Method decaying crop straw to produce matrix

A crop straw and substrate technology, which is applied in agriculture, fertilizer mixture, application, etc., can solve the problems of restricting the sustainable development of rural economy, the effect of crop growth is not obvious, and pollute the atmospheric environment, so as to improve the physical and chemical properties of soil and solve the problem of random stacking , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

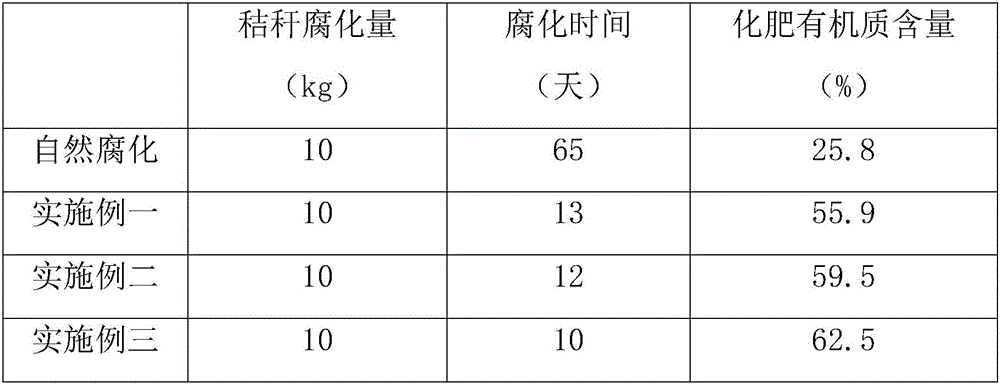

Examples

Embodiment 1

[0021] The invention provides a technical solution: a method for decomposing a substrate by crop stalks, comprising the following steps:

[0022] A. Digging a decay pond: Dig a cuboid pond at the corner of the field, and pile the excavated soil around the pond. The length of the cuboid pond is 3m, the width is 2.2m, and the depth is 2.1m;

[0023] B, preparation of corrosive agent: preparation of 10kg corrosive agent includes the following raw materials in parts by weight: 10 parts of pyrogenic actinomycetes, 7 parts of saccharomyces, 12 parts of filamentous fungi, 20 parts of Trichoderma viride, 7 parts of nitrogen-fixing bacteria, thermophilic spores 2 parts of bacteria, 12 parts of Bacillus subtilis, 30 parts of urea, 12 parts of accelerator and 6 parts of ammonium bicarbonate;

[0024] C, crushing straw: the harvested crop straw is crushed with a pulverizer, and the length of the crushed straw is 20cm;

[0025] D, lay farmhouse manure at the bottom of the septic tank: spr...

Embodiment 2

[0035] A method for decomposing a substrate by crop stalks, comprising the following steps:

[0036] A. Digging the decay pool: dig a cuboid pool at the corner of the field, and pile the excavated soil around the pool. The length of the cuboid pool is 3.5m, the width is 2.6m, and the depth is 2.3m;

[0037] B, preparation of corrosive agent: preparation of 10kg corrosive agent includes the following raw materials in parts by weight: 15 parts of pyrogenic actinomycetes, 12 parts of saccharomyces, 18 parts of filamentous fungi, 25 parts of Trichoderma viride, 16 parts of nitrogen-fixing bacteria, thermophilic spores 6 parts of bacteria, 17 parts of Bacillus subtilis, 40 parts of urea, 20 parts of accelerator and 10 parts of ammonium bicarbonate;

[0038] C, crushing straw: crush the harvested crop straw with a pulverizer, and the length of the crushed straw is 25cm;

[0039] D, lay farmhouse manure at the bottom of the septic tank: spread one deck of farm manure at the bottom o...

Embodiment 3

[0049] A method for decomposing a substrate by crop stalks, characterized in that it comprises the following steps:

[0050] A. Digging the decay pond: dig a cuboid pond at the corner of the field, and pile the excavated soil around the pond. The length of the cuboid pond is 3.2m, the width is 2.5m, and the depth is 2.2m;

[0051] B, preparation of corrosive agent: preparation of 10kg corrosive agent includes the following raw materials in parts by weight: 12 parts of thermoactinomycetes, 10 parts of saccharomyces, 16 parts of filamentous fungi, 22 parts of Trichoderma viride, 12 parts of nitrogen-fixing bacteria, thermophilic spores 4 parts of bacteria, 15 parts of Bacillus subtilis, 35 parts of urea, 16 parts of accelerator and 8 parts of ammonium bicarbonate;

[0052] C, crushing straw: the harvested crop straw is crushed with a pulverizer, and the length of the crushed straw is 22cm;

[0053] D, lay farmhouse manure at the bottom of the septic tank: spread one deck of far...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com