Reversal copper foil production process

A production process and copper foil technology, applied in the field of reversed copper foil production process, can solve the problems of affecting the elongation of the plate, the surface bonding force is reduced, and the residual glue is easy to remain, so as to reduce the risk of falling off, increase the surface area, The effect of reducing the residual copper rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1, electrolytic raw foil and surface treatment, the surface treatment includes: micro-etching→acid washing→water washing→surface alloying treatment→water washing→surface anti-oxidation treatment→water washing→passivation→coating anti-adhesive film on the rough surface →silanization treatment→drying, the composition and content of each component in the coating anti-adhesive film are: organochlorosilane 40wt%, organopolysiloxane resin 30wt%, aminosilane 15wt%, polyester resin 11wt%, acidic The clay catalyst is 4wt%, and the thickness of the coated anti-adhesive film is 3 μm. with H 2 SO 4 Pickling the rough side of the inverted copper foil, followed by coating of the anti-adhesive film, H 2 SO 4 The concentration is 80g / L, and the concentration is 30g / L H before the pickling process. 2 SO 4 The solution was soaked for 0.5h, and then kept at a humidity of 45%RH for 0.5h. Put the coated inverted copper foil at 20°C and 60% RH, and keep it for 0.5h, and then us...

Embodiment 2

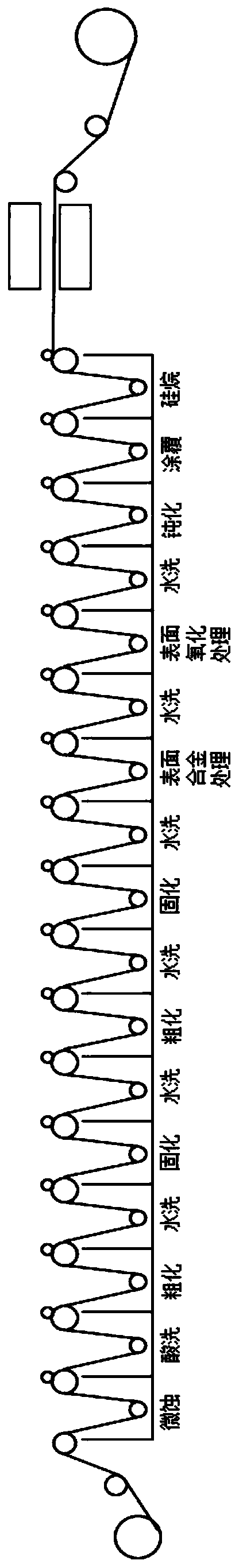

[0021] Example 2, figure 1The process flow chart of Example 2 of the present invention, electrolytic raw foil and surface treatment, the surface treatment includes: micro-etching → pickling → roughening → water washing → curing → water washing → roughening → water washing → curing → water washing → surface alloying Treatment→water washing→surface anti-oxidation treatment→water washing→passivation→coating anti-adhesive film on the rough surface→silanization treatment→drying, the composition and content of each component in the coated anti-adhesive film is: organochlorosilane 40wt% , organopolysiloxane resin 30wt%, aminosilane 15wt%, polyester resin 11wt%, acid clay catalyst 4wt%, and the thickness of the coated anti-adhesive film is 3 μm. with H 2 SO 4 Pickling the rough side of the inverted copper foil, followed by coating of the anti-adhesive film, H 2 SO 4 The concentration is 80g / L, and the concentration is 30g / L H before the pickling process. 2 SO 4 The solution was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com