Surface treatment process of high-quality-surface stainless steel workpiece

A surface treatment and stainless steel technology, which is applied in the field of surface treatment of high-quality surface stainless steel workpieces, can solve the problems of water pollution, stainless steel workpiece size, increased cost, etc., to achieve good anti-corrosion performance, small size impact, The effect of saving processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A surface treatment process for a high-quality surface stainless steel workpiece, comprising the following steps:

[0038] (1) First, the surface of the stainless steel workpiece is mechanically polished, and then the surface is degreased;

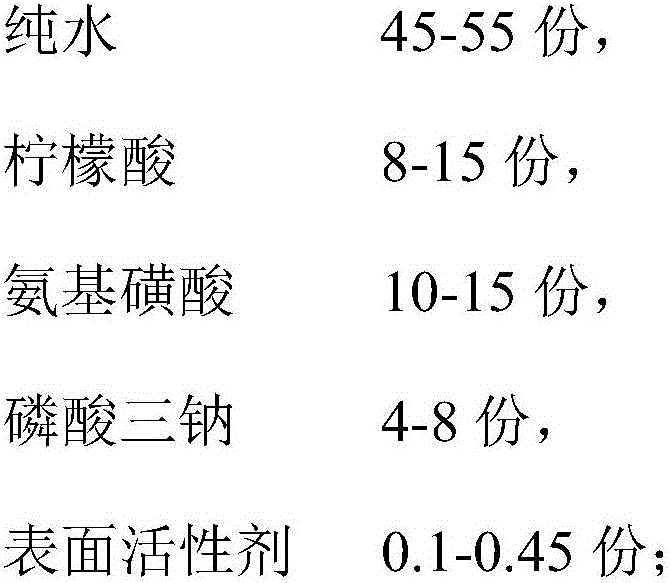

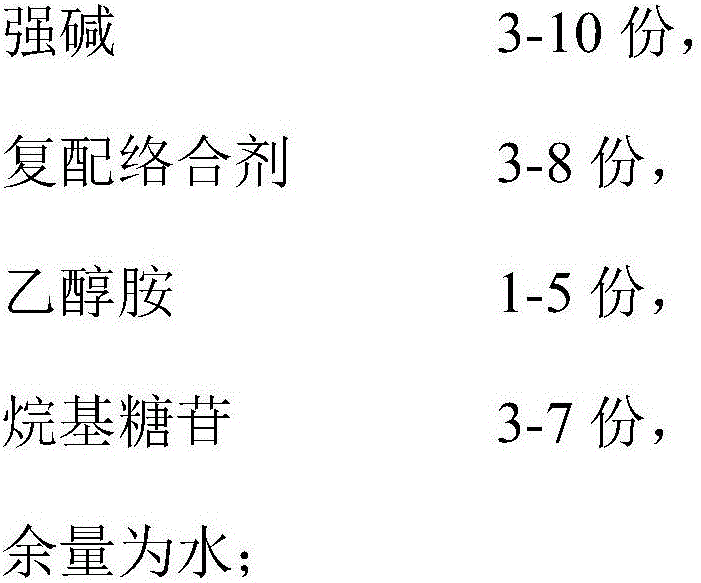

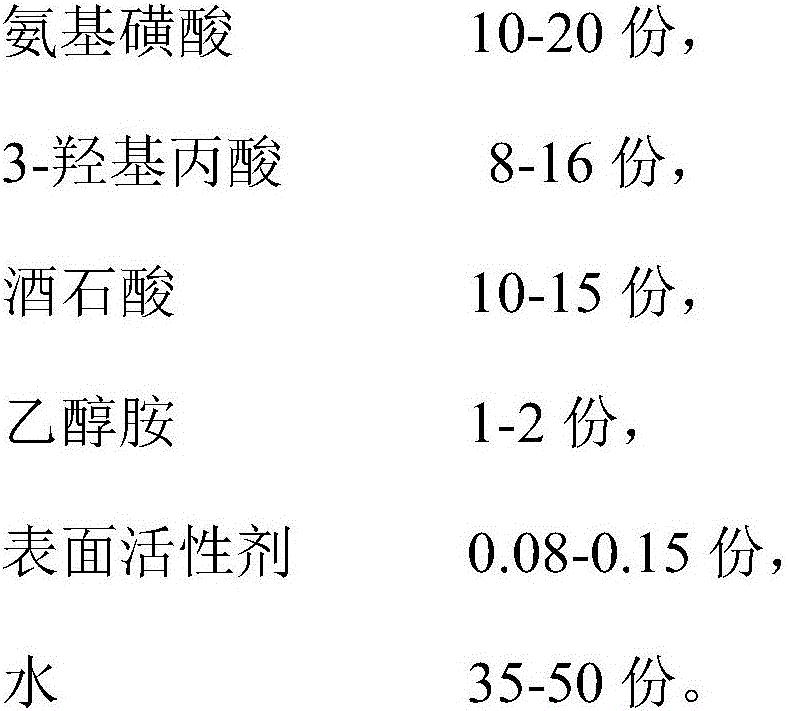

[0039] Wherein, the degreasing agent during degreasing treatment is made up of the following components by weight:

[0040] 10 parts of sulfamic acid, 8 parts of 3-hydroxypropionic acid,

[0041] 10 parts of tartaric acid, 1 part of ethanolamine,

[0042] 0.08 parts of surfactant, 35 parts of water;

[0043] The surfactant is a mixture of alkyl glucoside and sodium lauryl sulfate;

[0044] (2) wash the stainless steel surface after degreasing, then carry out pickling;

[0045] Wherein the pickling agent that adopts during pickling is made up of the following components by weight:

[0046] 50 parts of pure water,

[0047] 15 parts of organic acid,

[0048] 1 part of alkyl glycoside;

[0049] The organic acid is a mixture of h...

Embodiment 2

[0062] A surface treatment process for a high-quality surface stainless steel workpiece, comprising the following steps:

[0063] (1) First, the surface of the stainless steel workpiece is mechanically polished, and then the surface is degreased;

