount of adhesive weighted tape includes a controller adapted to receive a request for a desired amount of adhesive weighted tape and an elongated track member adapted to receive a supply of the adhesive weighted tape. A sensor is mounted adjacent a second end of the track member. The sensor in communication with the controller is operable to transmit a signal to the controller corresponding to a measured amount of weighted tape passing thereby. A motive apparatus in communication with the controller is adapted to move the weighted tape from a first end to the second end of the track member in response to the signal from the sensor. A cutting member disposed adjacent the second end of the track member is in communication with the controller and is adapted to cut the weighted tape in response to the signal from the sensor.

Owner:GM GLOBAL TECH OPERATIONS LLC

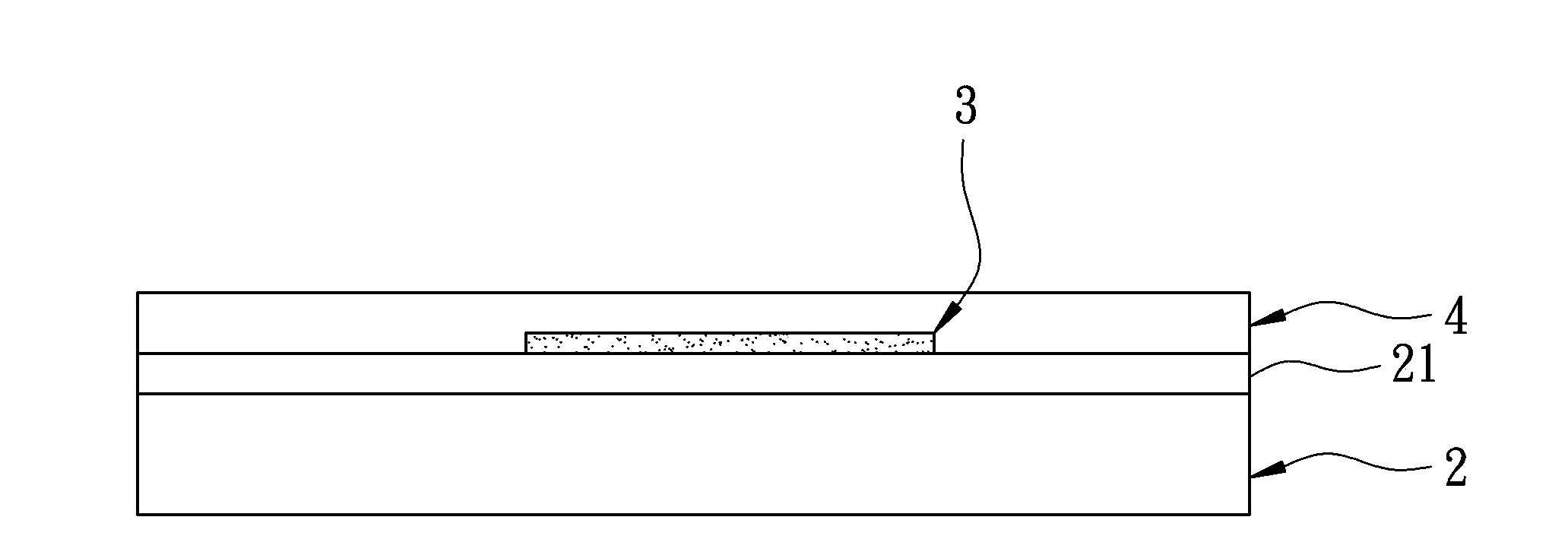

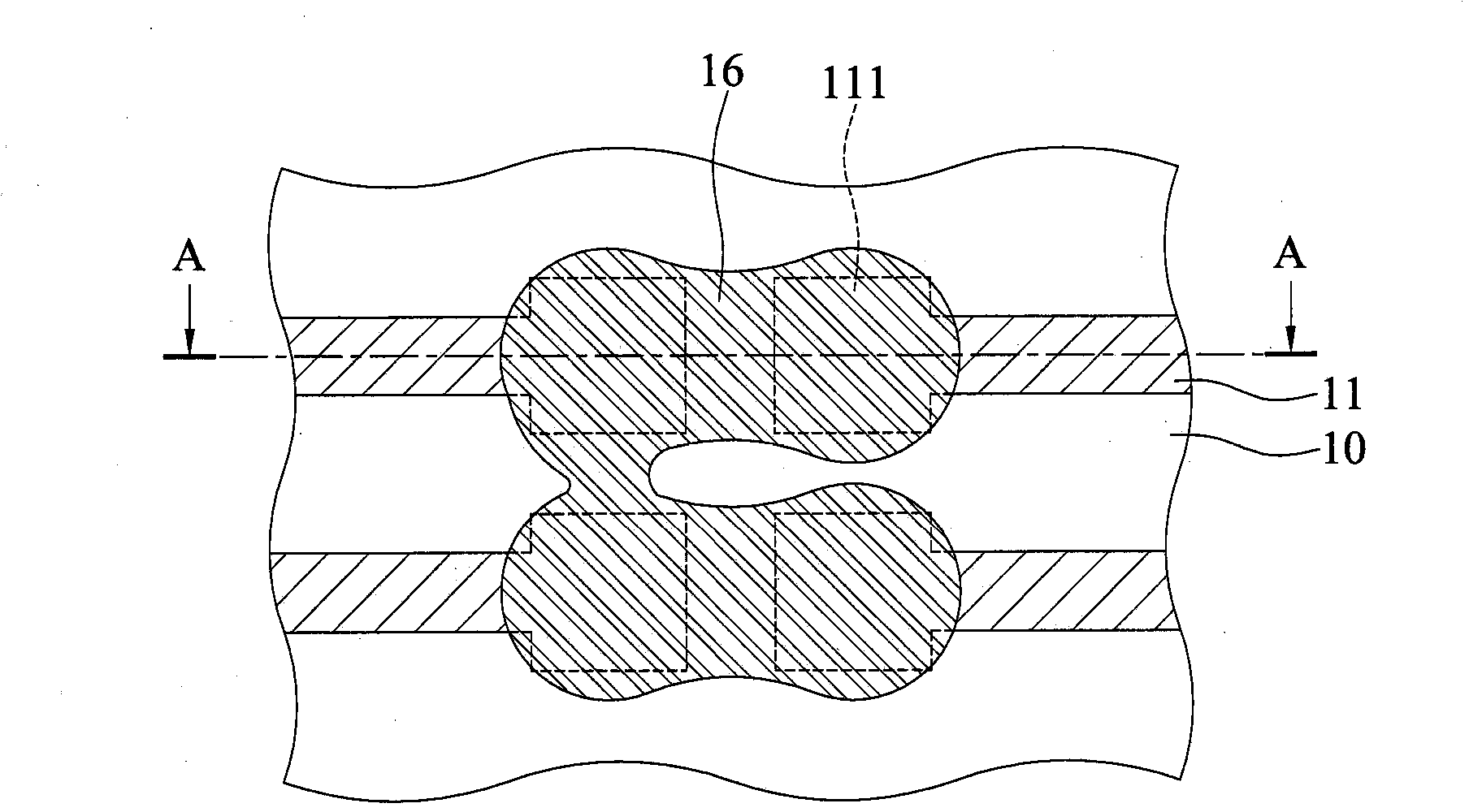

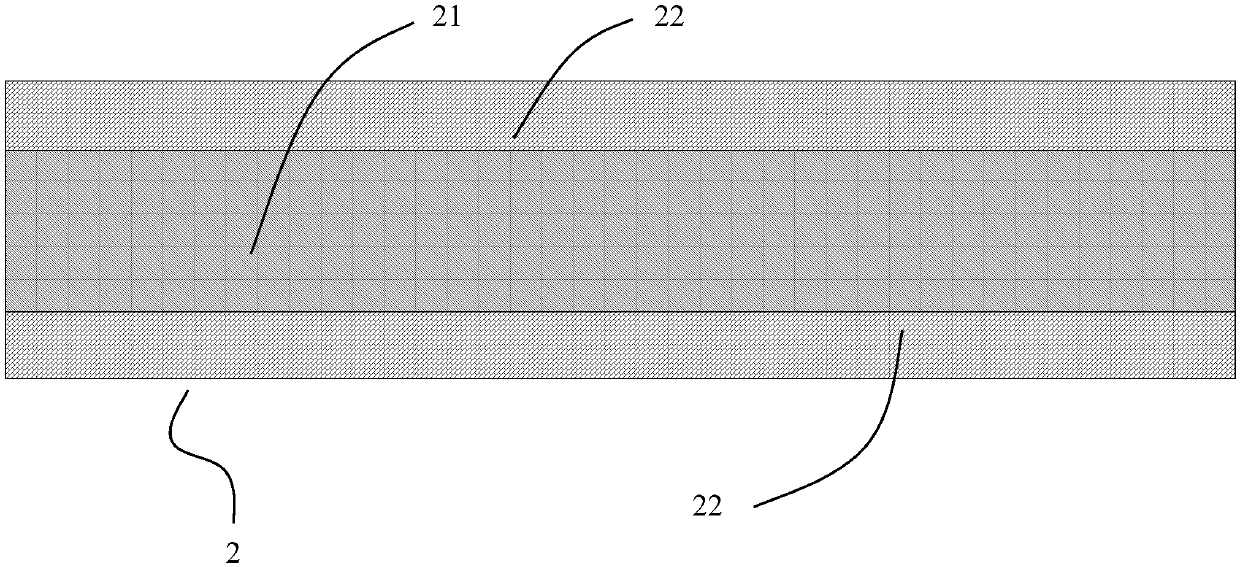

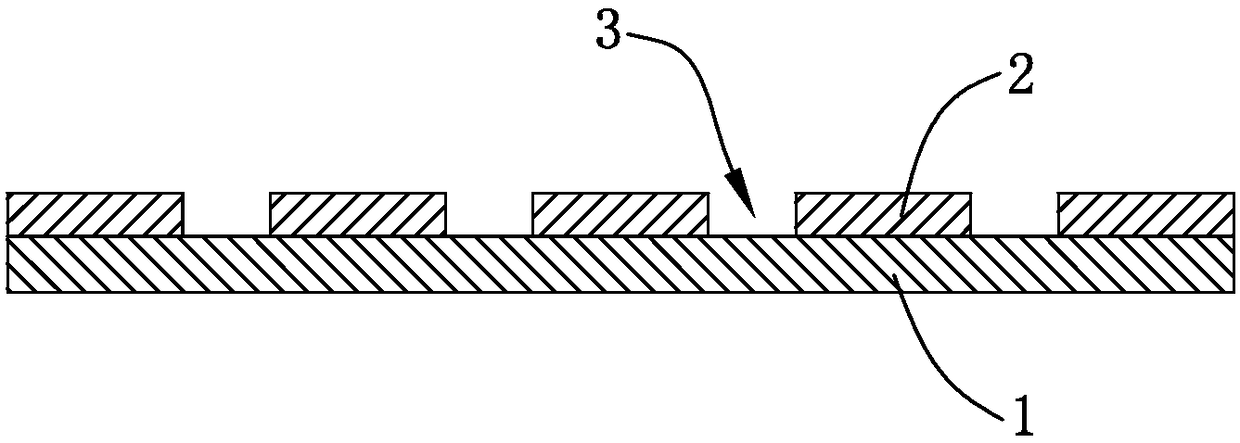

Manufacturing method for touch panel edge wire routing, touch panel and touch display device

InactiveCN103384451AAvoid bad situationsBad or error signal goodConductive material chemical/electrolytical removalInput/output processes for data processingTouch panelSurface smoothness

The invention provides a manufacturing method for touch panel edge wire routing, a control panel with the edge wire routing and a touch display device. The manufacturing method comprises the following steps of (a) forming a photosensitive conductive paste layer on an edge area of a substrate with a transparent conductive layer, enabling the photosensitive conductive paste layer to be at least in partial overlapping with the transparent conductive layer, (b) exposing the photosensitive conductive paste layer by using a mask, and (c) carrying out developing on the exposed photosensitive conductive paste layer to form a patterning edge wire routing unit on the edge area of the substrate. The manufacturing method is beneficial to improving the precision of a wire route under the situation that the wire width of the edge wire routing is narrowed, and can enable the wire route to have good surface smoothness.

Owner:INNOCOM TECH SHENZHEN +1

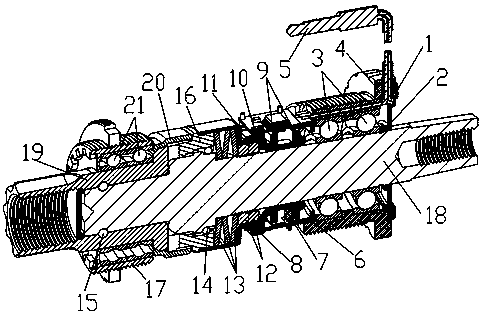

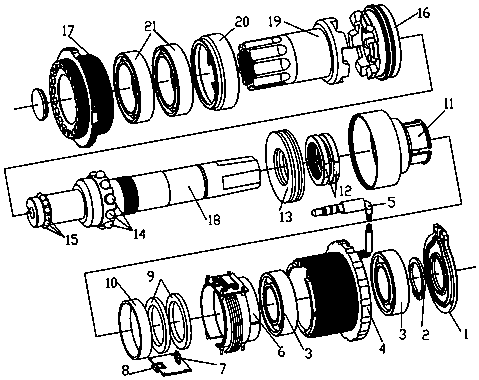

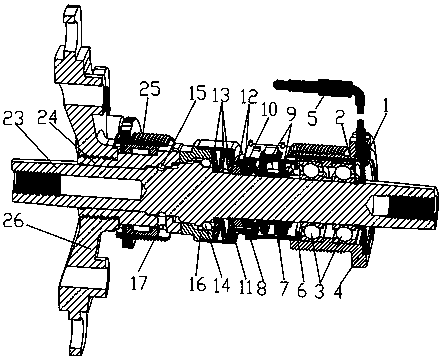

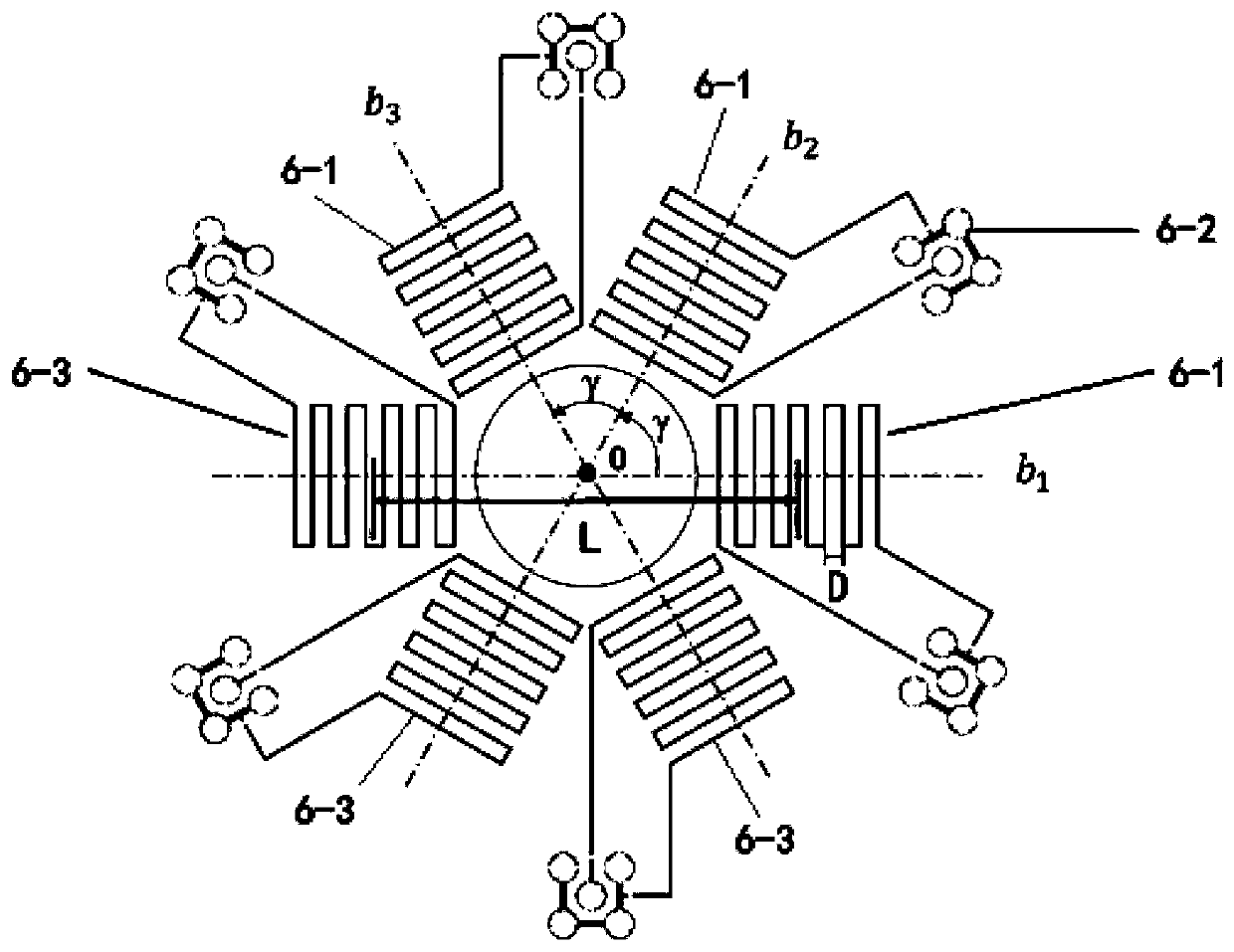

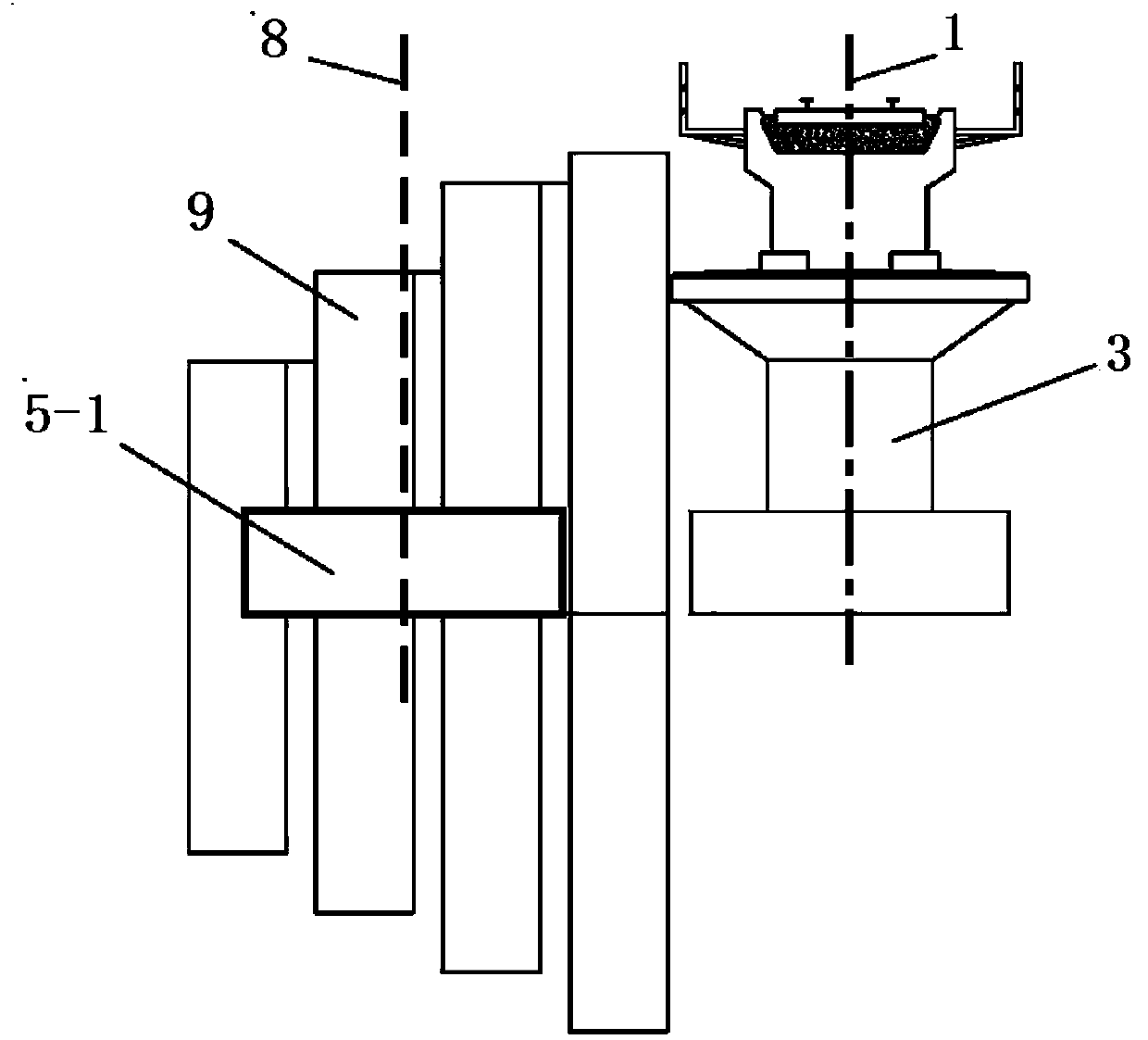

Bicycle assisting force system adopting middle-axis torque sensor

ActiveCN105711727AReduce manual operationsReduce line spacingOptical signalCycle sensorsNeedle roller bearingKey pressing

The invention discloses a bicycle assisting force system adopting a middle-axis torque sensor. With the adoption of the system, a torsion moment, a rotary speed and a direction of a middle axis are measured by adopting the middle-axis torque sensor; after code table treatment, a voltage signal, which is the same as that of an electronic rotary handle of an electric vehicle, is output to a motor driver; and corresponding power is output by a wheel hub motor, and the power and a treading torque form a proportional assisting force. A torque input end with a first type of structure is a tapered semi-axis and a spline semi-axis is a torque output end; and a limiting ring and a semi-axis spherical bearing are further included. A second type of structure adopts two ends of the tapered middle axis to input torques; a torque output end is a thread semi-axis; and a rolling needle bearing and sprocket wheel four jaws are further included. The assisting force system disclosed by the invention is strong in stability and is suitable for various types of bicycle types; and the assisting force can be effectively provided for the bicycle, and an assisting force gear is set by reversely treading for a pre-set angle by a foot or pressing a key of a code table by a hand in a riding process.

