Circuit board manufacturing method and circuit board

A production method and circuit board technology, which is applied in the fields of printed circuit manufacturing, printed circuit, electrical components, etc., can solve problems such as complex process, insufficient bonding strength, and difficult to solve the sandwich problem, so as to enhance the thickness of copper plating, save process, The effect of shrinking the line spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

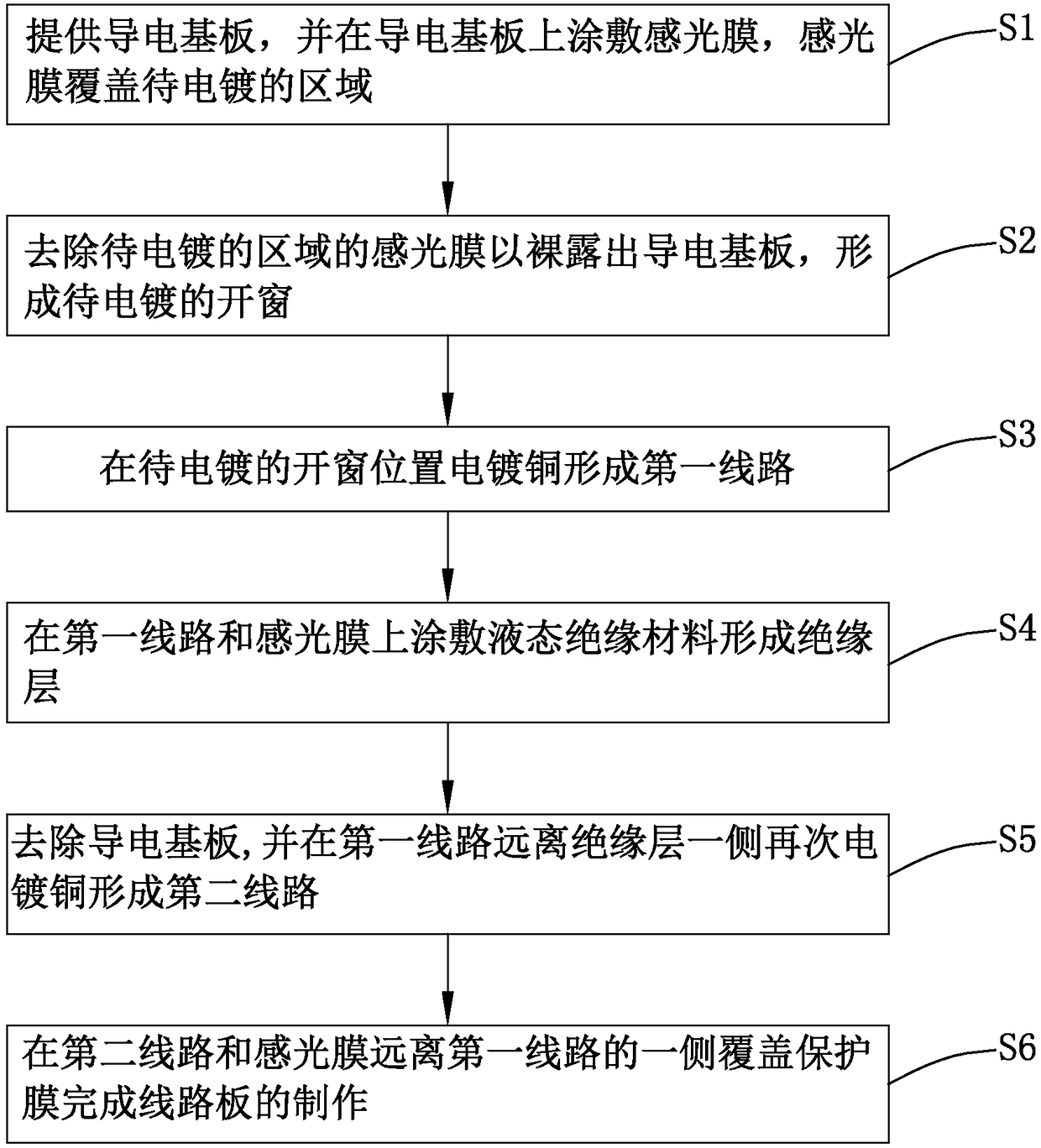

[0032] see figure 1 , the present invention provides a kind of manufacturing method of circuit board, comprises the following steps:

