Circuit-embedded type single-sided flexible circuit board and preparation method thereof

A flexible circuit board and embedded technology, which is applied in the fields of printed circuit manufacturing, printed circuit, printed circuit components, etc., can solve problems such as the inability to meet the needs of low line spacing circuit boards, reduce the risk of short circuit in the package, and improve assembly , good bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

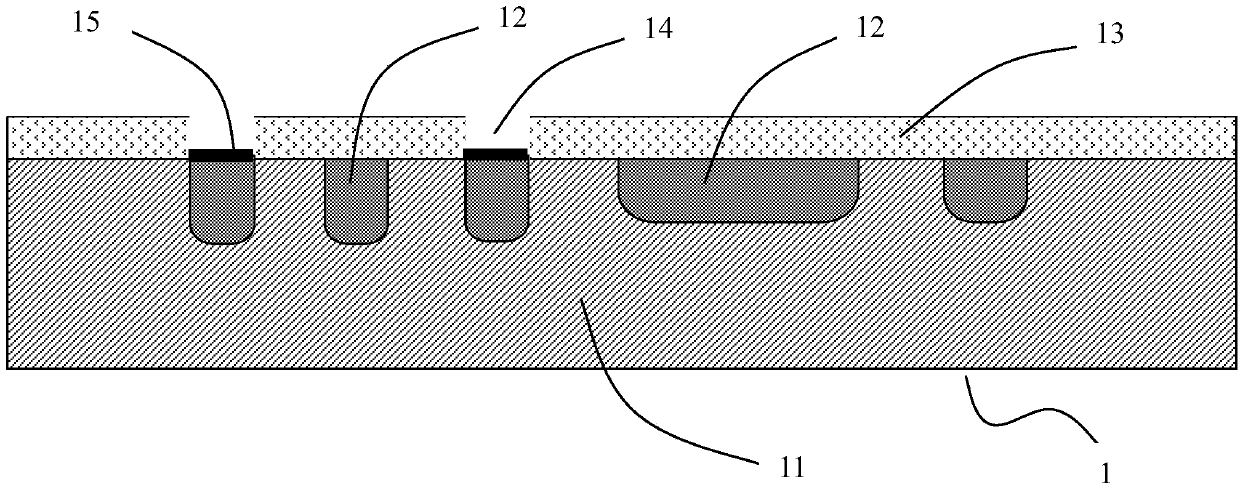

[0039] see Figure 1 to Figure 9 , a single-sided flexible circuit board 1 of the present embodiment includes an insulating layer 11 and a circuit 12 embedded in the insulating layer 11. There are several pad areas 14 on the circuit 12, and the upper surface of the circuit 12 in the pad area 14 has The surface treatment layer 15 has a solder resist layer 13 on the upper surface of the circuit 12 except the pad region 14 and the upper surface of the insulating layer 11 . In this embodiment, the material of the insulating layer 11 is polyimide (PI), the material of the solder resist layer 13 is solder resist ink, and the surface treatment layer is a metal plating layer, which is a gold layer, a palladium layer and a nickel layer from top to bottom. , the thickness is 0.05-0.15 μm, 0.05-0.15 μm, 3-8 μm in turn.

