Patents

Literature

94results about How to "Size has little effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Die release agent and preparation method thereof

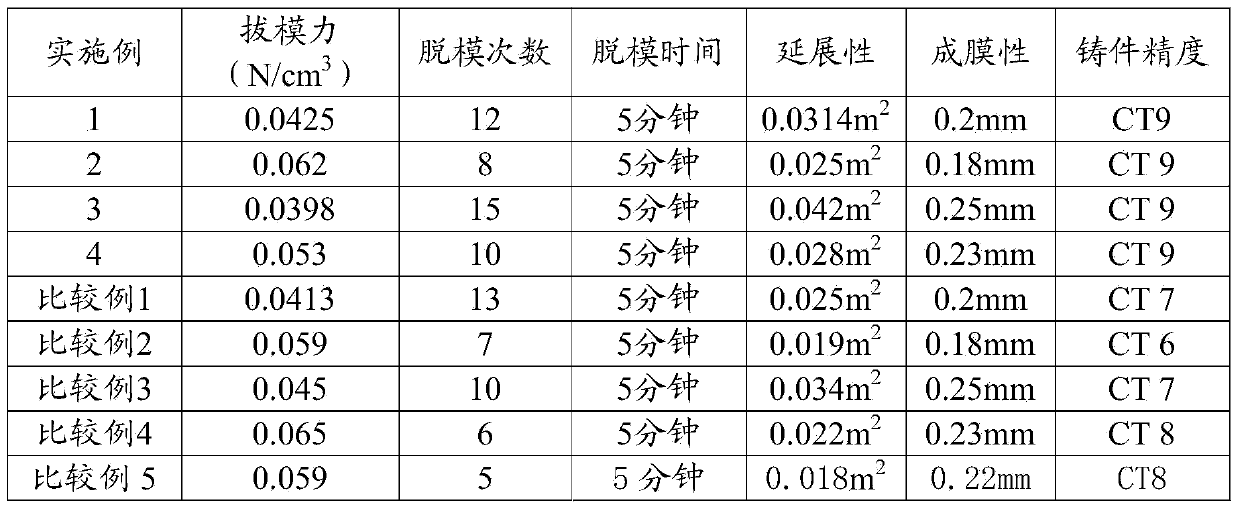

The invention discloses a die release agent. The die release agent comprises the following components in parts by weight: 5-15 parts of die release powder, 1-10 parts of an oil compound, 0.1-1 part of an emulsification agent, 70-90 parts of a solvent, 0.1-1 part of a defoaming agent and 0.1-5 parts of graphene. The invention provides a preparation method of the die release agent. The preparation method of the die release agent comprises the following steps: emulsifying the die release powder, the oil compound, the emulsification agent, the defoaming agent, the solvent and the graphene to obtain the die release agent. According to the die release agent, the graphene can be used for enabling the die release agent to form a relatively thin, hard and dense coating on the surface of a cavity, so that the direct contact between sand and a die can be effectively isolated; the die release agent is relatively good in extensibility, film formation property and adhesive force. In addition, a casting part prepared by the die release agent is relatively high in precision.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Preparation method of metal resin complex and metal resin complex prepared thereby

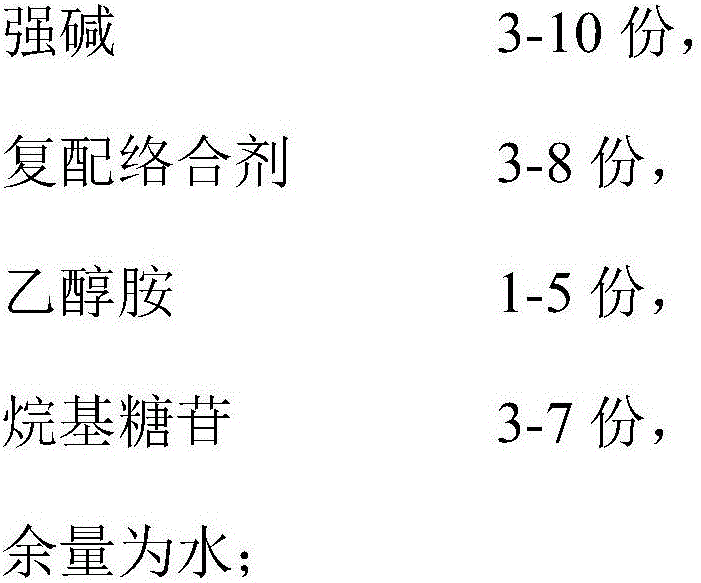

ActiveCN103448202AEasy accessSize has little effectAnodisationLaminationAlloy substrateWater soluble

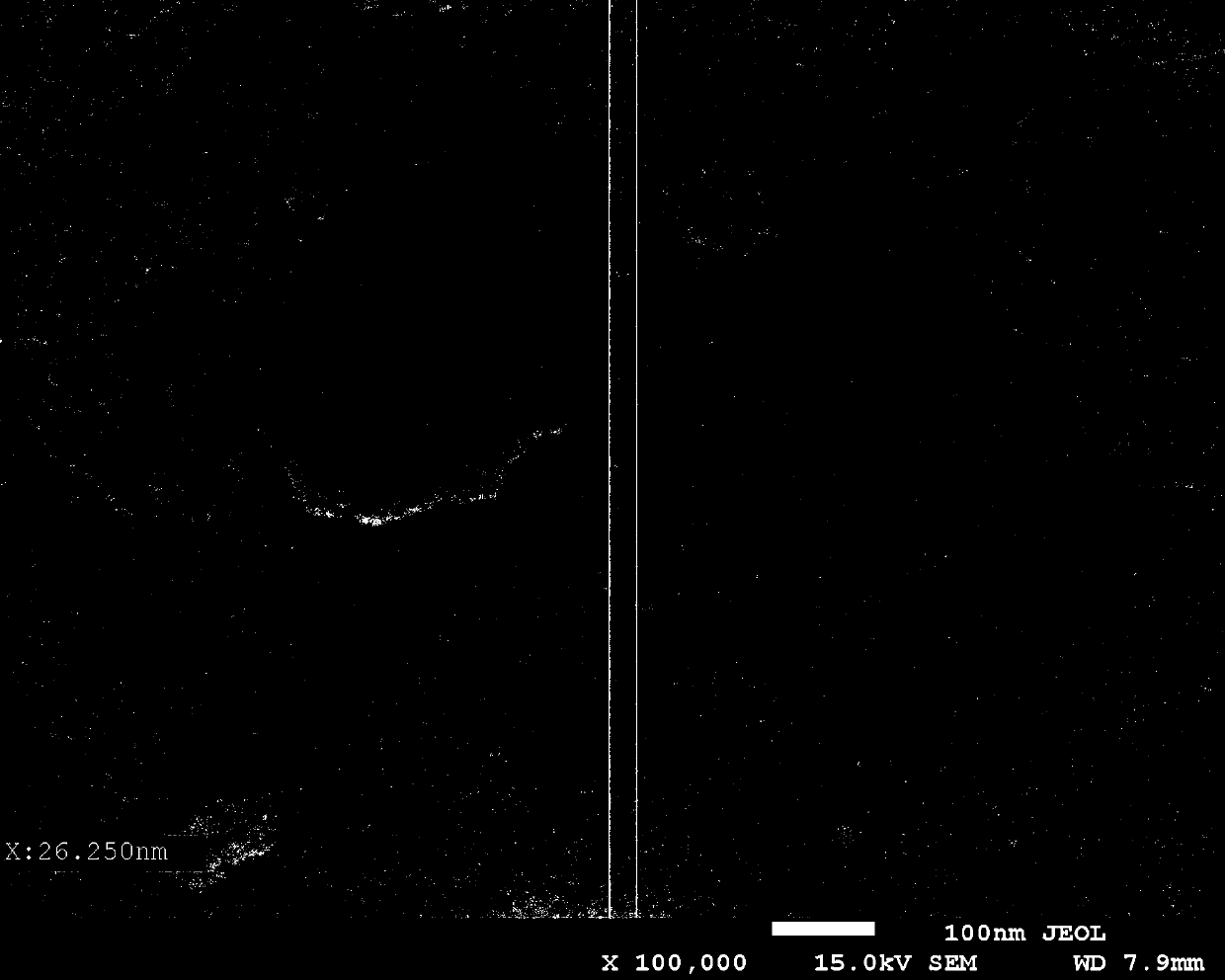

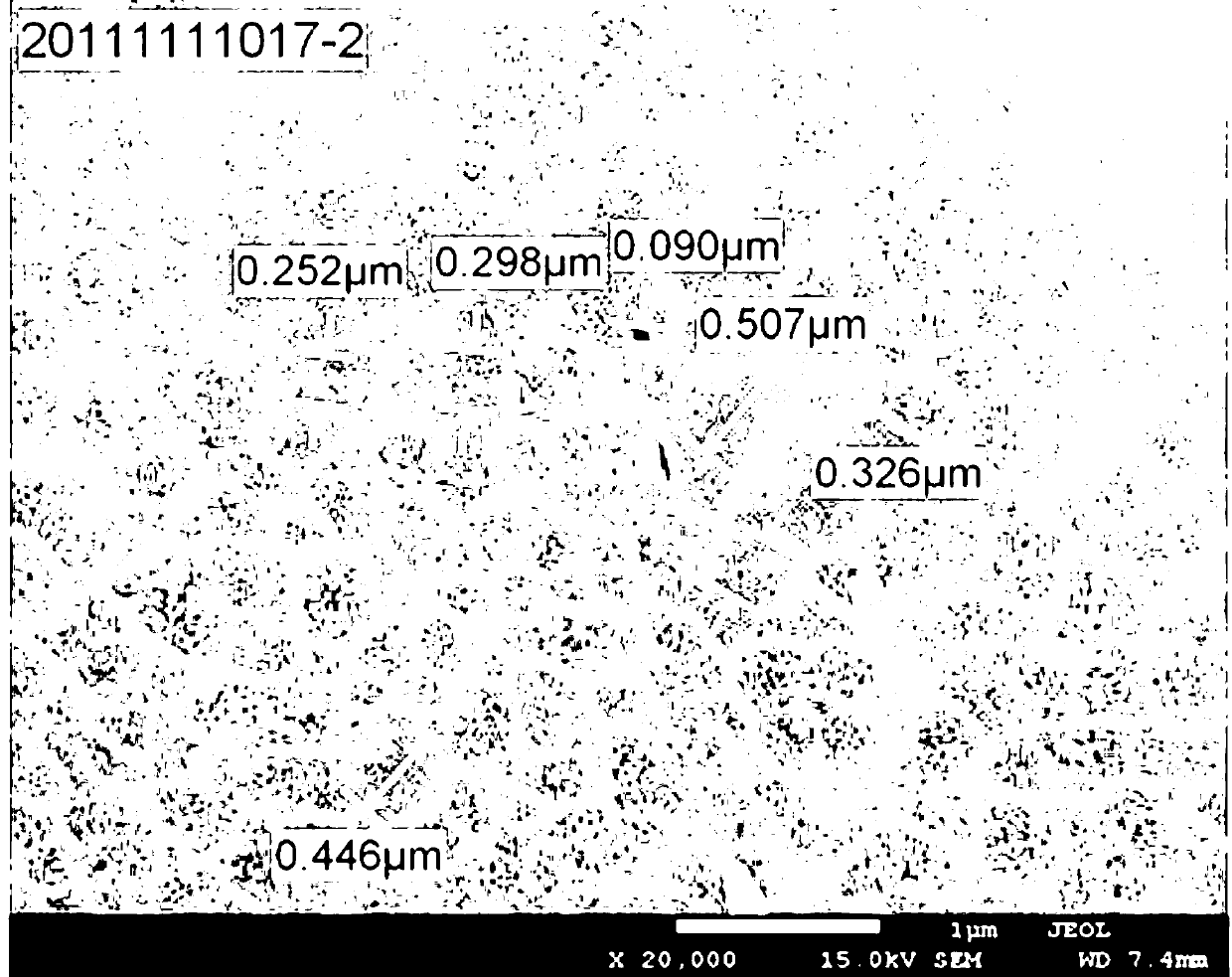

The invention provides a preparation method of a metal resin complex and the metal resin complex prepared thereby. The preparation method of the metal resin complex comprises the following steps: S1, micropores are formed on the surface of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, the metal substrate having the micropores on the surface thereof and obtained by the step S1 is soaked in a water-soluble polymer solution for modification; and S3, the surface of the treated metal substrate modified by soaking in the step S2 is coated with a resin composition, and after molding the metal resin complex is obtained. In the metal resin complex, the binding force between metal and resin is strong, and the process is simple, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

Preparation method of aluminum alloy-resin composite and aluminum alloy-resin composite prepared by using same

ActiveCN103286995AHigh strengthUnique structureAnodisationAutomatic/semiautomatic turning machinesAlloy substrateAnodic oxidation

The invention provides a preparation method of an aluminum alloy-resin composite and an aluminum alloy-resin composite prepared by using the same. The preparation method comprises the following steps: S1. anodizing a pretreated aluminum alloy substrate to obtain an aluminum alloy of which the surface contains a nanoporous oxide film layer; S2. soaking the aluminum alloy containing the nanoporous oxide film layer obtained in the step S1 in an alkaline solution with the pH value of 10-13 to form corrosion pores on the outer surface layer of the oxide film layer, thereby obtaining the surface-treated aluminum alloy substrate; and S3. putting the surface-treated aluminum alloy substrate in a mold, injecting a resin composition into the mold to be combined with the surface-treated aluminum alloy substrate, and forming to obtain the aluminum alloy-resin composite. A unique double-layer stereoscopic porous structure can be formed on the surface of the aluminum alloy to enhance the binding force between the resin and the aluminum alloy; and the invention has the advantages of easier formation, basically no influence on the appearance of the aluminum alloy, wider application range and no environment pollution, and is more suitable for large-scale production.

