PCB manufacturing method capable of preventing green oil hole plugging

A manufacturing method and PCB board technology, applied in printed circuit manufacturing, lithography/pattern, pattern and lithography, etc., can solve problems such as lack of gold plating in SMT, open circuit of electric via hole, plugged hole of solder resist ink, etc., to improve production The pass rate, improve the product pass rate, the effect of circuit graphics intact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

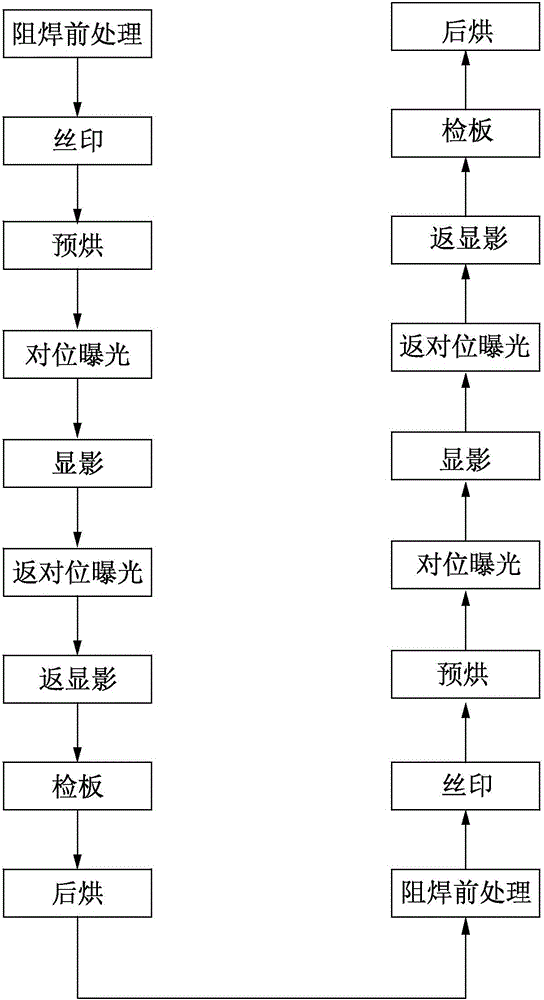

[0011] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the present invention provides a PCB manufacturing method for preventing green oil plug holes, which effectively solves the problem of green oil plug holes in micro-holes, HDI blind holes or back-drilled holes. The copper layer on the upper and lower surfaces of the inner core board is provided with a number of functional holes on the PCB. The functional holes can be micro-holes, HDI blind holes, back-drilled holes or through holes. The PCB manufacturing method for preventing green oil plug holes includes the following step:

[0013] (1) Pre-treatment of solder mask, cleaning and roughening the copper surface of the PCB board before solder mask screen printing, which includes the following processes: A. Washing and pickling to remove oxides on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com