Method for manufacturing outer-layer line by using hard board with large drop

A technology of outer layer circuit and production method, which is applied in the fields of printed circuit manufacturing, printed circuit, photolithography/patterning, etc., can solve the problems of poor quality of the outer layer circuit of hard board, reduce bonding instability and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

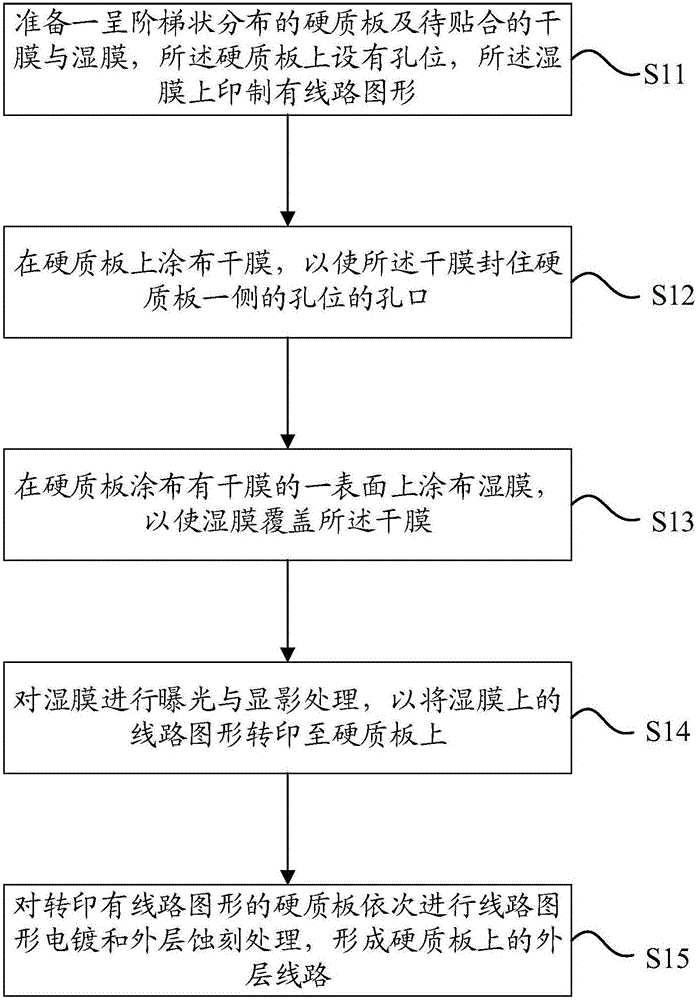

[0026] Please refer to figure 1 , the invention provides a method for manufacturing an outer layer circuit of a hard board with a large drop, comprising the following steps:

[0027] Step S11 , preparing a hard board distributed in a step shape and a dry film and a wet film to be bonded, the hard board is provided with holes, and the wet film is printed with a circuit pattern. Specifically, the hard plate can be a thick copper plate. The drop at the step of the thick copper plate is greater than 0.15mm, and the strength on the dry film is better, which is used for sealing holes and has strong anti-plating ability, while the wet film has better flow It can be used to fill the drop on the hard board. Of course, the hard board in this embodiment has undergone pre-treatment of the outer layer, such as drilling, cleaning, and surface polishing, so as to facilitate the sticking of the dry film and the wet film. It should be pointed out that, in this embodiment, when the surface of...

Embodiment 2

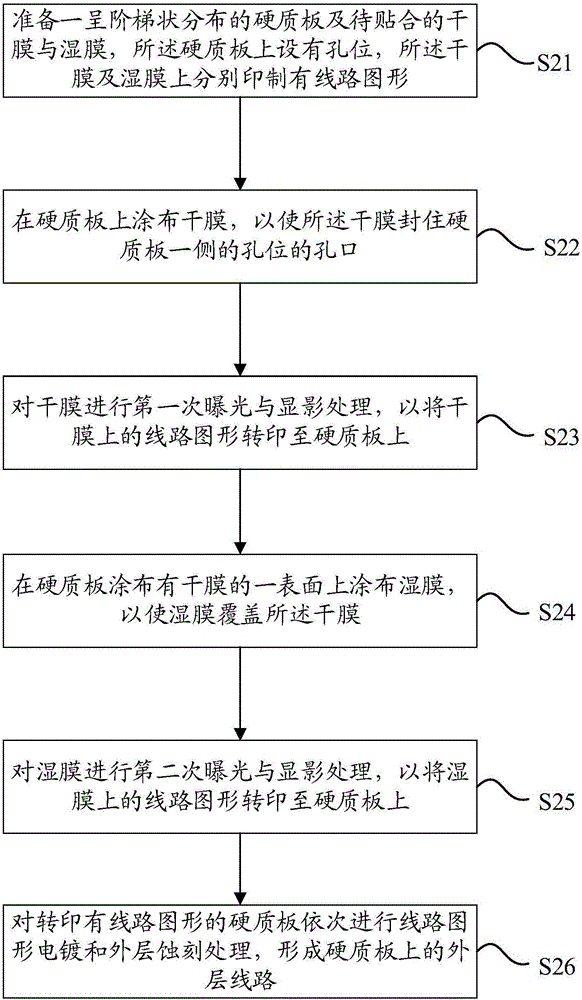

[0040] Please refer to figure 2 , the invention provides a method for manufacturing an outer layer circuit of a hard board with a large drop, comprising the following steps:

[0041] Step S21 , preparing a hard board distributed in a step shape and a dry film and a wet film to be laminated, the hard board is provided with holes, and circuit patterns are printed on the dry film and the wet film respectively. Specifically, the hard plate can be a thick copper plate. The drop at the step of the thick copper plate is greater than 0.15mm, and the strength on the dry film is better, which is used for sealing holes and has strong anti-plating ability, while the wet film has better flow It can be used to fill the drop on the hard board. Of course, the hard board in this embodiment has undergone pre-treatment of the outer layer, such as drilling, cleaning, and surface polishing, so as to facilitate the sticking of the dry film and the wet film. It should be pointed out that, in this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com