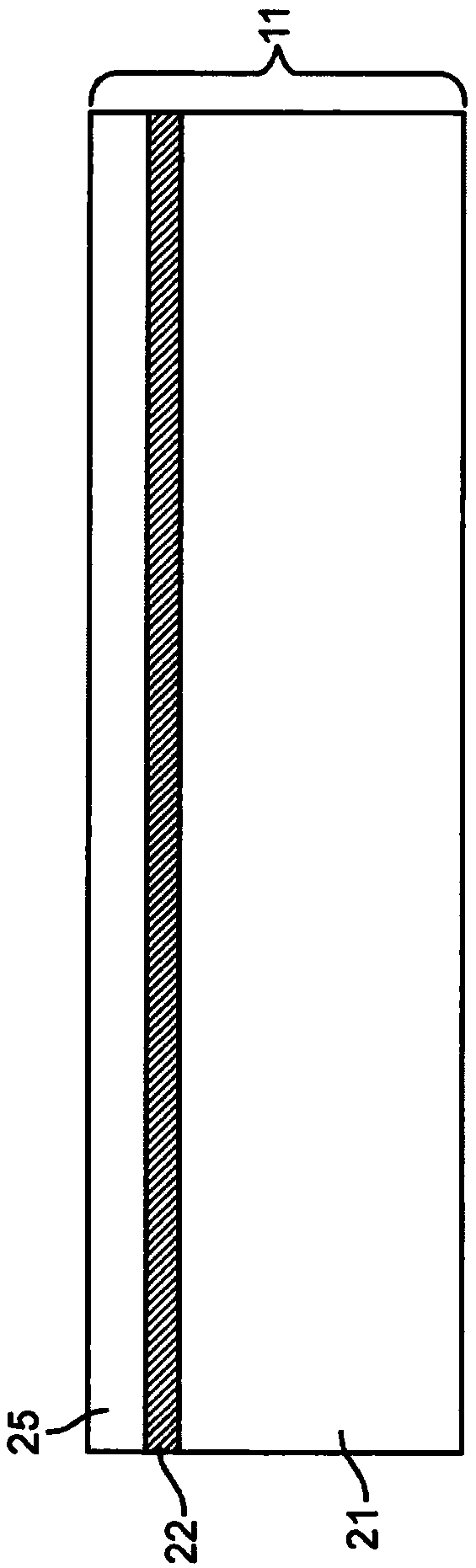

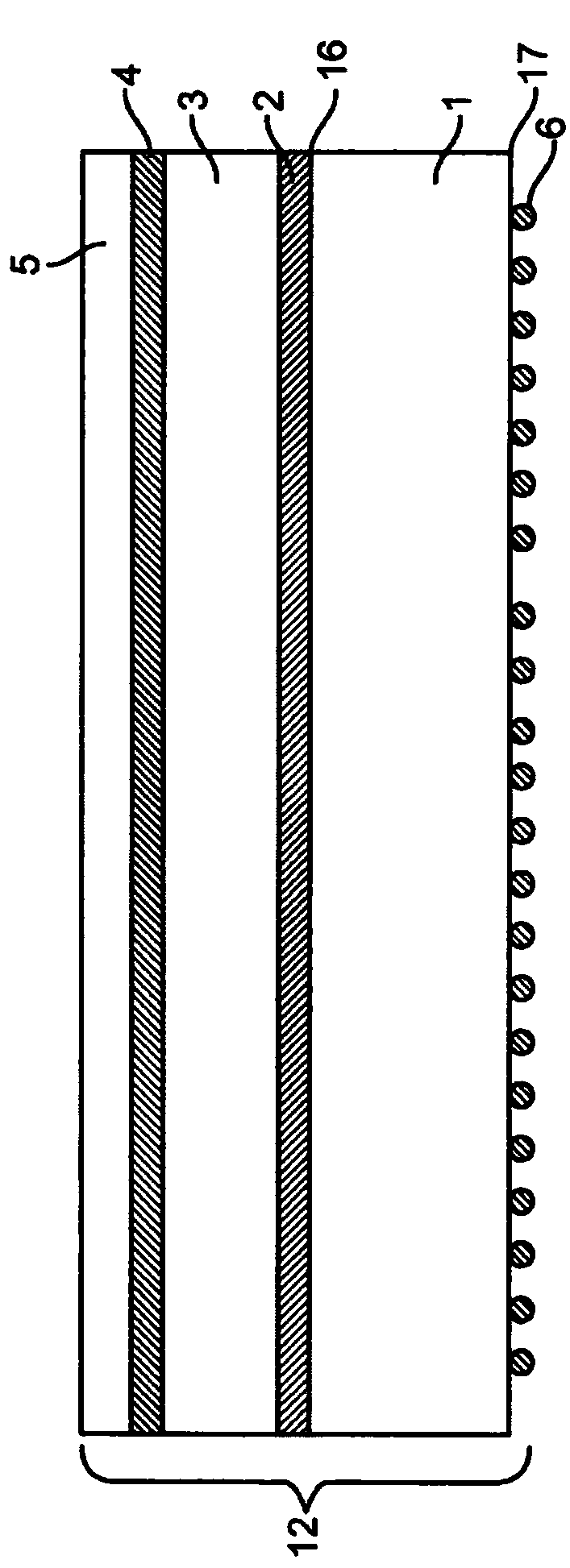

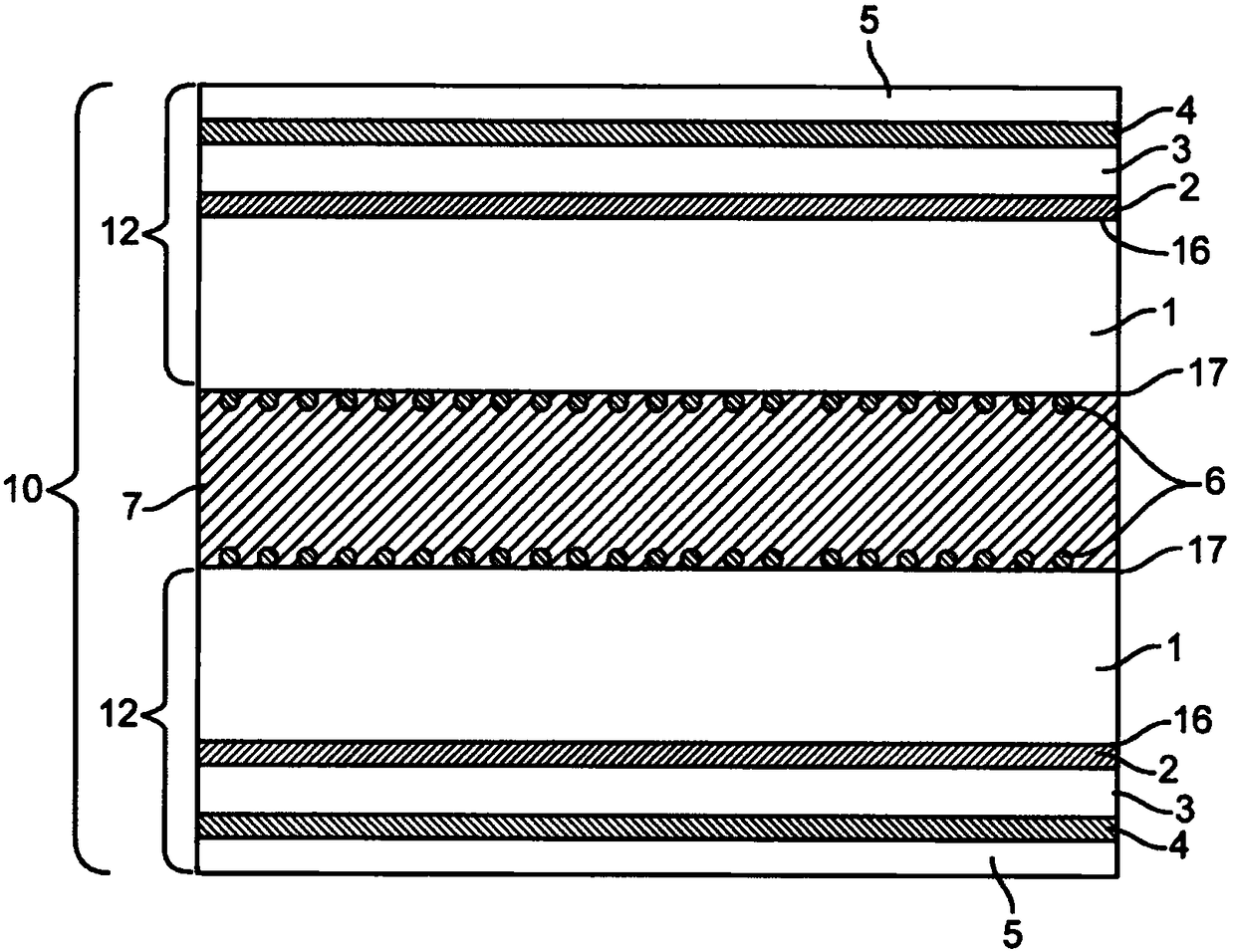

Multilayer carrier foil

A multi-layer carrier and carrier foil technology, which is applied in the direction of multi-layer circuit manufacturing, layered products, metal layered products, etc., can solve problems such as consumption, more energy, and affecting the consistency of peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0109] Preparation of copper carrier layer

[0110] Copper wire was dissolved with 50% by weight of sulfuric acid aqueous solution to prepare copper sulfate pentahydrate (CuSO4) containing 320 g / L. 4 ·5H 2 O) Copper sulfate electrolyte with 110 g / L sulfuric acid. Add 5.5 mg of low molecular weight gum (DV, manufactured by Nippi Co., Ltd.), 3 mg of sodium 3-mercaptopropanesulfonate (MPS, manufactured by Polymer International Co., Ltd.) and 25 mg of per liter of copper sulfate electrolyte. Hydrochloric acid (manufactured by RCI Labscan Co., Ltd.), at a liquid temperature of 50°C and a temperature of 50 amperes / square decimeters (A / dm 2 ) Electrolytic copper foil with a thickness of 18 microns was prepared under the current density.

[0111] A typical apparatus for making copper foil includes a metal cathode roll, which is rotatable and has a mirror-polished surface, and an insoluble metal anode. The insoluble metal anode is mounted on about the lower half of the metal cathod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com