The Method of Eliminating Micro-crack Defects on the Edge of Ito Blank During Pressure Grouting

A technology of grouting molding and eliminating pressure, applied in the direction of ceramic molding core, ceramic molding machine, ceramic molding mandrel, etc., can solve the problems of unqualified ITO body, micro-crack defects, etc., and achieve the effect of eliminating micro-crack defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

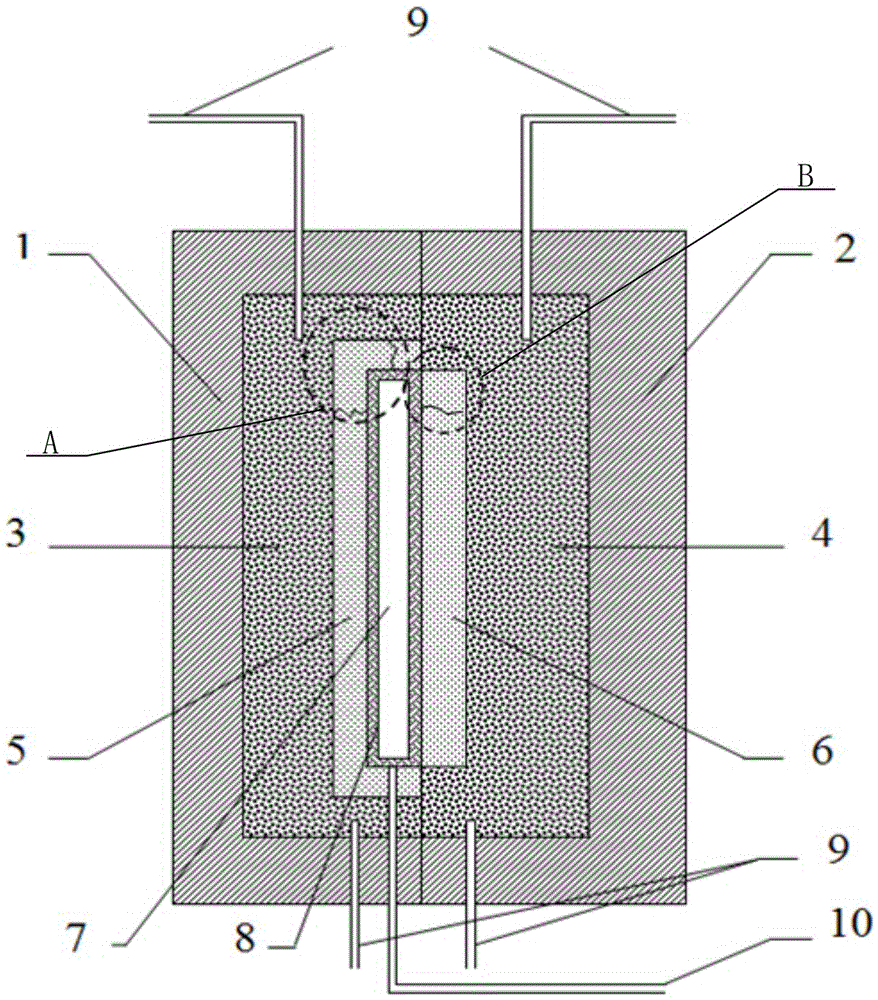

[0024] The present invention is a method for eliminating microcrack defects at the edge of ITO blanks during pressure grouting molding. The method aims at the causes of microcrack defects in ITO blanks in the background technology, so as to eliminate the density gradient and transition layer of ITO blanks during molding. As the main line, the micro-crack defects of the ITO body are eliminated by painting the spray material on the inner mold, so as to ensure the yield of the ITO body.

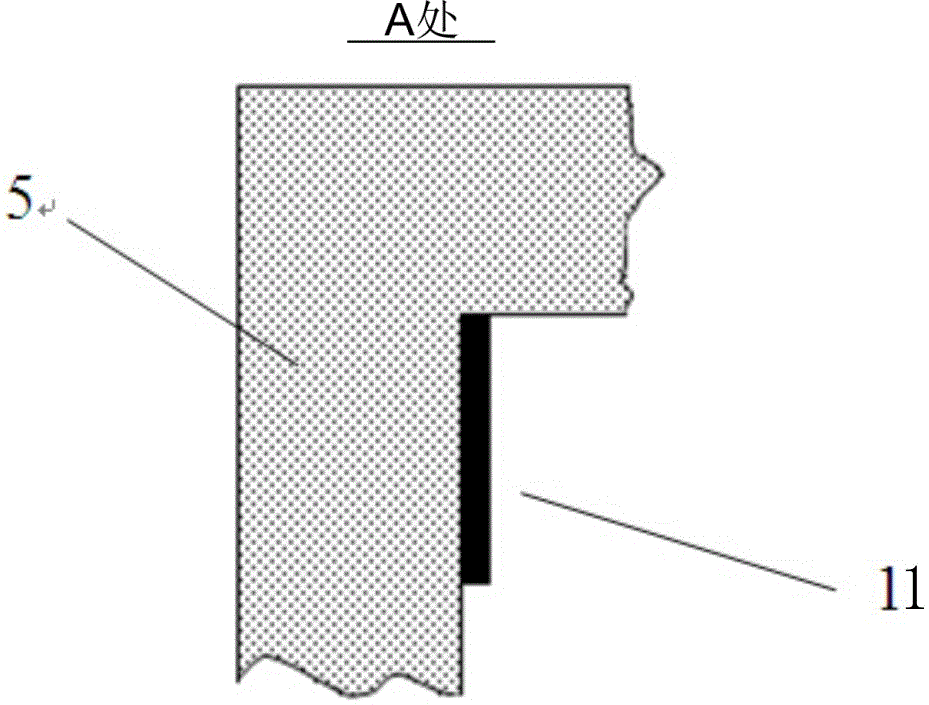

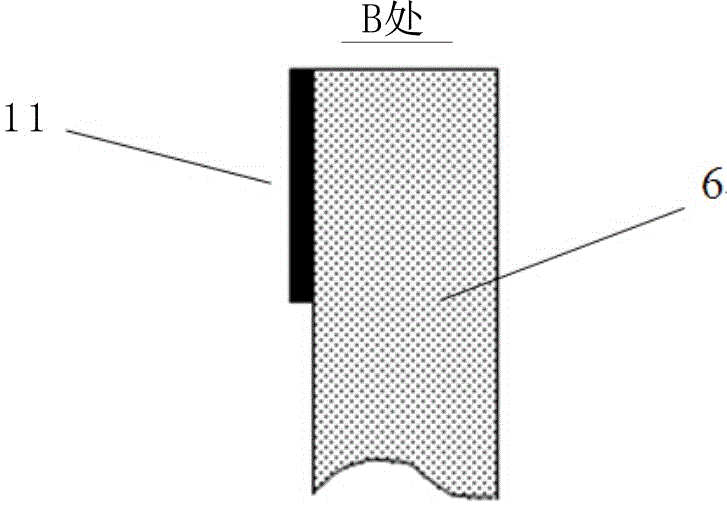

[0025] combine Figure 1-3 , first set the molding size of the ITO green body as high Gcm×length Ccm×thickness Hcm, the left inner mold and the right inner mold are used to form the ITO green body, the left inner mold and the right inner mold are both microporous molds, microporous The maximum micropore size of the mold is 2-15 μm, and the molded ITO green body is provided by ITO slurry, according to figure 1 The upper and lower dimensions of the left inner mold and the right inner mold shown a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com