Roadbed pile pipe curtain supporting structure after addition of two-line-platform to railway

A second-line platform and curtain technology, applied in infrastructure engineering, roads, excavation, etc., can solve the problems of land occupation, increase in filling (excavation) volume investment, low construction efficiency, and high construction risk, so as to ensure normal operation and safety, reduce the support structure, and reduce the construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

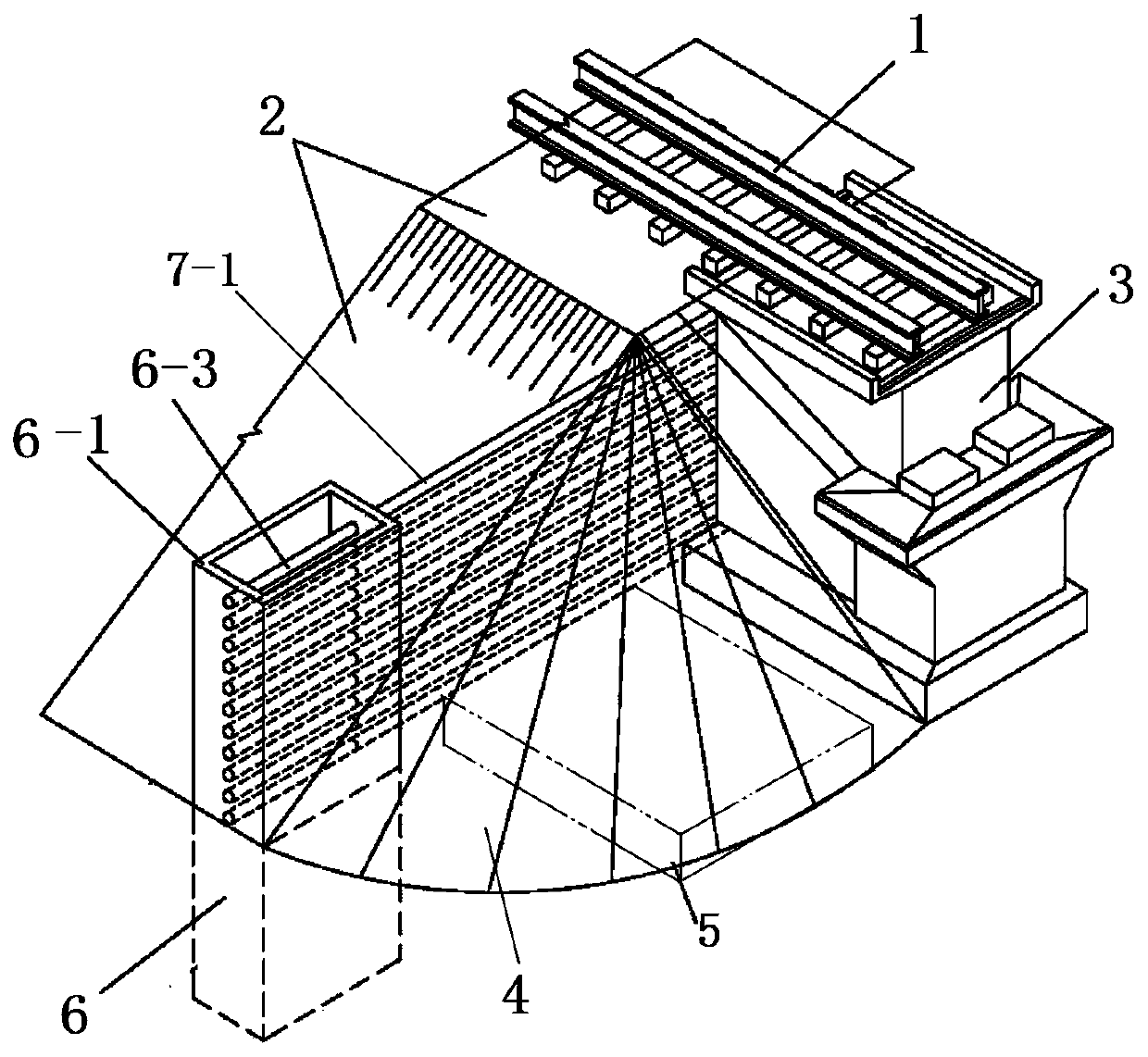

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

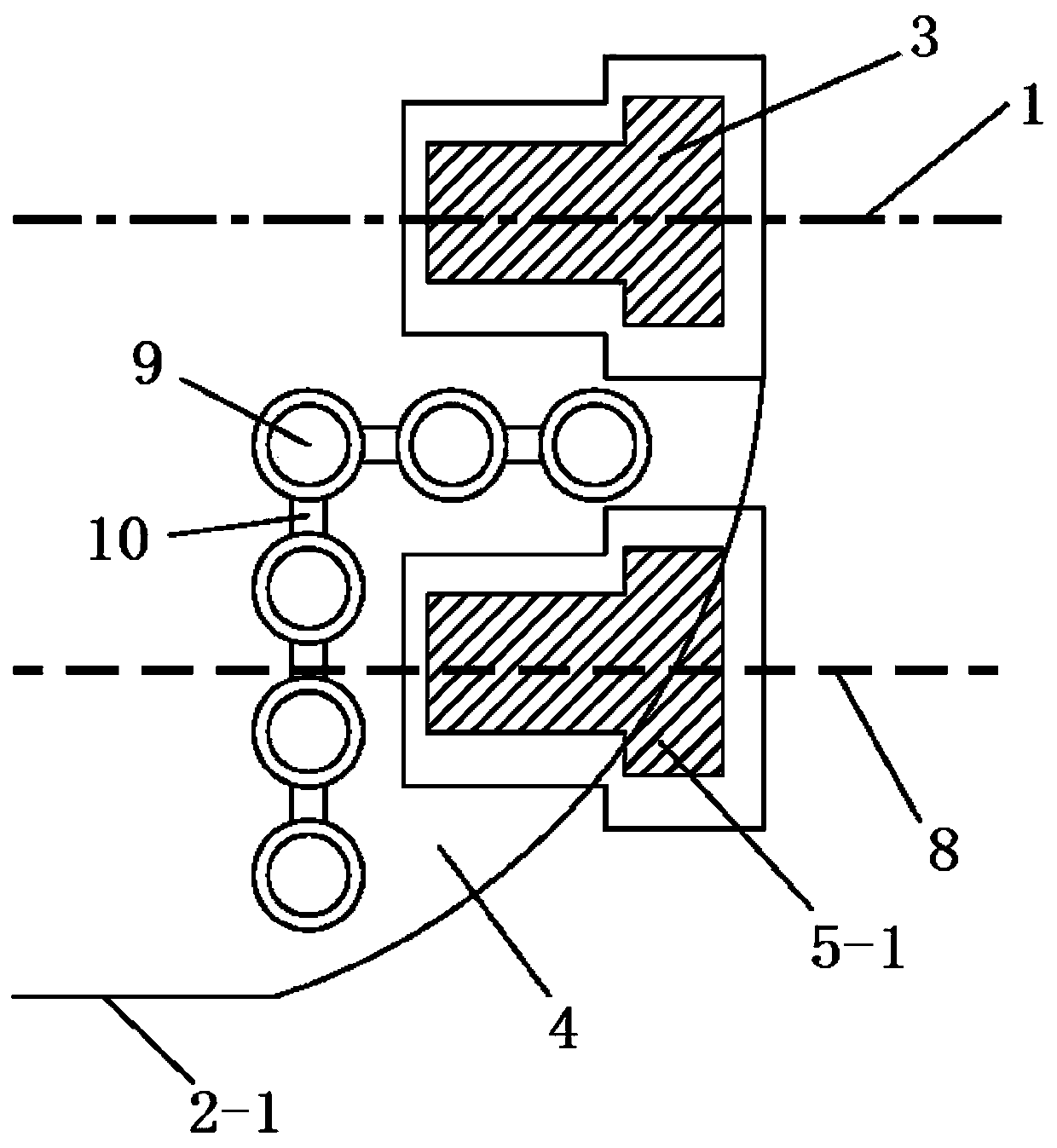

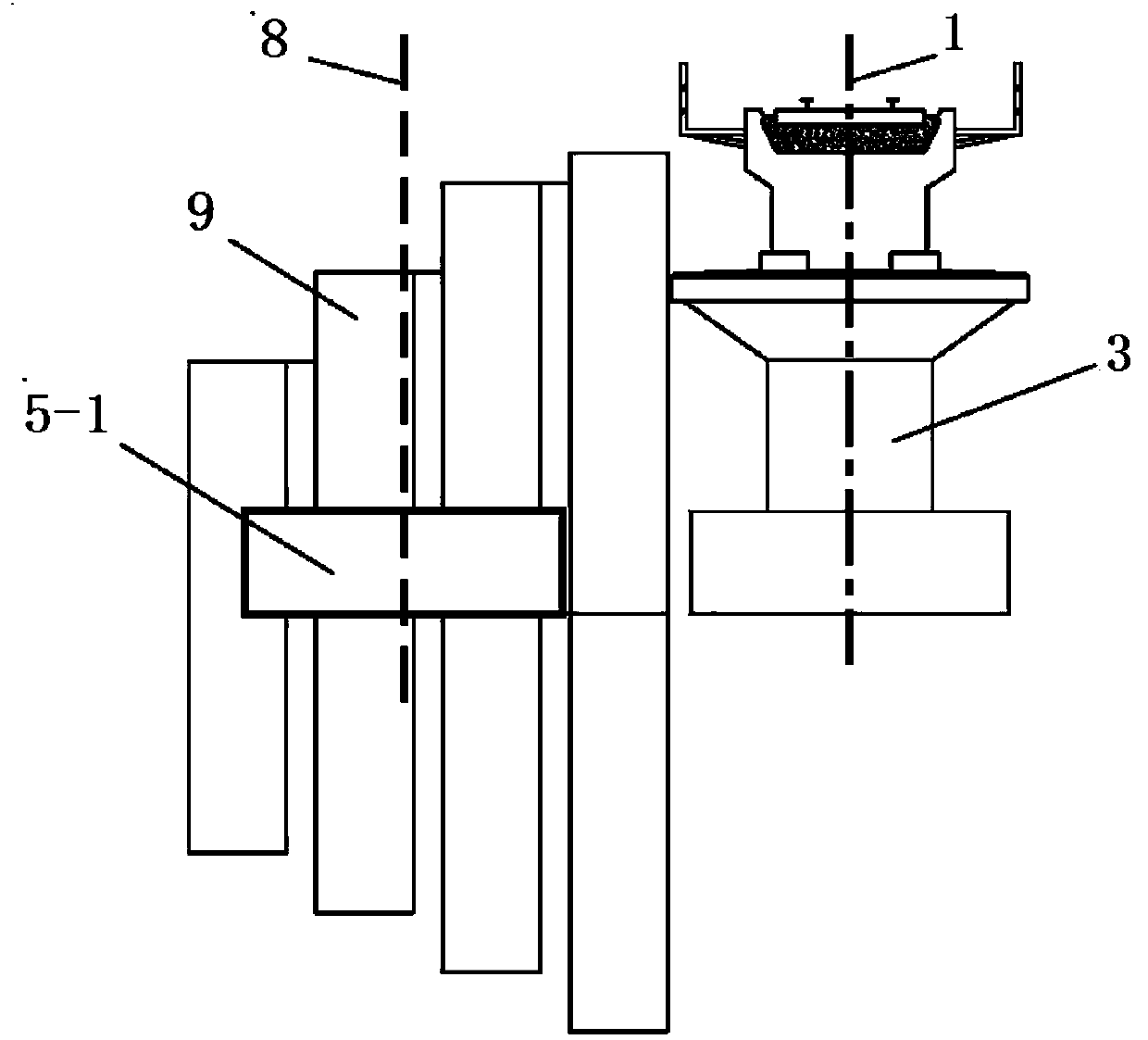

[0030] At present, the conventional protection schemes for the excavation of the foundation pit of the newly added second-line abutment include: the existing railway lines within the construction scope shall be protected by "erecting 3-5-3 buckle hanging rail beams", and the second-line abutment 5-1 shall rely on the existing The abutment 3 and the slope of the foundation pit on one side of the subgrade are protected by "multiple excavated piles 9 plus cast-in-place reinforced concrete walls 10" (referred to as "pile-slab continuous wall"). The gap between piles 9 and 9 is cast-in-place Reinforced concrete wall 10 (thickness 20cm) is used for secondary protection, and woven bag cofferdam is used to protect the slope toe. figure 1 , figure 2 Shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com