Owner:钟德斌

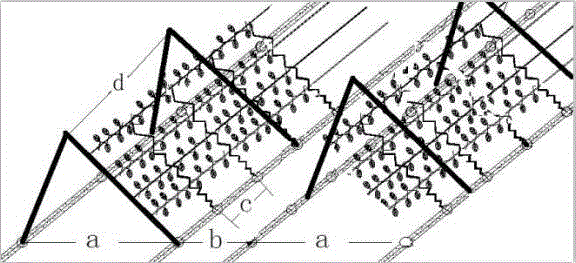

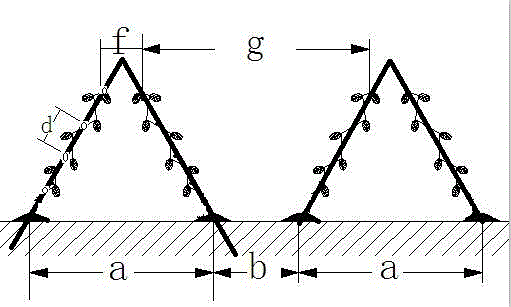

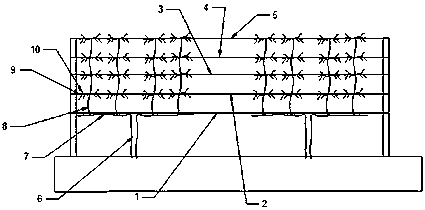

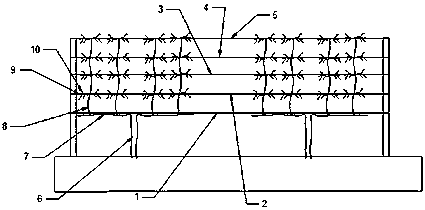

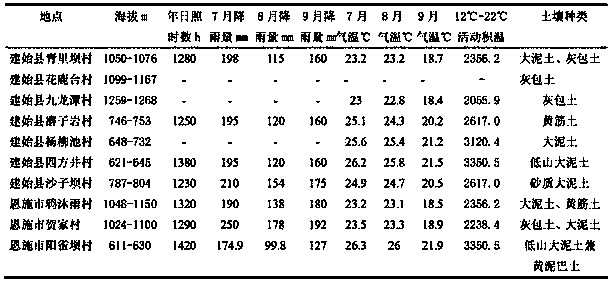

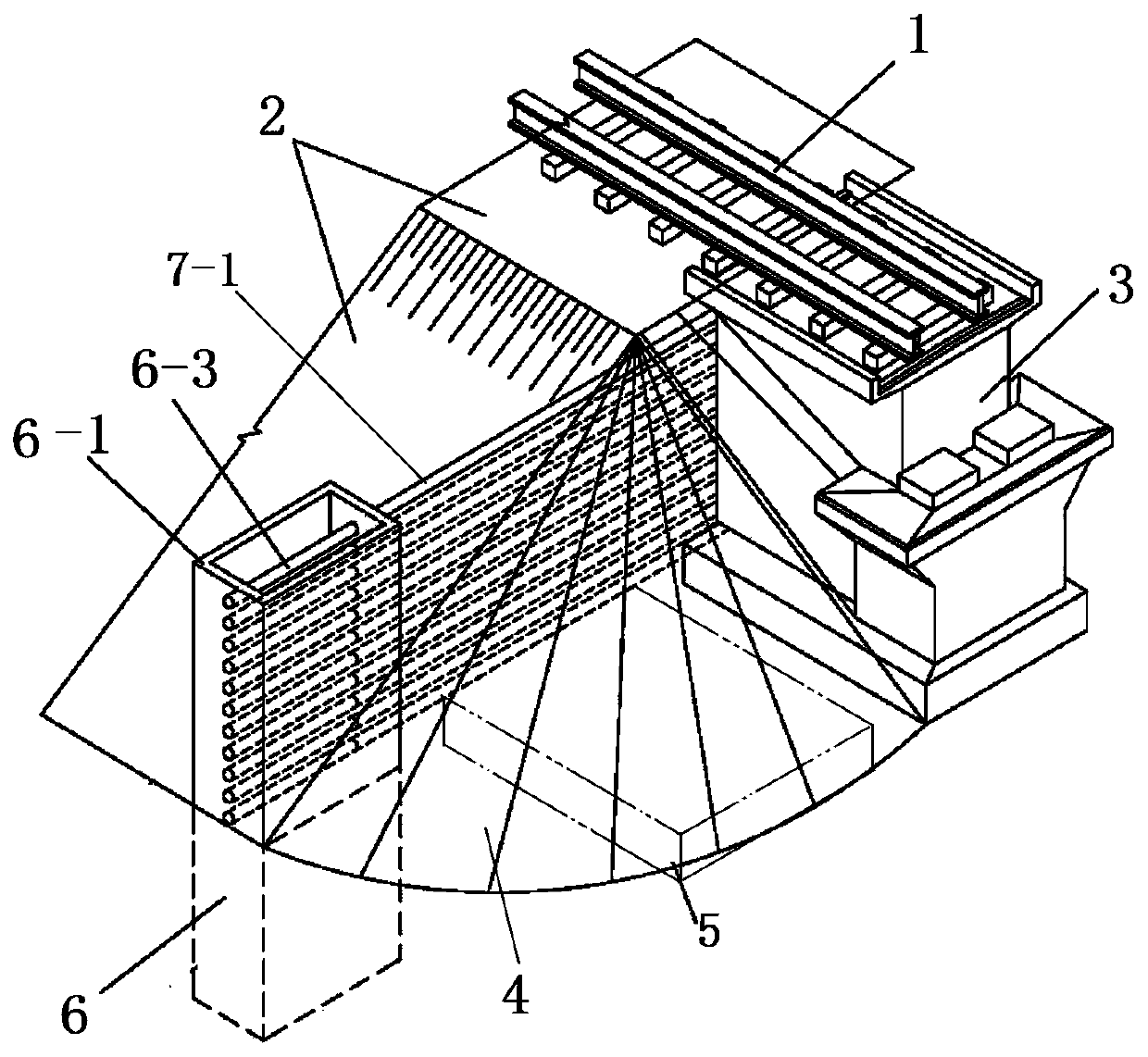

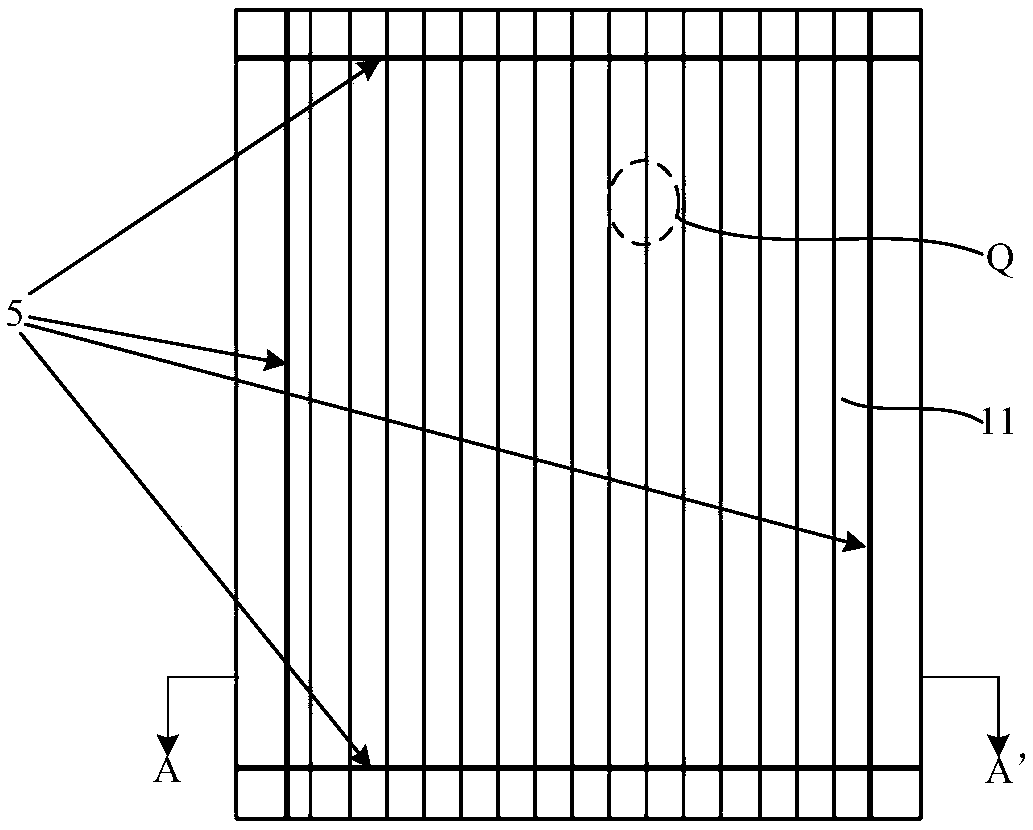

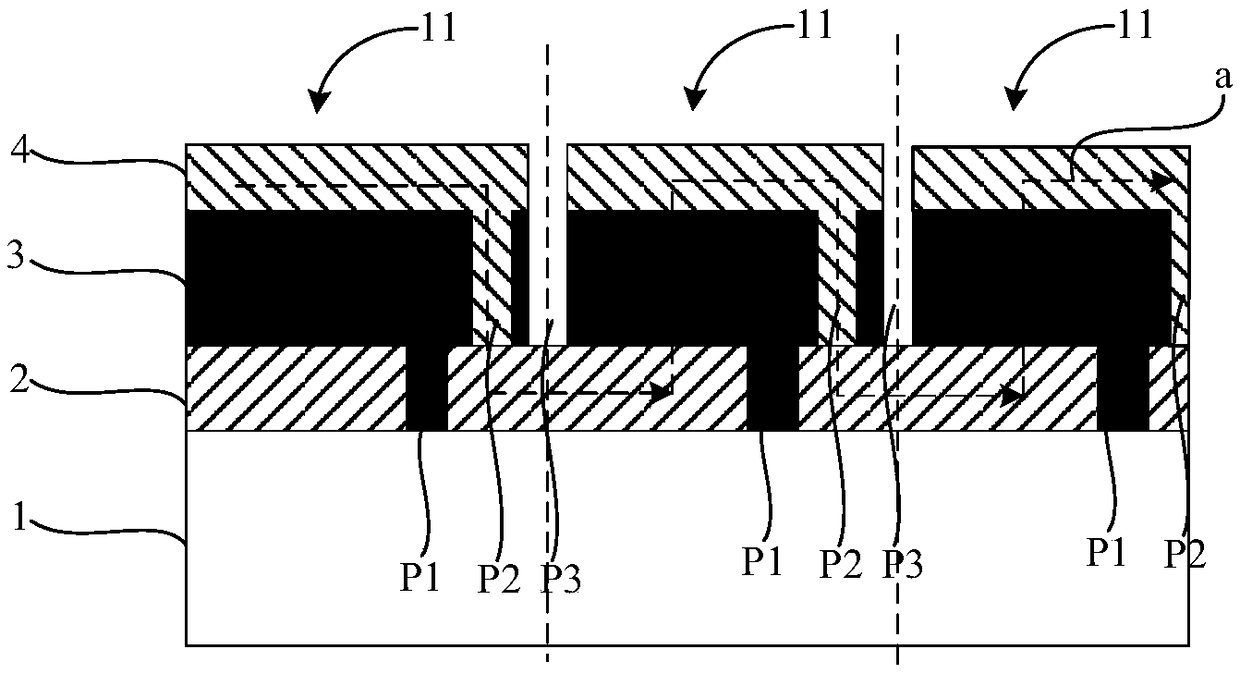

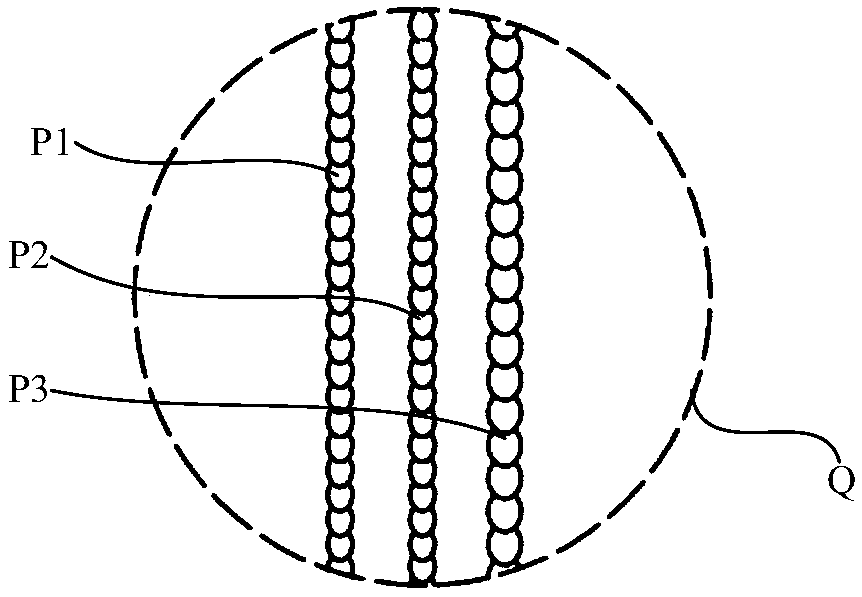

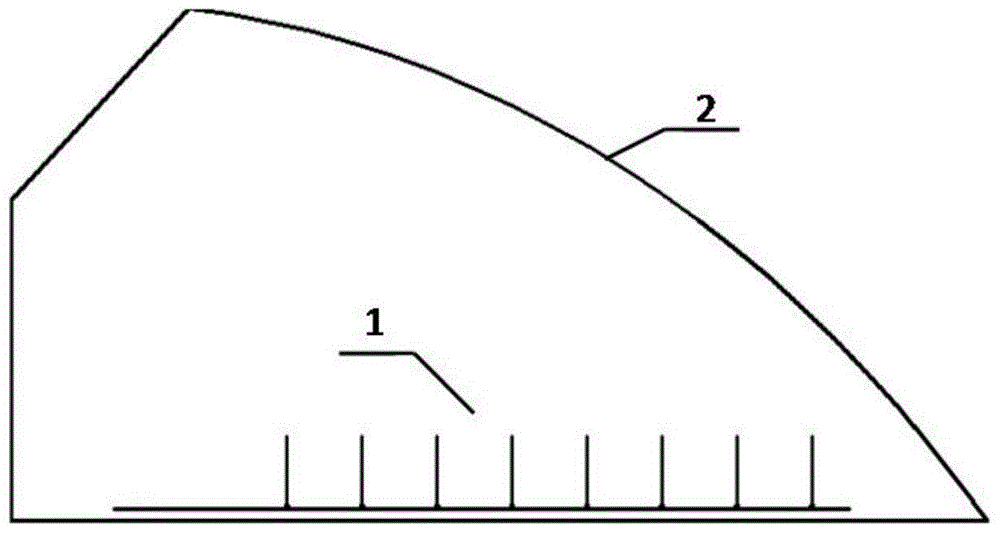

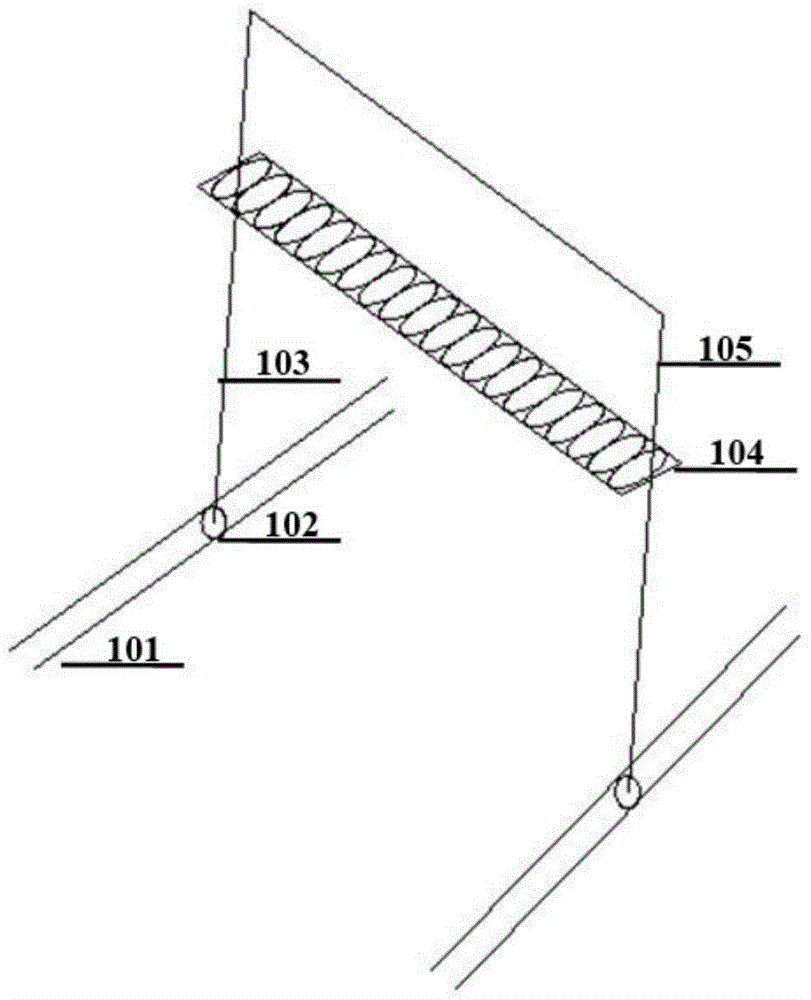

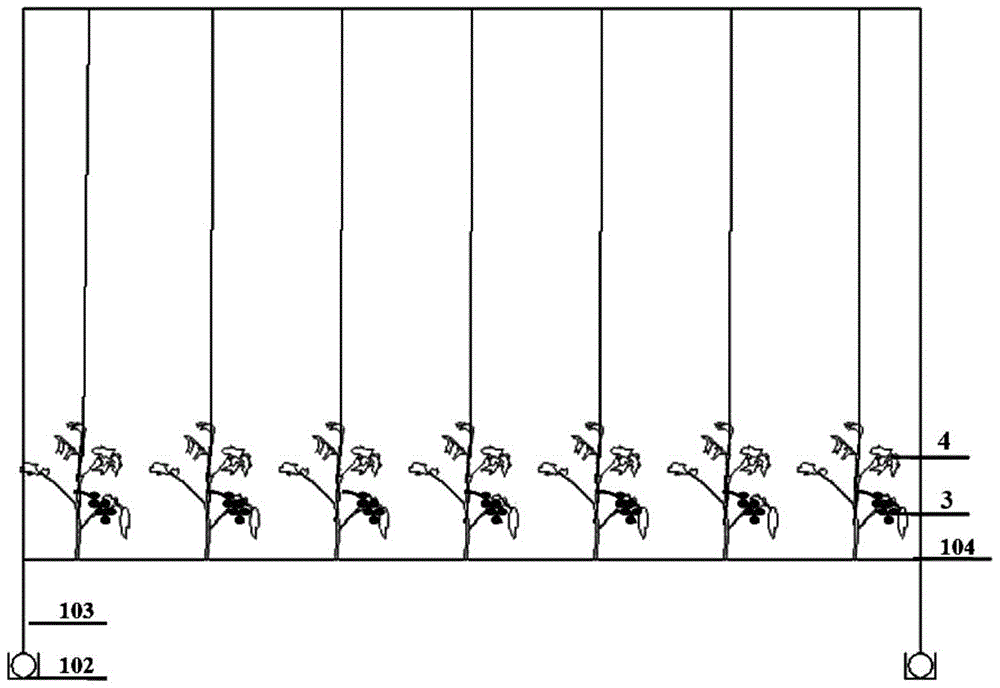

New method for wide and narrow row and compact planting of kiwi fruits by adopting tilting trellises

InactiveCN105594542AMethod scienceSimple and fast operationCultivating equipmentsEcological environmentActinidia

The invention relates to a new method for wide and narrow row and compact planting of kiwi fruits by adopting tilting trellises. The kiwi fruits are planted in wide and narrow rows, and tilting trellises are built along the rows; in each wide row, a plurality of column units are arranged; each column unit consists of two vertical columns with the same length; the two columns tilt towards each other between the wide rows, and the upper ends of the two vertical columns intersect to form a herringbone; the column units in two adjacent rows are equidistantly arranged in a staggered way; four iron wires are equidistantly arranged vertically on the tilting vertical columns in each row for the kiwi fruits to climb; only trunks of the kiwi fruits climb onto the trellises, and a single-arm four-layer or two-arm four-layer shaping technology is adopted; through herringbone intersections at the upper ends of the column units, an intersect parallel iron wire mesh is formed in vertical and horizontal directions, and the iron wire mesh is covered by a wind-proof and sunlight-shading net or a brightening and cold-proof film. Compared with the prior art, the new method has the advantages as follows: the planting density is more reasonably increased, the population structure is more scientifically improved, the utilization rate of light energy is more effectively improved, ecological resources are more fully utilized, and production targets of high yield, high quality and high efficiency are achieved.

