Medium and low speed magnetic levitation small linear interval single-crossover turnout

A technology with small line spacing and maglev, applied in the directions of roads, tracks, buildings, etc., can solve the problems of large area of turnout area, increased line spacing of turnout area, and influence of station design, so as to reduce the occupation and difficulty, reduce The overall cost and the effect of reducing unreliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

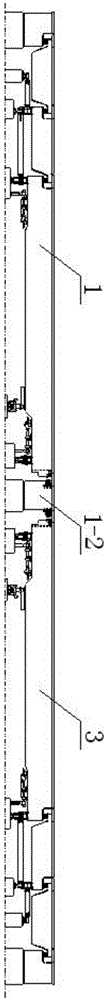

[0038] Overall structure plan:

[0039] 1. Beam structure

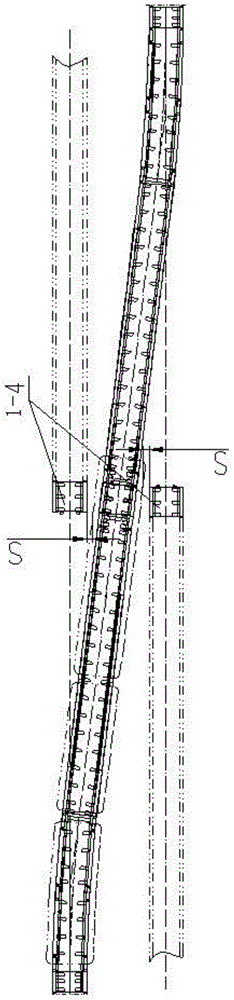

[0040] Two single turnouts are used for docking, and the middle stacking beam is removed. In order to allow vehicles to pass safely at the position of the side line, an avoidance beam is added. Vehicles pass through the line, and the straight line position fully meets the vehicle limit requirements. In order to ensure that vehicles pass laterally from the turnout to meet the limit requirements, as shown in the figure: L 车宽 +L 轨道宽 +2S=3.36+2.2+2X0.335=6.23m. In order to allow vehicles to pass safely, the fixed beams in the past are designed as avoidance beams and moved a certain distance to allow vehicles to pass smoothly.

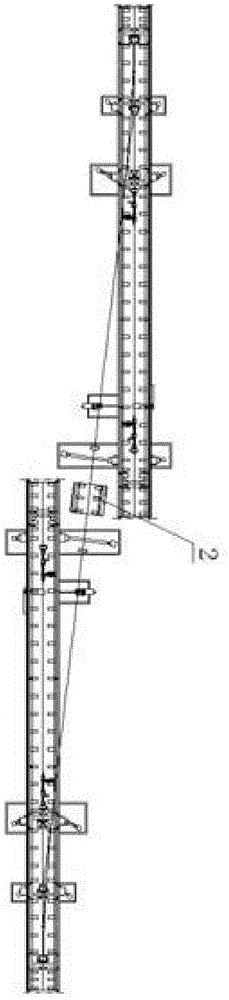

[0041] 2. Beam follower mechanism

[0042] In order to move the avoidance beam, a set of beam follower device is designed. The main beam is driven by a motor to drive the crank to drive the turnout beam to move. The avoidance beam does not design an independent drive system, but a set of followe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com