Method for treating trivalent-chromium chromium-plating wastewater

A treatment method and technology for trivalent chromium, which are applied in the fields of metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as difficulty in reaching the standard of trivalent chromium, achieve good market application prospects, low treatment costs, and reduce The effect of COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

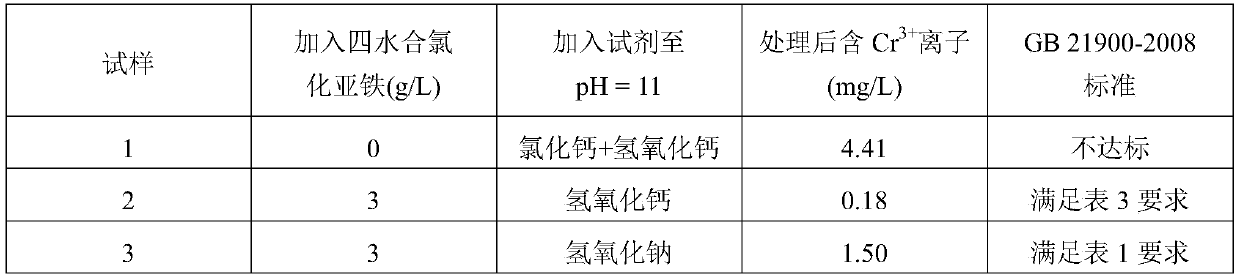

[0047] Embodiment 1: process the trivalent chromium plating wastewater containing citric acid

[0048] This embodiment provides a treatment method for trivalent chromium chrome-plating wastewater in a sulfate system, to process trivalent chromium chromium-plating wastewater containing 300 mg / L of trivalent chromium ions and 400 mg / L of citric acid. Organic additive; comprising the steps of:

[0049] Step 1, add ferrous chloride

[0050] The trivalent chromium-plating wastewater is imported from the wastewater regulating tank to the feeding tank, and under mechanical stirring, 15L ferrous chloride solution is added to every ton of wastewater.

[0051] Step 2, precipitation of citric acid and trivalent chromium

[0052] The wastewater flows from the feeding tank into the sedimentation tank. Under mechanical stirring, lime emulsion is added to make the pH of the wastewater to 10-12. Ferrous ions and calcium ions form precipitates with citric acid, and trivalent chromium ions re...

Embodiment 2

[0063] Embodiment 2: process the trivalent chromium plating wastewater containing malic acid

[0064] This embodiment provides a treatment method for trivalent chromium chromium plating wastewater in a sulfate system, to process trivalent chromium chromium plating wastewater containing 100 mg / L of trivalent chromium ions and 800 mg / L of malic acid. Organic additive; comprising the steps of:

[0065] Step 1, add ferrous chloride

[0066] The trivalent chromium-plating wastewater is imported from the wastewater regulating tank to the feeding tank, and under mechanical stirring, 25L ferrous chloride solution is added to every ton of wastewater.

[0067] Step 2, precipitation of malic acid and trivalent chromium

[0068] The wastewater flows from the feeding tank into the sedimentation tank, and under mechanical stirring, lime emulsion is added to make the pH of the wastewater to 10-12, ferrous ions and calcium ions form precipitates with malic acid, and trivalent chromium ions ...

Embodiment 3

[0079] Embodiment 3: process the trivalent chromium plating waste water containing formic acid

[0080] This embodiment provides a treatment method for trivalent chromium plating wastewater in a chloride system to treat trivalent chromium chromium plating wastewater containing 400 mg / L of trivalent chromium ions and 600 mg / L of formic acid. The wastewater contains a small amount of surfactants additive; comprising the following steps:

[0081] Step 1, add ferrous chloride

[0082] The trivalent chromium-plating wastewater regulating tank is input into the feeding tank, and under mechanical stirring, 20L ferrous chloride solution is added in every ton of wastewater.

[0083] Step 2, precipitation of formic acid and trivalent chromium

[0084] The wastewater flows from the feeding tank into the sedimentation tank, and under mechanical stirring, lime emulsion is added to make the pH of the wastewater to 10-12, ferrous ions and calcium ions form precipitates with formic acid, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com