Owner:张恩祥

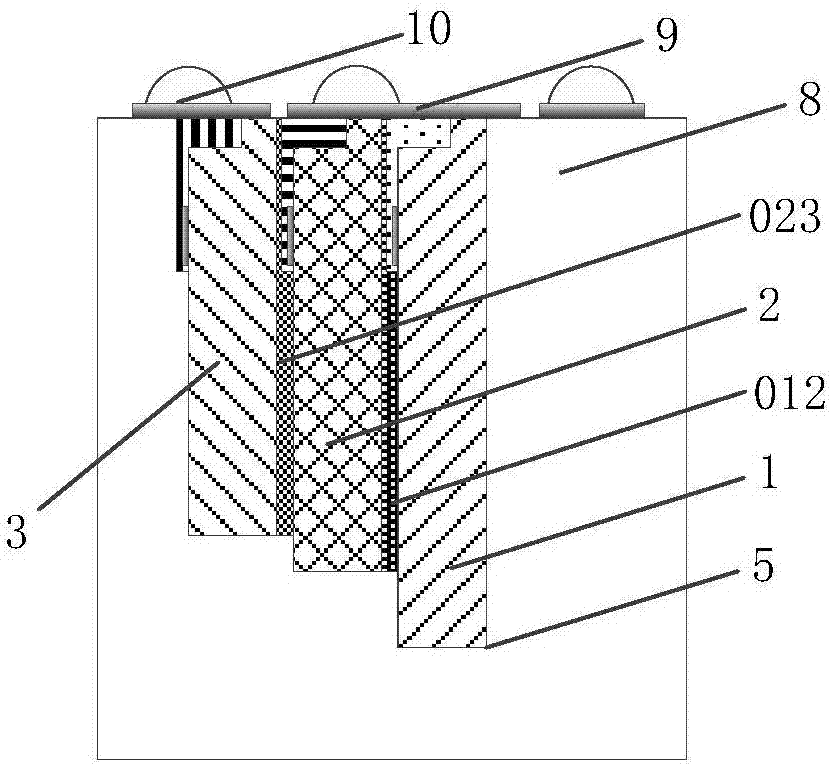

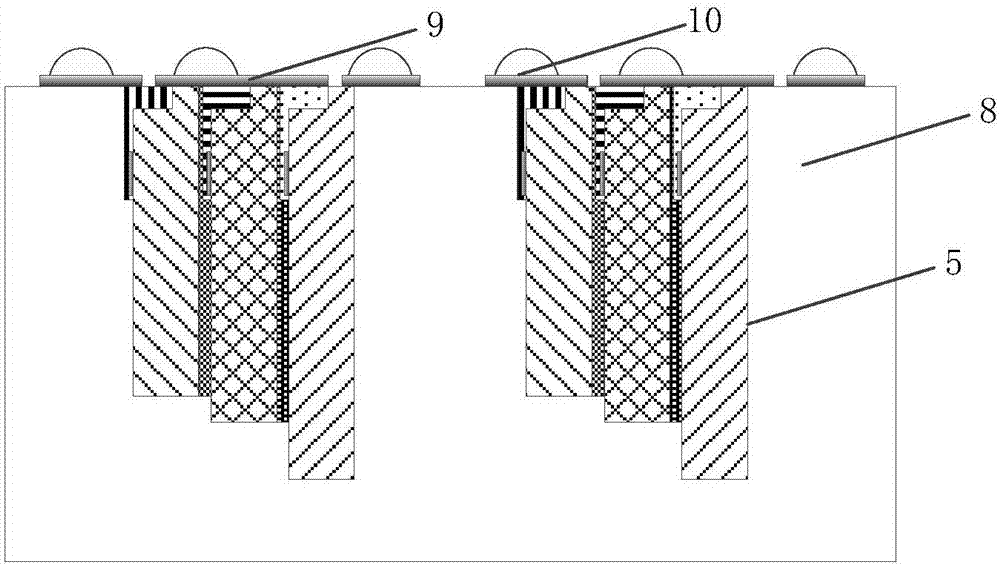

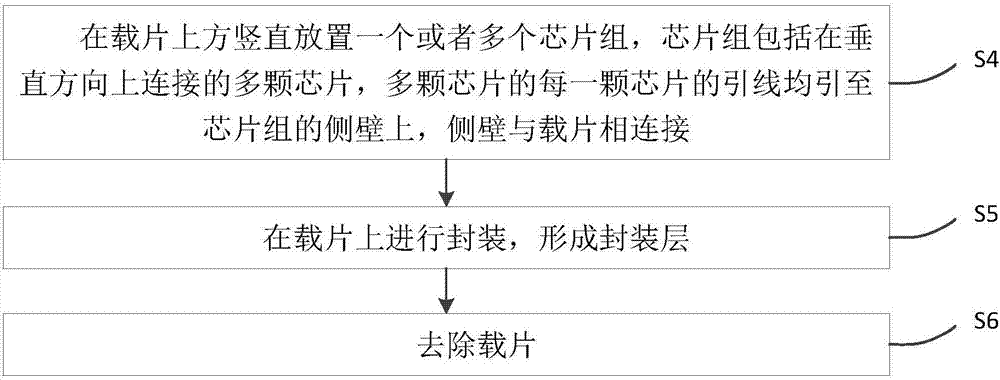

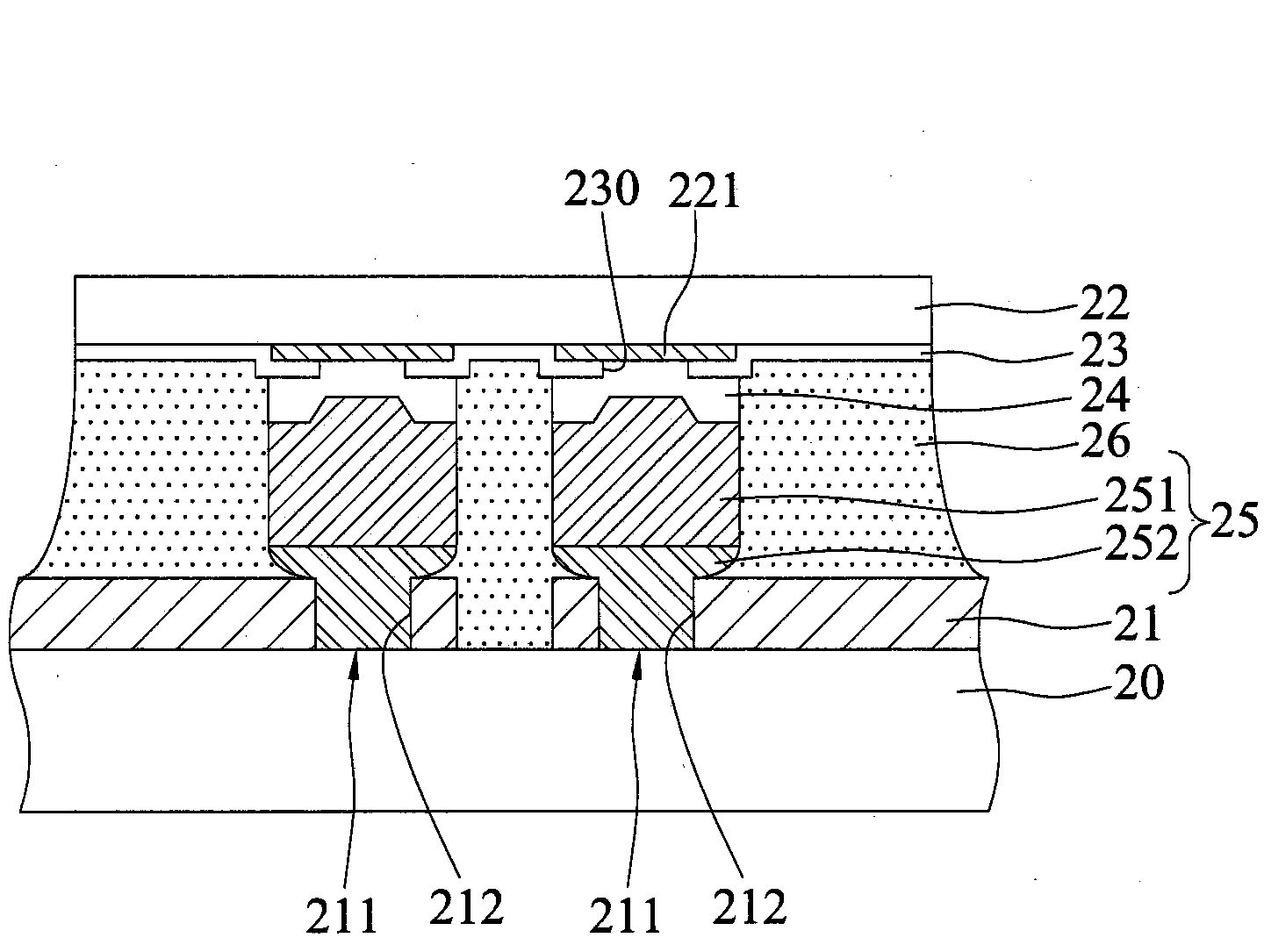

Semiconductor device package structure and package method

InactiveCN108010906AImprove reliabilityReduce package sizeSemiconductor/solid-state device detailsSolid-state devicesPerpendicular directionSemiconductor

The invention provides a semiconductor device package structure and package method. The package structure comprises a chip group, wherein the chip group is arranged in a package layer and comprises aplurality of chips, the plurality of chips are connected in a perpendicular direction, a lead of each chip in the plurality of chips is arranged on a side wall of the chip group, and a side wall is exposed out of the package layer. The lead of each chip in the chip group is connected to the side wall of the chip group from a bonding pad, the lead is connected from the side wall, the line distanceamong chips is reduced, so that a signal is more rapidly transferred, and various TSV double-side processes are prevented; and the semiconductor device is high in reliability, small in package size, good in integral performance, simple in fabrication process and high in production efficiency.

Owner:SHANGHAI XIANFANG SEMICON CO LTD

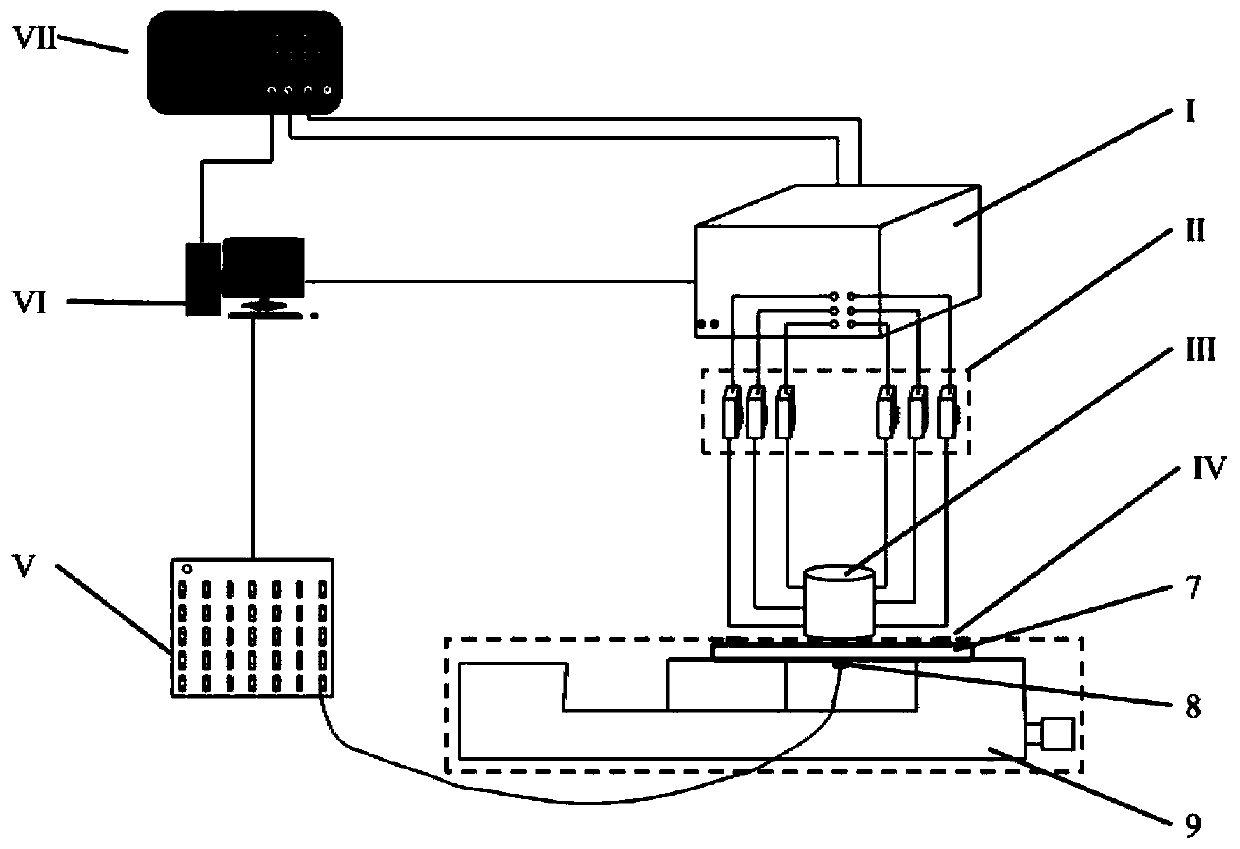

Electromagnetic ultrasonic detection method for plane residual stress

ActiveCN110632177AReduce spacingImprove spatial resolutionAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationPrincipal stress

The invention relates to an electromagnetic ultrasonic detection method for plane residual stress, belongs to the technical field of ultrasonic detection, and relates to an electromagnetic ultrasonicdetection system and detection method for plane residual stress. The method comprises the steps of: firstly, assembling the electromagnetic ultrasonic detection system, and measuring stress detectionultrasonic signal waveforms in three directions by using ultrasonic coils in an electromagnetic ultrasonic surface wave probe so as to calibrate an acoustic elastic coefficient of a material. The surface wave signals in three directions of a point to be measured are collected, and the magnitude and direction of plane stress are calculated by using an ultrasonic detection theoretical formula. In the method, one-time positioning of the two principal stresses in the plane stress state and the included angle between the two principal stresses, and simultaneous measurement of multiple parameters are realized by using the surface wave probe with the function of three-transmitting and three-receiving. The distance between receiving and transmitting probes is reduced and the spatial resolution ofthe probe are improved by reducing the turns per coil, the line width and the line distance of ultrasonic transmitting and receiving coils. A circuit board and an impedance matching network are connected by using a radio frequency connector, thereby facilitating the installation and repeated use for multiple times, the detection method is simple, and the efficiency is high.

Owner:DALIAN UNIV OF TECH

Shaping and pruning method for plum trees and apricot trees

ActiveCN111108949AIncrease productionSmall footprintCultivating equipmentsHorticulture methodsFruit treeAlcohol sugars

The invention relates to the technical field of fruit farming, in particular to a shaping and pruning method for plum trees and apricot trees. According to the shaping and pruning method for plum trees and apricot trees, the first year growth period: seedlings are planted in autumn or early spring, and primary main branches are cultivated; the first year dormancy period: secondary main branches are cultivated; the second year growth period: the secondary main branches are established; the second year dormancy period: lateral branches are cultivated; the third year growth period: the lateral branches are established; the third year dormancy period: fruiting branches are cultivated; overdense weak branches of the primary main branches, the secondary main branches and the lateral branches aresparsely separated from the base, leaving a short cut of 2-5 cm when over 1 / 2 of the thickness of a raw branch; in the fourth year of growth, potassium dihydrogen phosphate and sugar alcohol boron are sprayed once in June and July respectively to ensure flower buds differentiation in summer and fruit bearing in the next year; and in the fourth year of dormancy, tree shape is kept, and excessive branches and overdense branches disturbing the tree shape are removed to ensure that the thickness of branches is progressively reduced. The shaping and pruning method can make full use of cubical space, save land resources and prone to managing.

Owner:SICHUAN AAS HORTICULTURE RES INST

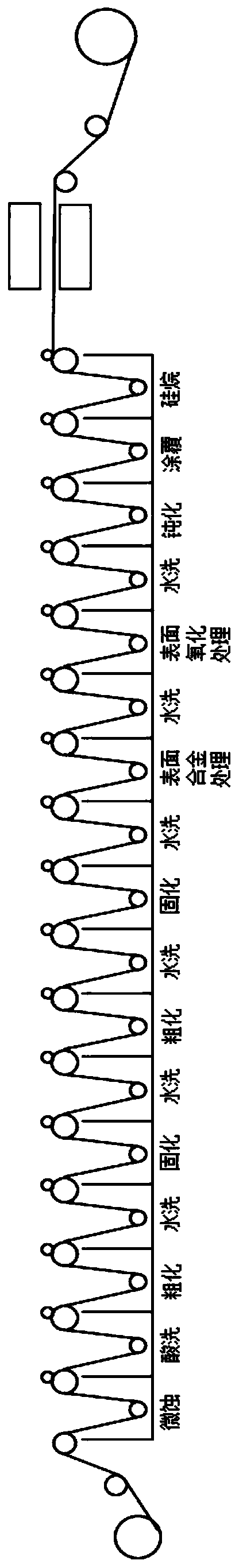

Reversal copper foil production process

InactiveCN111424294AGuaranteed elongationReduce ridgesElectroforming processesPolyester coatingsPtru catalystElectrolysis

The invention relates to a reversal copper foil production process, belonging to the technical field of electrolytic copper foils. The process comprises electrolysis of raw foil and surface treatment,wherein the surface treatment comprises microetching, acid pickling, roughening, washing, curing, washing, roughening, washing, curing, washing, surface alloying treatment, washing, surface anti-oxidation treatment, washing, passivation, applying of an anti-sticking film on a rough surface, silanization treatment, and drying; the applied anti-sticking film comprises the following components according to the weight percentage: 35.5-46 wt% of organochlorosilane, 27.8-33 wt% of organopolysiloxane resin, 12.7-20.1 wt% of aminosilane, 10.2-12.2 wt% of polyester resin, and 2-8.2 wt% of acid carclazyte catalyst; and the applied anti-sticking film has the thickness of 3 micrometers. The production process can reduce the residual copper rate on the surface of a copper foil while ensuring the bonding force between the surface of the copper foil and an etching resist, and ensures the elongation rate of the copper foil.

Owner:惠州联合铜箔电子材料有限公司

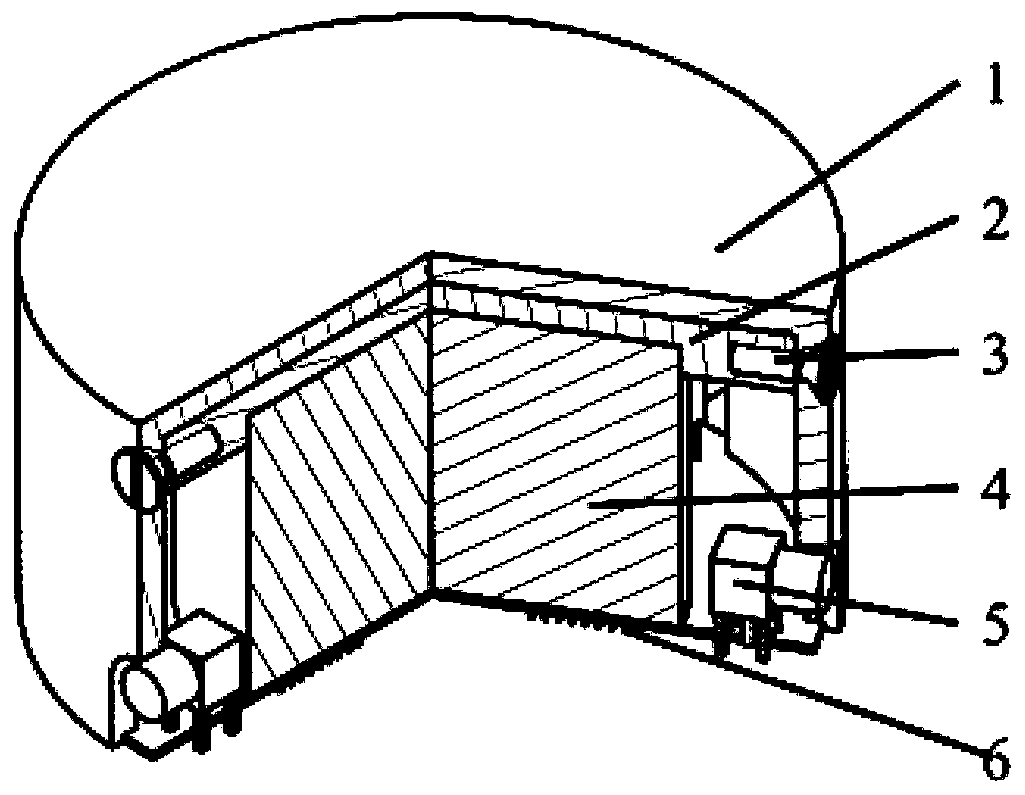

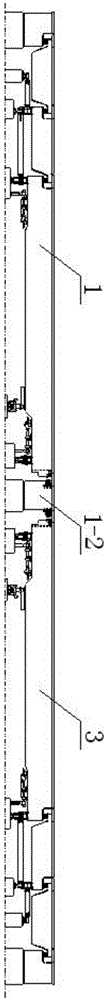

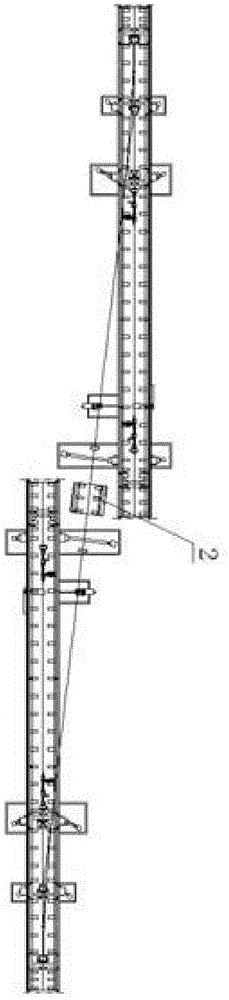

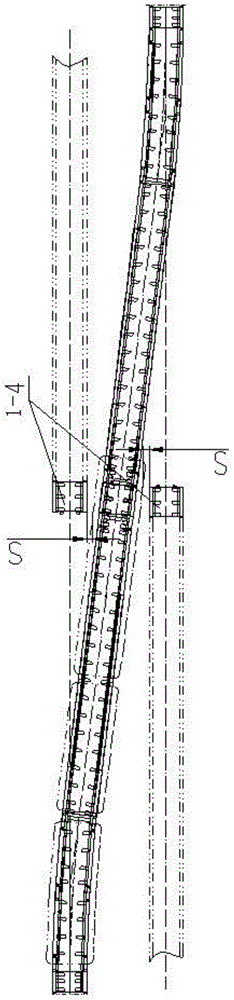

Medium and low speed magnetic levitation small linear interval single-crossover turnout

A medium and low speed magnetic levitation small linear interval single-crossover turnout is characterized by comprising two lateral turnouts in butt joint, an avoiding beam is arranged on one side of each lateral turnout and provided with a beam body servo device enabling the avoiding beam to move away, and meanwhile a fixed end stack beam is connected with the tail end of each avoiding beam. The linear interval of the crossover turnout is reduced from 6.23 m to 4.6 m and can meet the requirement of a 4.6m-interval road, the occupied space and difficulty of overall design of the road are reduced, and the overall manufacturing cost is reduced.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

No-tillage no-hole farming method for directly seeding broad bean in rice stubble

InactiveCN102090260ASave labor to fight for the seasonFavorable stable and high yieldHorticultureFertilizerHorticulture

The invention discloses a no-tillage no-hole farming method for directly seeding broad bean in rice stubble, comprising the following steps: (A) earthing up broad bean ridges: lofting, ditching and earthing up the ridges on a rice stubble soil-compaction field, wherein the width of each ridge surface is 100cm, and the width of each ridge ditch is 40cm; (B) directly seeding broad beans: sowing two rows of broad beans on each ridge along with a rib strip, wherein the inter plant distance is 30cm, the row space is 60cm, the inter plant distance between the ridges is 80cm, 3170 holes are dug per acre, two broad beans are planted in each hole, and 6340 broad beans are planted per acre; (C) carrying out base fertilizer furrow application: carrying out fertilizer furrow application along with the inner sides of ribs; (D) deep digging furrows: ploughing ditch soil below an opposite ridge by a farmer standing on the ridge surfaces, deep ploughing the furrows to be 20cm below a field surface, and evenly putting upturned soils on the ridge surface; and (E) carrying out field management. The no-tillage no-hole farming method has the advantages that all types of field can be ploughed under any weather, no-tillage no-hole rice stubble row planting can be carried out, the row space is enlarged, the inter plant distance is reduced, double-row strip seeds are performed with reasonable close planting, soil is heaped in zanjon for logging and preserving soil moisture, manual striving seasons are saved, and the method is favourable for the high and stable yield of the broad beans.

Owner:狄正兴

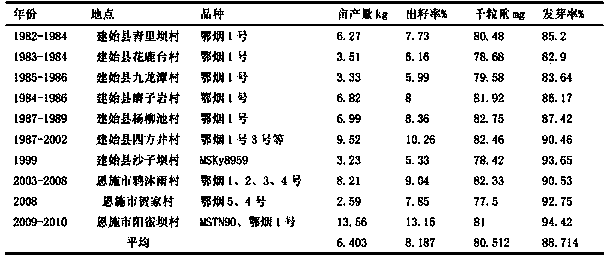

Economical and efficient production method of tobacco male sterile first generation hybrid seed

InactiveCN103348909AAvoid catastrophic lossReduce line spacingPlant genotype modificationHybrid seedNicotiana tabacum

The invention provides an economical and efficient production method of a tobacco male sterile first generation hybrid seed. The method includes: at an altitude of less than 700 meters, under the climate conditions meeting the requirements of early vegetative growth and later reproductive growth of tobacco plants, conducting seedling culture on a maternal tobacco plant and a paternal tobacco plant separately, then employing isolation planting, performing topping on the maternal tobacco plant, then collecting paternal pollen and preparing pollination, during pollination, adding starch and blending them, adopting an artificial pollination pen or pollination gun to perform pollination, carrying out deblossoming on the maternal tobacco plant both before and after pollination, and when the capsule pericarp browning reaches more than 80%, conducting single fruit harvesting in batches and performing drying, then conducting threshing processing to obtain the male sterile first generation hybrid seed. The method provided in the invention has the advantages of reasonable design, low production investment, and high seed yield. On the basis of ensuring a variety purity (99%) and a seed germination rate (95%), maximization of a high-quality germplasm propagation coefficient is realized, the seed yield is greatly improved, and the seed production cost is decreased significantly.