Owner:BYD CO LTD

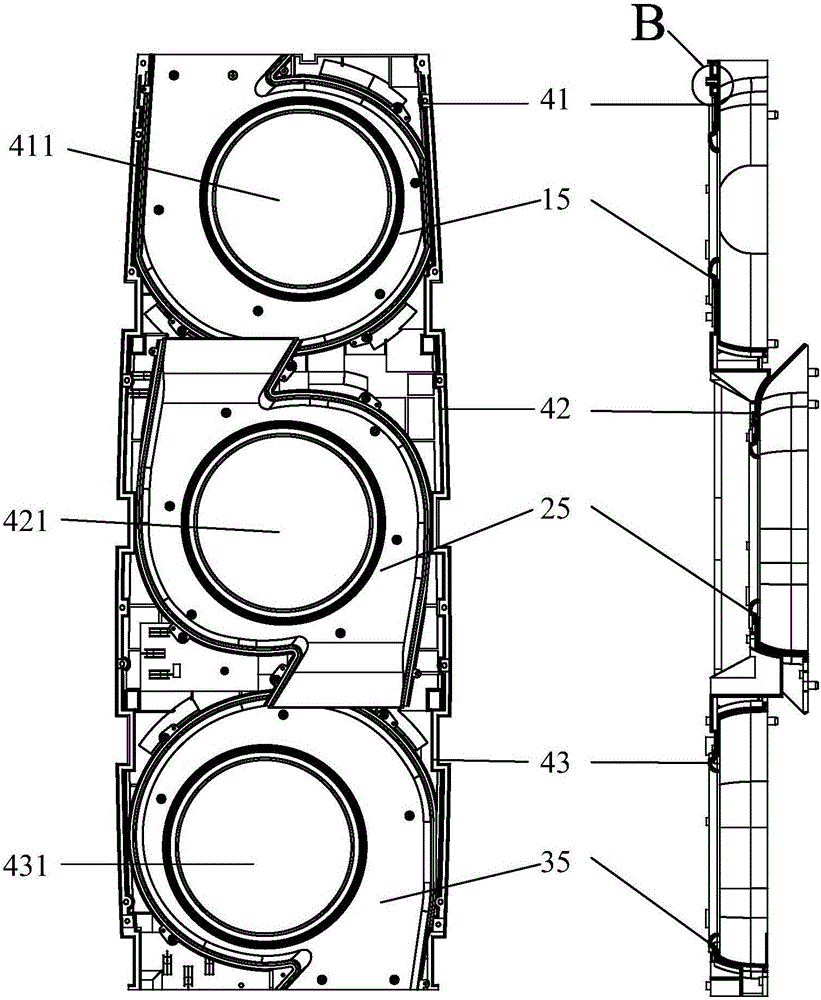

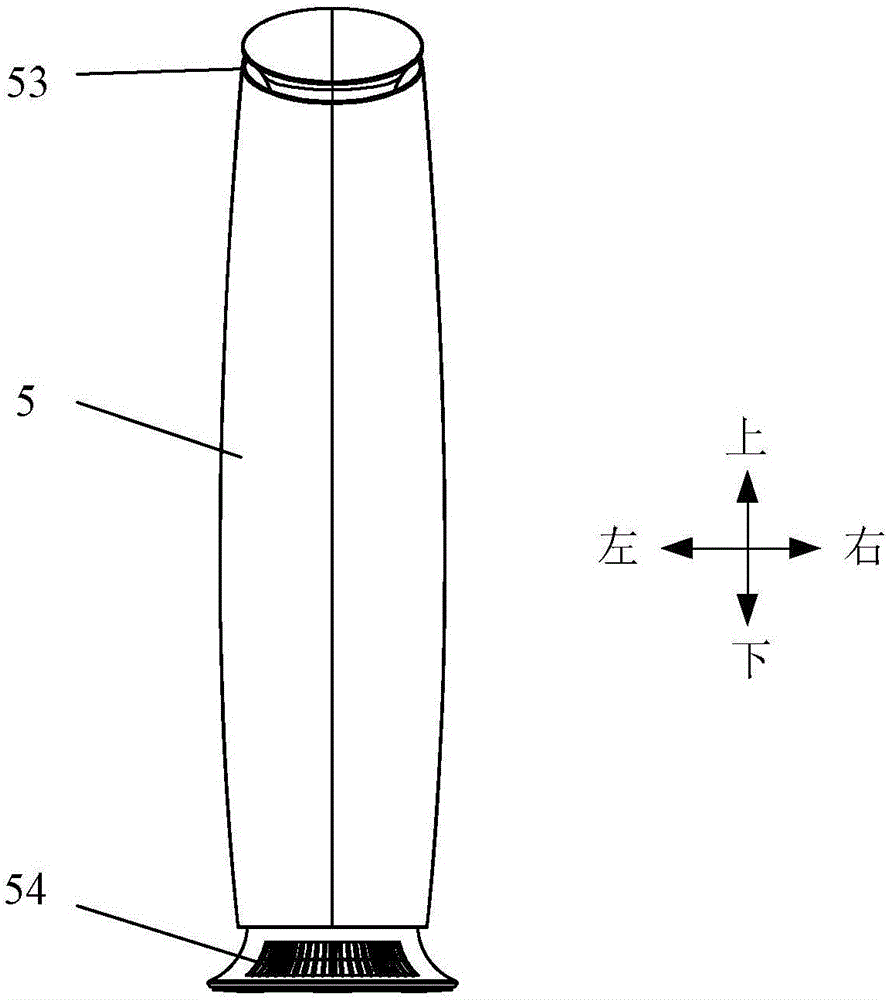

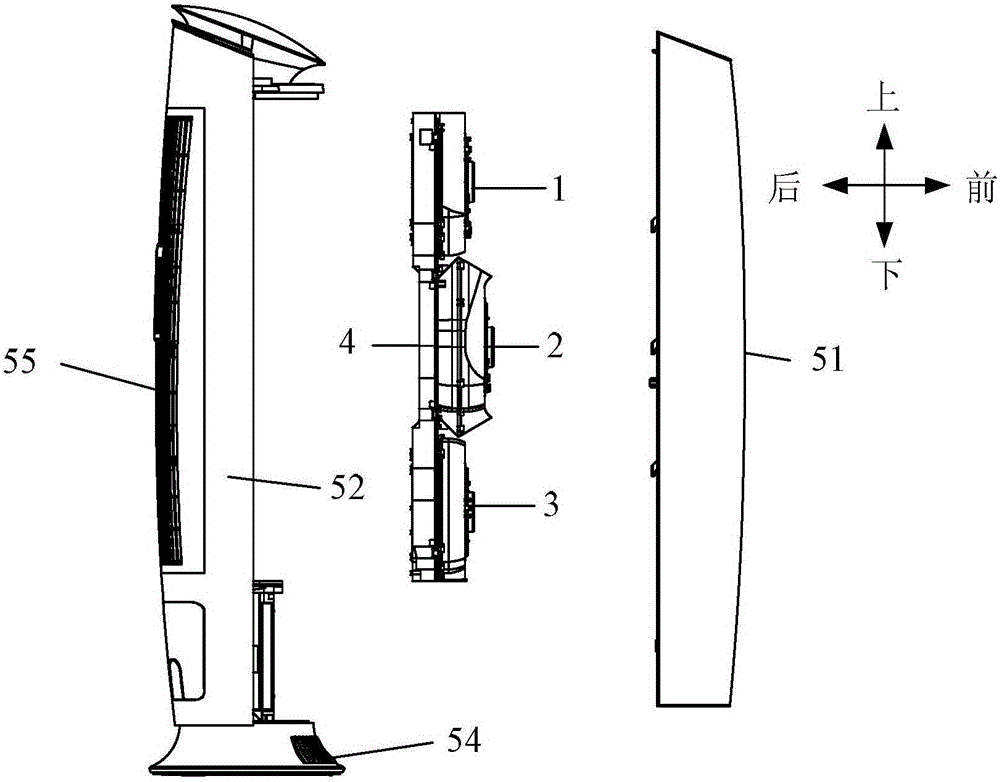

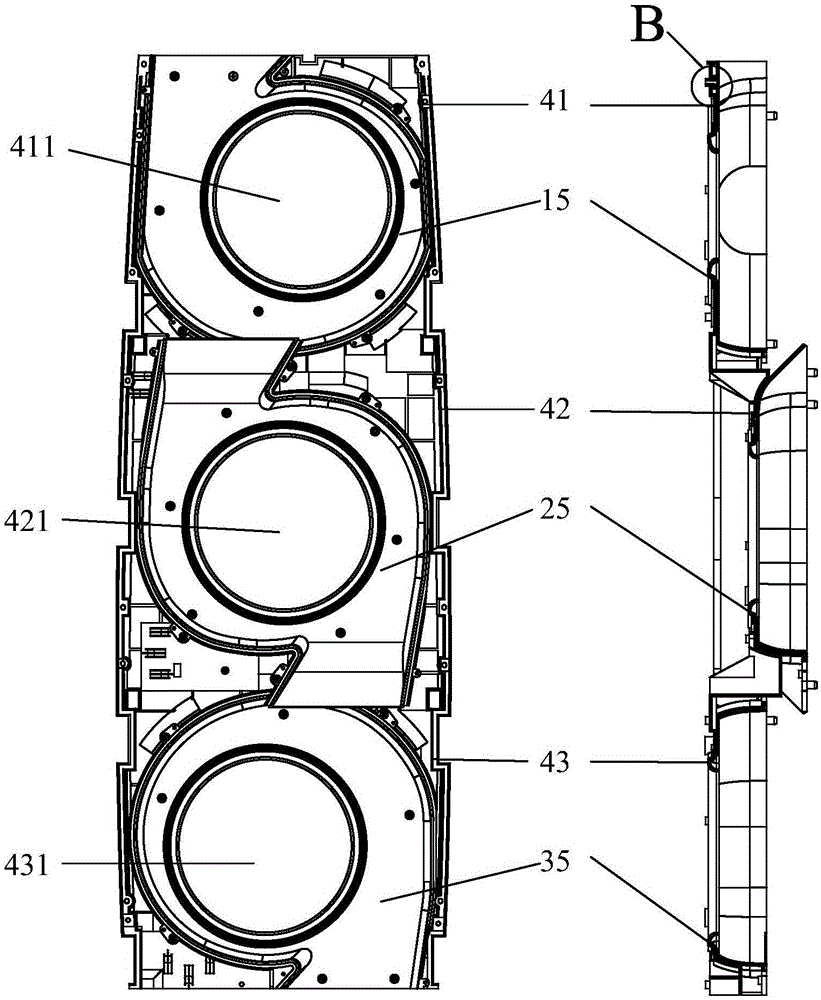

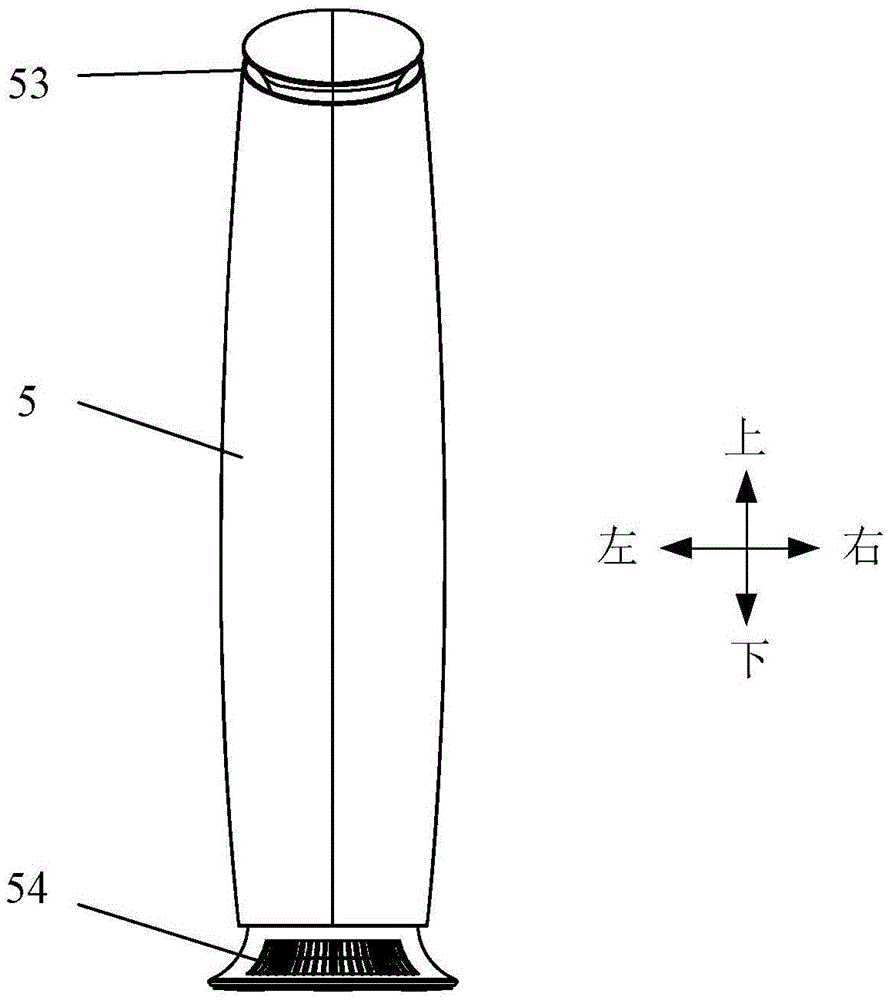

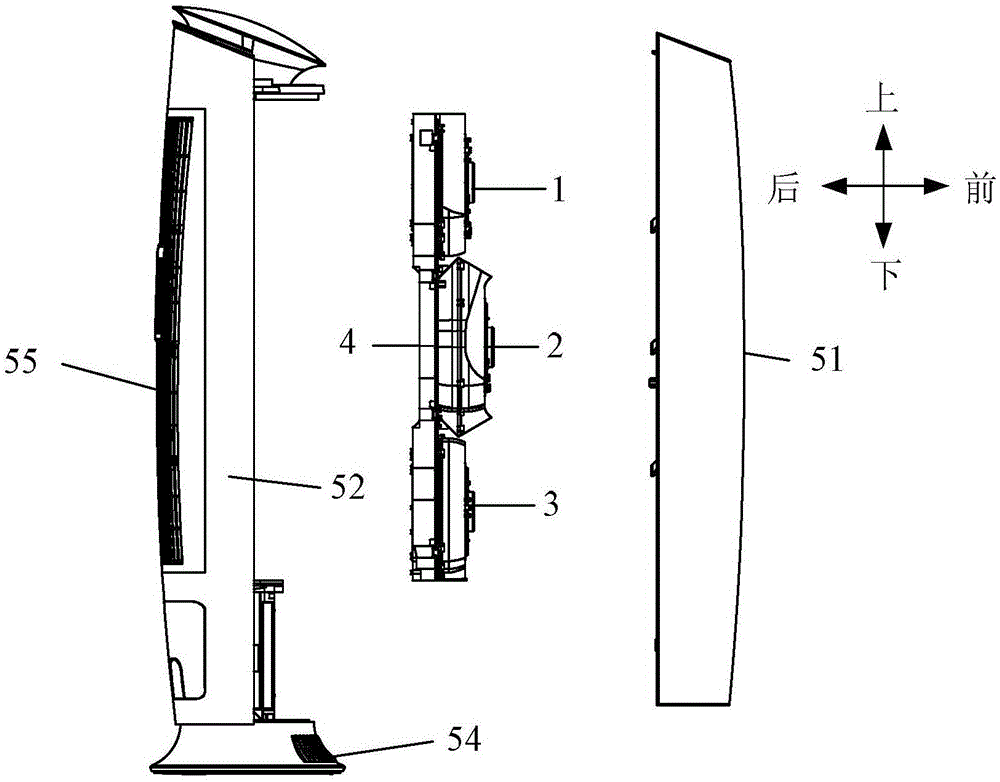

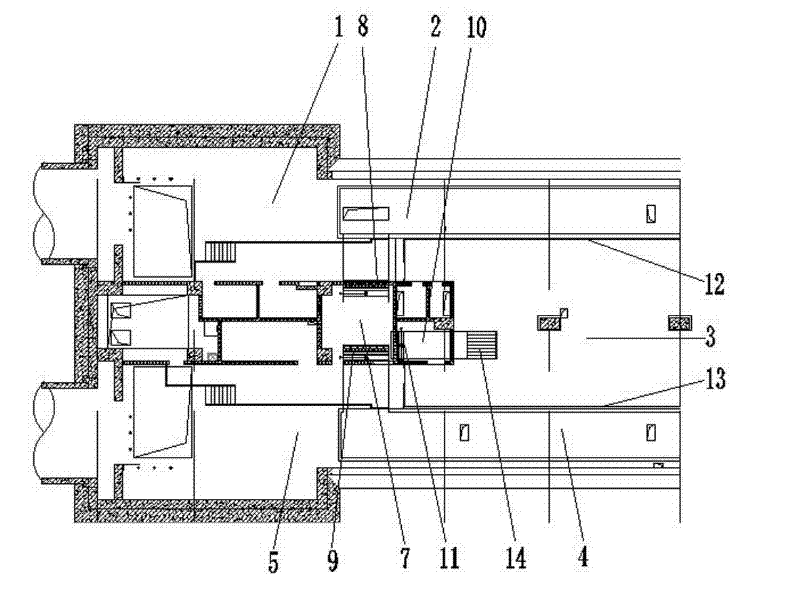

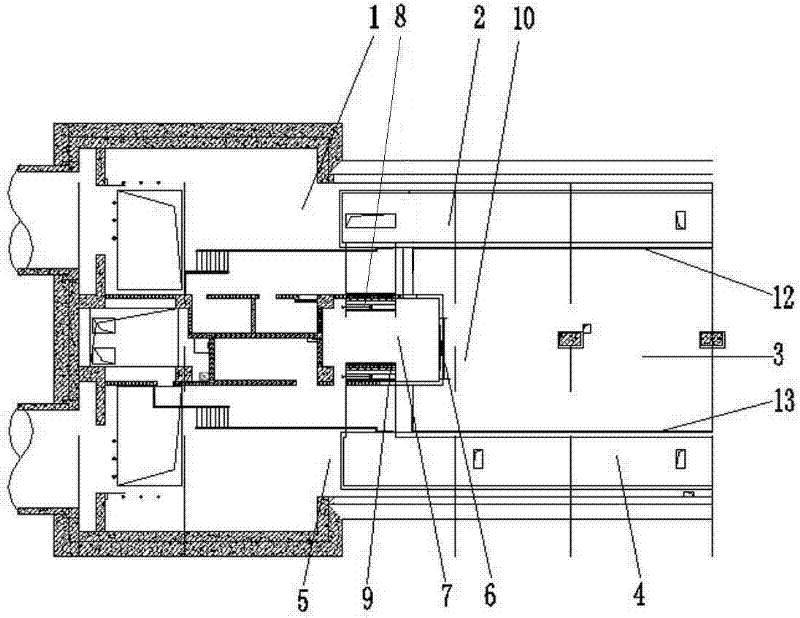

Volute fan combined structure and vertical air conditioner

ActiveCN105156344ALarge air volumeReduce the impactPump componentsLighting and heating apparatusAerospace engineering

The invention provides a volute fan combined structure which mainly solve the problem how to reduce influences of volutes of two volute fans at two ends on air outflow of a middle volute fan in an air supply device provided with the three volute fans. The structure comprises an installation plate and at least two adjacent volute fans installed on the installation plate. One of the two adjacent volute fans is provided with a middle oblique air outlet located between the two adjacent volute fans, and the middle oblique air outlet obliquely extends in the direction away from a volute of the volute fan provided with middle oblique air outlet from back to front. The second volute fan, the first volute fan and the third volute fan are arranged on the installation plate in a staggered mode so that an air outlet of the second volute fan, the first volute fan and the second volute fan can be staggered, and interference is reduced. The invention further aims at providing a vertical air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