[0064] Wherein, the degreasing agent during degreasing treatment is made up of the following components by weight:

[0065] 20 parts of sulfamic acid, 16 parts of 3-hydroxypropionic acid,

[0066] 15 parts of tartaric acid, 2 parts of ethanolamine,

[0067] 0.15 parts of surfactant, 50 parts of water;

[0068] Described tensio-active agent is the mixture of sodium lauryl sulfate, sodium dodecylbenzenesulfonate;

[0069] (2) wash the stainless steel surface after degreasing, then carry out pickling;

[0070] Wherein the pickling agent that adopts during pickling is made up of the following components by weight:

[0071] 80 parts of pure water,

[0072] 49 parts of organic acid,

[0073] 5 parts of alkyl glycoside;

[0074] Th...

Embodiment 3

[0087] A surface treatment process for a high-quality surface stainless steel workpiece, comprising the following steps:

[0088] (1) First, the surface of the stainless steel workpiece is mechanically polished, and then the surface is degreased;

[0089] Wherein, the degreasing agent during degreasing treatment is made up of the following components by weight:

[0090] 12 parts of sulfamic acid, 10 parts of 3-hydroxypropionic acid,

[0091] 11 parts of tartaric acid, 1.2 parts of ethanolamine,

[0092] 0.1 part of surfactant, 37 parts of water;

[0093] The surfactant is an alkyl glycoside;

[0094] (2) wash the stainless steel surface after degreasing, then carry out pickling;

[0095] Wherein the pickling agent that adopts during pickling is made up of the following components by weight:

[0096] 60 parts of pure water,

[0097] 20 parts of organic acid,

[0098] 2 parts of alkyl glycoside;

[0099] The organic acid is a mixture of hydroxypropionic acid and citric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com