Owner:TOBACCO RES INST OF HUBEI PROVINCE

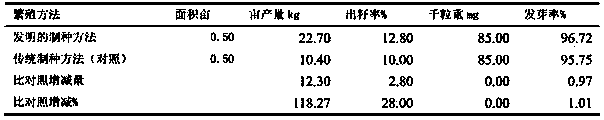

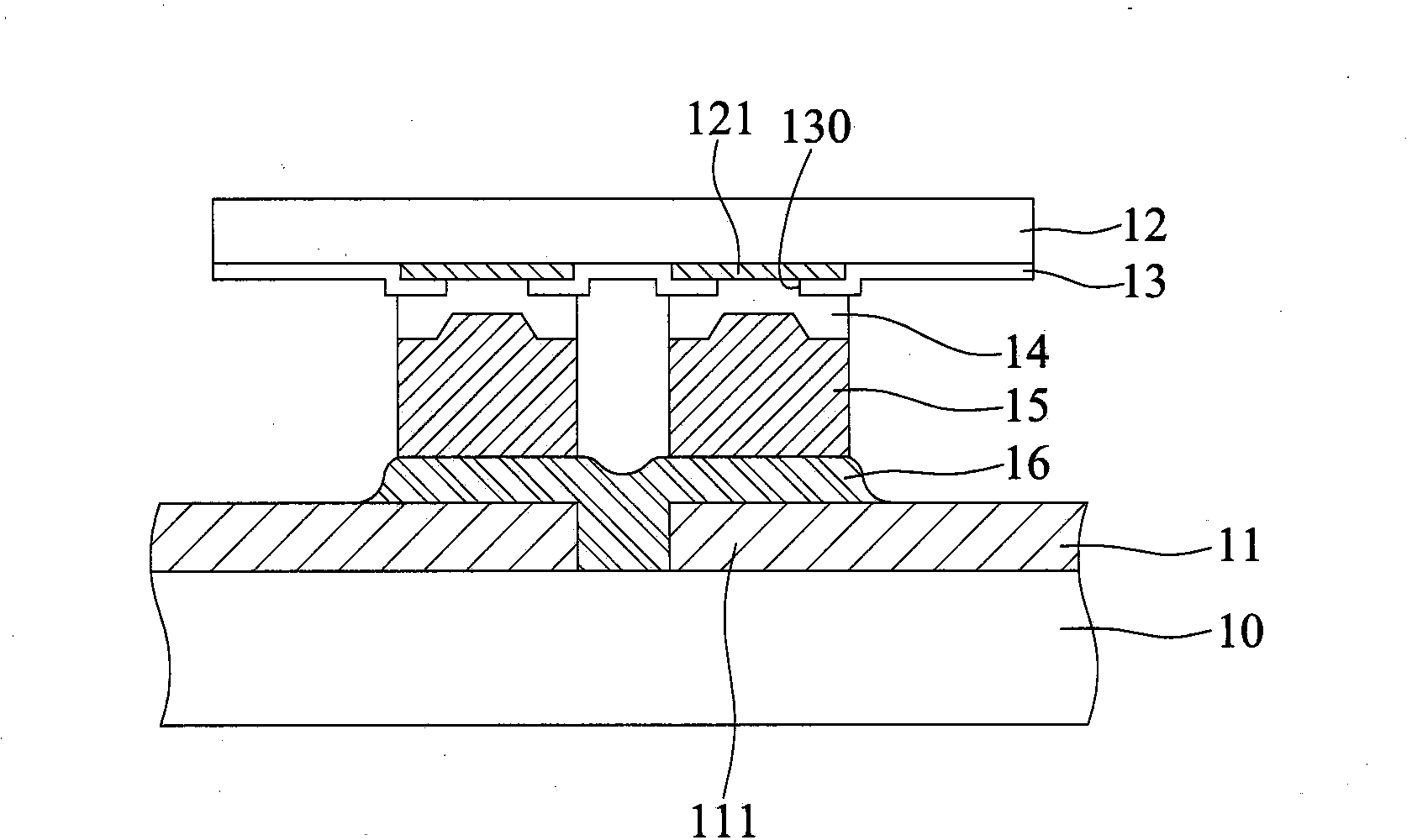

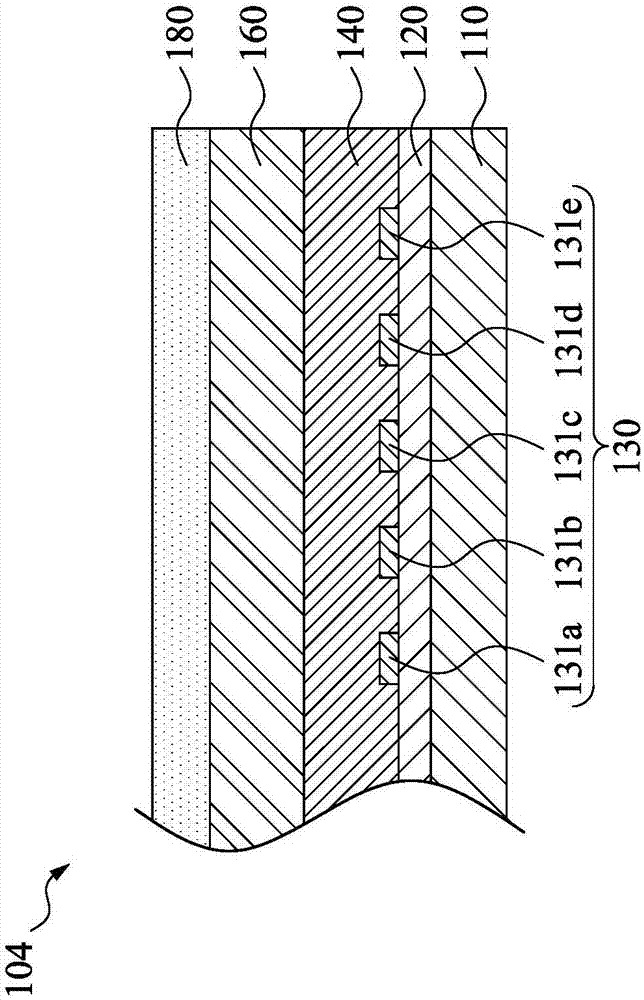

Substrate structure and package structure

InactiveCN103515345ANot easy to overflowReduce dosageSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationEngineering

A substrate structure and a package structure are provided. The substrate structure includes a substrate body and a plurality of traces formed on a surface of the substrate body. At least one of the traces has an electrical contact formed in a groove thereof for electrically connecting an external element, thereby meeting the demands of fine line / fine pitch and miniaturization and improving the product reliability.

Owner:SILICONWARE PRECISION IND CO LTD

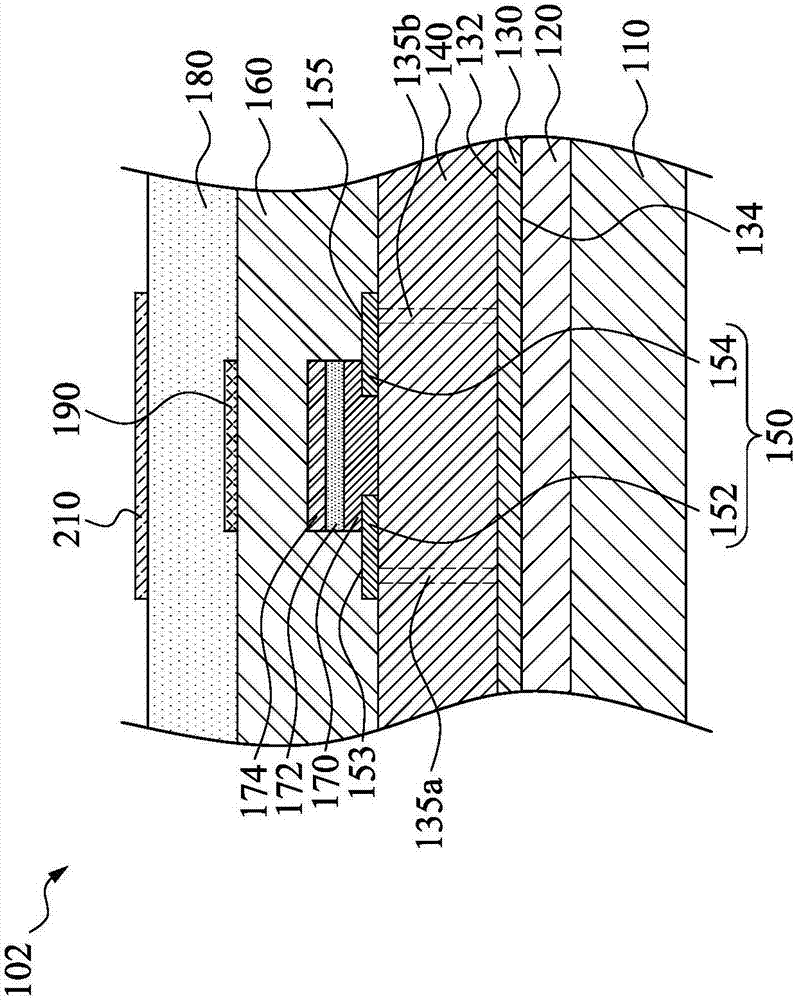

Flexible display device

ActiveCN107579090AAvoid breakingBreak will notSolid-state devicesSemiconductor devicesFlexible displayMaterials science

A flexible display device includes a flexible substrate, an inorganic barrier layer, a metal layer, an organic buffer layer, and an insulating layer. The inorganic barrier layer is located on the flexible substrate. The metal layer is located on the inorganic barrier layer and in contact with the inorganic barrier layer. The organic buffer layer covers the inorganic barrier layer and the metal layer, and has at least one conductive via connected to the metal layer. The insulating layer is located on the organic buffer layer. Since the metal layer is non-organic material, it allows excellent adhesion between the metal layer and the inorganic barrier layer. When the flexible display device is bent due to the force, the metal layer is less likely to be broken by bending.

Owner:E INK HLDG INC

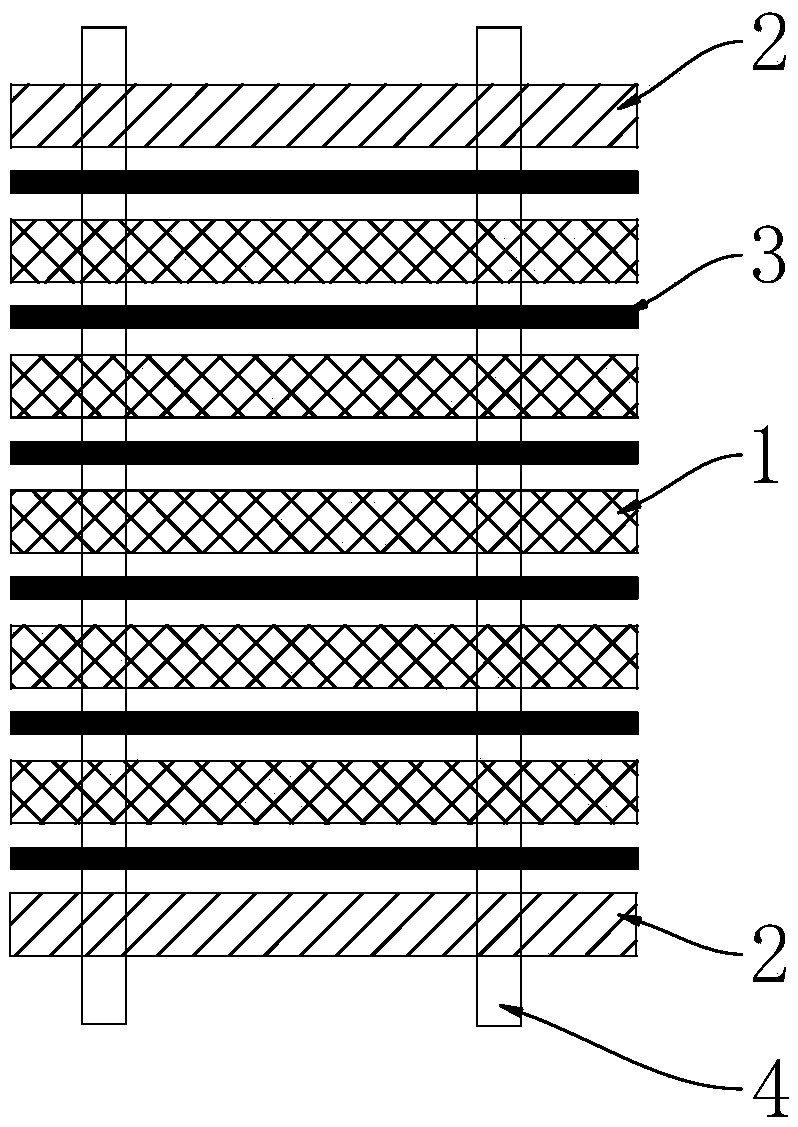

Inner layer manufacturing method of multilayer thick copper plate

ActiveCN111050495ASmall slot widthReduce line spacingCircuit metal processingMultilayer circuit manufactureCopper foilEtching

The invention provides an inner layer manufacturing method of a multilayer thick copper plate, which comprises the steps of obtaining a copper foil plate, and carrying out surface treatment on the copper foil plate; carrying out pattern processing on the copper foil plate by adopting a laser cutting method to form a pre-compiled pattern; adding prepreg between two copper foil plates, and laminating the prepreg and the copper foil plates in sequence; and carrying out vacuum heating and press-fitting to form a laminated plate. According to the invention, the copper foil is cut by laser, and thekerf width is small, i.e., the line spacing between lines is small; chemical etching is not needed in laser cutting, and the whole process is environmentally friendly and free of pollution; meanwhile,the edges of the kerfs are smooth, the side etching phenomenon of chemical etching is avoided, the instantaneous current impact resistance of the coil is further enhanced, and the consistency of products is improved at the same time. In the copper foil cutting process, gaps are filled with resin for the kerfs, so that the local pattern can be prevented from falling off, and the stability of the pattern is enhanced on the one hand; and on the other hand, the gaps of the pattern are filled with resin in advance, the number of layers of prepreg in the press-fitting process can be reduced, and the plate thickness of a finished product is reduced.

Owner:QINGSHENG AUTOMATION TECH SHANGHAI

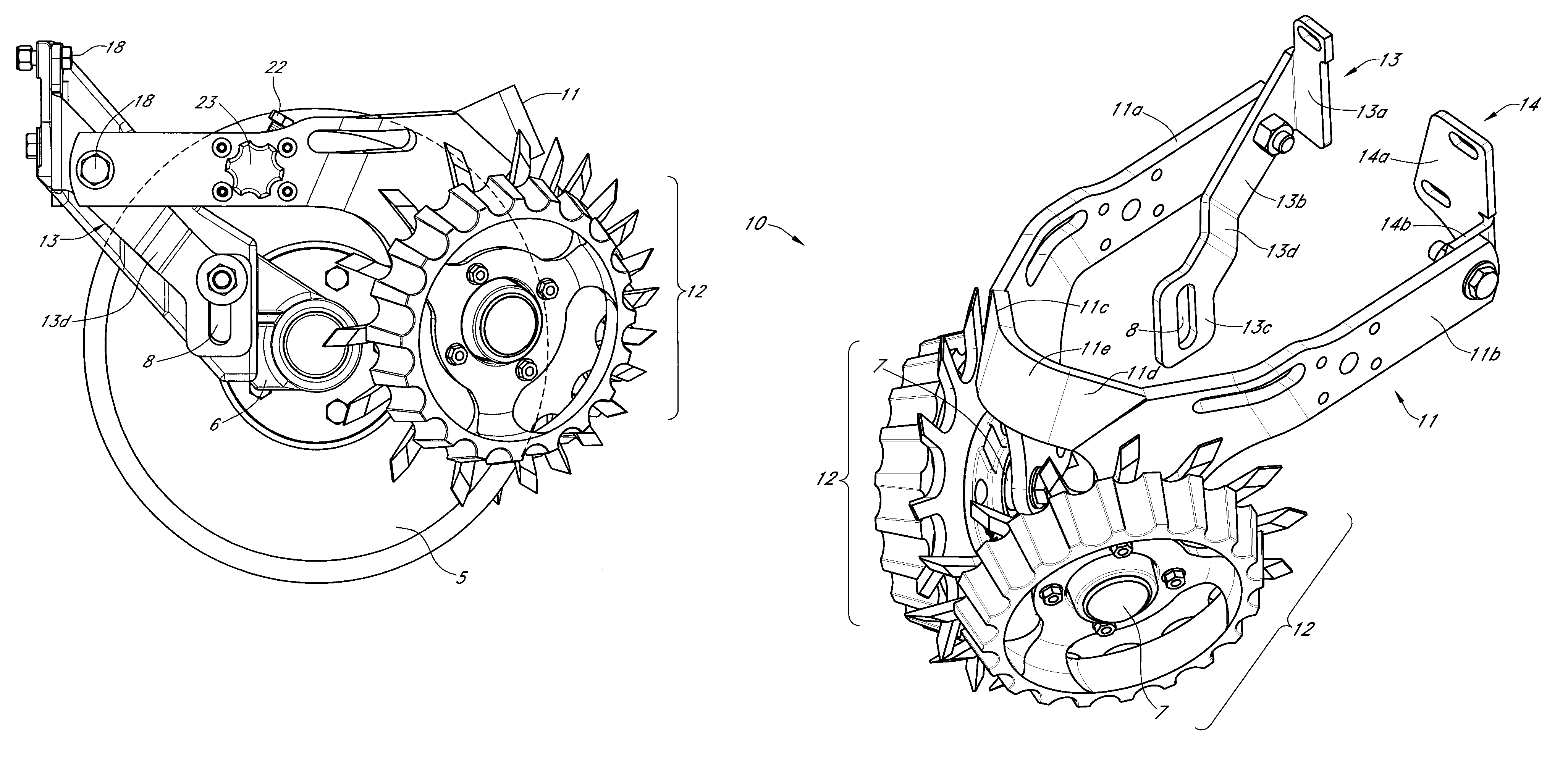

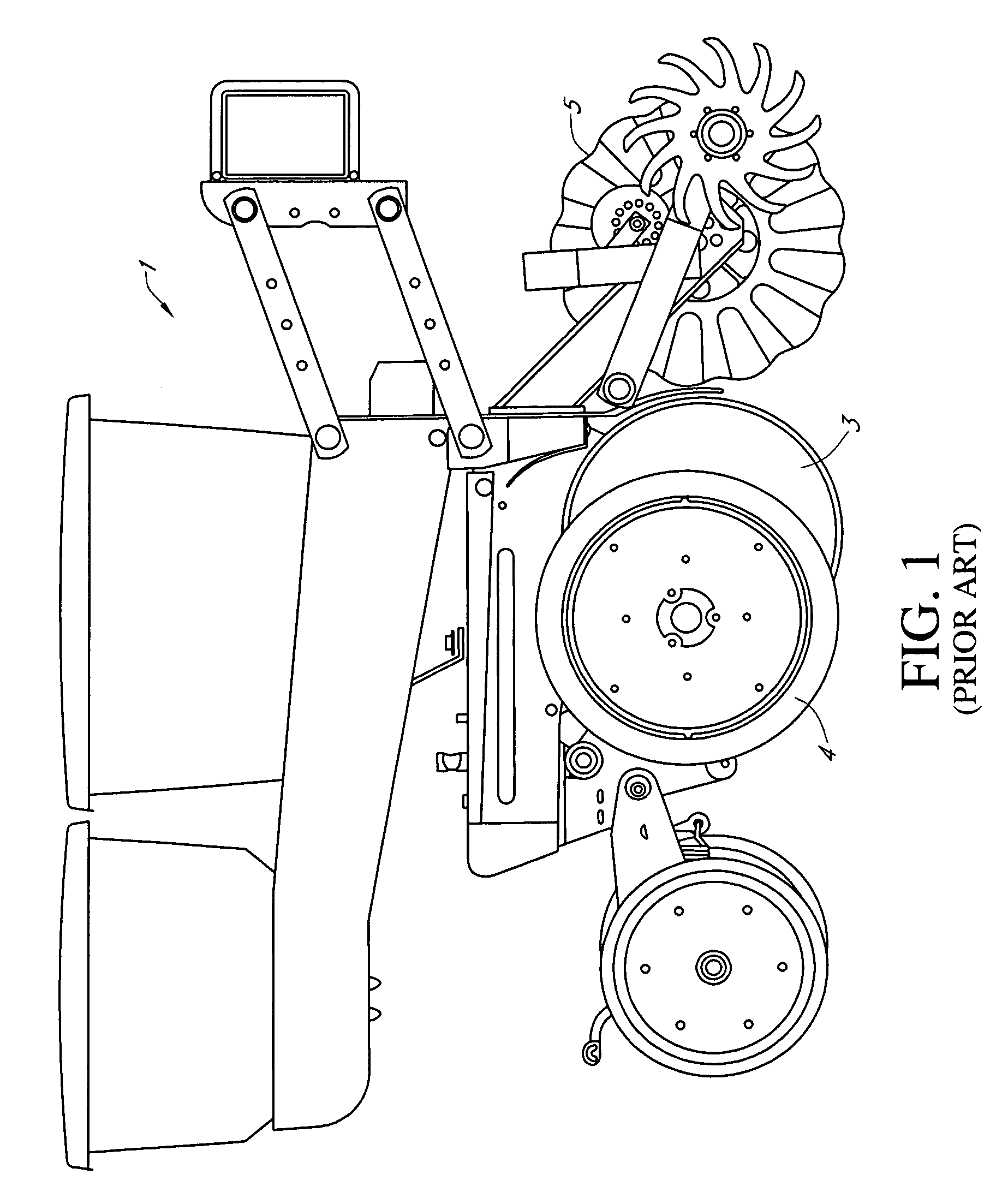

Compact floating row cleaner

A floating row cleaner assembly comprising a tool arm row cleaner mount, a row cleaner frame mounting plate, a row cleaner frame pivotally attached to the tool arm row cleaner mount and the row cleaner frame mounting plate. The periphery of the u-shaped row cleaner frame is composed of a combination of angled and curved portions to reduce the length and width of the frame to allow row cleaners to be used in combination with a coulter, or other tillage tool, and planter row unit spacing below 30 inches, while allowing necessary clearance between the row cleaner(s) and the coulter for terrain responsive operation.