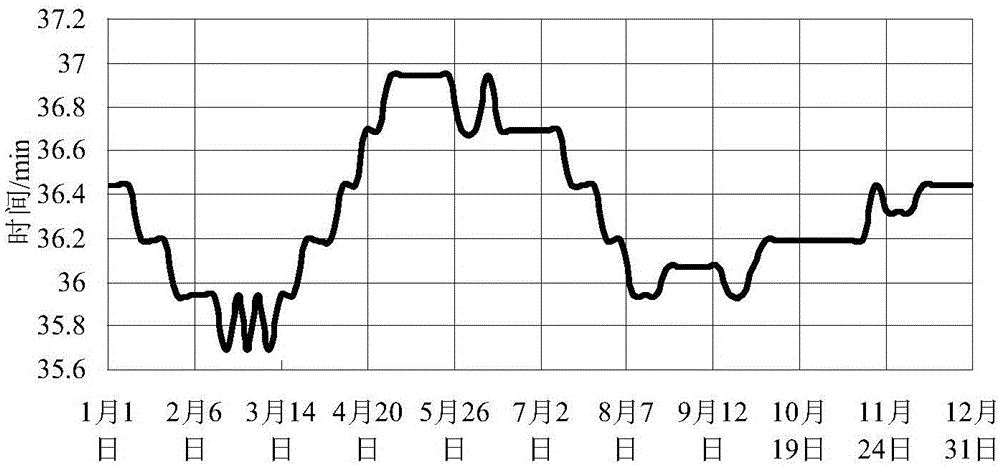

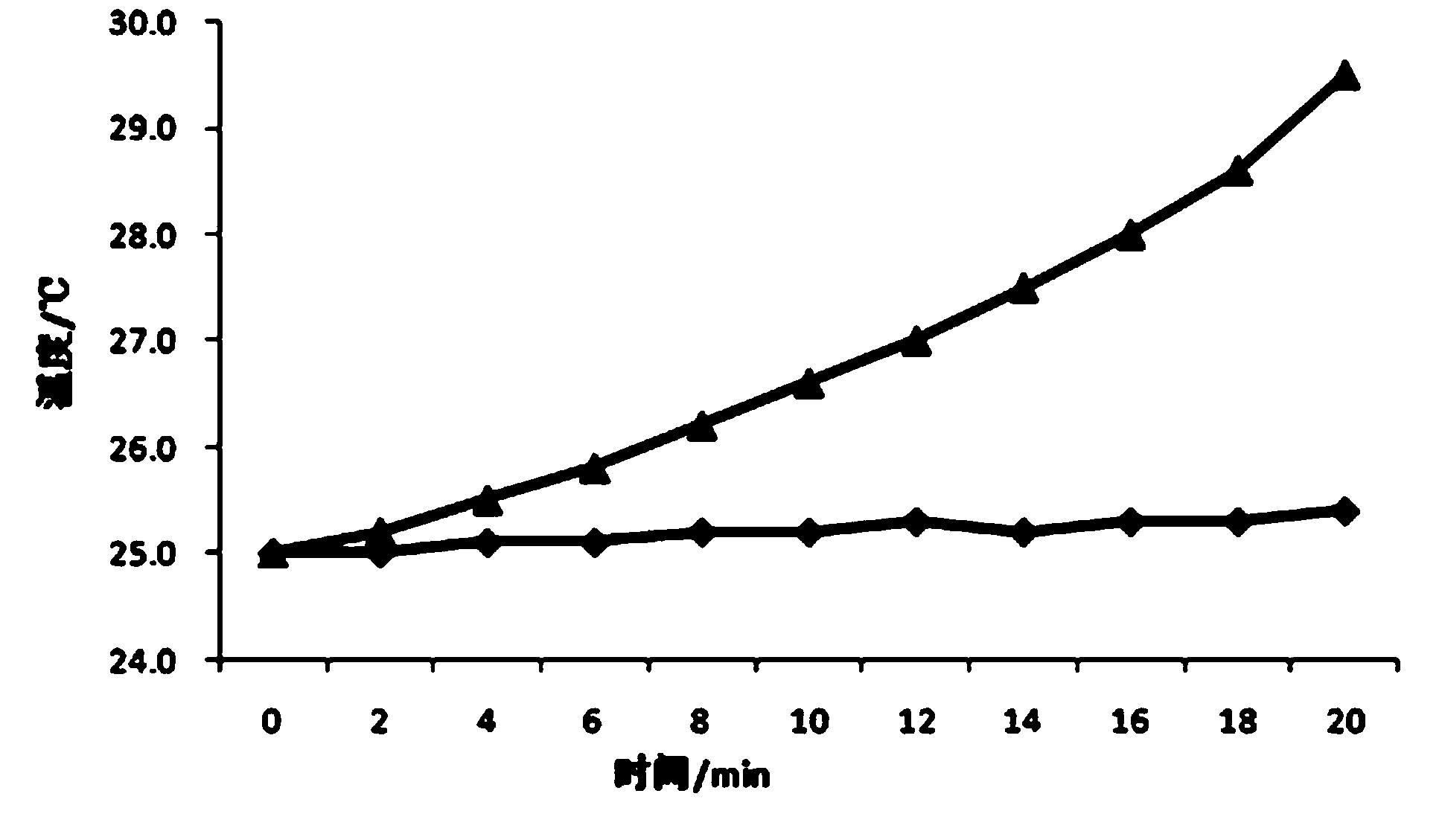

Thermal control method of spatial aircraft

InactiveCN105109708ASimple designLess electrical circuitsCosmonautic environmental control arrangementCosmonautic thermal protectionFlight vehicleInterior space

The invention discloses a thermal control method of a spatial aircraft. The thermal control method comprises the following steps: firstly sticking a heating piece, a thermistor and a temperature controller on a separating and releasing barrel of the spatial aircraft; before all equipment in the spatial aircraft is mounted, blackening all the equipment, and sticking F46 membranes; applying heat conducting grease or enabling a heat insulating pad to be additionally mounted in an assembly process; and finally coating the spatial aircraft in a multi-layer manner with a multi-layer heat insulating assembly so as to complete the thermal control on the spatial aircraft. Compared with a conventional active-passive complex thermal control manner or a conventional active thermal control manner, the thermal control method disclosed by the invention is simple in design, few in electrical loops and high in reliability; in addition, thermal control equipment can be closely attached to the appearance of the spatial aircraft, so that a small inner space is occupied, the thermal control method has a small influence on external envelope sizes, is high in space utilization rate, convenient and quick to implement and simple to operate, and can be suitable for a quick transmitting task of the spatial aircraft.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

Surface treated metal and surface treatment method thereof and metal resin complex and preparation method of metal resin complex

ActiveCN103451701AIncrease corrosion rateReduce corrosion rateAnodisationPore diameterAnodic oxidation

The invention provides a surface treated metal and a surface treatment method thereof and a metal resin complex and a preparation method of the metal resin complex. The surface treated metal comprises a metal body and an anodic oxidation film layer which is located on the surface of the metal body, the anodic oxidation film layer includes a barrier layer which is in contact with the metal body and a loose layer located on the outer surface of the barrier layer, the loose layer contains anodic oxidation film micropores, the pore diameter of the anodic oxidation film micropores is 10 nm-800 mum, the barrier layer contains barrier layer corrosion pores, the pore diameter of the barrier layer corrosion pores is 10 nm-800 mum, the metal body includes a corrosion layer which is in contact with the barrier layer, the corrosion layer contains metal corrosion pores, the pore diameter of the metal corrosion pores is 10 nm-1 mm, the metal is aluminum alloy or aluminum, the bonding force between the metal and resin is strong, and the surface treated metal is simple in process, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

Preparation method of metal resin complex and metal resin complex prepared thereby

The invention provides a preparation method of an aluminum alloy resin complex and the aluminum alloy resin complex prepared thereby. The preparation method of the aluminum alloy resin complex comprises the following steps: S1, anodic oxidation: a metal substrate with a surface comprising an anodic oxidation film layer is obtained by anodic oxidation of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, treatment with an etching liquid: the metal substrate containing the anodic oxidation film layer and obtained by the step S1 is immersed in the etching liquid for treatment to obtain a surface treated metal substrate; S3, injection: the surface of the surface treated metal substrate is injected with a resin composition, and then the metal resin complex is obtained after molding; and the etching liquid contains HCl and a soluble halogen acid salt, or contains H3PO4 and a soluble phosphate. In the metal resin complex, the binding force between aluminum alloy and resin is strong, and the process is simple, and is easy for large-scale production.

Owner:BYD CO LTD

Preparation method of metal resin complex and metal resin complex prepared thereby

ActiveCN103451704AReduce reaction exothermImprove bindingSurface reaction electrolytic coatingAlloy substratePhosphoric acid

The invention provides a preparation method of a metal resin complex and the metal resin complex prepared thereby. The preparation method of the metal resin complex comprises the following steps: S1, anodic oxidation: a metal substrate with a surface comprising an anodic oxidation film layer is obtained by anodic oxidation of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, treatment with phosphoric acid: the metal substrate containing the anodic oxidation film layer and obtained by the step S1 is immersed in a phosphoric acid solution for treatment to obtain a surface treated metal substrate; and S3, injection: the surface of the surface treated metal substrate is injected with a resin composition, and then the metal resin complex is obtained after molding. In the metal resin complex, the binding force between metal and resin is strong, and the process is simple, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

Preparation method of stainless steel-resin composite and stainless steel-resin composite prepared by same

ActiveCN103895160ADoes not affect appearanceAppearance has no effectMolten spray coatingLamination ancillary operationsAl powderPolymer science

Provided are stainless steel-resin composite and method of preparing the same. The method comprises steps of: providing a stainless steel substrate; spraying aluminum particles onto a first surface of the stainless steel substrate via thermal spraying to form an aluminum layer on the first surface of the stainless steel substrate; removing the aluminum layer via dipping the stainless steel substrate into an alkaline solution with a p H value greater than or equal to 10 so as to form a porous surface; and injecting a resin composition onto the porous surface of the stainless steel substrate so as to form a resin layer.

Owner:BYD CO LTD

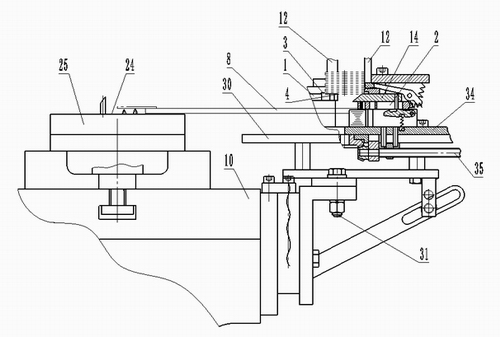

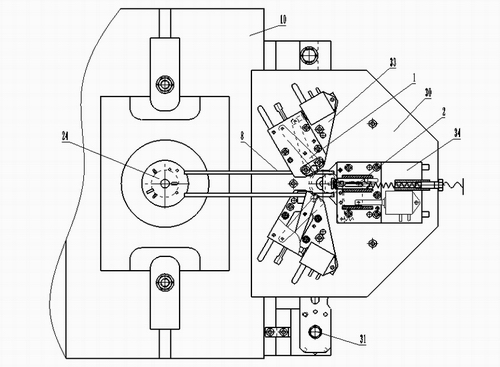

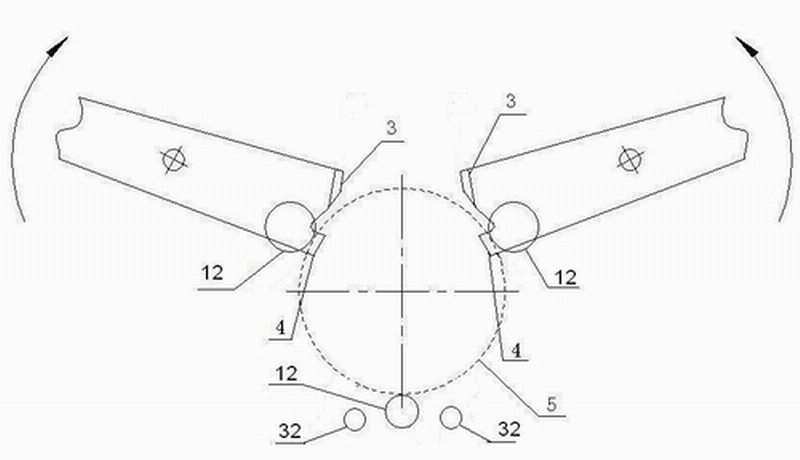

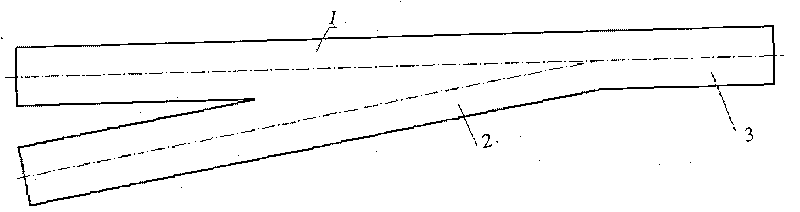

Sheet stock blank feeding equipment for punching process

InactiveCN101879561AAvoid separationAvoid the effects of plastic deformationMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention relates to sheet stock blank feeding equipment for punching process, comprising a rack. The sheet stock blank feeding equipment is characterized in that the rack is provided with a material delivery platform; a longitudinal blanking guide bracket is arranged above the material delivery platform; the lower port of the longitudinal blanking guide bracket is provided with a single-sheet separation device of a sheet stock blank stacking part; one side of the blanking end of the material delivery platform is provided with an elastic striking mechanism; the single-sheet separation device of the sheet stock blank stacking part comprises at least one pair of single-sheet sidewise shifting rocking blocks, and each single-sheet sidewise shifting rocking block is correspondingly provided with a longitudinal limiting rocking block along a rotating direction; the other side of the lower end part of the sheet stock blank stacking part is correspondingly provided with a supporting telescopic slide block; and the rack is provided with a stop block preventing other sheet stock blank stacking parts from being shifted. The invention has the advantages of simple structure, convenient use, reliable work, high commonality, easy and convenient installation of connecting with a punching machine and capability of high-efficient automatic punching production.

Owner:陈石云

Volute fan combined structure and vertical air conditioner

ActiveCN105156345AReduce wind disturbanceAvoid interferencePump componentsLighting and heating apparatusEngineering

The invention provides a volute fan combined structure which mainly solves the problem how to reduce influences of volutes of adjacent volute fans on air outflow in an air supply device provided with the adjacent volute fans. The structure comprises an installation plate and at least two adjacent volute fans installed on the installation plate. One of the two adjacent volute fans is provided with a middle air outlet located between the two adjacent volute fans, and compared with the other volute fan, the volute fan provided with the middle air outlet is located in front in the front-back direction perpendicular to the installation plate. The second volute fan, the first volute fan and the third volute fan are arranged on the installation plate in a staggered mode so that an air outlet of the second volute fan, the first volute fan and the second volute fan can be staggered, and interference is reduced. The invention further aims at providing a vertical air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

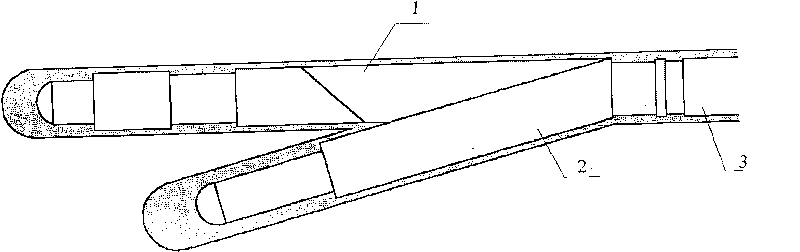

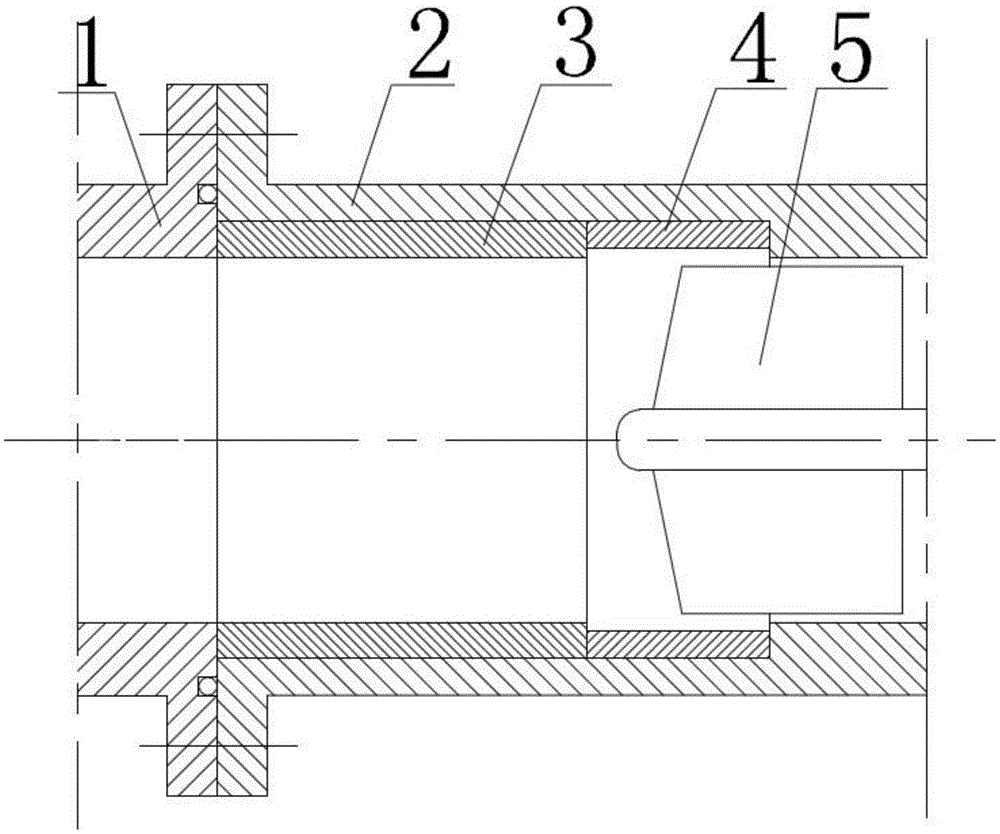

Branch well window sealing method

InactiveCN101748989AAchieving a hydraulic sealSize has little effectDirectional drillingSealing/packingDie castingWater well

The invention discloses a branch well window sealing method for sealing branch well windows of oil and water wells. The method is implemented through a sealing device; the device consists of a main borehole under the window, a branch borehole and a main borehole above the window; the sealing device is made of a material which has certain elasticity, can expand and can recover deformation, and the sealing device is molded by die casting or tube welding; after the sealing device and a running tool are dropped to the branch well window, the sealing device is firstly expanded by hydraulic pressure, and simultaneously a drilling tool is dropped to make the sealing device descend till to the designed position; after the sealing device is completely expanded, a feeding pipe column is pressed down to shear a connecting dowel between the running tool and the sealing device so that the running tool and the sealing device are separated; the feeding pipe column and the running tool are extracted from the well; and an expanding tool is dropped to push an expanding cone by using hydraulic pressure to expand the sealing device so that the sealing device is expanded to the inner wall of a sleeve at the other window to be fully jointed and the communication between two branches are ensured. The method solves the problem that the window has no mechanical seal in the prior art. The method can be used for the sealing operation for the branch wells of the oil and water wells.

