Preparation process of micro-nano texture seamless splicing texture mold

A technology of seamless splicing and preparation process, applied in the exposure methods of radiation-sensitive masks, printed circuit manufacturing, circuit covers, etc., can solve the problems of edge chipping texture, missing, glue accumulation and air bubbles in the edge area. Achieve the effect of avoiding edge collapse and dirt and discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

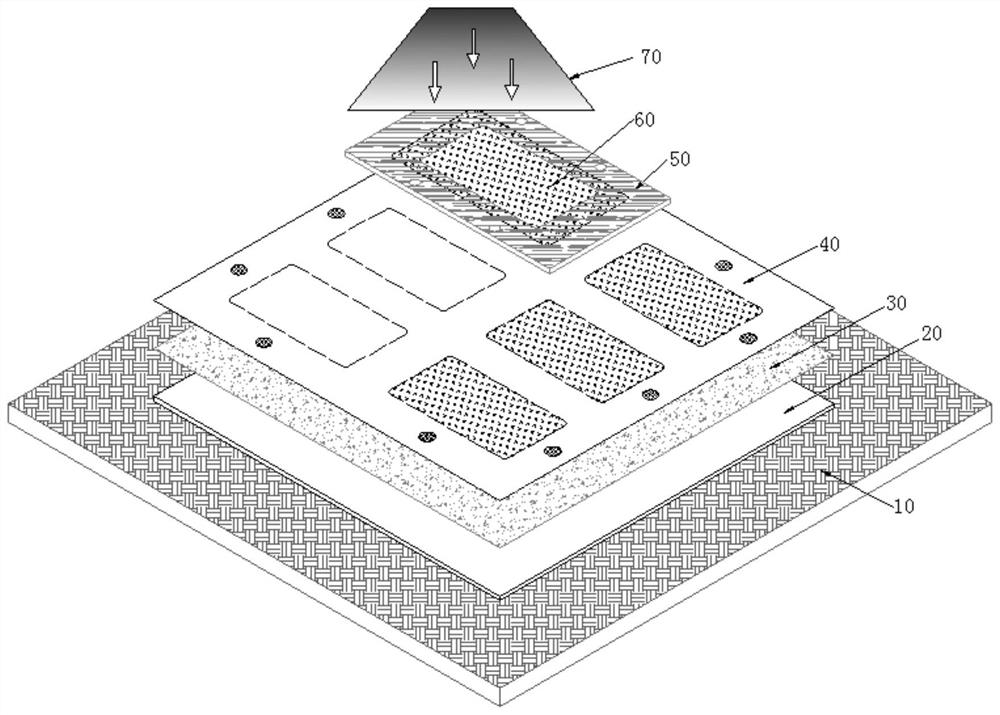

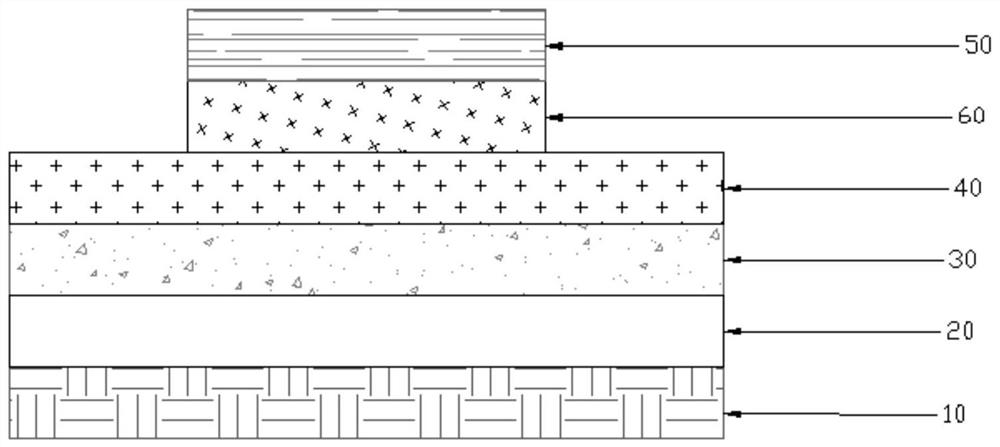

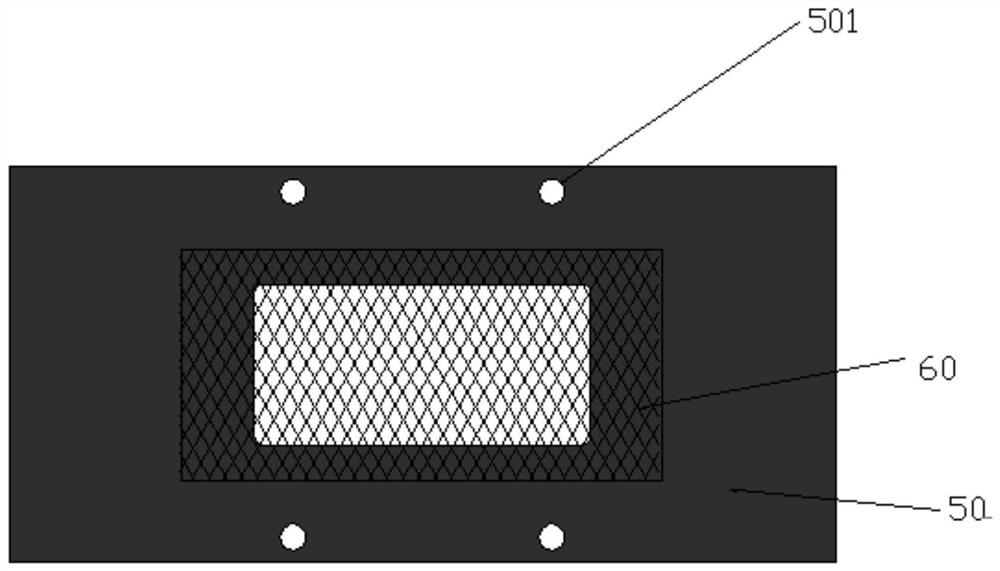

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention, but this does not limit the protection scope of the present invention.

[0038] The invention provides a preparation process for texture templates that realize the seamless splicing of micro-nano textures. The micro-nano seamless splicing is realized by means of film shielding and UV local exposure, and the target positioning of the upper and lower platforms is captured by the CCD, and different textures are set. Row and column spacing realize multi-mode typesetting, which can make a single film spliced into multiple films, thus solving the long development cycle and high development cost of the texture master mold, and the preparation process of the present invention can quickly Realize multi-mode production, improve production efficiency and reduce development costs.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com