Owner:MARTIN RONALD S

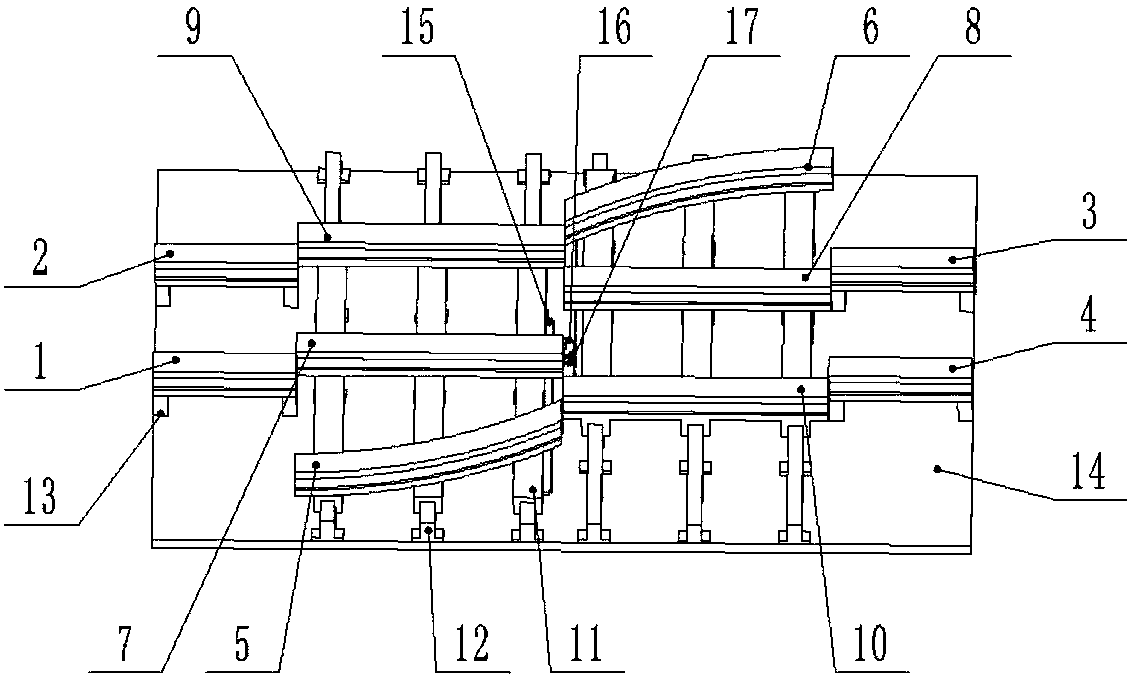

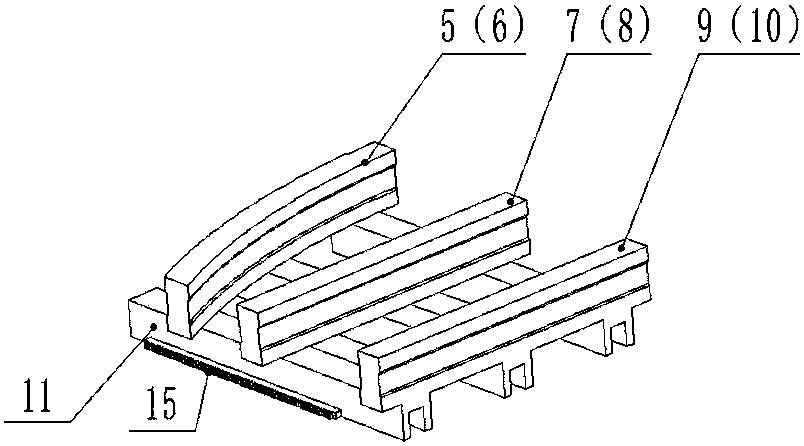

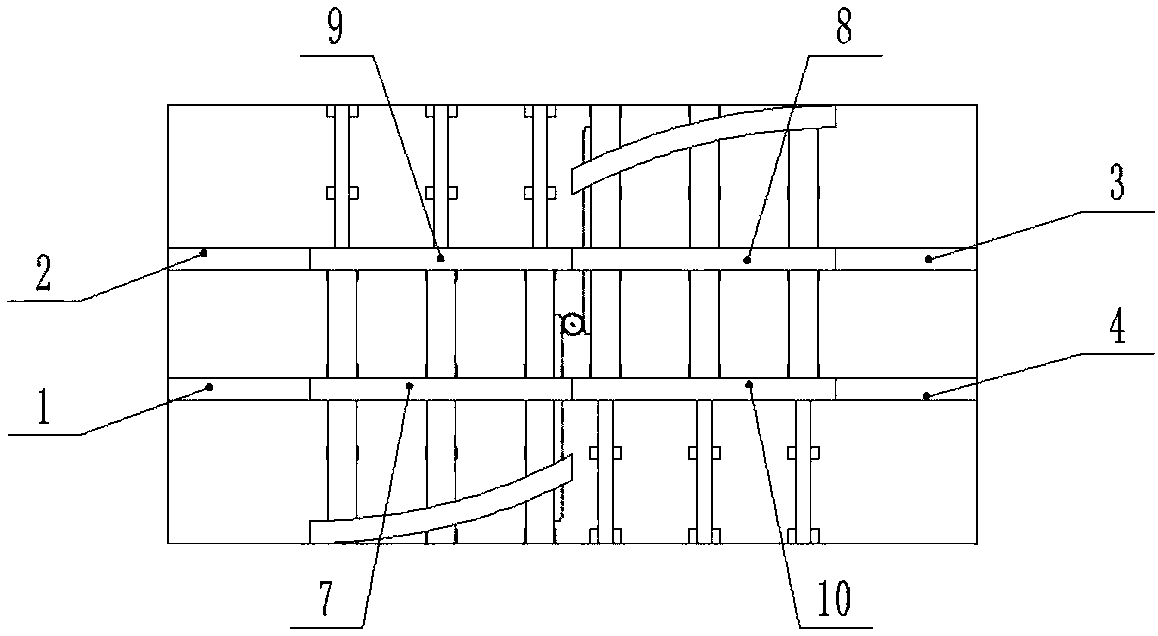

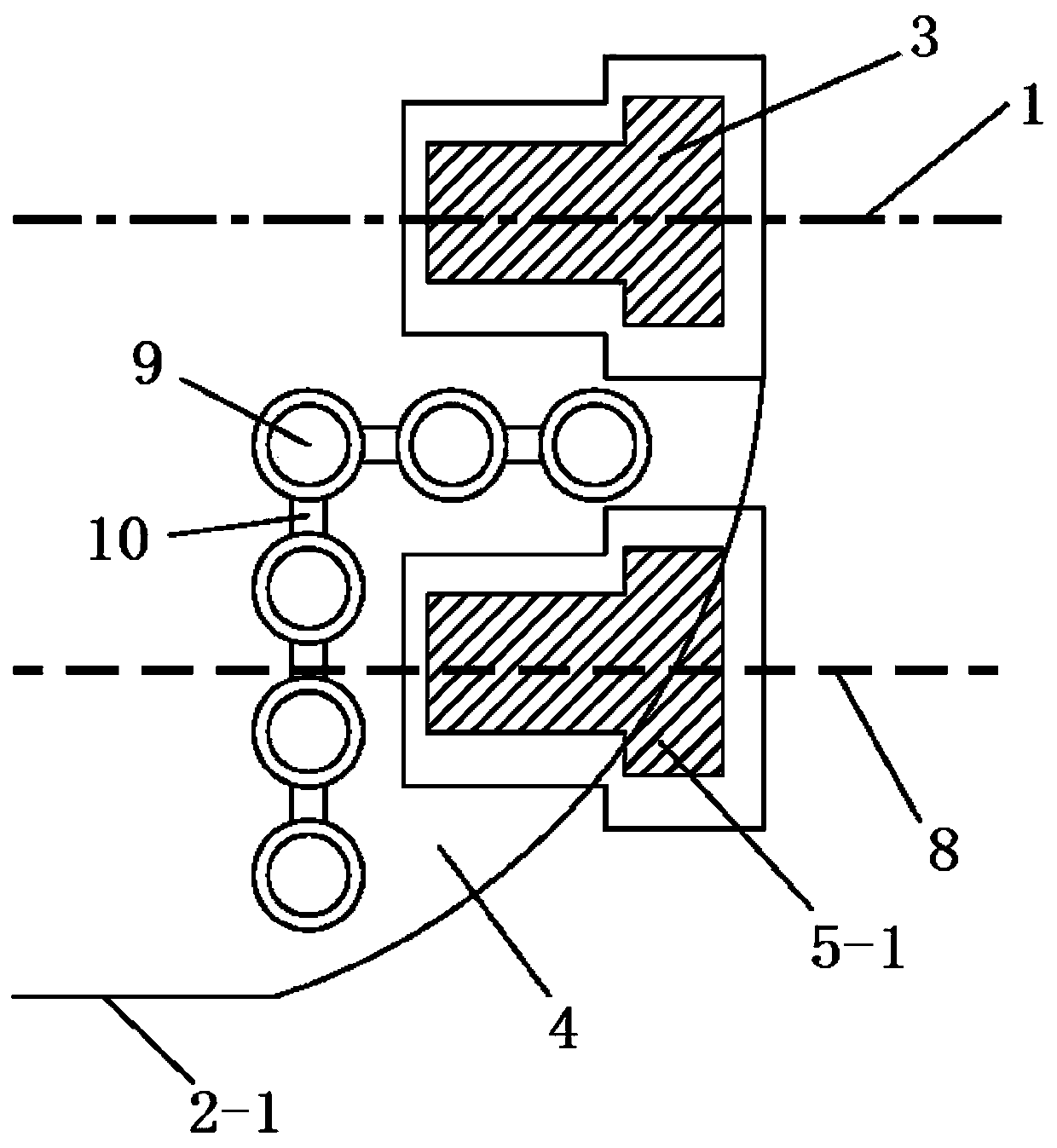

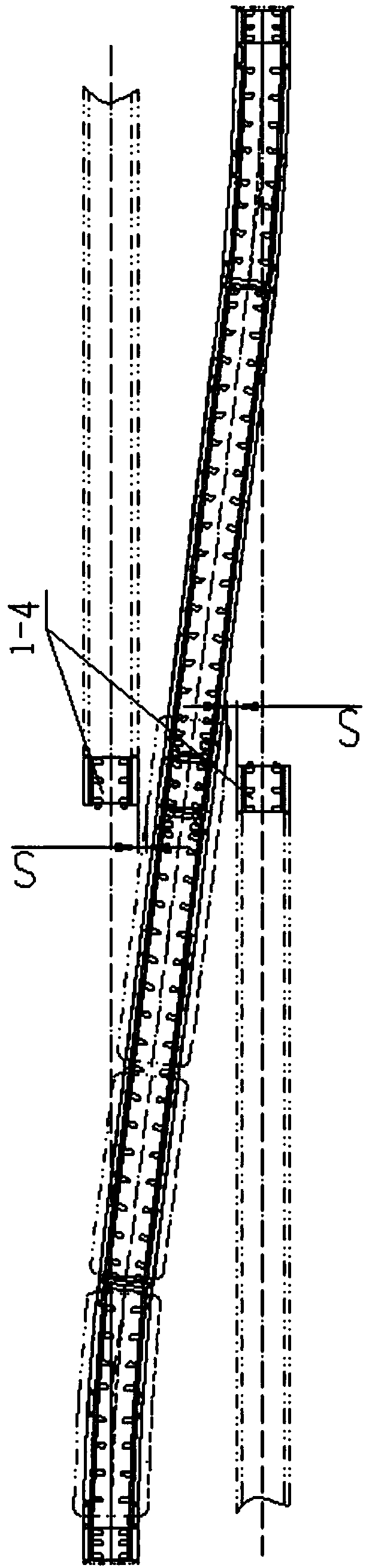

Transversely-moving type small-line-center-distance single-crossover monorail turnout

The invention discloses a transversely-moving type small-line-center-distance single-crossover monorail turnout which comprises a turnout base (14) and turnout beam fixing components. Multiple guide rails (12) are arranged between the turnout beam fixing components and provided with a crossover turnout component and a linear turnout component. The crossover turnout component comprises a first crossover turnout transversely-moving beam (5) and a second crossover turnout transversely-moving beam (6). The linear turnout component comprises a first linear turnout transversely-moving beam (7), a third linear turnout transversely-moving beam (9), a second linear turnout transversely-moving beam (8) and a fourth linear turnout transversely-moving beam (10). By the adoption of the transversely-moving type small-line-center-distance single-crossover monorail turnout, multiple sets of transversely-moving turnout beam components are arranged between the turnout beam fixing components, the guide rails and sliding blocks are arranged between the transversely-moving turnout beam components and the turnout base, a gear and a rack are driven through a drive motor, so that the different transversely-moving turnout beam components are driven to move, and quick change and removal under different working conditions are achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Roadbed pile pipe curtain supporting structure after addition of two-line-platform to railway

PendingCN109989407ALess materialLess investmentRailway tracksExcavationsSupporting systemEngineering

The invention discloses a roadbed pile pipe curtain supporting structure after addition of a two-line-platform to a railway, and the supporting structure is a vertical excavation supporting system formed by a horizontal steel pipe curtain and a soil blocking plate with newly-added supporting piles at the back of an existing bridge abutment or at a road shoulder position behind the bridge abutmentand newly-added supporting piles at a slope toe position of an existing railway roadbed as supporting points. The structure is composed of an existing bridge abutment, the supporting piles, the horizontal steel pipe curtain, the soil blocking plate and the like. The structure is safe and convenient, supporting is not prone to losing stability or causing collapse, operation of an existing railway is not affected, and normal operation and safety of the existing railway can be guaranteed. In addition, the foundation pit supporting structure is novel, fewer materials are used on the basis that safety is guaranteed, cost is saved, the mechanical construction efficiency is higher, and the line spacing can be reduced to a maximum extent.

Owner:新疆铁道勘察设计院有限公司

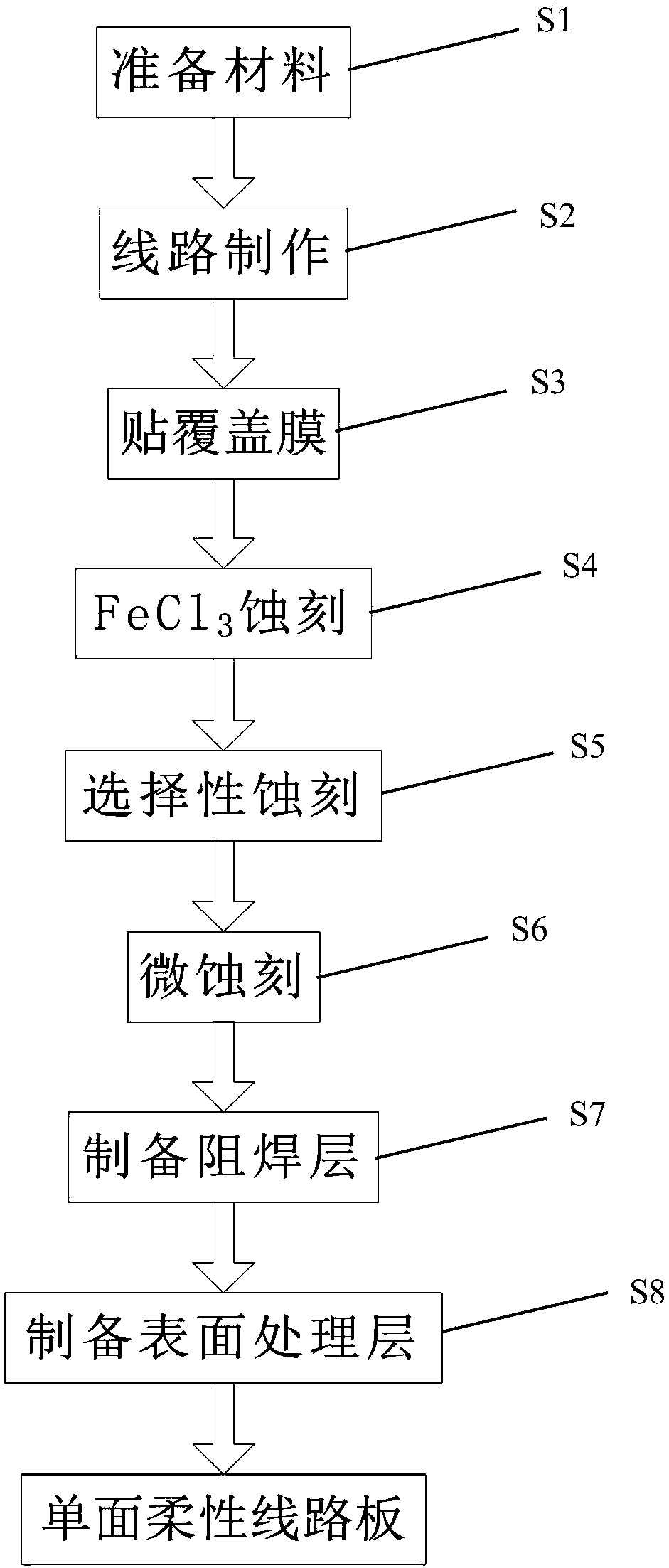

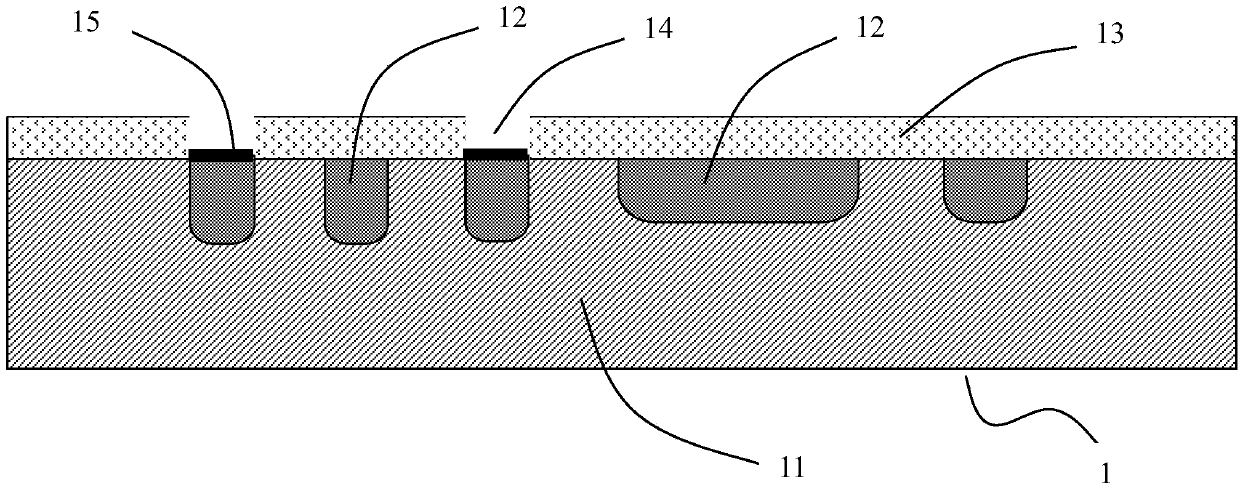

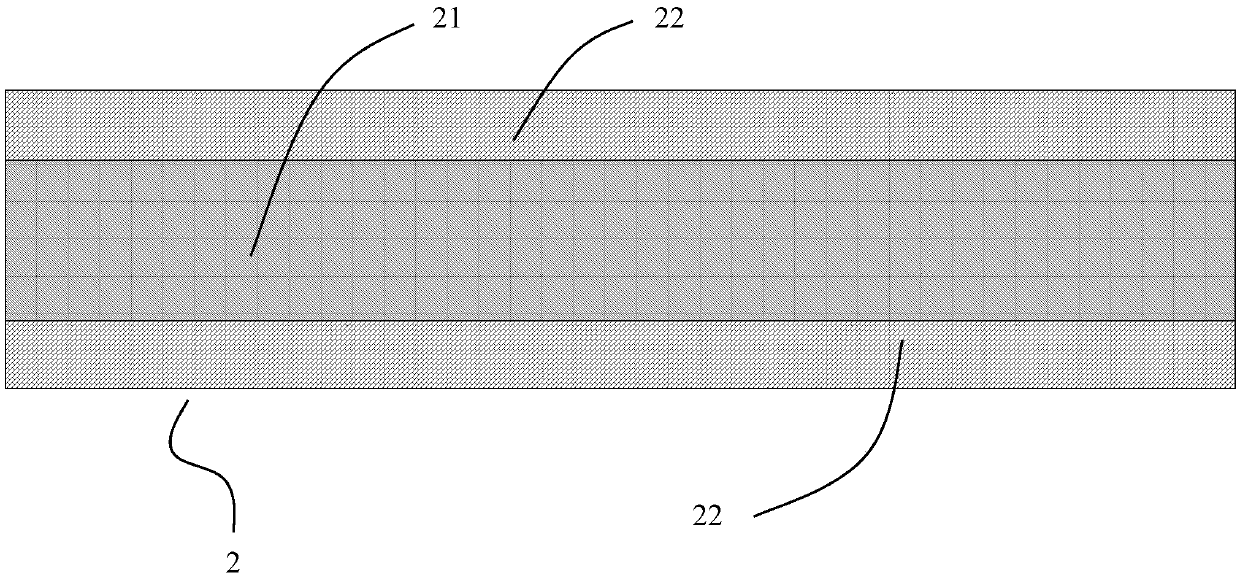

Line-embedded flexible printed circuit and film pasting preparation technology thereof

ActiveCN107624002AImprove reliabilityLow manufacturing process costNon-metallic protective coating applicationSolder maskProtection layer

The invention discloses a line-embedded flexible printed circuit. The flexible printed circuit comprises a bonding layer, lines embedded into the bonding layer, a solder mask layer located on one sideof the bonding layer and a surface protection layer located on the other side of the bonding layer, the solder mask layer is provided with a plurality of pad areas which are connected and communicatewith the lines, and the upper surfaces of the lines in the pad areas are provided with surface processing layers. According to the flexible printed circuit, the lines are embedded into the bonding layer, the width and the line spacing of the lines are decreased on the premise that the high reliability is kept, the product is ultrathin and good in bendability and assemblability, and the packagingshort circuit risk of a client can be reduced. The invention further discloses a film pasting preparation technology of the flexible printed circuit. The film pasting preparation technology of the flexible printed circuit is low in cost, high in reliability, easy to achieve and capable of achieving batch production.