Owner:CNPC GREATWALL DRILLING ENG

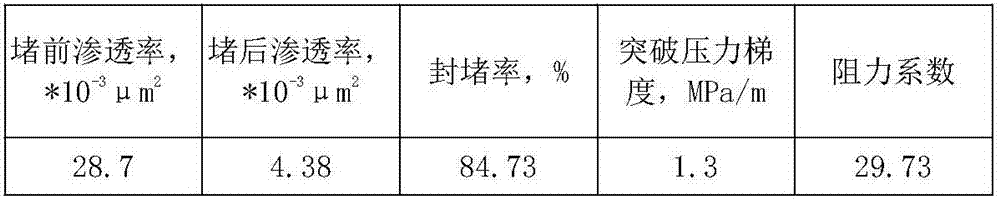

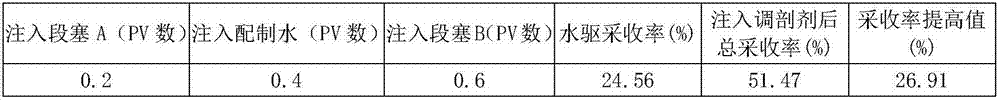

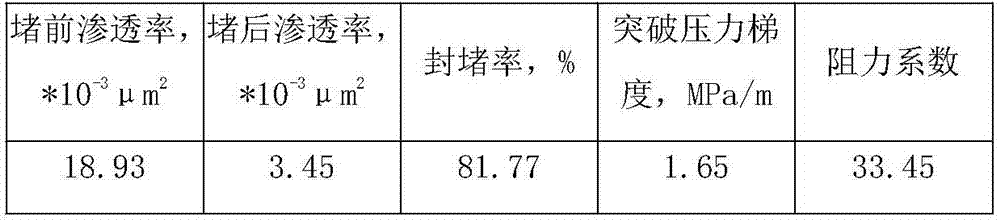

Compound polymer type profile control agent for low-permeability sandstone reservoir and use method of profile control agent

InactiveCN107338033AImprove heterogeneityLow viscosityFluid removalDrilling compositionRecovery methodPolymer science

The invention relates to a low-permeability sandstone reservoir composite polymer type profile control agent and its application method, which relate to the field of oilfield applied chemistry. The present invention injects low-permeability sandstone reservoirs in the form of double slugs. The pre-slug is a multi-molecular compound polymer, which can be combined with insoluble suspended matter particles in the reservoir to form a polymer with a molecular coil structure around the core. Selective plugging of micro-fractures and large pores in the reservoir; the rear slug is a low-viscosity compound polymer, and an appropriate amount of clay stabilizer and surfactant is added to control and flood unplugged areas, which can suppress low-viscosity The phenomenon of clay swelling in seepage sandstone reservoirs can improve the deposition of wax, colloid and asphaltene near the wellbore; the invention can improve the heterogeneity of reservoirs, increase the follow-up water flooding sweep coefficient, and suppress dead oil areas in low-permeability sandstone reservoirs Formed to improve the disadvantages of traditional oil recovery methods such as low recovery rate and poor economic benefits of low-permeability sandstone reservoirs.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

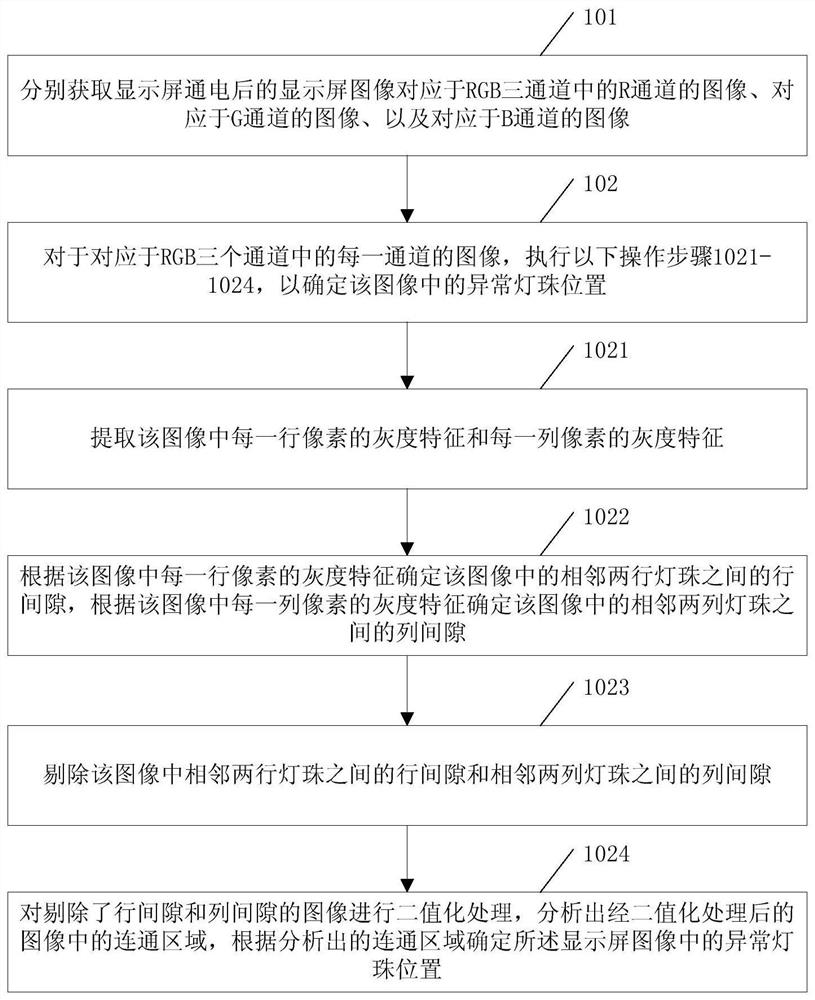

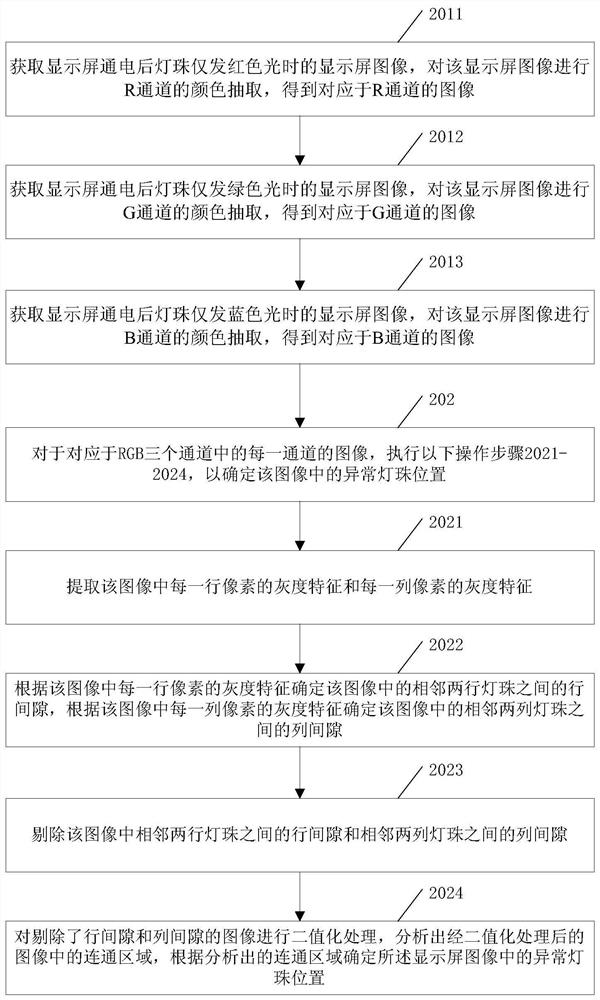

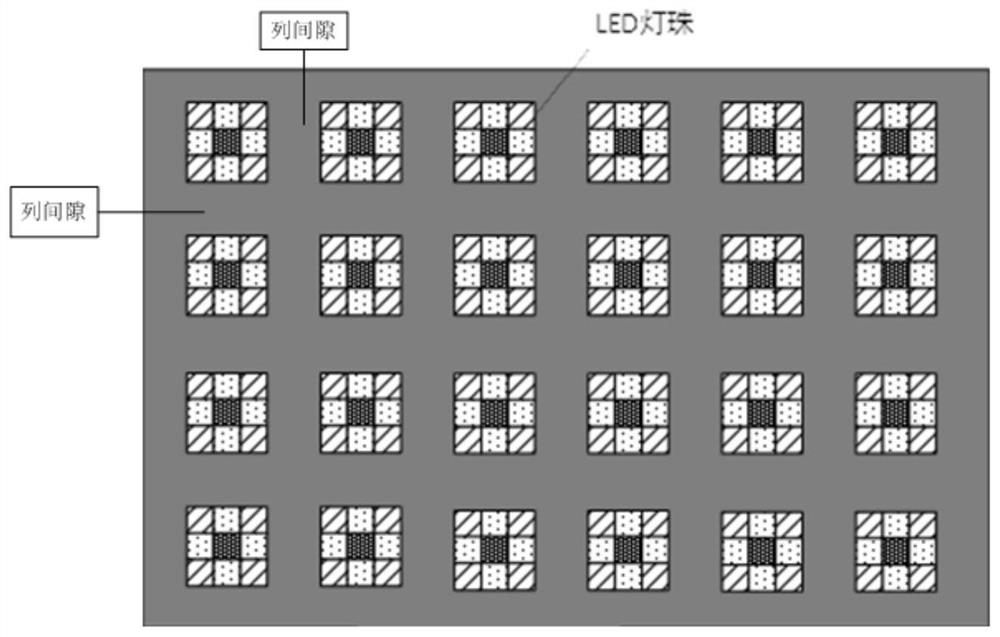

Abnormal lamp bead positioning method and device and storage medium

ActiveCN112785545ASize has little effectSmall amount of calculationImage analysisComputer graphics (images)Engineering

The invention provides an abnormal lamp bead positioning method and device and a storage medium. The abnormal lamp bead positioning method comprises the steps of respectively acquiring images, corresponding to an R channel, a G channel and a B channel, of a display screen image after a display screen is electrified; for the image corresponding to each channel in the RGB three channels, executing the following operations: extracting the gray features of each row of pixels and the gray features of each column of pixels in the image; determining a row gap between two adjacent rows of lamp beads in the image according to the gray features of each row of pixels in the image, and determining a column gap between two adjacent columns of lamp beads in the image according to the gray features of each column of pixels in the image; removing a row gap between two adjacent rows of lamp beads and a column gap between two adjacent columns of lamp beads in the image; and binarizing the image without the row gap and the column gap, analyzing a connected region in the image after binarization processing, and determining the position of an abnormal lamp bead in the display screen image according to the analyzed connected region.

