Method for repairing chromium-contaminated soil

A technology of chromium-contaminated soil and soil, applied in the restoration of polluted soil, etc., to achieve the effect of solving the problem of yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

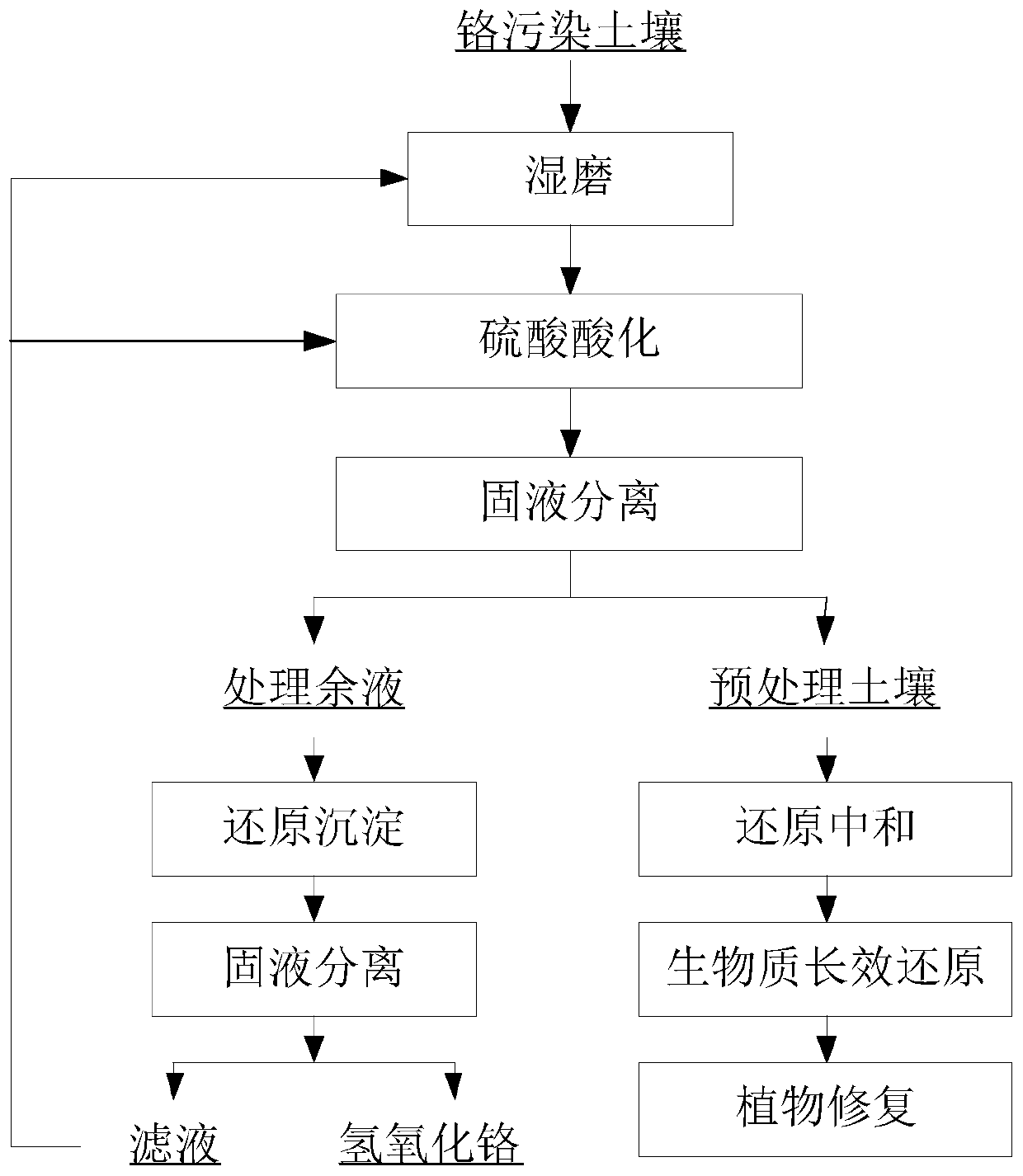

[0068] The invention provides a method for remediating this chromium-contaminated soil, said method comprising the following steps:

[0069] (1) The chromium-contaminated soil containing 8000mg / kg of hexavalent chromium and the grinding solution are wet-milled to obtain a slurry; wherein, the particle size of the chromium-contaminated soil particles in the slurry is 160 mesh, and in the slurry The content of chromium-contaminated soil is 50%;