Owner:AKM ELECTRONICS INDAL PANYU

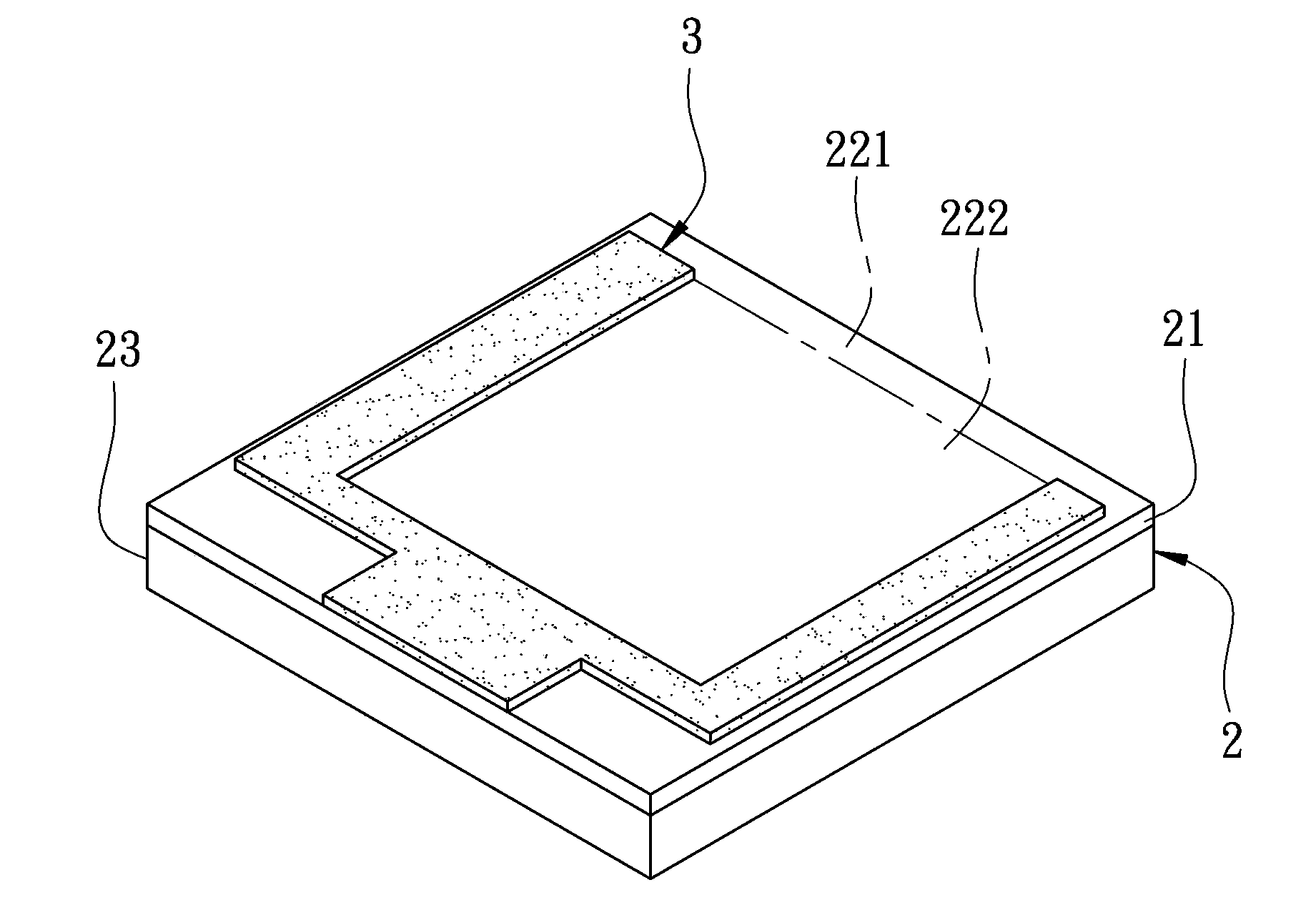

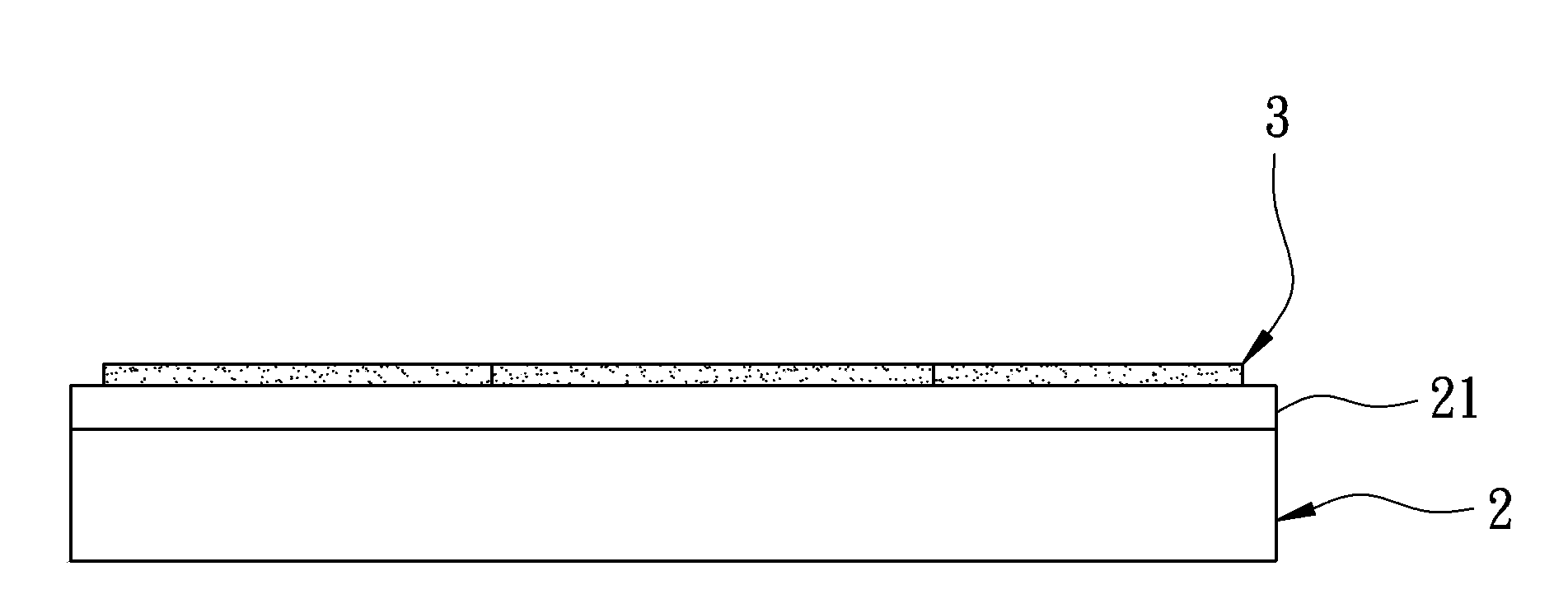

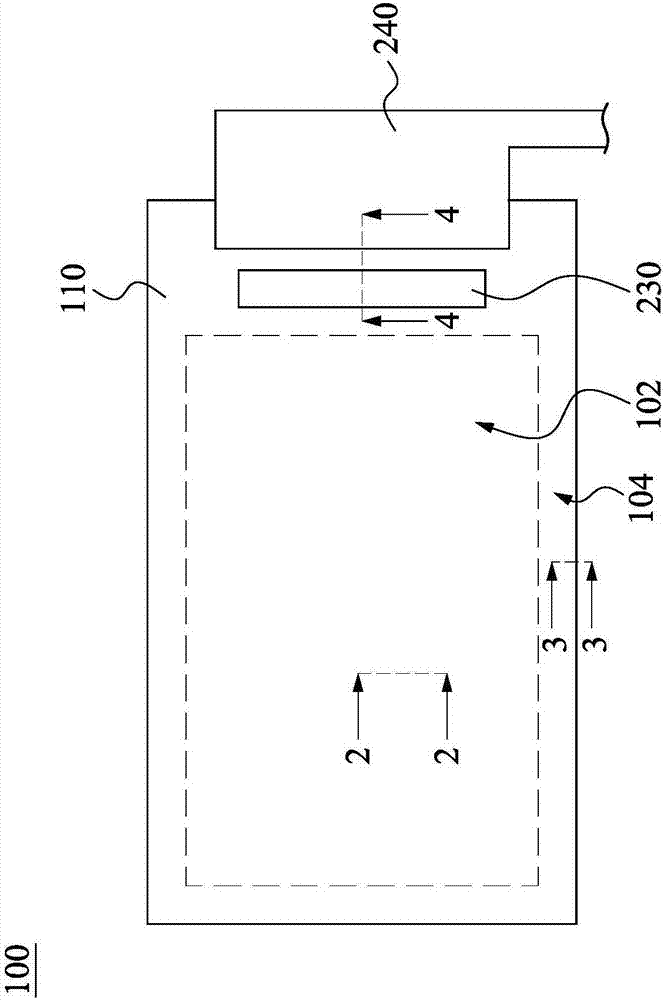

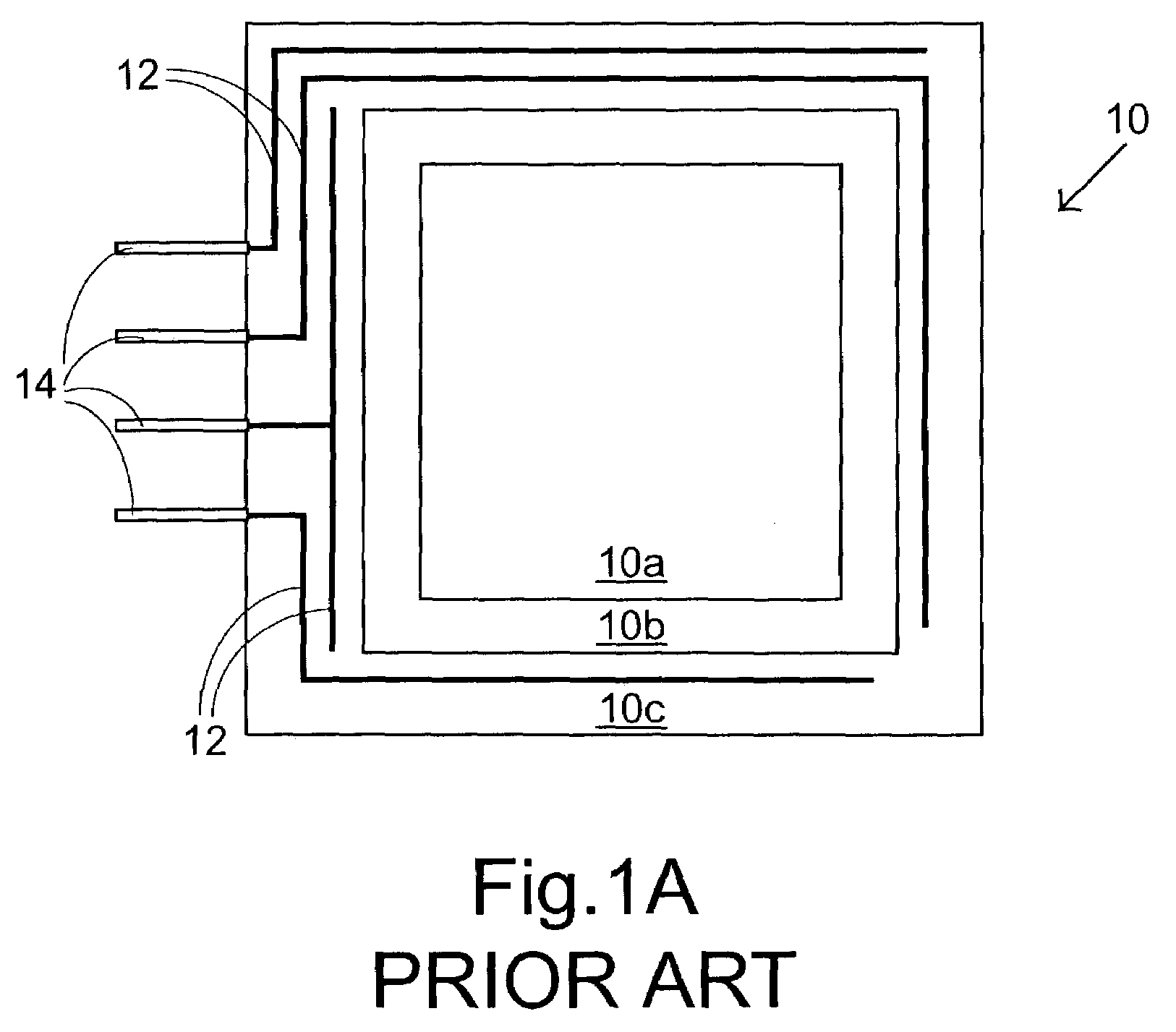

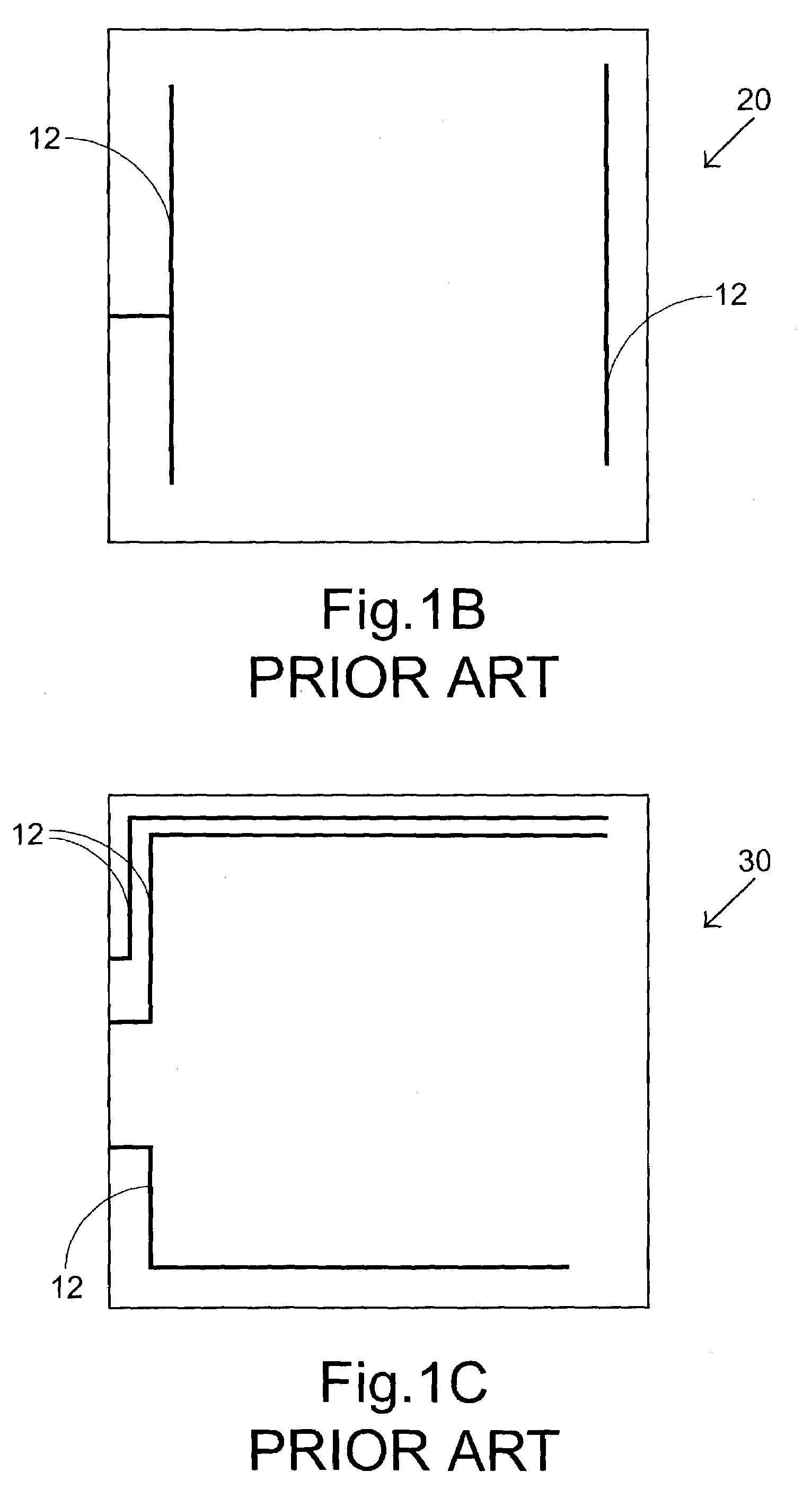

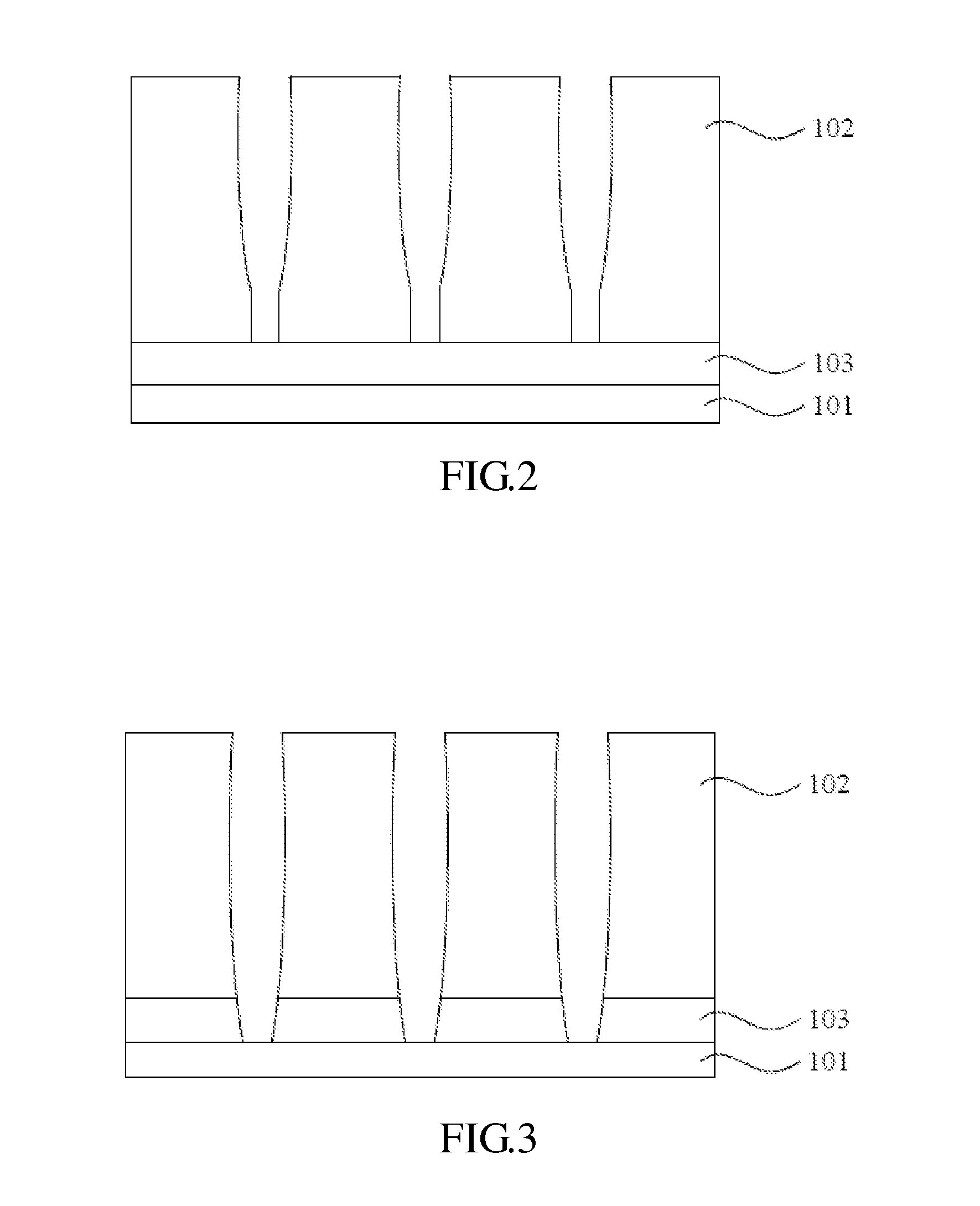

Process for implementing conductive tracing layout in touch panel

ActiveUS7131188B2Narrow widthReduce line spacingLine/current collector detailsPrinted electric component incorporationResistEngineering

The touch panel comprises two conductive substrates arranged in parallel and secured to each other with a gap existing between the conductive substrates The process for implementing a conductive tracing layout in a touch panel includes steps of forming a first conductive layer on at least one of the conductive substrates; forming a first photo-resist layer on the first conductive layer; removing a specified portion of the first photo-resist layer to form a first specified mask on a specified portion of the first conductive layer; and removing the first conductive layer except the specified portion of the first conductive layer to form a first conductive tracing layout.

Owner:INNOLUX CORP

Repairing method for laser marking-off anomaly of solar cell panel and solar cell panel

InactiveCN108899382ASolve the problem of risk of obsolescenceReduce line spacingPhotovoltaic energy generationSemiconductor devicesSolar powerSolar cell

The invention relates to the technical field of solar power generation and in particular relates to a repairing method for laser marking-off anomaly of a solar cell panel and the solar cell panel, aiming at solving the problems in the prior art that single cells are short-circuited due to the laser marking-off anomaly, even the solar cell panel is confronted with scraping. According to the repairing method for the laser marking-off anomaly of the solar cell panel, the solar cell panel is divided into a plurality of the single cells which are connected in series along a first direction throughlaser marking-off; the method comprises the following steps: determining a marking-off position of a first short-edge insulation line again according to a position of a region with the laser marking-off anomaly; marking off the insulation line again at the marking-off position of the first short-edge insulation line, which is determined again, so as to obtain a second short-edge insulation line toisolate the region with the laser marking-off anomaly from a region enclosed by the second short-edge insulation line and other original insulation lines except the first short-edge insulation line,wherein the first short-edge insulation line is any one short-edge insulation line parallel to a first direction in the original insulation lines.

Owner:GUANGDONG HANERGY THIN FILM SOLAR CO LTD

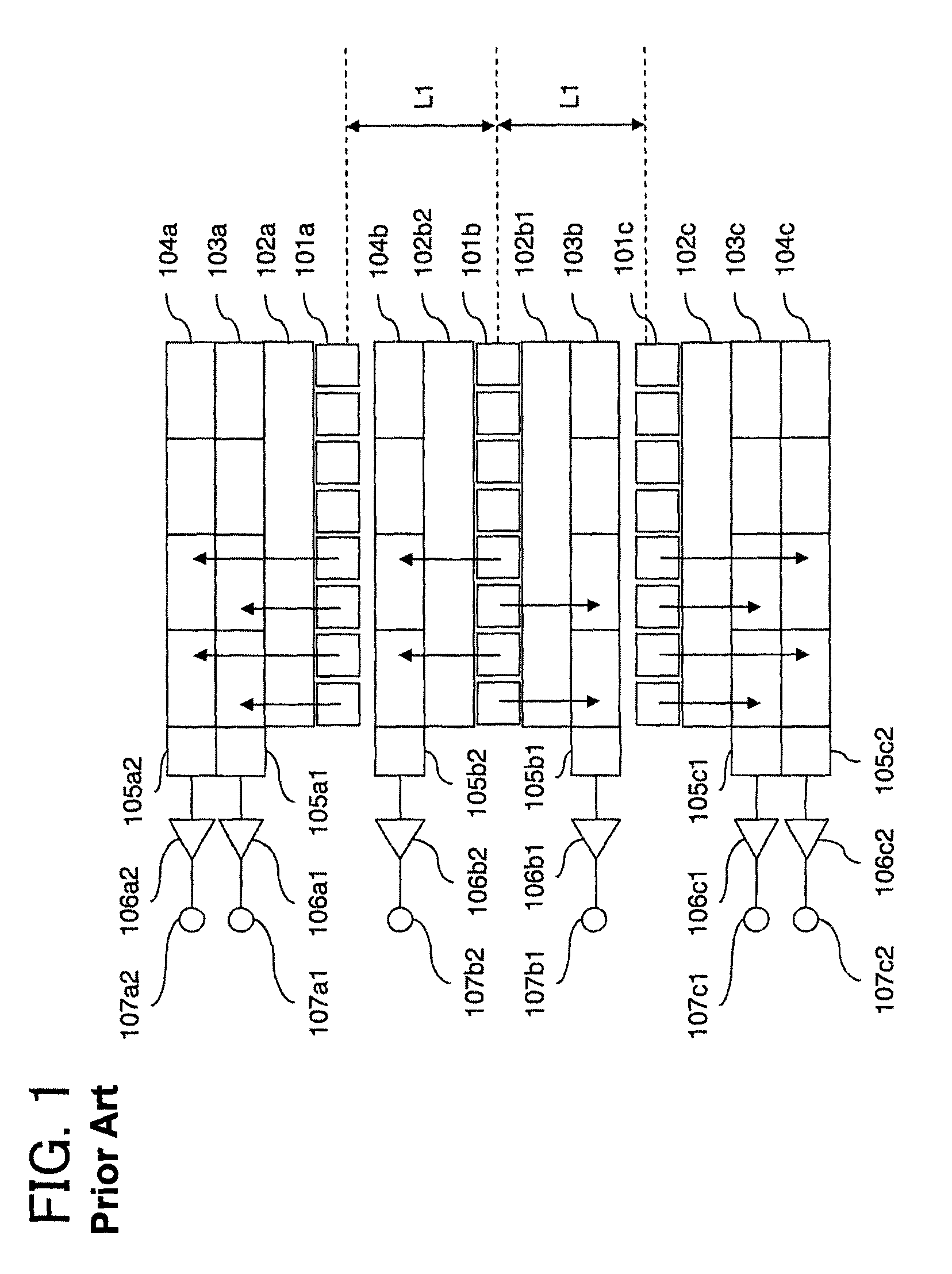

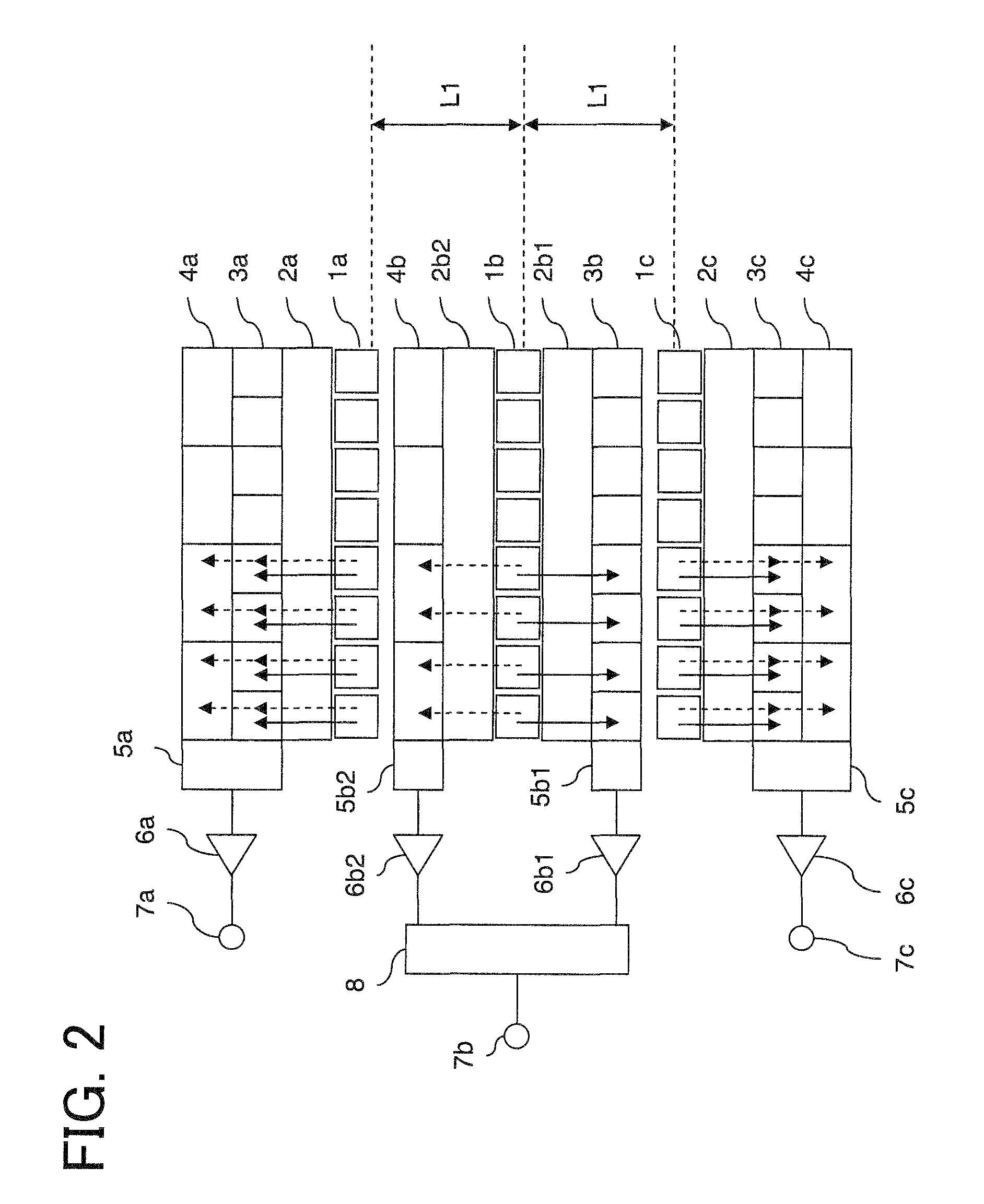

Linear image sensor

InactiveUS8059176B2Avoid mechanical misalignmentReduce memory capacityTelevision system detailsTelevision system scanning detailsLow noiseShift register

A linear image sensor with low noise and low power consumption comprises both high and low resolution analog shift registers for each photocell array. Noise in the output signals is decreased by driving either the low resolution analog shift register or the high resolution analog shift register depending on a required resolution. The power consumption of the linear image sensor is decreased because a charge detector receives charges from the high and low resolution analog shift registers.