Owner:HANGZHOU HIKVISION DIGITAL TECH

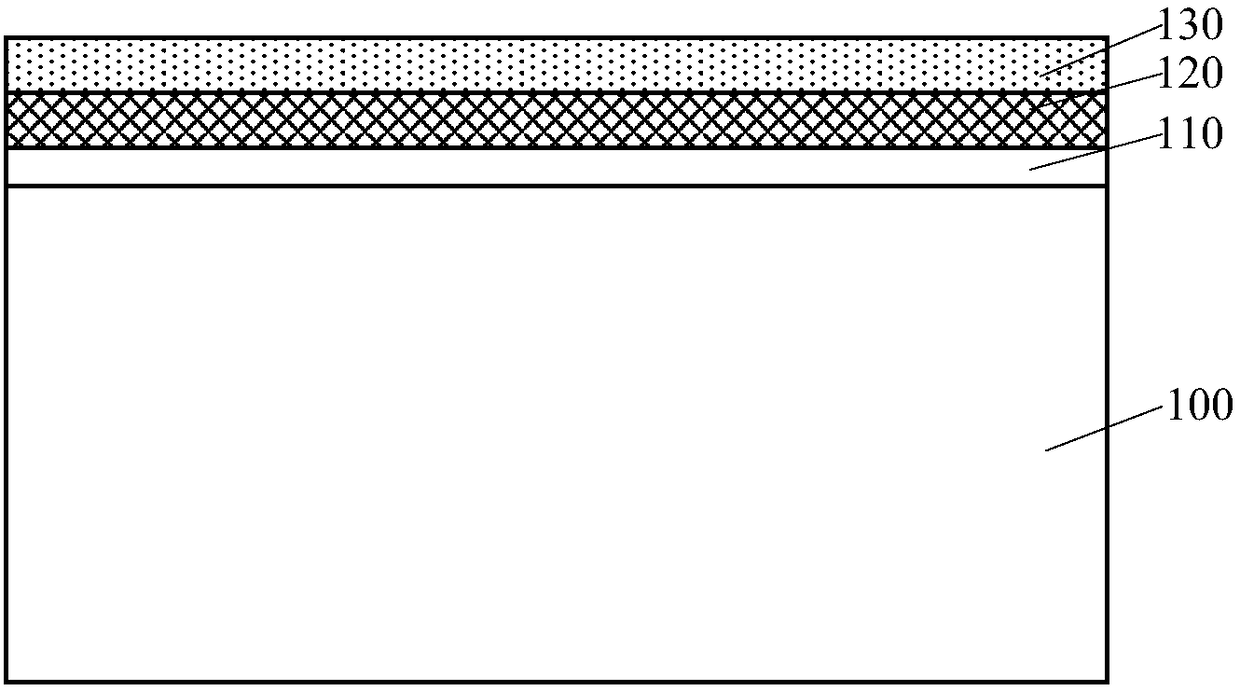

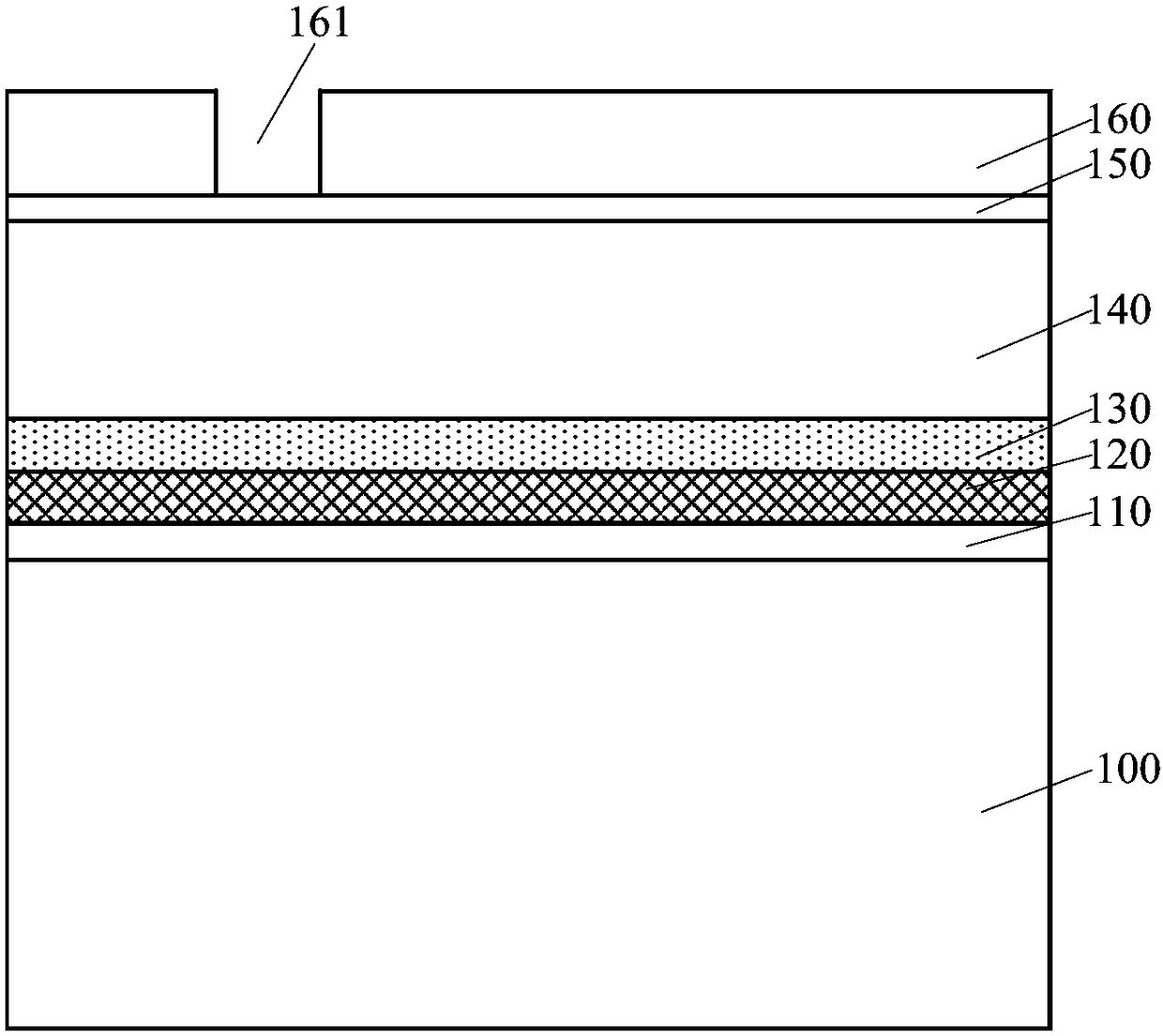

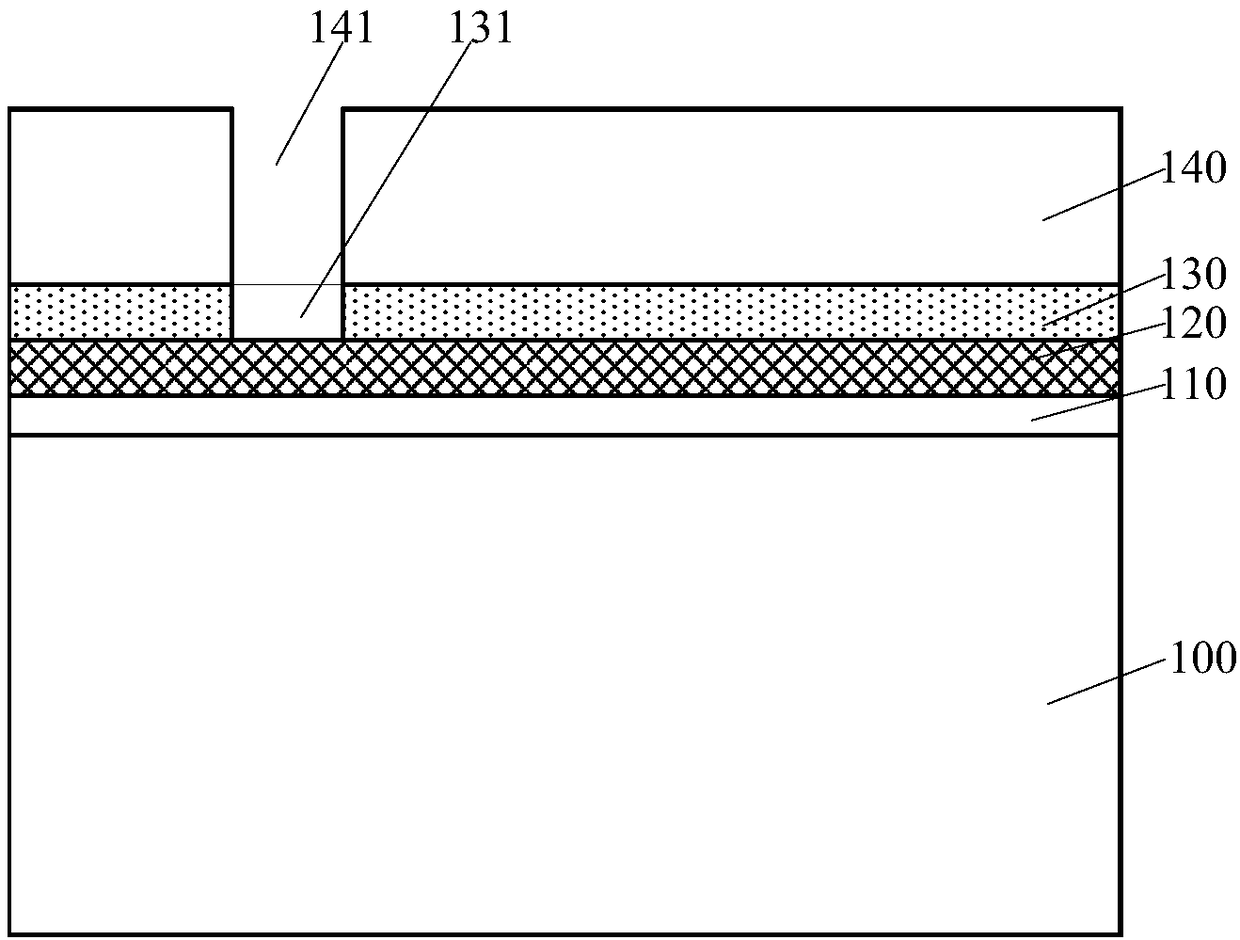

Semiconductor device and forming method thereof

ActiveCN109148272AImprove performanceReduce lossSemiconductor/solid-state device manufacturingEngineeringMask layer

The invention provides a semiconductor device and a forming method thereof. The method includes providing a material layer to be etched, wherein the material layer to be etched is provided with a toplayer mask layer; forming a first opening running through the top layer mask layer in the top layer mask layer, the sidewall material of the first opening having a first density; performing a first surface treatment process on the sidewall of the first opening such that the sidewall material of the first opening has a second density, the second density being greater than the first density; performing an intermediate patterning process after the first surface treatment process; and after performing the intermediate patterning process, forming a second opening running through the top layer masklayer in the top layer mask layer, the second opening and the first opening being separated from each other. The method improves the performance of the semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

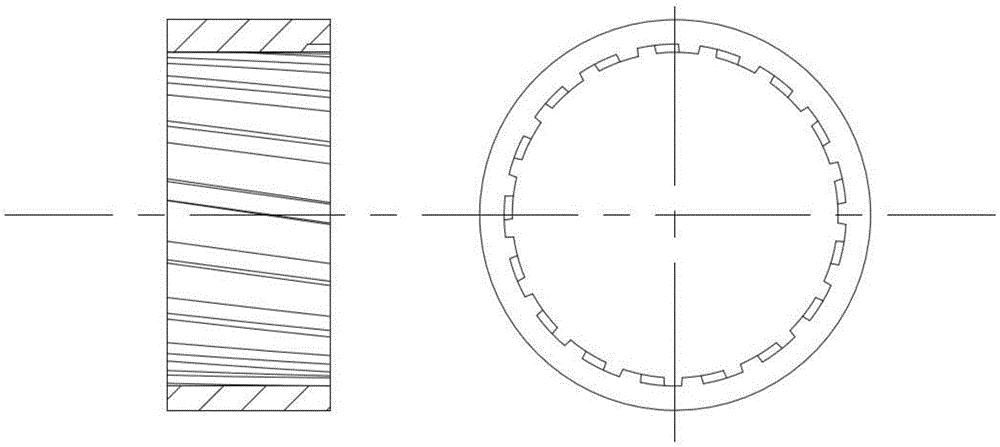

Spiral groove shell used for improving cavitation performance of inducer

InactiveCN105545814AImprove cavitation performanceImprove flow conditionsPump componentsPumpsCavitationEngineering

The invention discloses a spiral groove shell used for improving the cavitation performance of an inducer. The spiral groove shell comprises an upstream pipeline, a pump shell, a sleeve, spiral grooves and the inducer. The spiral grooves are installed at an inlet of the inducer, and the turning direction of the spiral grooves is opposite to that of the inducer. The sleeve is used for fixing the positions of the spiral grooves. When the inducer works, backflow of blade tip clearances is enhanced due to the existence of the spiral grooves, and the spiral grooves work on fluid at the same time, so that life of the inducer remains unchanged or is increased slightly.

Owner:BEIHANG UNIV

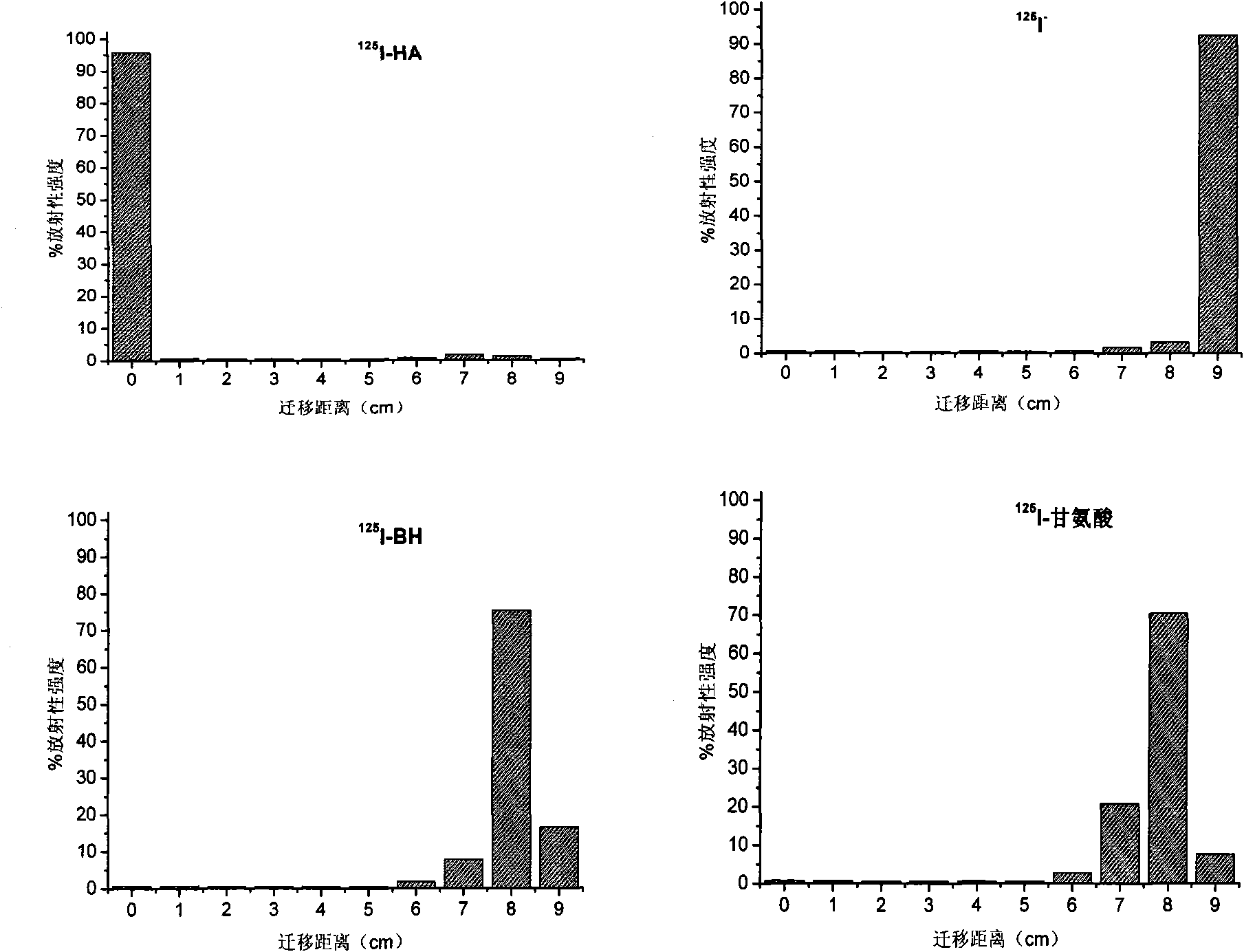

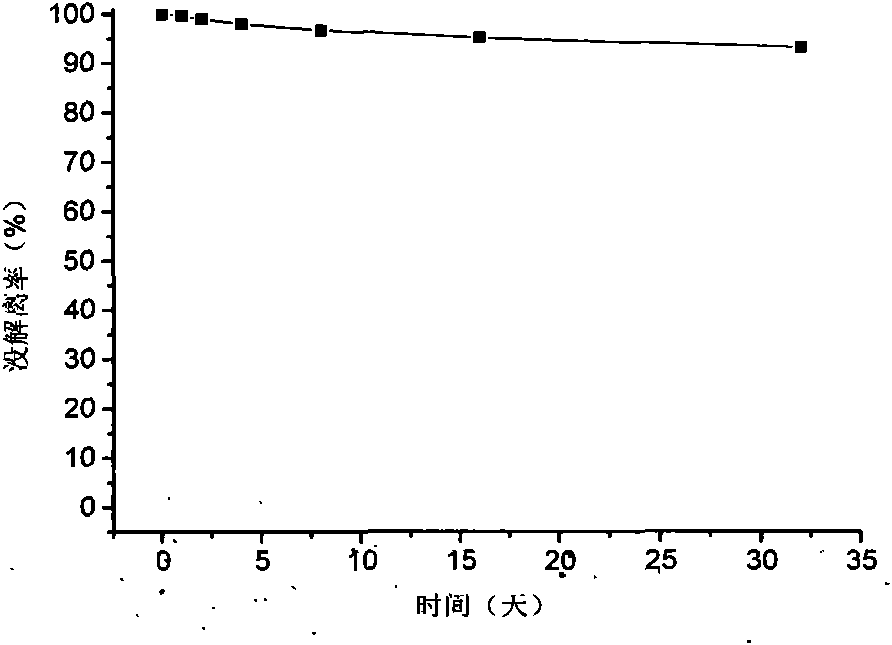

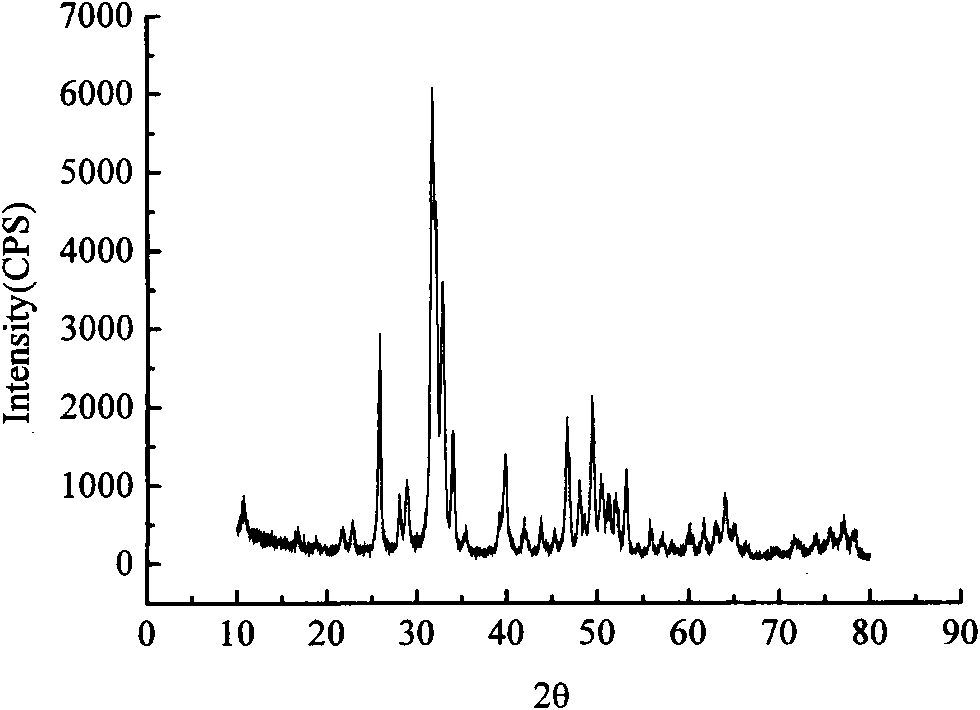

Hydroxyapatite nanoparticle radionuclide marked product and preparation method thereof

InactiveCN101829341AEasy and fast in vivo imagingEasy and fast biological distribution studyRadioactive preparation carriersHalf-lifeIn vivo

The invention discloses a hydroxyapatite nanoparticle radionuclide marked product and a preparation method thereof. The hydroxyapatite nanoparticle radionuclide marked product may be prepared by a method comprising: a, performing the amination surface modification of hydroxyapatite nanoparticles by using silane coupling agent; b, preparing a 125I-BH maker; and c, connecting the 125I-BH maker and the modified hydroxyapatite nanoparticles. In the invention, the 125I radionuclide with high chemical activity is used, and the 125I radionuclide has a proper radioactive half-life of 60 days. The 125I marked product obtained by the marking method is stable and can be used in researches on the in-vivo development and distribution of the hydroxyapatite nanoparticles.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Floor mounting method

InactiveCN101037890AAdjustable humiditySize has little effectBuilding insulationsFlooringEngineering

Owner:杨瑞宁

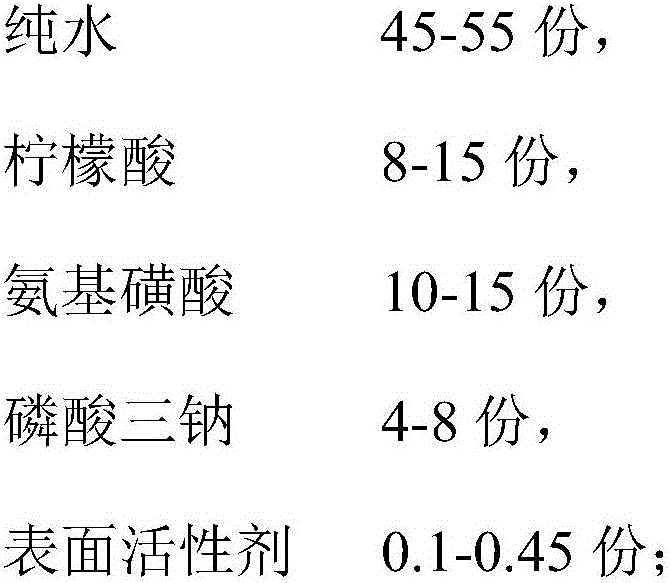

Surface treatment process of high-quality-surface stainless steel workpiece

InactiveCN106435610ASize has little effectImprove corrosion resistanceEnvironmental resistanceSurface roughness

The invention discloses a surface treatment process of a high-quality-surface stainless steel workpiece. The surface treatment process of the high-quality-surface stainless steel workpiece comprises the following steps: mechanically polishing the surface of a stainless steel workpiece at first, and then carrying out oil removal treatment on the surface; washing the stainless steel surface with water after oil of the surface is removed, and then carrying out pickling; washing the surface of the stainless steel workpiece with water after pickling; adding the washed stainless steel workpiece in an oscillating mill, and adding a grinding material and grinding fluid; cleaning the surface of the ground stainless steel workpiece by using a grinding fluid cleaning agent; and feeding the treated stainless steel workpiece in a temper mill, and carrying out surface roughness homogenized finishing treatment to obtain the high-quality-surface stainless steel workpiece. The surface of the stainless steel workpiece treated by the method is glossy, roughness is greatly reduced, rust resistance is good, and a treating agent used in a treating process is environmentally friendly and non-toxic, and is harmless to the environment.