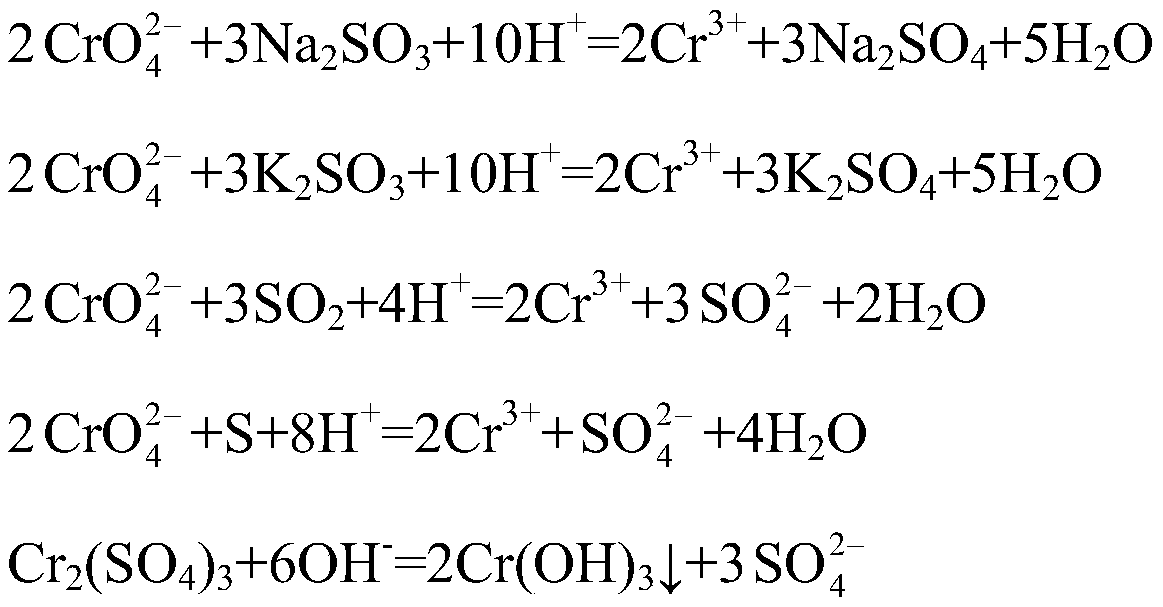

[0070] (2) mixing the slurry obtained in step (1) with 80% sulfuric acid and the return solution, and performing an acidification treatment for 2 hours to obtain the acidification treatment slurry, which was subjected to solid-liquid separation to obtain a treatment residue and pretreated soil; wherein , the amount of sulfuric acid added is H 2 SO 4 The ratio of meter to chromium-contaminated soil quality in the slurry is 0.2:1; wherein, 99.2% of the acid-soluble hexavalent chromium and water-soluble hexavalent chromium in the soil ar...

Embodiment 2

[0077] The invention provides a method for remediating this chromium-contaminated soil, said method comprising the following steps:

[0078] (1) The chromium-contaminated soil containing 16000 mg / kg of hexavalent chromium and the grinding solution are wet-milled to obtain a slurry; wherein, the particle size of the chromium-contaminated soil particles in the slurry is 200 mesh, and in the slurry The content of chromium-contaminated soil is 60%;

[0079] (2) mixing the slurry obtained in step (1) with sulfuric acid with a concentration of 95% and the return solution, and performing an acidification treatment for 2 hours to obtain the acidification treatment slurry, and through solid-liquid separation, to obtain a treatment residual liquid and pretreated soil; wherein , the amount of sulfuric acid added is H 2 SO 4 The ratio of meter to chromium-contaminated soil quality in the slurry is 0.3:1; wherein, 99.3% of the acid-soluble hexavalent chromium and water-soluble hexavalent...

Embodiment 3

[0086] The invention provides a method for remediating this chromium-contaminated soil, said method comprising the following steps:

[0087] (1) The chromium-contaminated soil containing 5000 mg / kg of hexavalent chromium and the grinding solution are wet-milled to obtain a slurry; wherein, the particle size of the chromium-contaminated soil particles in the slurry is 120 mesh, and in the slurry The content of chromium-contaminated soil is 50%;

[0088] (2) mixing the slurry obtained in step (1) with 80% sulfuric acid and the return solution, and performing an acidification treatment for 2 hours to obtain the acidification treatment slurry, which was subjected to solid-liquid separation to obtain a treatment residue and pretreated soil; wherein , the amount of sulfuric acid added is H 2 SO 4 The ratio of meter to chromium-contaminated soil quality in the slurry is 0.15:1; wherein, 99.1% of the acid-soluble hexavalent chromium and water-soluble hexavalent chromium in the soil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com