Owner:RENESAS ELECTRONICS CORP

Medium and low speed maglev small line spacing single crossing line turnout

A medium and low speed magnetic levitation small linear interval single-crossover turnout is characterized by comprising two lateral turnouts in butt joint, an avoiding beam is arranged on one side of each lateral turnout and provided with a beam body servo device enabling the avoiding beam to move away, and meanwhile a fixed end stack beam is connected with the tail end of each avoiding beam. The linear interval of the crossover turnout is reduced from 6.23 m to 4.6 m and can meet the requirement of a 4.6m-interval road, the occupied space and difficulty of overall design of the road are reduced, and the overall manufacturing cost is reduced.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

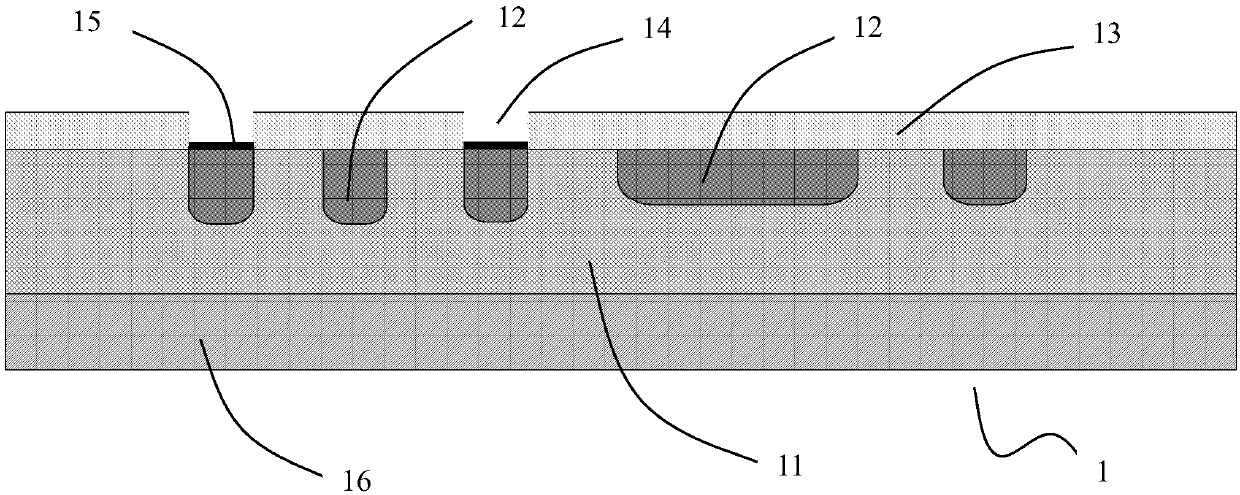

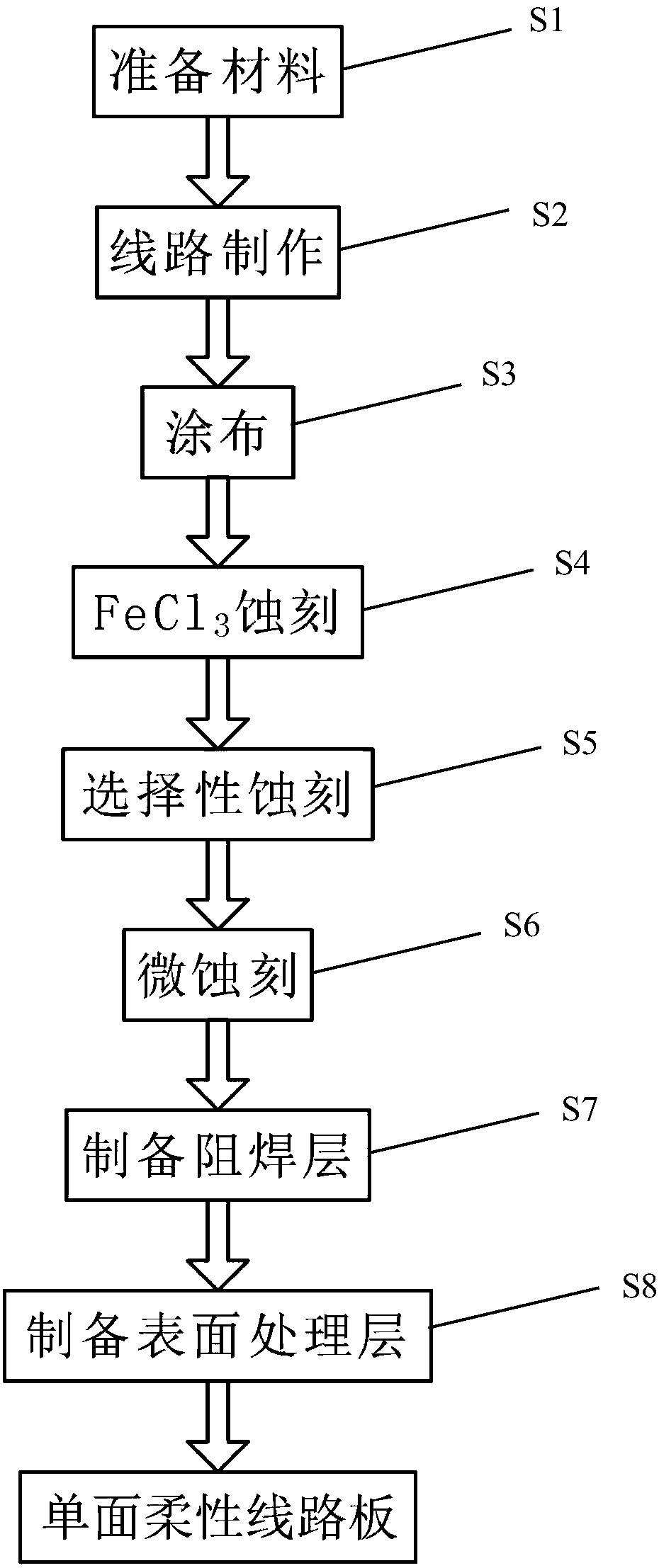

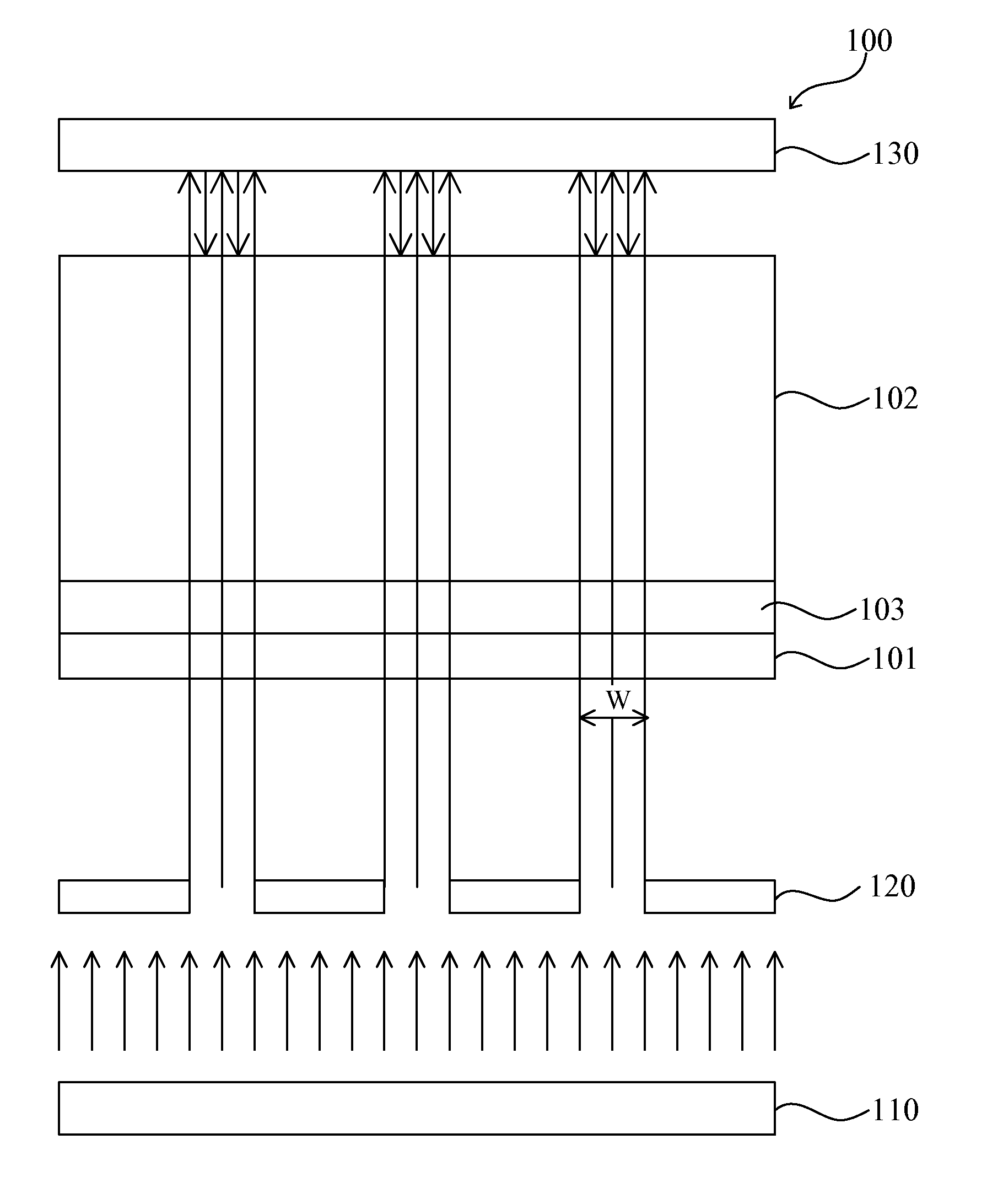

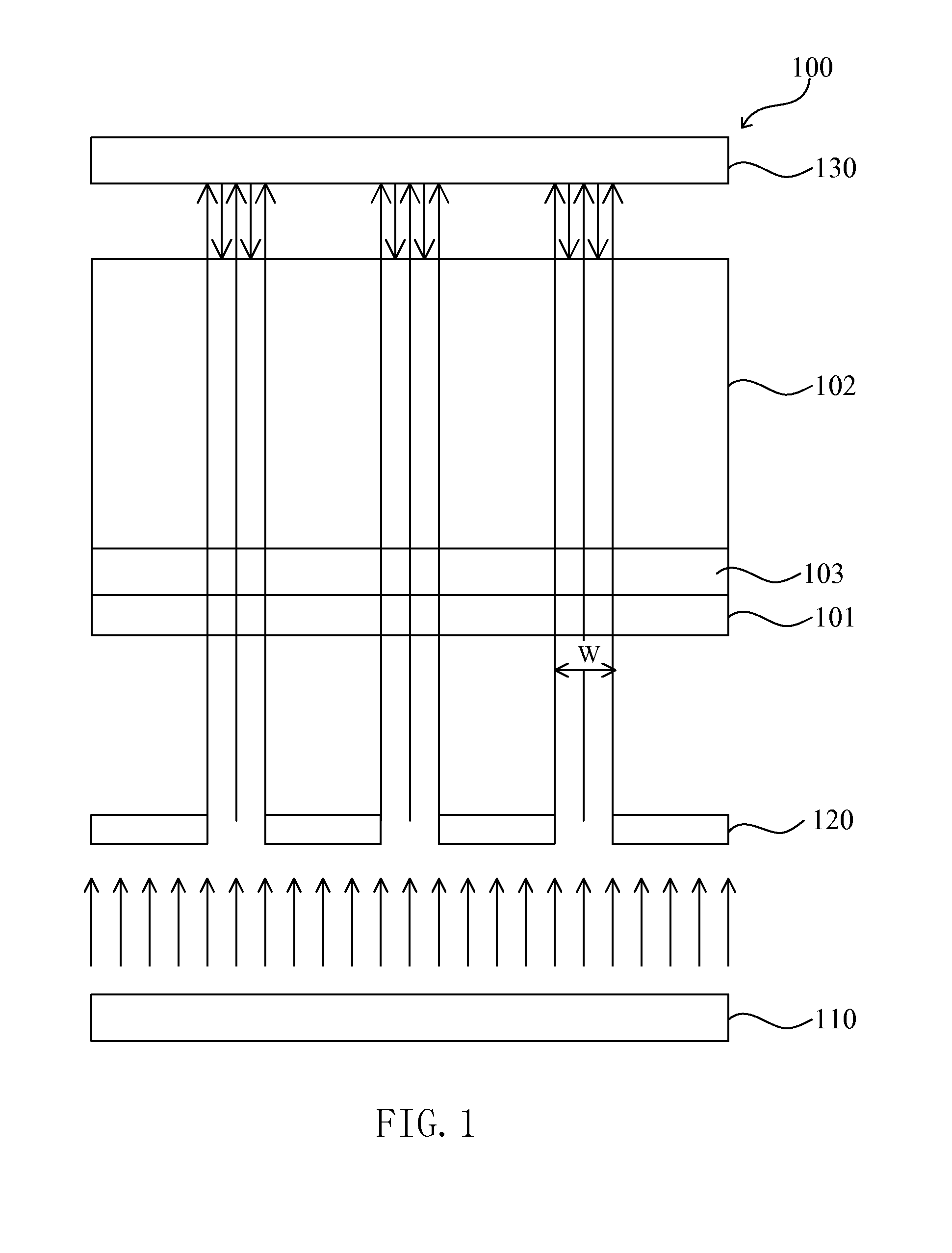

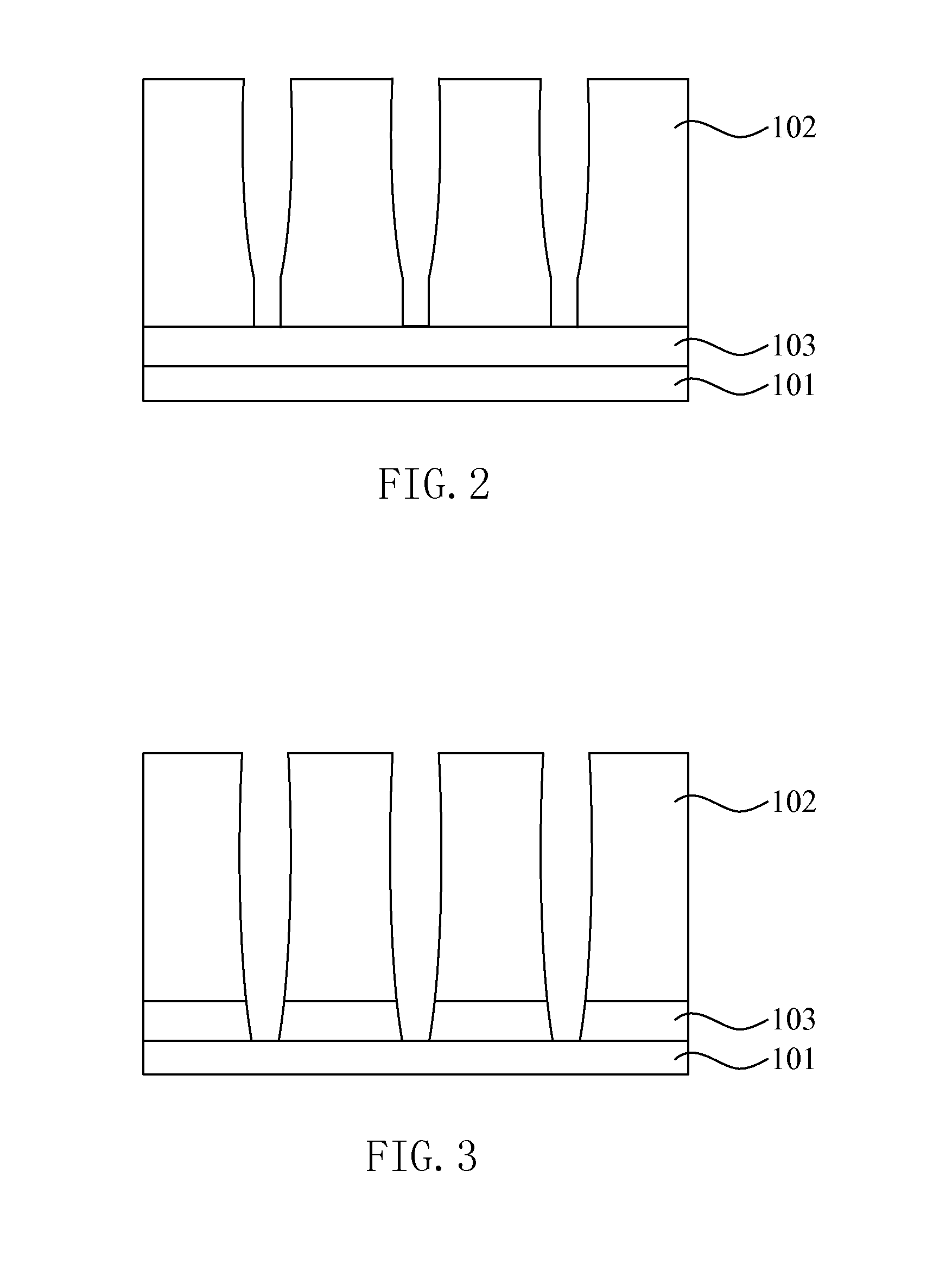

Circuit-embedded type single-sided flexible circuit board and preparation method thereof

ActiveCN107645842AImprove reliabilityLow costElectrical connection printed elementsConductive pattern reinforcementSolder maskFlexible circuits

The invention discloses a circuit-embedded type single-sided flexible circuit board comprising an insulating layer and a circuit embedded in the insulating layer. A plurality of bonding pad areas areformed at the circuit; surface treatment layers are formed on the upper surface of the circuit in the bonding pad areas; and solder mask layers are formed on the upper surface of the circuit except the bonding pad areas and the upper surface of the insulating layer. According to the invention, the circuit of the single-sided flexible circuit board is embedded into the insulating layer, so that thehigh reliability is kept and the width and line spacing of the circuit are reduced; the product is extremely thin; the bending and assembling properties are good; and the packaging short-circuit riskof the client is reduced. In addition, the preparation method of the single-sided flexible circuit board has advantages of low cost and high reliability and is easy to realize; and batched productionis realized.

Owner:AKM ELECTRONICS TECH SUZHOU

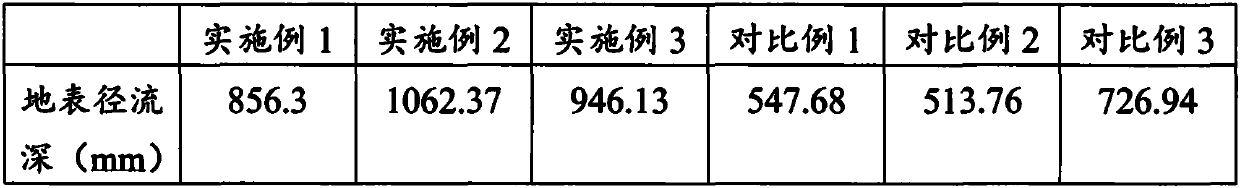

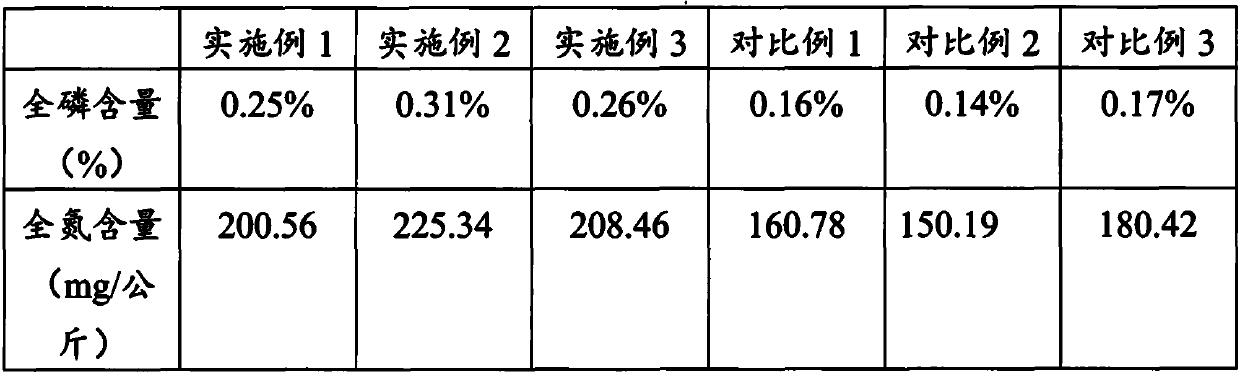

Allocation method of river protection forest

InactiveCN111345194AConducive to survivalImprove protection efficiencyFlowers cultivationCultivating equipmentsProtection forestLand preparation

The invention discloses an allocation method of a river protection forest. The allocation method comprises the following steps: 1) land preparation and earth filling; 2) planting of herbaceous plantsin a 0-3 m range from two sides of a river; 3) planting of small trees in a 3-10 m range from two sides of the river; 4) planting of ornamental plants in a 10-15 m range from two sides of the river; and 5) planting of tall trees in a 15-20 m range from two sides of the river. By use of a belt and block mixing and agricultural and forest mixing manner, the allocation method avoids water and soil loss, and meanwhile, the surface runoff and the content of nutrient ingredients in soil are regulated.