Owner:广州市雅色绅力金属制品有限责任公司

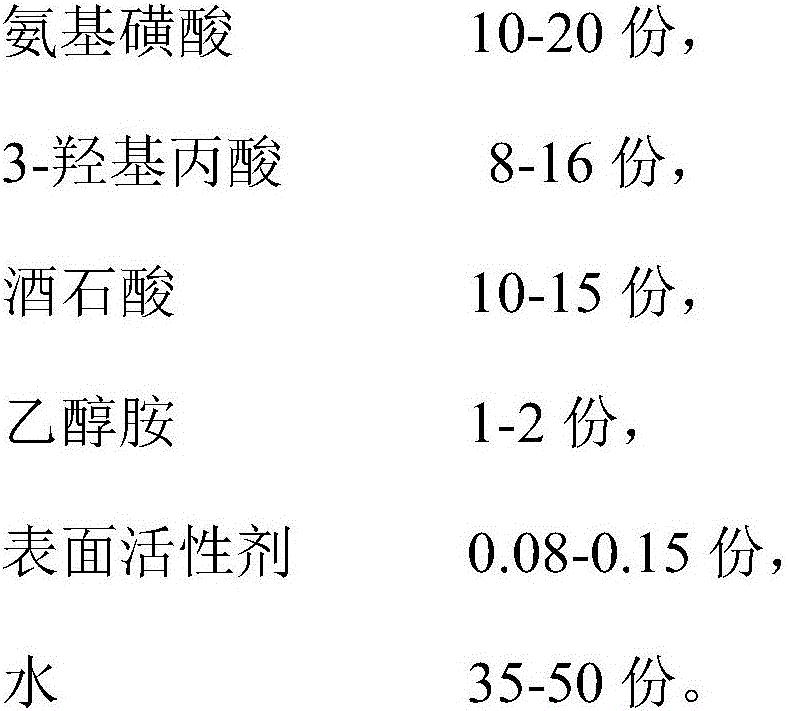

Soft die for composite product and manufacturing method of soft die

The invention discloses a soft die for a composite product and a manufacturing method of the soft die. The soft die comprises a core layer made of a plastic material and a surface layer; the surface layer is tightly fitted to the core layer; the core layer is covered by the surface layer; and the surface layer is made of a polypropylene film, one surface of the surface layer is smooth and clean, the other surface of the surface layer is viscous, and the viscous surface is in contact with the core layer. The soft die disclosed by the invention is relatively soft, has plasticity and a certain deformability under the action of an external force before being shaped and is reduced in plasticity and improved on elasticity after being shaped so as to be made to be various shapes and be widely applied to pressure transfer in places such as an angle R, an angle V and an angle U in the vacuum curing process of the composite product.

Owner:HENGSHEN

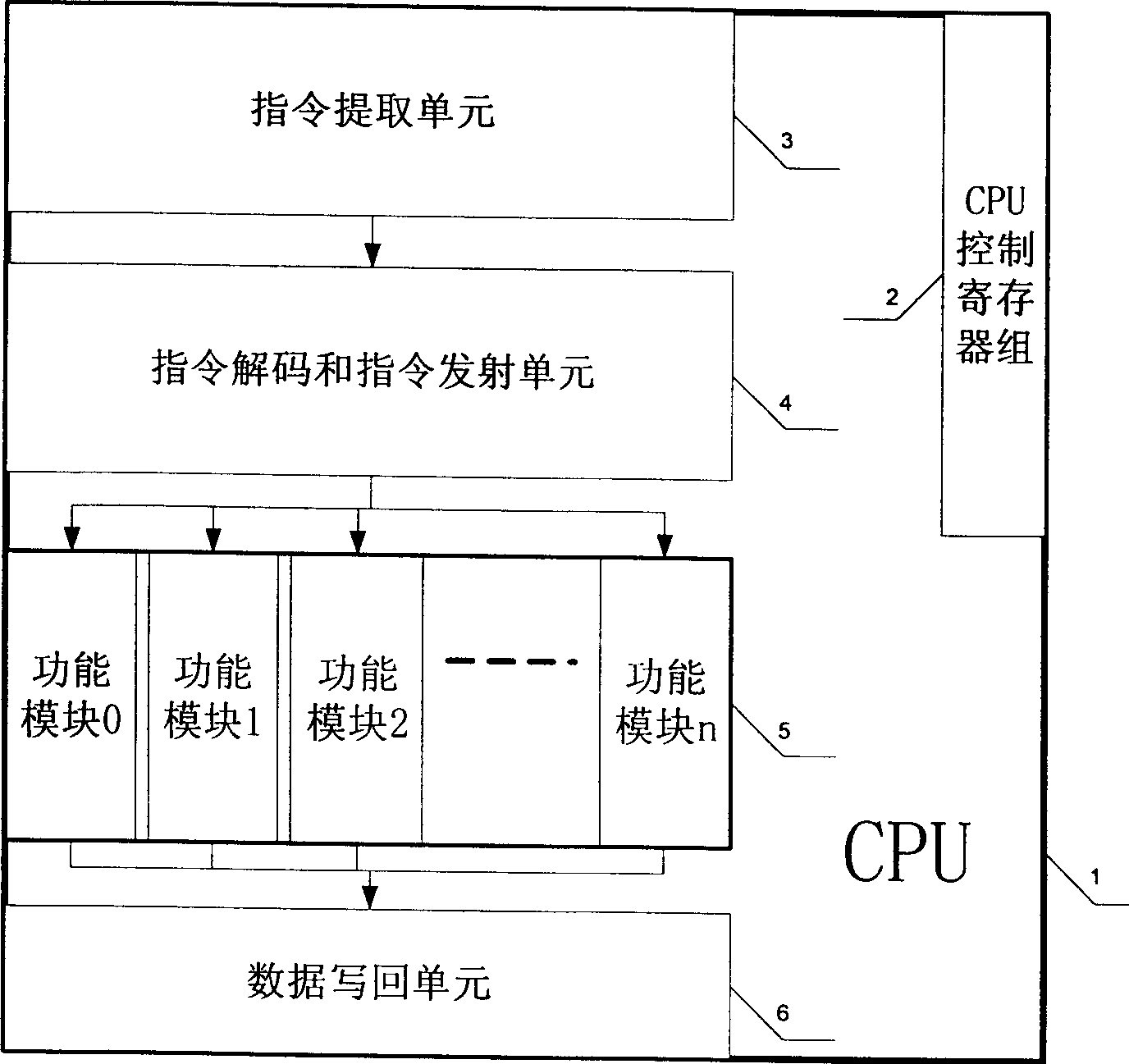

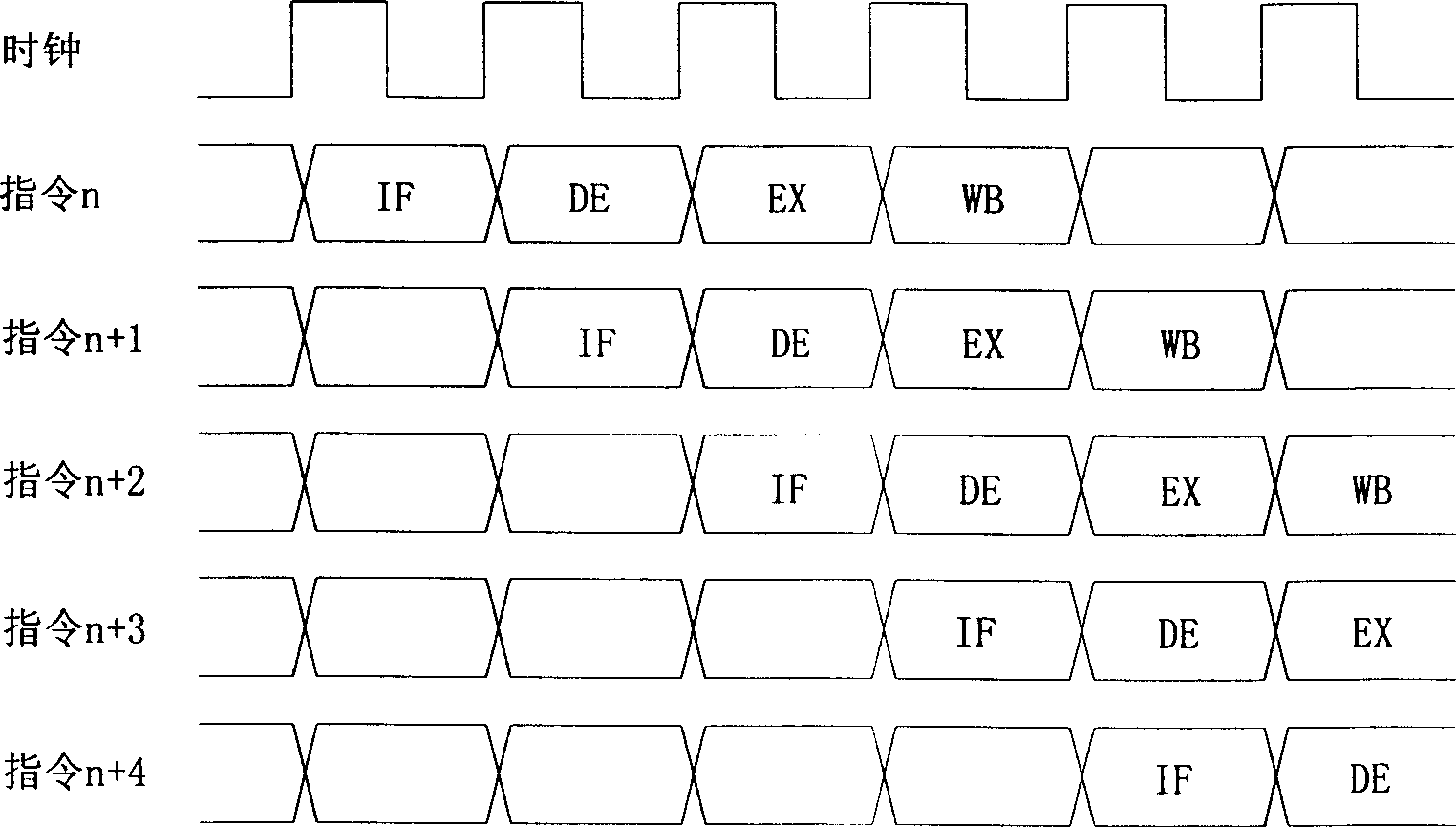

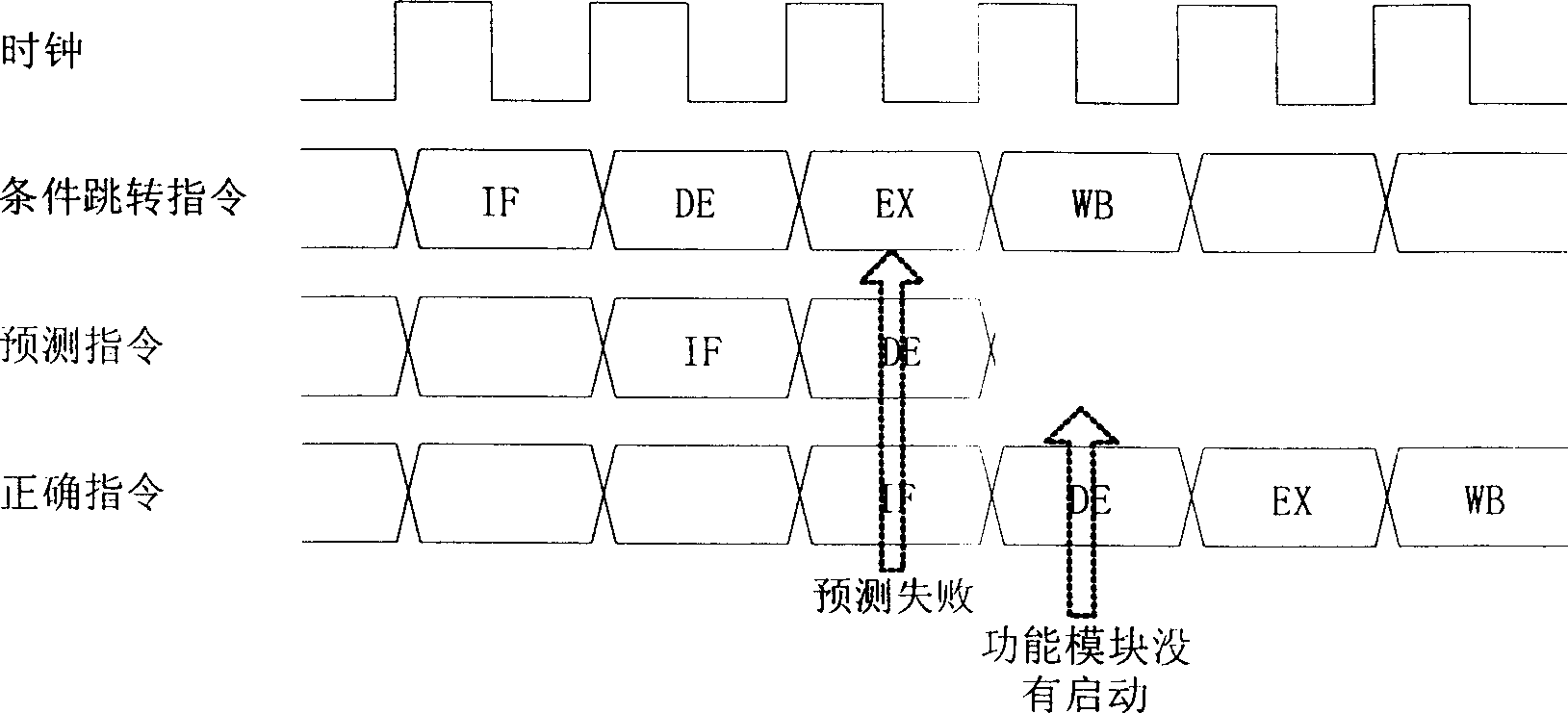

Analytical method designed in CPU for preventing linearity and differentiate power consumption

InactiveCN1447230ADoes not affect the maximum operating frequencySize has little effectRandom number generatorsConcurrent instruction executionSmart cardCritical path method

This invention discloses a method for preventing linear and differential power loss analysis designed in CPU characterizing in introducing random dummy orders and control the emitting frequency of these dummy orders and each emitting numbers, at the same time, these dummy orders are used to fill in the empty places of flow lines resulted from CPU hop and transfer order, the dummy orders cost the same energy as the normal. Advantages: small logic content, not influencying key path of time sequence, allowing the code designers to select properly among the code performance.