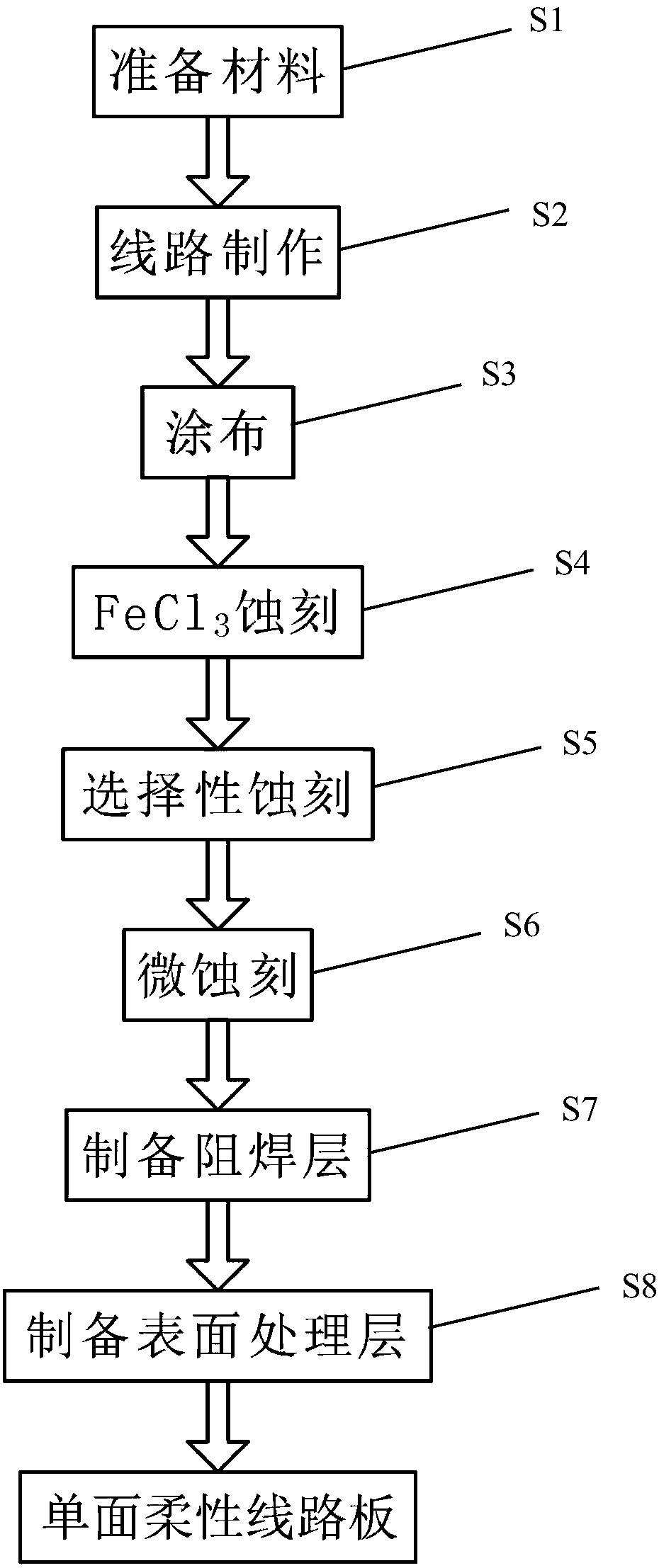

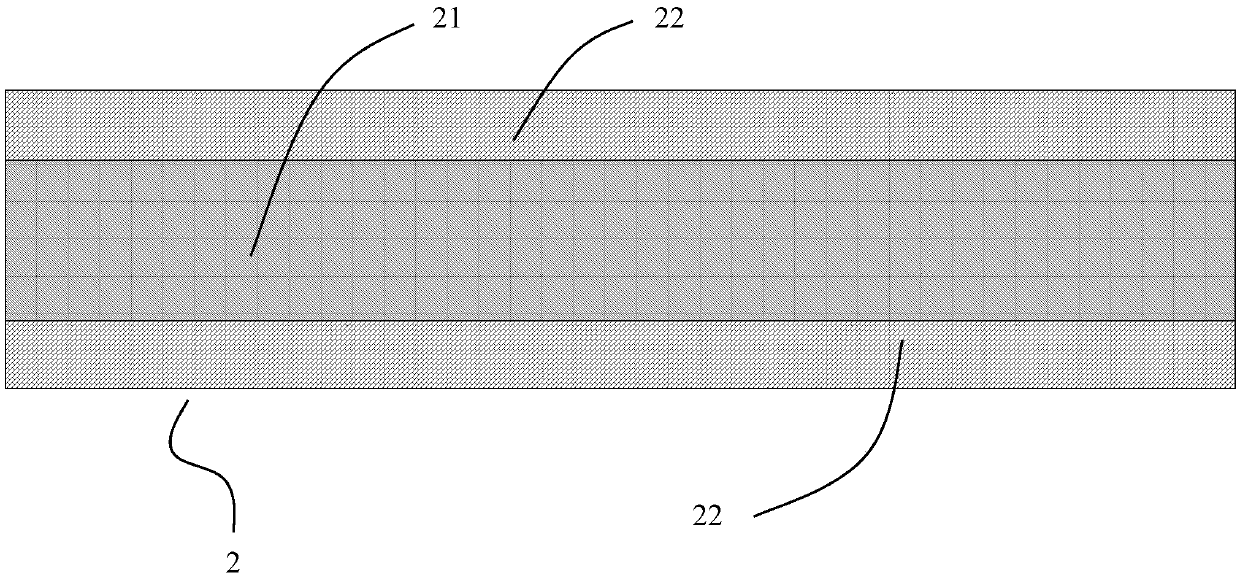

[0040] This embodiment also provides a method for preparing a single-sided flexible circuit board, such as figure 2 As shown, it specifically includes the following s...

Embodiment 2

[0060] see Figure 1 to Figure 8 and Figure 10 to Figure 12 , a single-sided flexible circuit board 1 of the present embodiment includes an insulating layer 11 and a circuit 12 embedded in the insulating layer 11. There are several pad areas 14 on the circuit 12, and the upper surface of the circuit 12 in the pad area 14 has The surface treatment layer 15 has a solder resist layer 13 on the upper surface of the circuit 12 except the pad region 14 and the upper surface of the insulating layer 11 . In this embodiment, the material of the insulating layer 11 is polyimide (PI), the material of the solder resist layer 13 is polyimide, and the surface treatment layer is a metal plating layer, which is a gold layer, a palladium layer and a nickel layer from top to bottom. layer, the thickness is 0.05-0.15 μm, 0.05-0.15 μm, 3-8 μm in sequence.

[0061] This embodiment also provides a method for preparing a single-sided flexible circuit board, such as Figure 10 As shown, it specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com