Owner:JILIN CITY ACADEMY OF FORESTRY

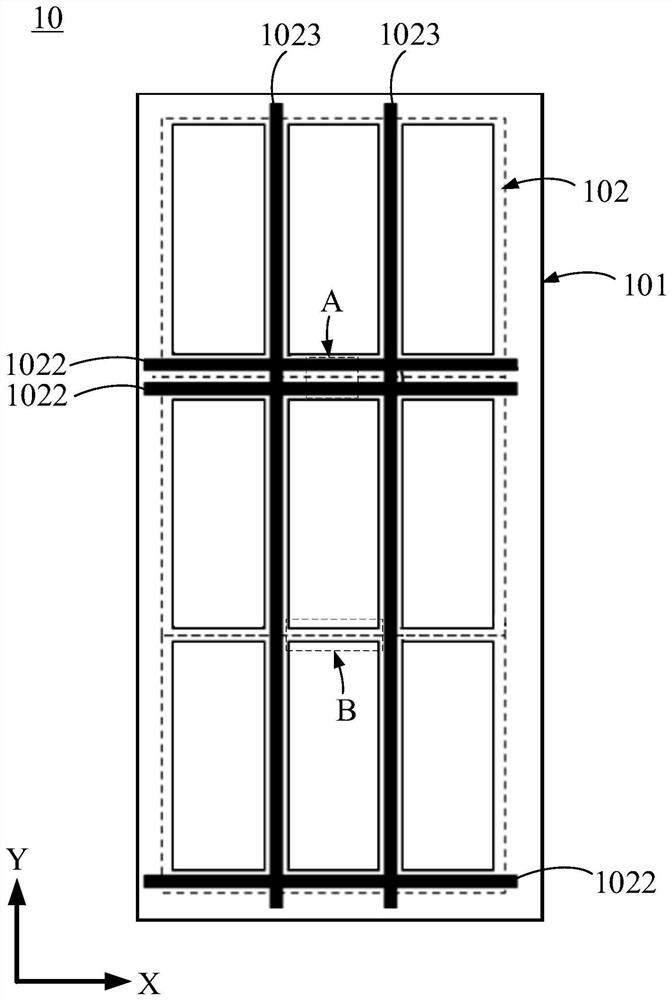

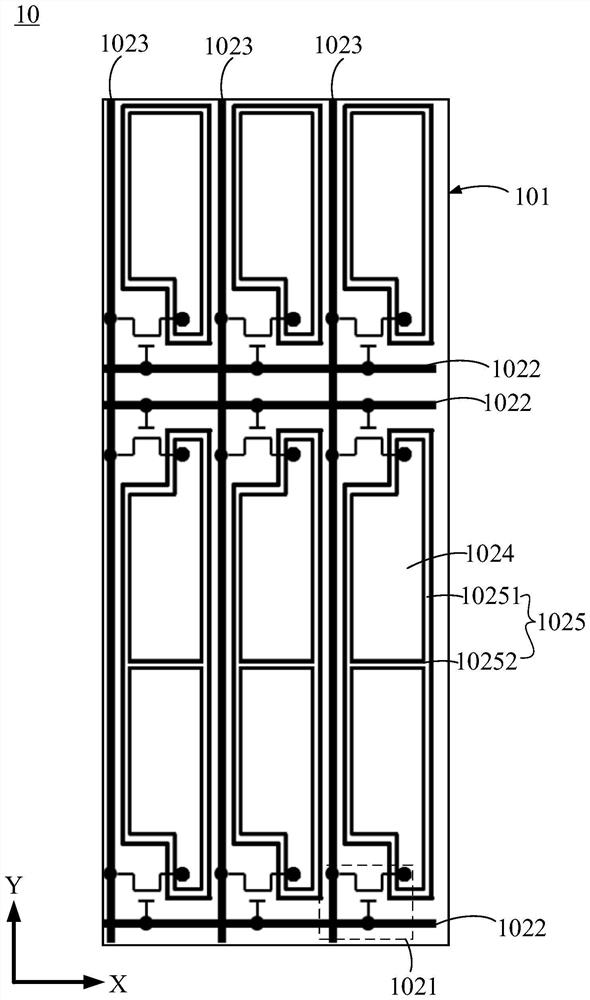

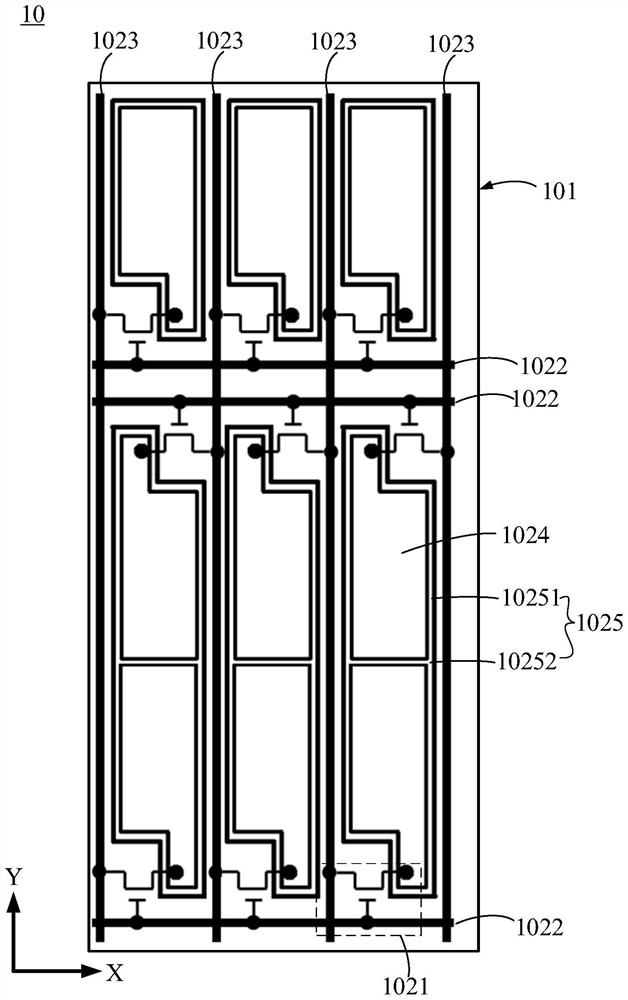

Array substrate, display panel and display device

PendingCN114089566AIncrease opening ratioImprove transmittanceNon-linear opticsLiquid-crystal displayScan line

The invention belongs to the technical field of display, and particularly relates to an array substrate, a display panel and a display device. The array substrate comprises a substrate body and a plurality of sub-pixels, and the sub-pixels are arranged on the substrate body in an array mode in the row direction and the column direction. Each sub-pixel comprises a transistor, a pixel electrode connected with the first end of the transistor, a data line connected with the second end of the transistor, a scanning line connected with the control end of the transistor, and a common electrode opposite to the pixel electrode in the thickness direction of the substrate, wherein at least two adjacent rows and / or at least two adjacent columns of sub-pixels share one edge of the common electrode. According to the scheme, the adjacent sub-pixels share one edge of the common electrode, so that a part of space can be saved to improve the aperture opening ratio of the sub-pixels, the purpose of improving the transmittance of the liquid crystal display panel can be achieved, and the display effect is improved.

Owner:CHANGSHA HKC OPTOELECTRONICS CO LTD +1

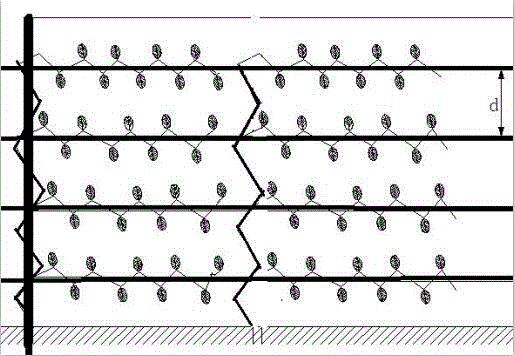

Movable cultivation device and multi-stage cultivation method for fruits and vegetables suitable for solar greenhouse

ActiveCN104604600BIncrease productionReduce the chance of occurrenceClimate change adaptationGreenhouse cultivationInsect pestFruits and vegetables

The invention discloses a movable cultivation device and a multi-stage cultivation method for fruits and vegetables suitable for a solar greenhouse. Through the multi-stage cultivation method combining mid-low section cultivation and long-section cultivation in a solar greenhouse, the back-end fruits and vegetables, especially the middle and lower sections, can be improved to receive light. At the same time, due to the short cultivation time in the low section, the probability of occurrence of diseases and insect pests is reduced; moreover, by adjusting the spacing of the movable cultivation device to adjust the spacing between fruits and vegetables with different cultivation sections, the land utilization rate in the greenhouse can be increased. , to increase fruit and vegetable yields.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

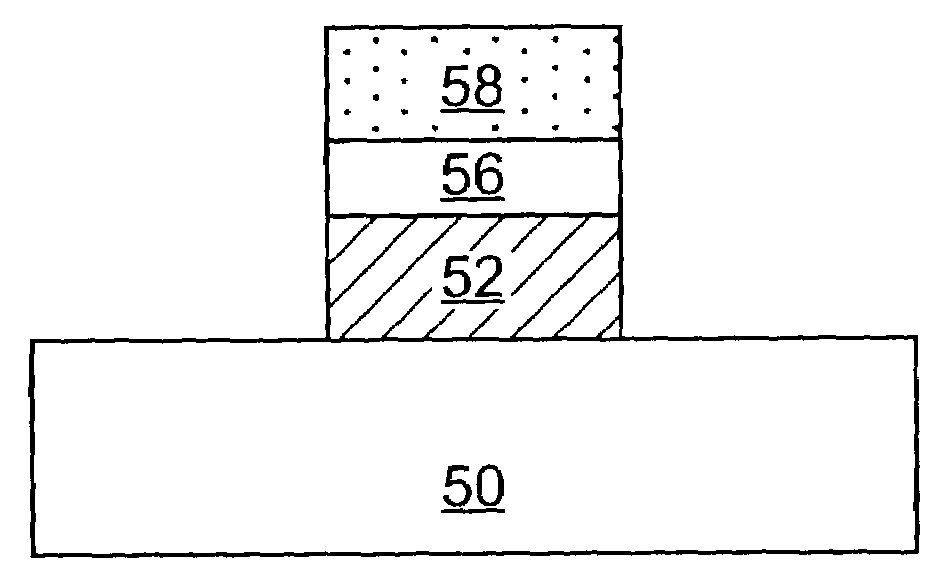

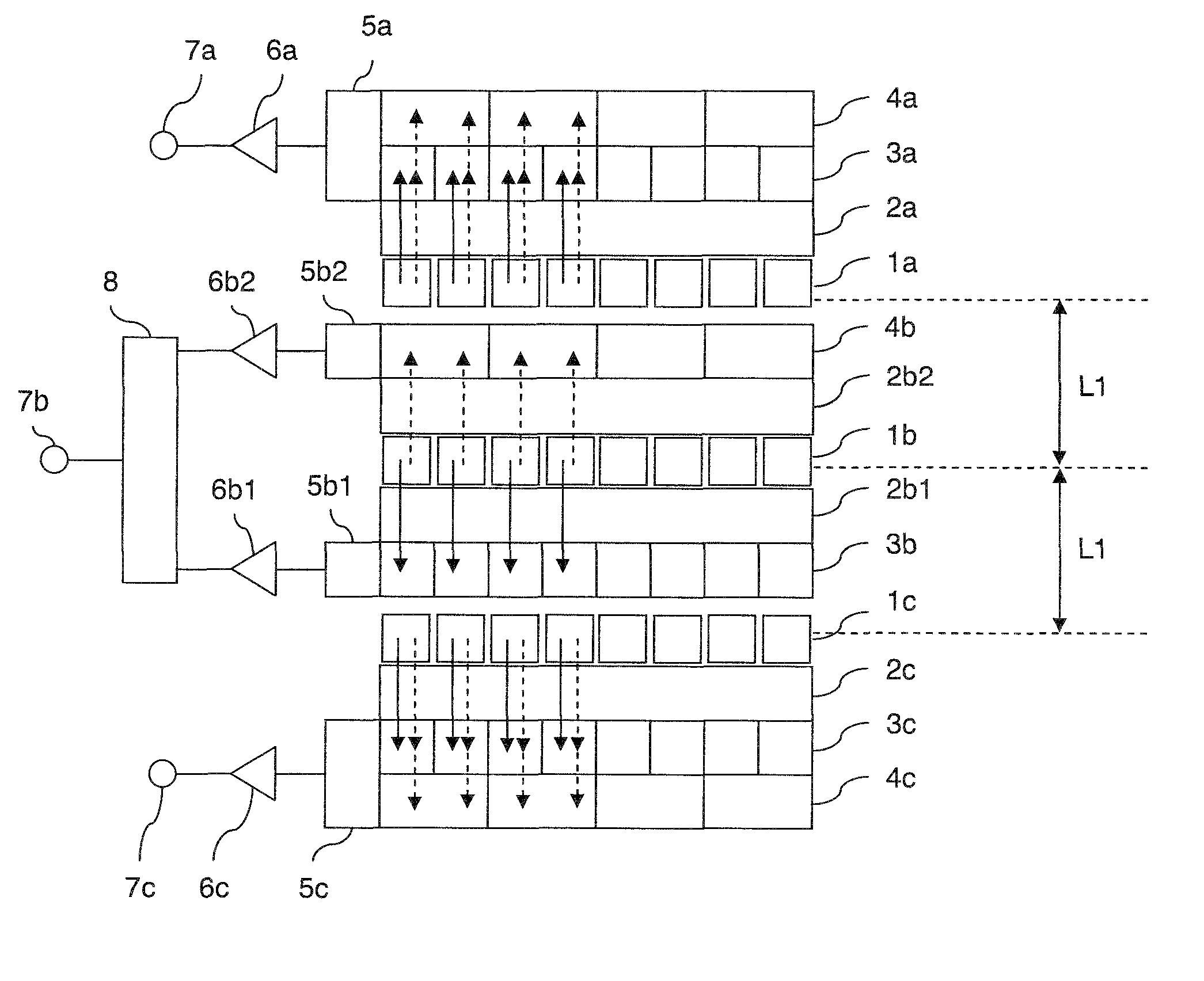

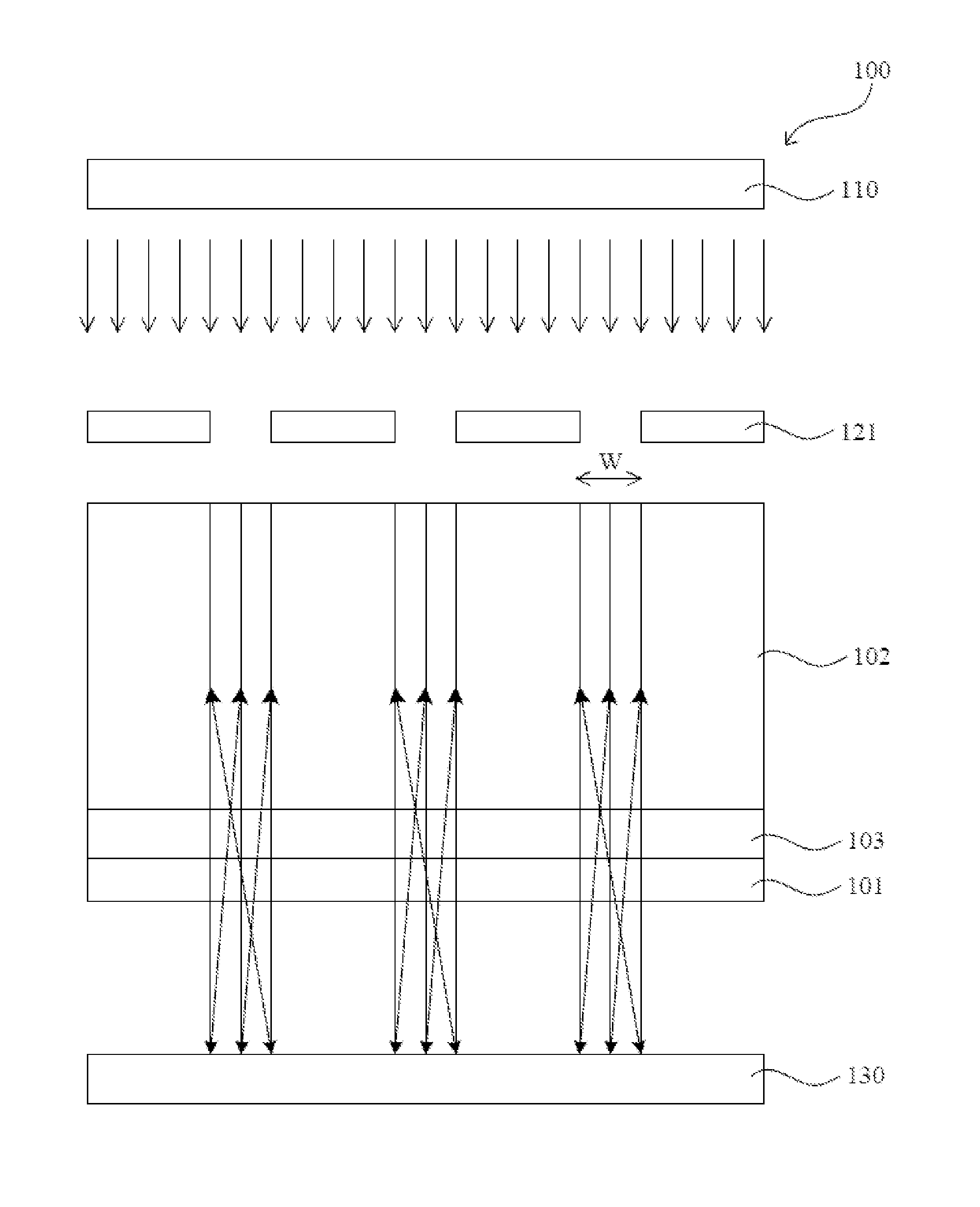

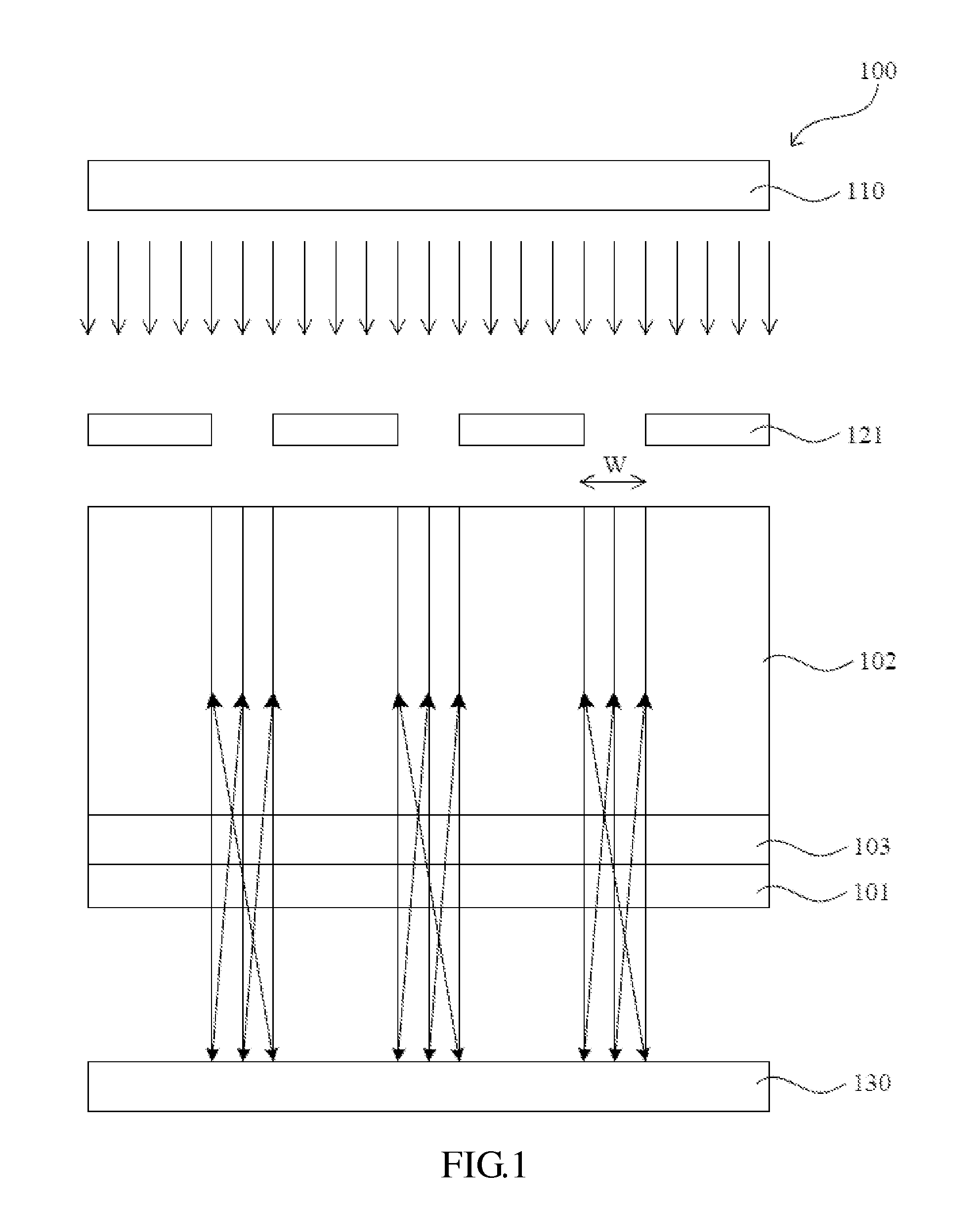

Exposure apparatus and exposure method

InactiveUS9041909B2Reduce line spacingImprove performanceSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistLight source

The present invention provides an exposure apparatus and an exposure method. The method comprises: utilizing an exposure light source to provide light rays to the photo-resist layer, wherein the light rays pass through the mask and the transparent substrate to reach the photo-resist layer; and utilizing a reflective plate to reflect the light rays passing through the transparent substrate and the photo-resist layer back to the photo-resist layer. The present invention can reduce a line space of a pattern of the photo-resist layer.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

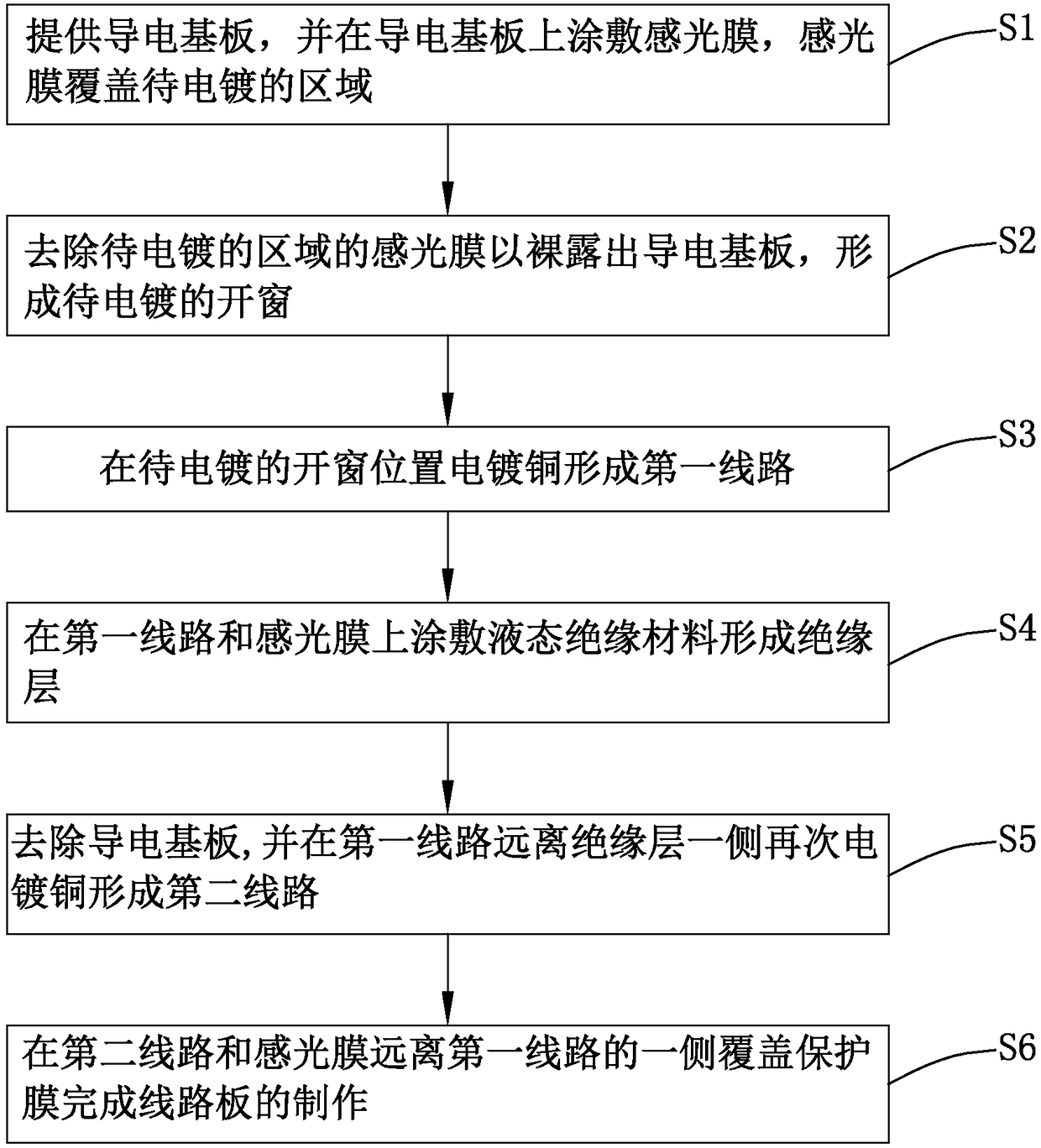

Circuit board manufacturing method and circuit board

InactiveCN108135091AReduce processReduced line spacingPrinted circuit manufactureCopper platingElectroplating

The invention provides a circuit board manufacturing method and a circuit board manufactured by adopting the circuit board manufacturing method. The circuit board manufacturing method includes steps of providing a conducting substrate and coating the conducting substrate with a photosensitive film which covers a to-be-electroplated area; removing the photosensitive film covering the to-be-electroplated area so as to expose the conducting substrate, and forming a to-be-electroplated window; forming a first circuit in the position of the to-be-electroplated window through copper electroplating;coating the first circuit and the photosensitive film with liquid insulation material so as to form an insulation layer; removing the conducting substrate and forming a second circuit on a side of thefirst circuit away from the insulation layer through copper electroplating; covering the second circuit with a protection film so as to complete manufacture of the circuit board. According to the invention, PI, LCP or PEN material is adopted as a mask and mask removal is not acquired after pattern electroplating, so that the line distance of a circuit obtained after electroplating is reduced andthe copper coating thickness is increased.

Owner:AAC TECH PTE LTD

Exposure apparatus and exposure method

ActiveUS20130155383A1Improve performanceHigh aspect ratioPhotomechanical apparatusPhotographic printingResistLight source

The present invention provides an exposure apparatus and an exposure method. The method comprises: utilizing an exposure light source to provide light rays to the photo-resist layer; and utilizing a reflective plate to reflect the light rays passing through the photo-resist layer and the transparent substrate back to the photo-resist layer. The present invention can reduce a line space of a pattern of the photo-resist layer.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com