Electromagnetic ultrasonic detection method for plane residual stress

An electromagnetic ultrasonic and residual stress technology, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, instruments, and materials to achieve the effects of reducing spacing, improving spatial resolution, facilitating installation and multiple reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

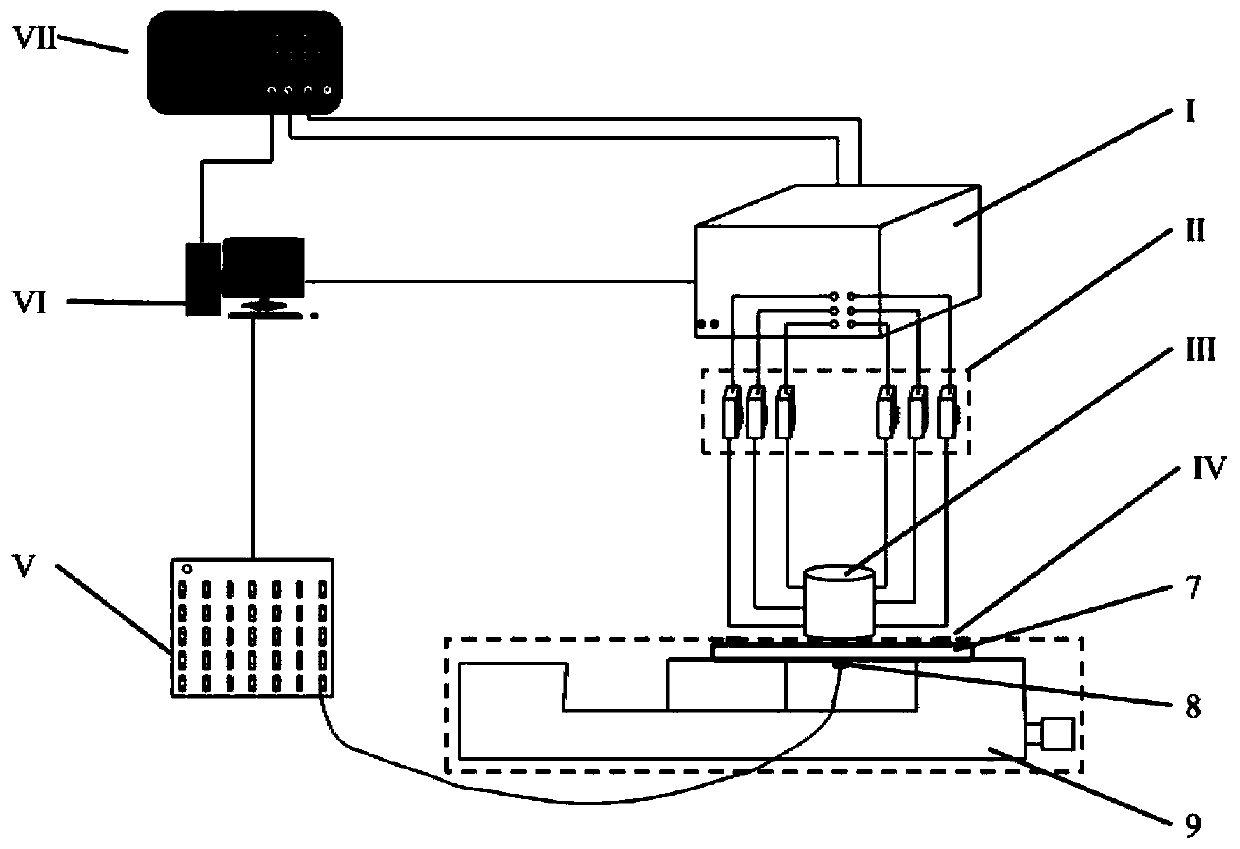

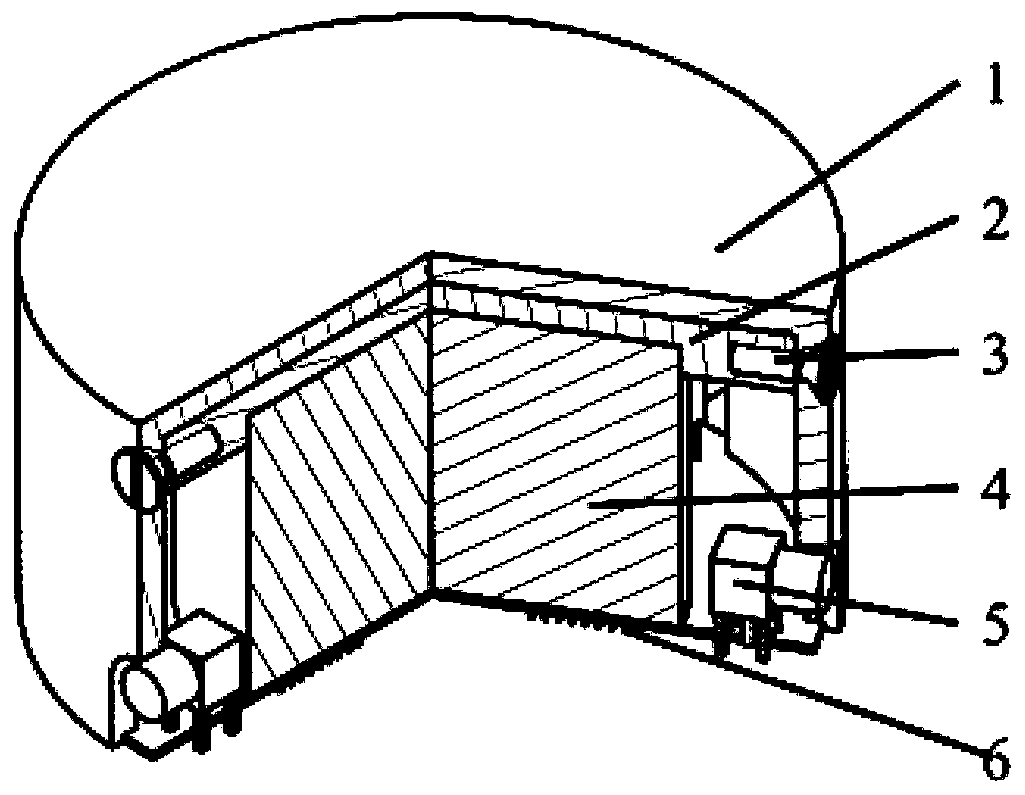

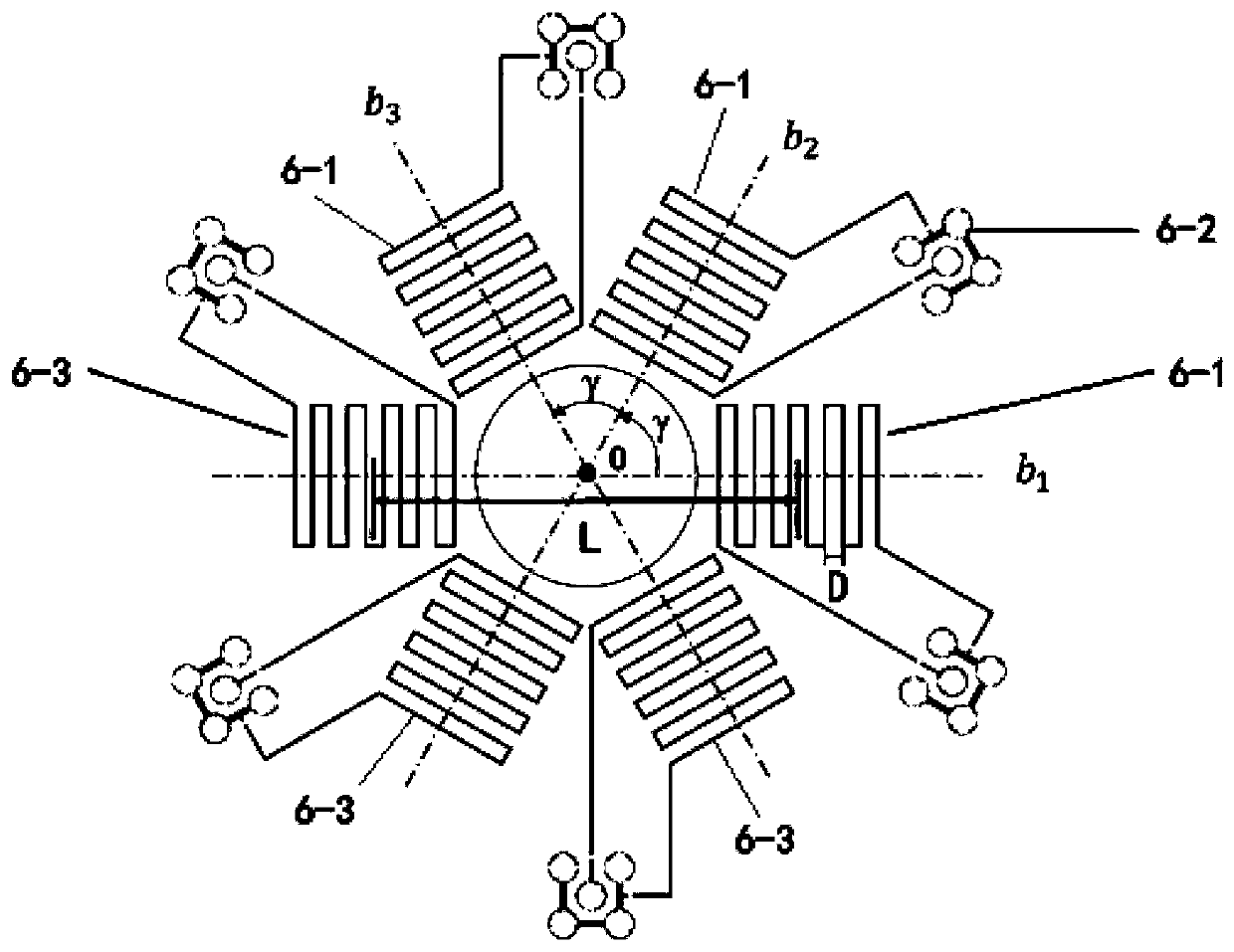

[0038] The implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions, and the electromagnetic ultrasonic testing method for plane residual stress will be described.

[0039] Measurement parameters: tensile test piece, material is 7075 aluminum, thickness 8mm; tested piece, welded 7075 aluminum alloy plate, size is 150mm×240mm, thickness is 8mm; ultrasonic transmitting coil 6-1 and ultrasonic receiving coil 6-3 are It is serpentine, the distance between adjacent wires is D=0.8mm, the ultrasonic frequency of the excited surface wave is 1.75MHz, and the distance between the ultrasonic transmitting coil 6-1 and the ultrasonic receiving coil 6-3 is L=19.2mm.

[0040] The concrete steps of the inventive method are as follows:

[0041] The first step is to assemble the electromagnetic ultrasonic testing system

[0042] The electromagnetic ultrasonic detection system consists of ultrasonic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com