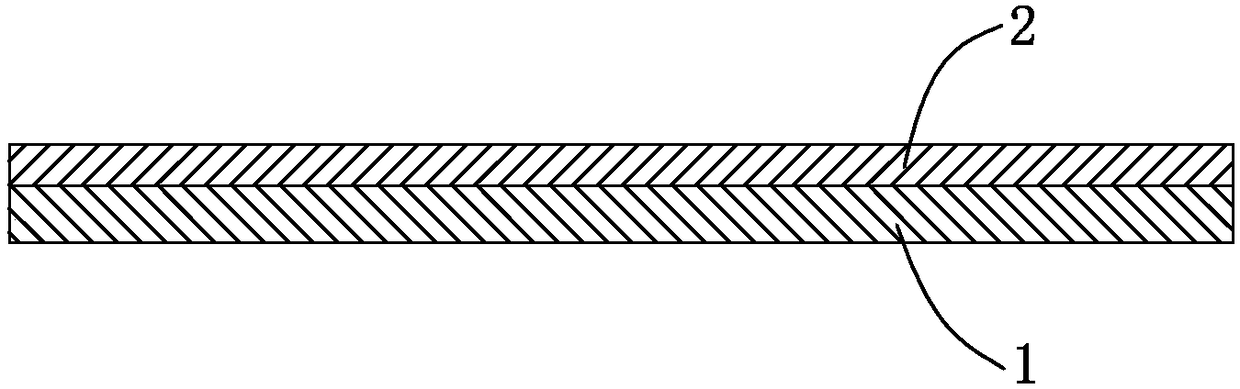

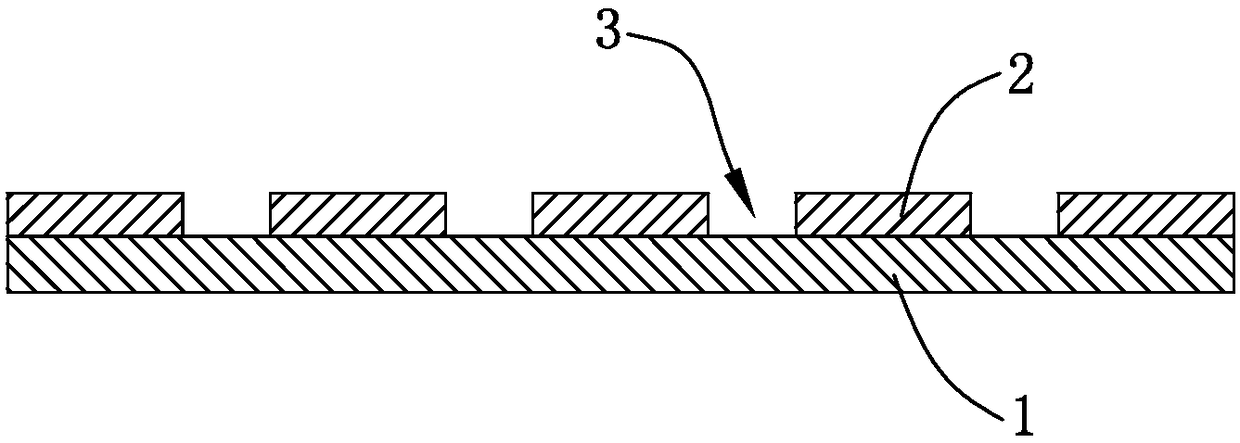

[0033] S1: Provide a conductive substrate 1, and coat a photosensitive film 2 on the conductive substrate 1. The photosensitive film 2 covers the area to be electroplated. For details, see figure 2 shown;

[0034] The conductive substrate 1 is made of conductive materials, preferably, the conductive substrate 1 is a mirror steel plate. The surface of the conductive substrate 1 can be plated with a copper layer by electroplating, and the copper layer can be peeled off the surface smoothly.

[0035] Specifically, under a yellow light environment, the photosensitive film 2 with a required thickness is pressed onto the light surface of the conductive substrate 1 under a first specified condition, and the first specified condition includes:

[0036] Temperature 65~120℃;

[0037] Pressure 1~6Kg / cm 2 ;

[0038] Speed 1~5m / min.

[0039] The p...

Embodiment 2

[0058] The invention provides a method for manufacturing a circuit board.

[0059] The difference between this embodiment and Embodiment 1 is that:

[0060] S2': removing the photosensitive film 2' in the area to be electroplated to expose the conductive substrate 1', forming an open window 3' to be electroplated;

[0061] Concrete, described step S2' comprises:

[0062] Bake at high temperature to fully cure the photosensitive film 2'.

[0063] Removing the photosensitive film 2' of the region to be electroplated by laser ablation;

[0064] Plasma cleaning is performed to expose the conductive substrate 1' to form an open window 3' to be electroplated.

[0065] At the same time, the present invention also provides a circuit board manufactured by applying the method for manufacturing the circuit board.

[0066] Compared with the related art, the photosensitive film 2 in the circuit board manufacturing method of the present invention is made of PI, LCP or PEN material, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com