Medium-carbon low-cost L245-L320-grade pipeline steel and manufacturing method thereof

A L245-L320, pipeline steel technology, applied in the field of low-alloy steel production technology, can solve the problem of high production cost, achieve the effects of reducing alloy cost, improving refinement degree and uniformity, and high production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

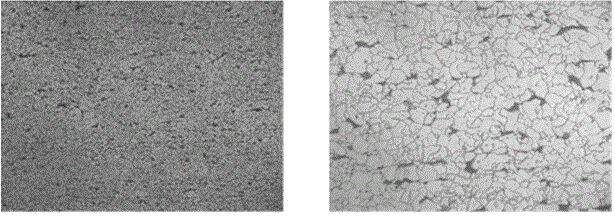

Image

Examples

Embodiment 1

[0025] Example 1 A medium-carbon low-cost L245-L320 grade pipeline steel and its manufacturing method

[0026] Its chemical composition is composed as follows by mass percentage:

[0027] C: 0.16%, Si: 0.19%, Mn: 0.6%, P: 0.013%, S: 0.002%, Al: 0.025%, and the rest are iron and unavoidable impurities.

[0028] Manufacturing process: KR→converter smelting→deoxidation alloying→CAS→LF→VD / RH→continuous casting→slab stacking and slow cooling for 48 hours→slab heating→scaling→rough rolling→finish rolling→ACC→straightening→ Cooling→flaw detection→marking and warehousing. in,

[0029] (1) Heating: The above-mentioned prepared raw materials are smelted on a 120-ton converter, the continuous casting slab is heated to 1220°C, the heating rate is 1cm / 9-10min, and the time in the furnace is 3h.

[0030] (2) Rolling: three-stage rolling of forming, widening, and elongation is adopted. The rolling start temperature of the roughing mill is 1150°C, and the reduction rate of the roughing pas...

Embodiment 2

[0034] Example 2 A medium-carbon low-cost L245-L320 grade pipeline steel and its manufacturing method

[0035] Its chemical composition is composed as follows by mass percentage:

[0036] C: 0.15%, Si: 0.15%, Mn: 0.55%, P: 0.011%, S: 0.003%, Al: 0.03%, and the rest are iron and unavoidable impurities.

[0037] Manufacturing process: KR→converter smelting→deoxidation alloying→CAS→LF→VD / RH→continuous casting→slab stacking and slow cooling for 48 hours→slab heating→scaling→rough rolling→finish rolling→ACC→straightening→ Cooling→flaw detection→marking and warehousing. in,

[0038] (1) Heating: The above-mentioned prepared raw materials are smelted in a 120-ton converter, and the continuous casting slab is heated to 1190°C with a heating rate of 1cm / 9-10min and a furnace time of 2.5h.

[0039] (2) Rolling: Three-stage rolling of forming, widening, and elongation is adopted. The rolling start temperature of the roughing mill is 1160°C, and the reduction rate of the roughing pass ...

Embodiment 3

[0042] Example 3 A medium-carbon low-cost L245-L320 grade pipeline steel and its manufacturing method

[0043] Its chemical composition is composed as follows by mass percentage:

[0044] C: 0.17%, Si: 0.14%, Mn: 0.5%, P: 0.01%, S: 0.0025%, Al: 0.036%, and the rest are iron and unavoidable impurities.

[0045] Manufacturing process: KR→converter smelting→deoxidation alloying→CAS→LF→VD / RH→continuous casting→slab stacking and slow cooling for 48 hours→slab heating→scaling→rough rolling→finish rolling→ACC→straightening→ Cooling → flaw detection → marking, storage. in,

[0046] (1) Heating: The above-mentioned prepared raw materials are smelted in a 120-ton converter, and the continuous casting slab is heated to 1200°C with a heating rate of 1cm / 9-10min and a furnace time of 3h.

[0047] (2) Rolling: Three-stage rolling of forming, widening, and elongation is adopted. The rolling start temperature of the roughing mill is 1140°C, and the reduction rate of the roughing pass is ≥12%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Shock value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com