Method for high-accuracy ink printed flexible circuit

An inkjet printing, flexible circuit technology, applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of low precision and resolution, unfavorable preparation of high-precision electronic circuits, etc., to improve resolution and good compatibility. , Improve the effect of printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

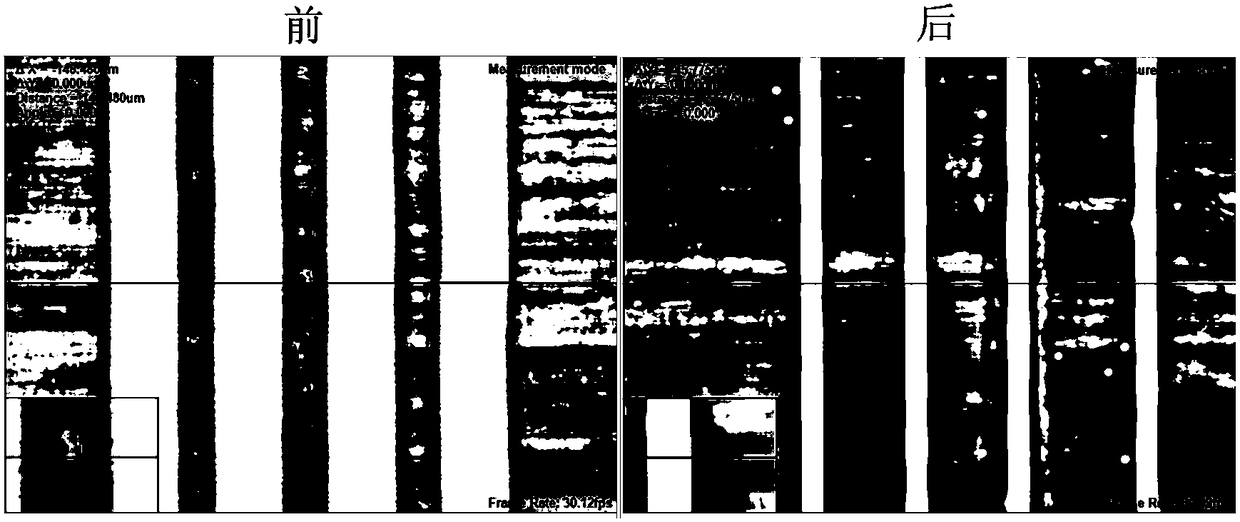

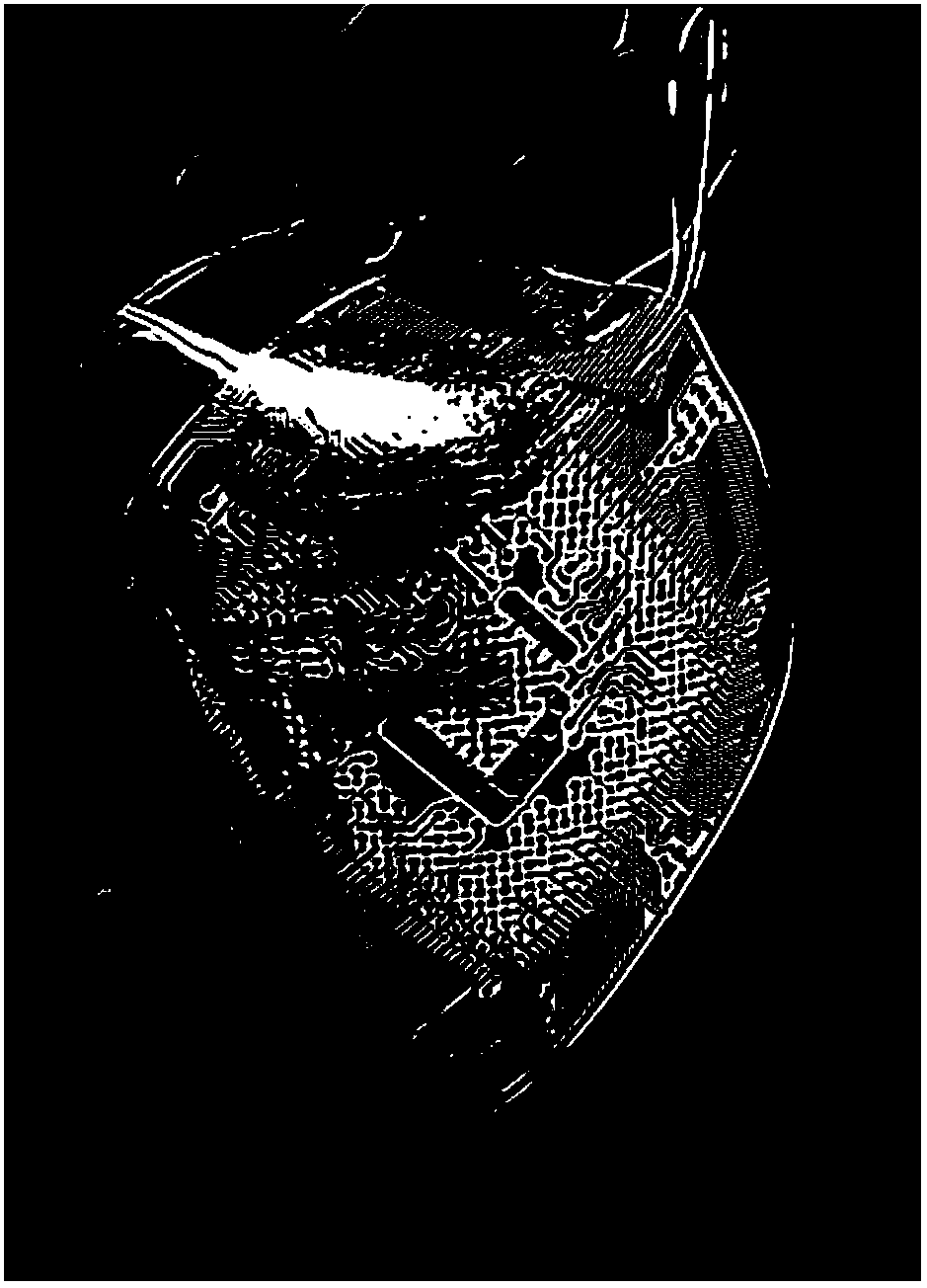

[0026] Spin-coat a layer of PDMS superhydrophobic material on the PET substrate, control the rotation speed at 8000rpm / s, spin-coating time is 30s, then control the temperature on the heating table to 120°C, and heat and cure for 1min. Then it was treated with oxygen plasma for 3s, and the treatment power was 700W. The processed substrate was placed on the printing platform, pre-heated to 55°C, and the control dot pitch was 35 μm to print the circuit.

Embodiment 2

[0028] A layer of PDMS superhydrophobic material was spin-coated on the PEN substrate, the rotation speed was controlled at 8000rpm / s, the spin-coating time was 30s, and then the temperature was controlled at 120°C on a heating platform, and heated and cured for 1min. Then it was treated with oxygen plasma for 3s, and the treatment power was 700W. The processed substrate was placed on the printing platform, preheated to 45°C, and the control dot pitch was 40 μm to print the circuit.

Embodiment 3

[0030] A layer of PDMS superhydrophobic material was spin-coated on the PI substrate, the rotation speed was controlled at 8000rpm / s, the spin-coating time was 30s, and then the temperature was controlled at 120°C on a heating platform, and heated and cured for 1min. Then it was treated with oxygen plasma for 3s, and the treatment power was 700W. The processed substrate was placed on the printing platform, preheated to 40°C, and the control dot pitch was 45 μm to print the circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com