Owner:C SKY MICROSYST CO LTD

In-situ self-assembled slapper ignition component and preparation method thereof

InactiveCN104387216ASimple processImprove manufacturing efficiencyDetonatorsPhotoresistAlumina ceramic

The invention discloses an in-situ self-assembled slapper ignition component and a preparation method thereof. Specifically, the in-situ self-assembled slapper ignition component comprises a pin equipped alumina ceramic substrate, a metal copper exploding foil, a Parylene C slapper layer, a photoresist structural layer and an acceleration chamber. The metal copper exploding foil is disposed on the alumina ceramic substrate, the Parylene C slapper layer is arranged on the metal copper exploding foil, the photoresist structural layer is disposed on the Parylene C slapper layer, and the acceleration chamber is disposed in the photoresist structural layer. The component provided by the invention has the characteristics of self-assembly and flexibility, and can meet the production needs of various slapper ignition components with different specifications. According to the invention, photoresist is applied to preparation of the acceleration chamber and tempering modification treatment thereon so as to further strengthen the mechanical properties. Thus, the acceleration chamber can effectively shear slappers.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

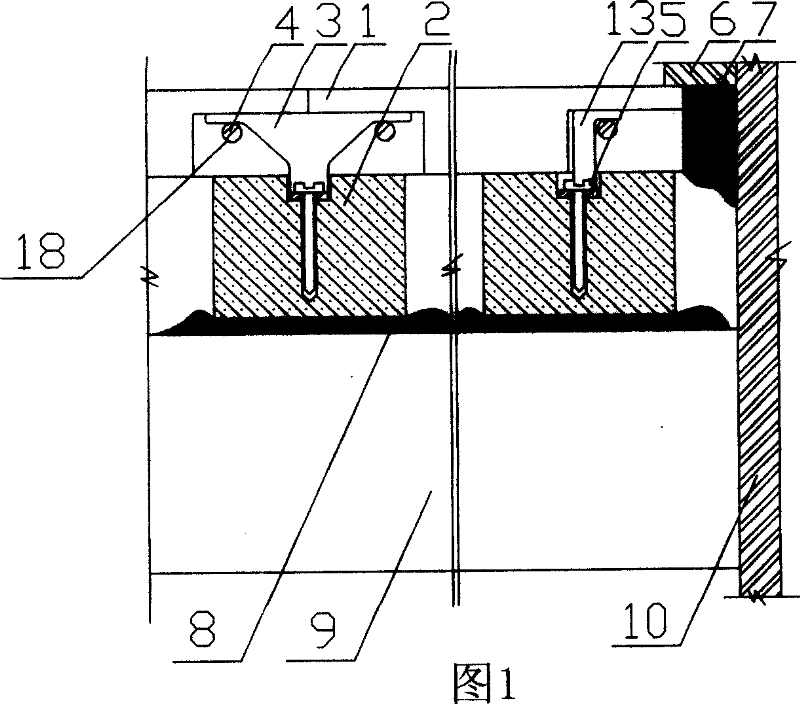

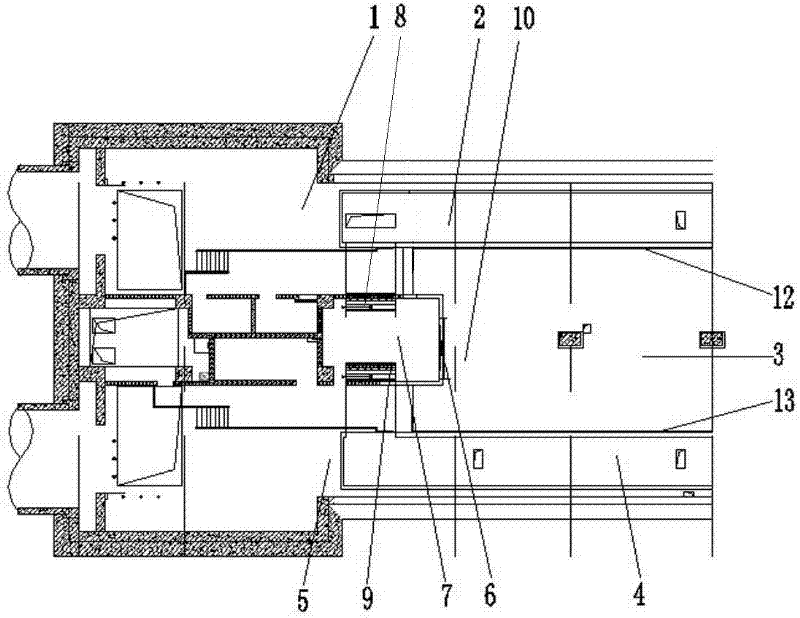

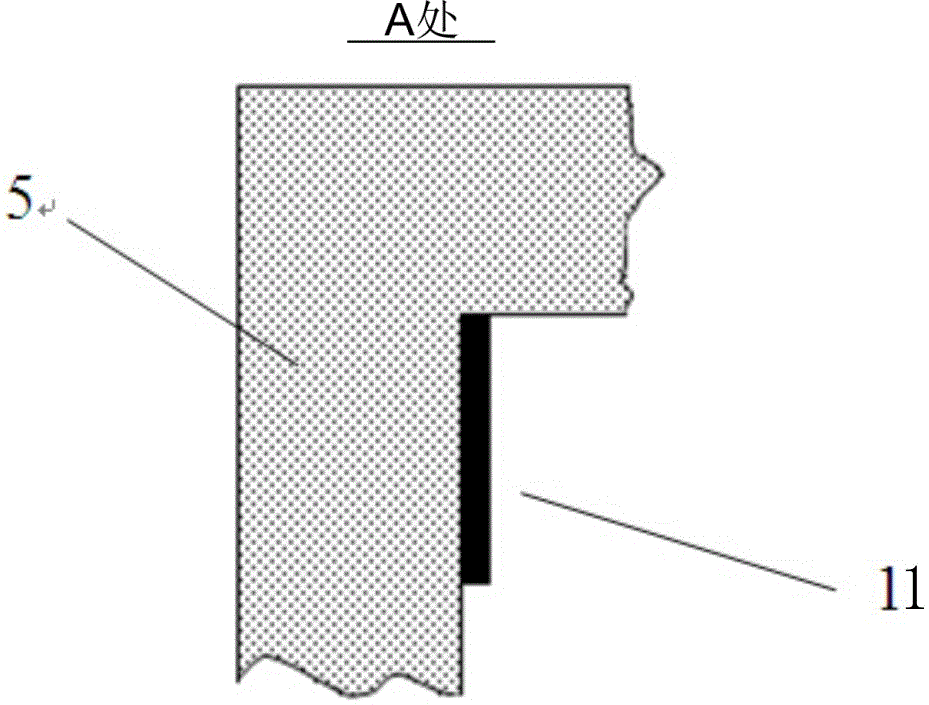

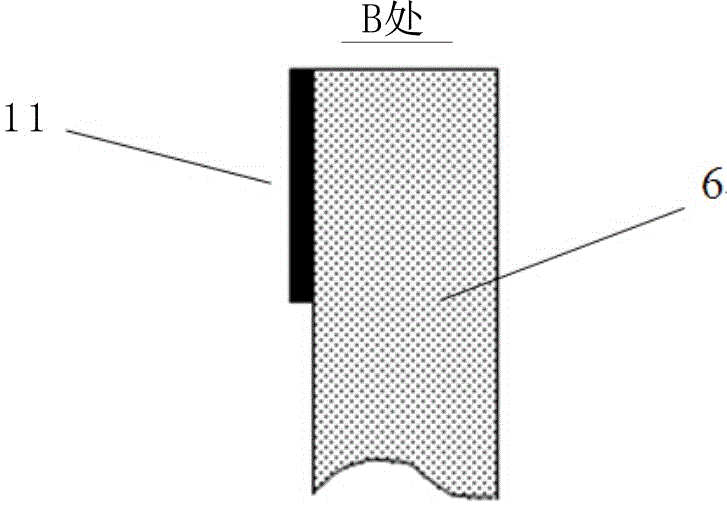

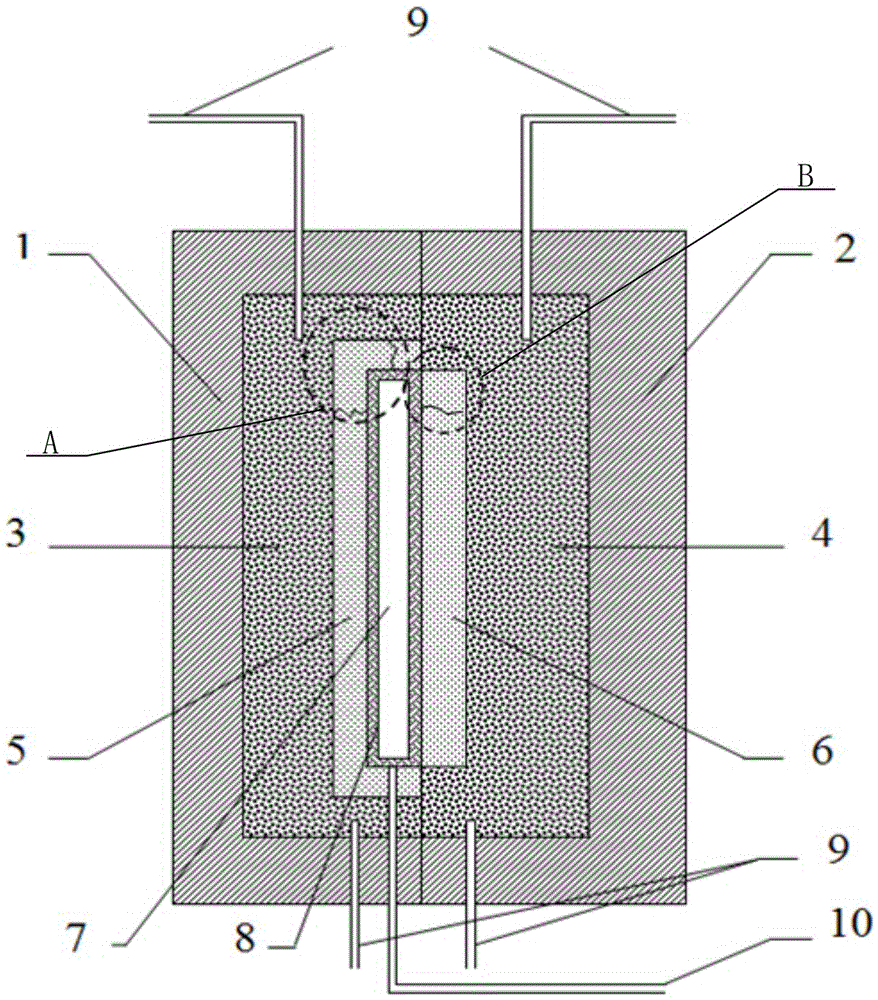

Fume exhaust layout structure for subway platform and screen door system

ActiveCN102513323AMeet smoke exhaust requirementsSize has little effectRailway componentsDirt cleaningEngineeringControl valves

The invention relates to the field of ventilation and fire prevention in track transport, in particular to a fume exhaust layout structure for subway platform and screen door system. The structure is characterized in that a fume exhaust is arranged at a side of a heat exhaust chamber close to the waiting platform, and the fume exhaust is connected with a control valve. The structure of the invention has the following advantages: the arranged fume exhaust or fume exhaust pipe helps to exhaust the fume of the platform zone inside the screen door, to form the fume exhaust way which combines even fume exhaust of initial vent pipes of the station and concentrated fume exhaust of heat exhaust fans. In this way, the normal fume exhaust requirement of the platform is satisfied, and the requirement of wind speed of 1.5m / s of stairway is also satisfied; the scale of the station is not significantly affected, and the fume is limited in the waiting zone of the station, so that the diffusion range of fume is not increased, and the secondary damage possibly caused by opening the screen door is avoided.

Owner:SHANGHAI TUNNEL ENGINEERING RAILWAY TRANSPORTATION DESIGN INSTITUTE

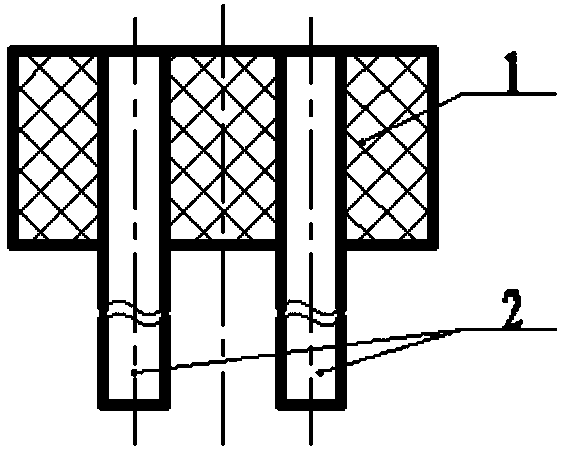

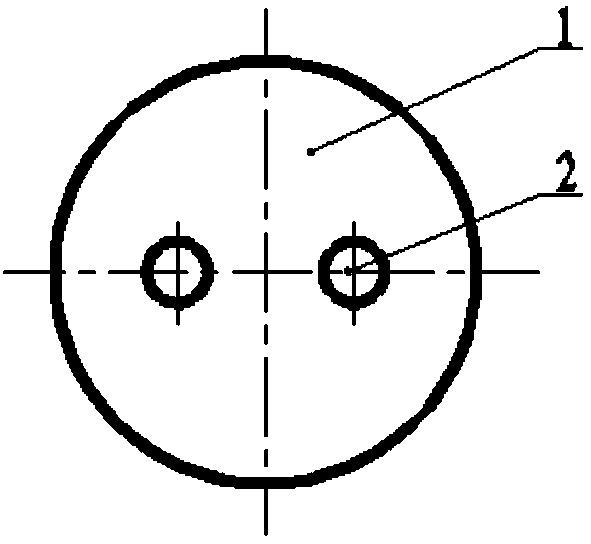

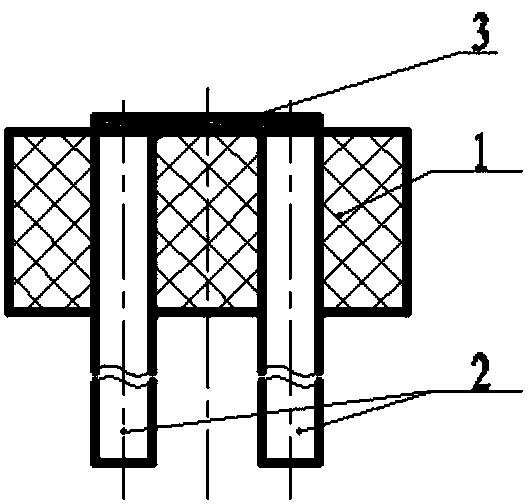

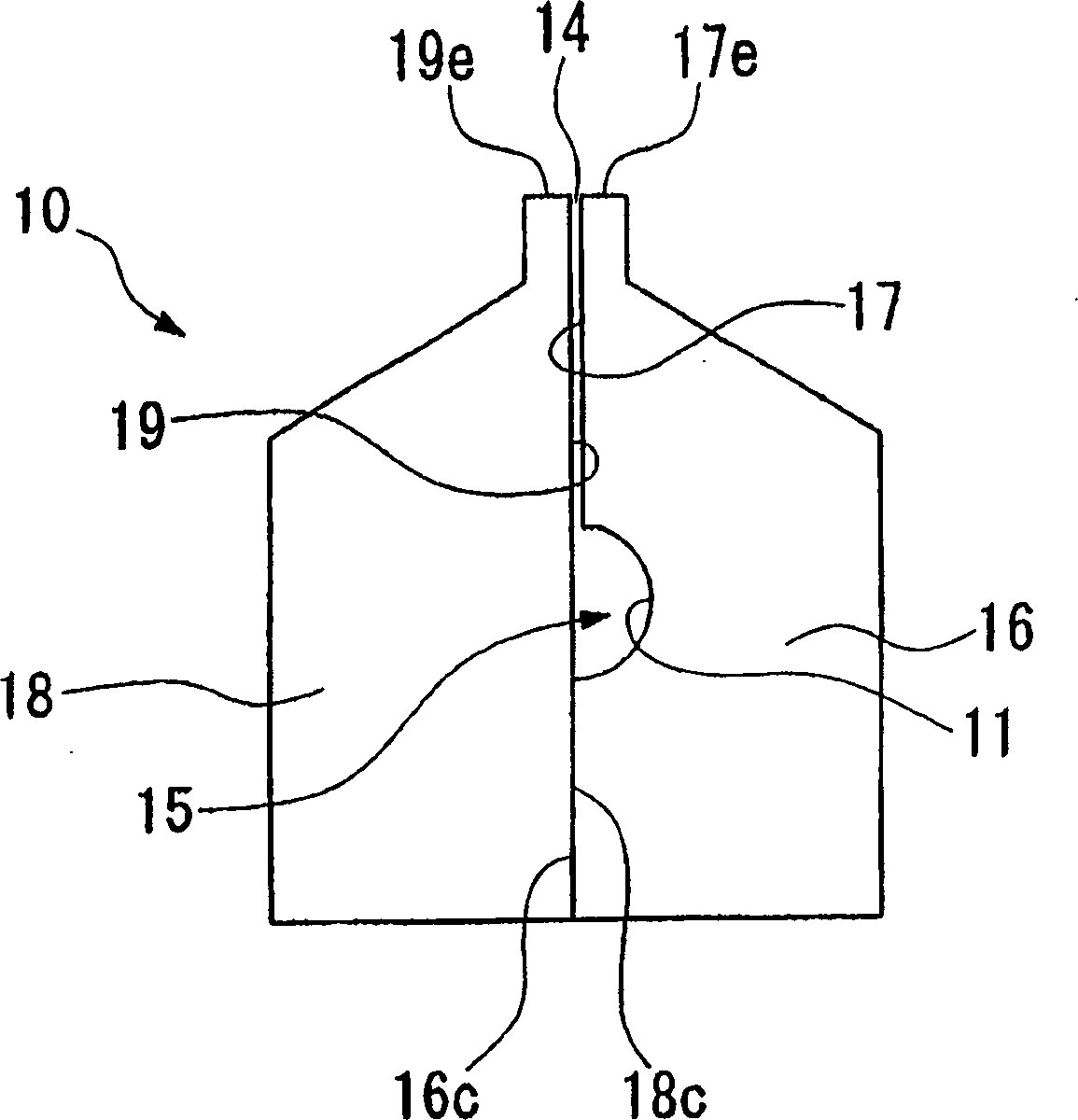

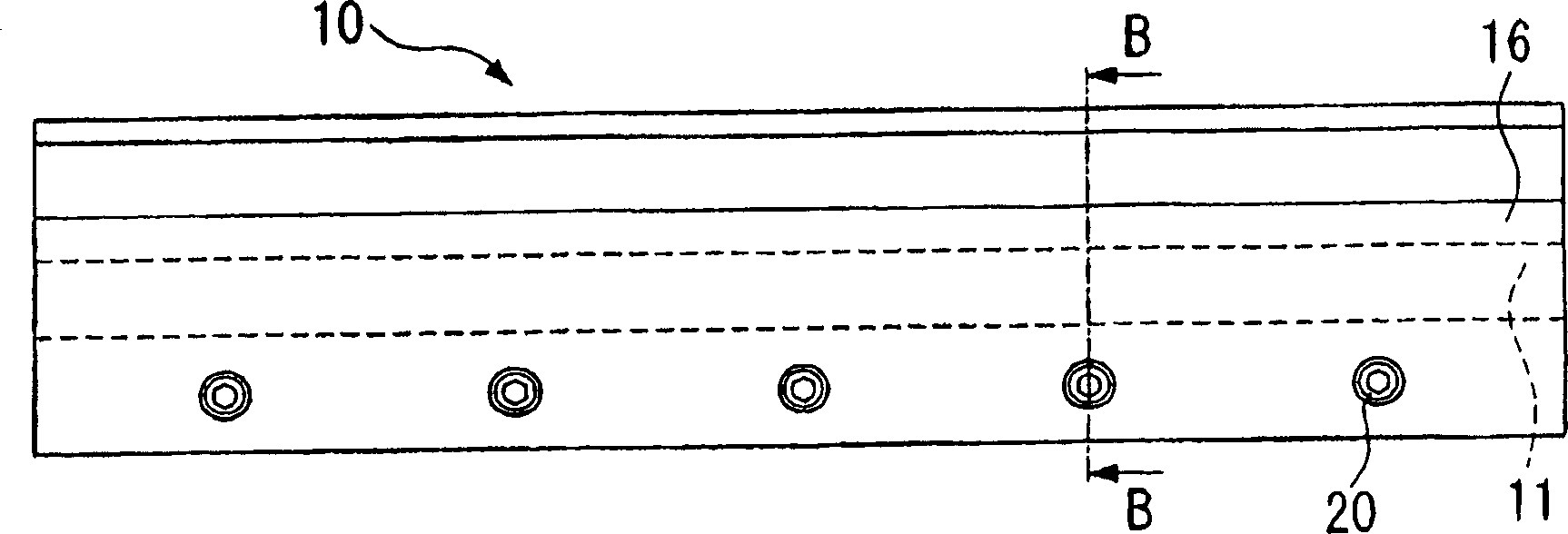

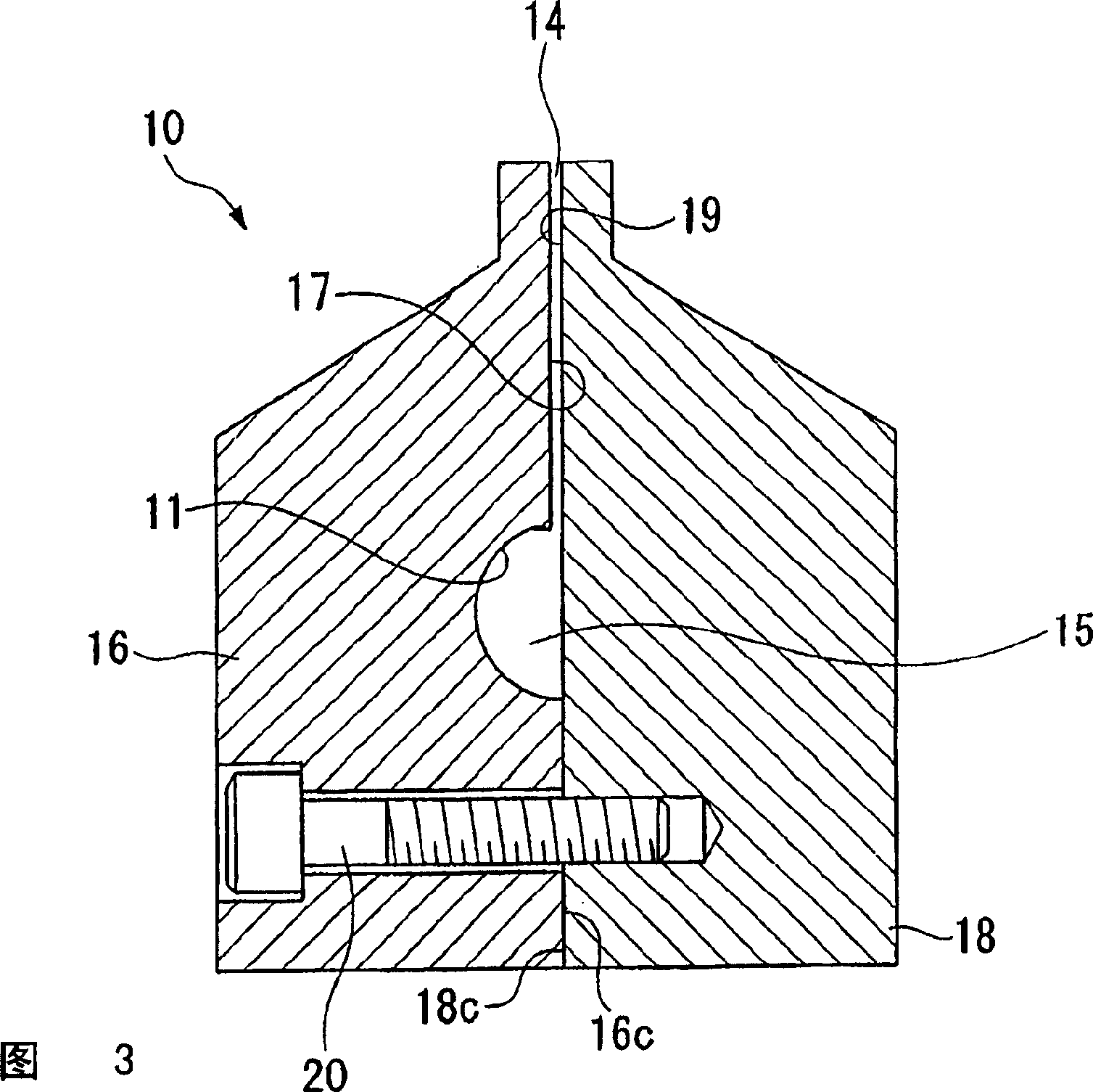

Coating tool

InactiveCN1812849AEasy to handleExtend your lifeLiquid surface applicatorsCoatingsEngineeringTitanium alloy

The present invention provides a coating tool, comprising a coating head (10) having a plurality of head members (16) and (18), wherein a groove-like slot (14) opened to the tip of the coating head (10) is demarcated between the side faces (17) and (19) of the plurality of head members (16) and (18) opposed to each other, and coating solution is jetted from the tip of the coating head (10) through the slot (14). The coating tool is characterized in that the materials of the head members (16) and (18) is a titanium alloy, and that the slot faces (17) and (19) demarcating the slot are formed of a material harder than the titanium alloy.

Owner:MITSUBISHI MATERIALS CORP

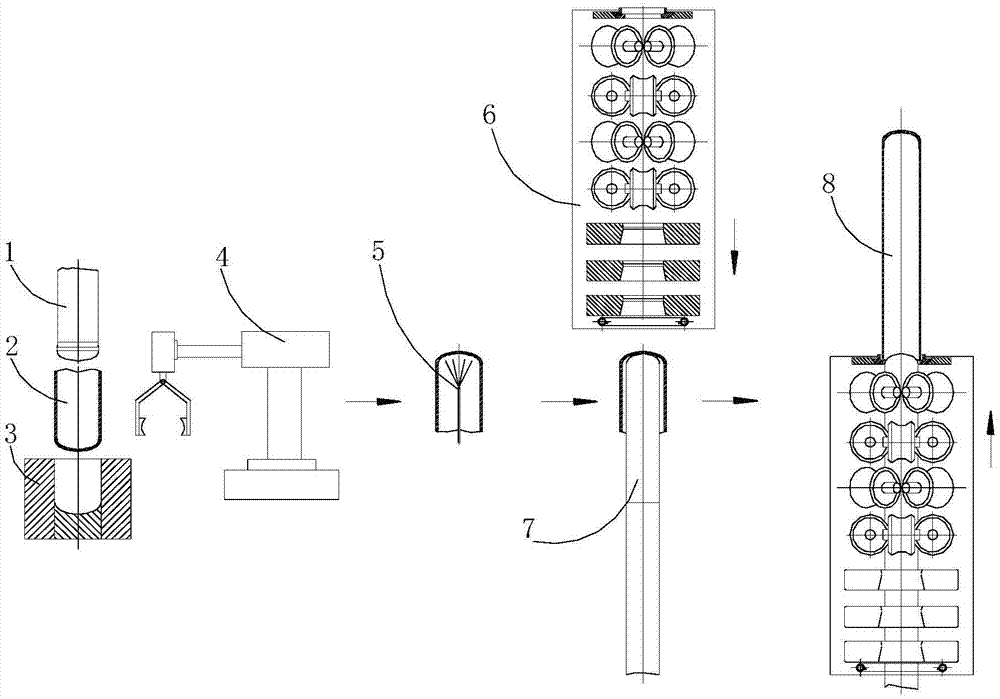

Vertical hot drawing technology for seamless cylinder

InactiveCN106975709ASmall wall thickness deviationReduce eccentricityHollow articlesGas cylinderEngineering

The invention relates to a vertical hot drawing technology for a seamless cylinder. The vertical hot drawing technology for the seamless cylinder is a process that a drawing mold and a vertical drawing press are adopted for draw forming of a cylinder blank after vertical hot piercing. The vertical hot drawing technology has the following technological steps of heating a blank after vertical blanking of a blind hole, placing the hot cylinder blank reversely for blowing impurities, placing the hot cylinder blank in place for preparation for drawing, hot drawing, returning and discharging. The vertical hot drawing technology for the seamless cylinder can reduce the deviation of the wall thickness of a seamless cylinder body, improve the quality of the seamless cylinder, prolong the service life of a mold, and reduce cost.

Owner:NANJING BANQIAO FIRE FIGHTING EQUIP

Chemical polishing solution and preparation method thereof and method for chemically polishing Kovar parts

The invention discloses a chemical polishing solution and a preparation method thereof and a method for chemically polishing Kovar parts. The chemical polishing solution comprises the following components in parts by volume: 300+ / -10 parts of nitric acid, 5+ / -0.2 parts of hydrochloric acid and 700+ / -15 parts of acetic acid. The method for chemically polishing Kovar parts comprises the following steps of: removing oil of Kovar parts, acid pickling, chemical polishing solution and drying. An aluminum substrate is subjected to oil removal and acid pickling, and the Kovar parts are chemically polished; moreover, the time and labor are saved, the finish degree of the surface of the Kovar parts is greatly improved, burrs are completely removed, and the influence on the size of the Kovar parts is small.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Discharging burr removal processing method for plasma tip

The invention relates to the technical field of copper base alloy manufacturing, in particular to a discharging burr removal processing method for a plasma tip. The method comprises the following steps of 1, a hanging process; 2, a cleaning process before polishing; 3, a plasma polishing process, wherein a workpiece obtained after the cleaning process and a hanging toll are placed in a plasma tankfor plasma polishing, wherein the working voltage in the plasma is 200-400 V, the concentration of the plasma is 30-80 g / L, the working temperature of the plasma is 30-90 DEG C, and the working timeis 30-50 seconds; the plasma is 30 millimeters or above, and 5-7 kilograms of polishing salt is added and dissolved in water; 4, a cleaning process after polishing; 5, a drying process; 6, a taking-down process. According to the discharging burr removal processing method for the plasma tip, the aims of reducing the cost, improving the production efficiency and product quality and the like are achieved.

Owner:DEQING TIANMA BEARING CO LTD

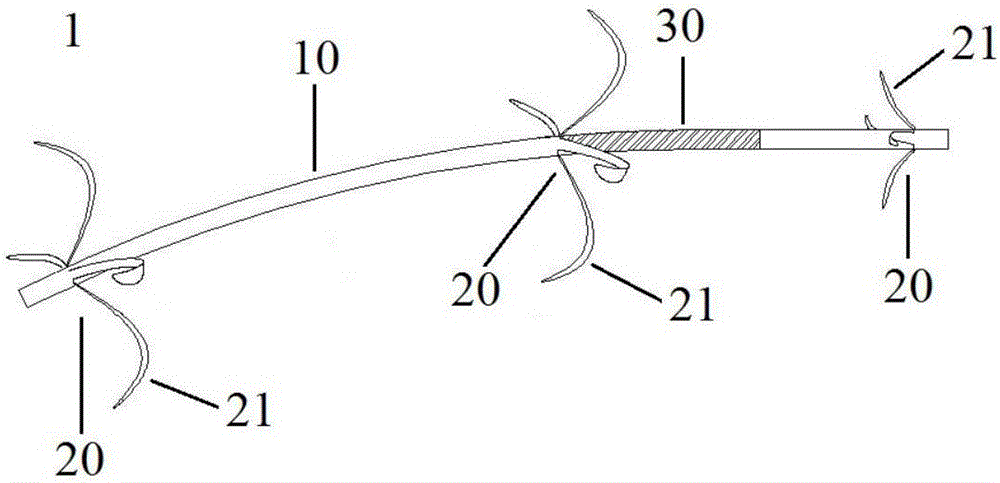

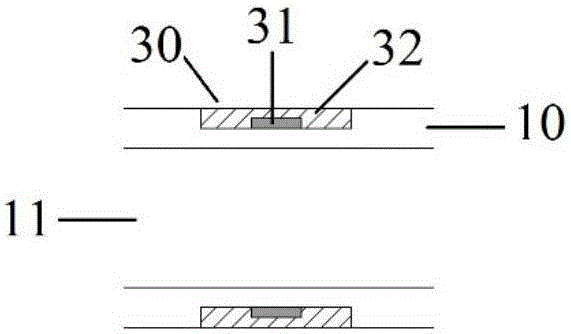

Radioactive lumen stent

PendingCN106512197ASize has little effectAvoid damageX-ray/gamma-ray/particle-irradiation therapyInsertion stentRadioactive agent

The invention relates to the technical field of medical instruments containing radioactive substances and discloses a radioactive lumen stent which comprises a tube body, a branch-shaped supporting side wing and a sheet-shaped radioactive core sealed in the wall of the tube body and carrying radioactive nuclide. The branch-shaped supporting side wing is used for fixing the stent at a specific position in a tube cavity to prevent displacement; the radioactive core carries the radioactive nuclide and also plays a role as an X-ray marker, and the radioactive nuclide releases radioactive rays to treat tumor during decaying. The radioactive lumen stent is simple in structure and high in flexibility, is maintained smooth on the surface, is convenient for implantation, extraction and replacement with the help of an endoscope and has effects of supporting, draining and treating; due to structure of the radioactive core arranged on the tube body, leakage of the radioactive nuclide can be avoided; the radioactive core is quite thin, thereby having little influence on size of the stent; a sectional radiation designing mode is adopted, so that 360-degree blind-spot-free radiation is realized, size of a radioactive area, type of nuclide, position on the support and activity of the nuclide can be adjusted according to clinical features like position and size of the tumor, and individualized precision treatment is realized.

Owner:窦春青 +1

The Method of Eliminating Micro-crack Defects on the Edge of Ito Blank During Pressure Grouting

ActiveCN104760119BEliminate microcrack defectsSize has little effectSlip casting mouldsCeramic shaping mandrelsVolumetric Mass DensityTransition layer

Disclosed is a method for eliminating ITO green body edge microcrack defects in the pressure slip casting process. The method comprises the steps that a glass plate is arranged on an inward concave face of a left inner mold and a contact face of a right inner mold, the glass plate is pasted on the inward concave face of the left inner mold at this moment, left long rectangular-ambulatory-plane cavities are formed at the non-pasted positions in the height direction and the length direction at equal intervals, the glass plate is pasted on the contact face of the right inner mold, right long rectangular-ambulatory-plane cavities are formed at the non-pasted positions in the height direction and the length direction at equal intervals, spraying materials are sprayed to the left long rectangular-ambulatory-plane cavities and the right long rectangular-ambulatory-plane cavities respectively to form a left long rectangular-ambulatory-plane spraying band and a right long rectangular-ambulatory-plane spraying band, and a water stopping area is formed by the left long rectangular-ambulatory-plane band and right long rectangular-ambulatory-plane band in mold closing in the forming process; the density gradient and a transition layer of an ITO green body in the forming process are eliminated through the water stopping area, it is guaranteed that the overall density and planeness of the ITO green body are consistent, and then the microcrack defects happening to the edge of the ITO green body are eliminated.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Aluminum alloy surface treatment method before injection molding

The invention relates to the technical field of aluminum alloys, in particular to an aluminum alloy surface treatment method before injection molding. The aluminum alloy surface treatment method comprises the following steps that (1) a to-be-treated aluminum alloy workpiece is degreased, and the degreased aluminum alloy workpiece is washed with water; (2) the aluminum alloy workpiece is placed inabsolute ethyl alcohol, and washing is conducted with water; (3) the aluminum alloy workpiece is polished with a chemical polishing solution, acid pickling is conducted after polishing, and then washing is conducted with water; (4) anodic oxidation treatment is conducted on the aluminum alloy workpiece; and (5) the aluminum alloy workpiece is put into an etching solution for etching. The aluminumalloy surface treatment method is adopted for treating the aluminum alloy workpiece before injection molding, the treated aluminum alloy workpiece is good in appearance effect, the surface aluminum oxide film layer is provided with combination holes with excellent performance, the combination strength of aluminum alloy and resin after injection molding can be improved, the product yield and the product reliability can be improved, and the aluminum alloy surface treatment method is easy and convenient to operate, easy to control, high in production efficiency, stable in product quality and capable of reducing environmental pollution.

Owner:广东东明新材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com