A cutting method of mesa silicon rectifier device

A cutting method and silicon rectification technology, which are applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of debris contamination of cutting width, easy edge collapse on both sides, and micro-damage, etc., and achieve smooth groove bottom. , the effect of eliminating micro-crack defects and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

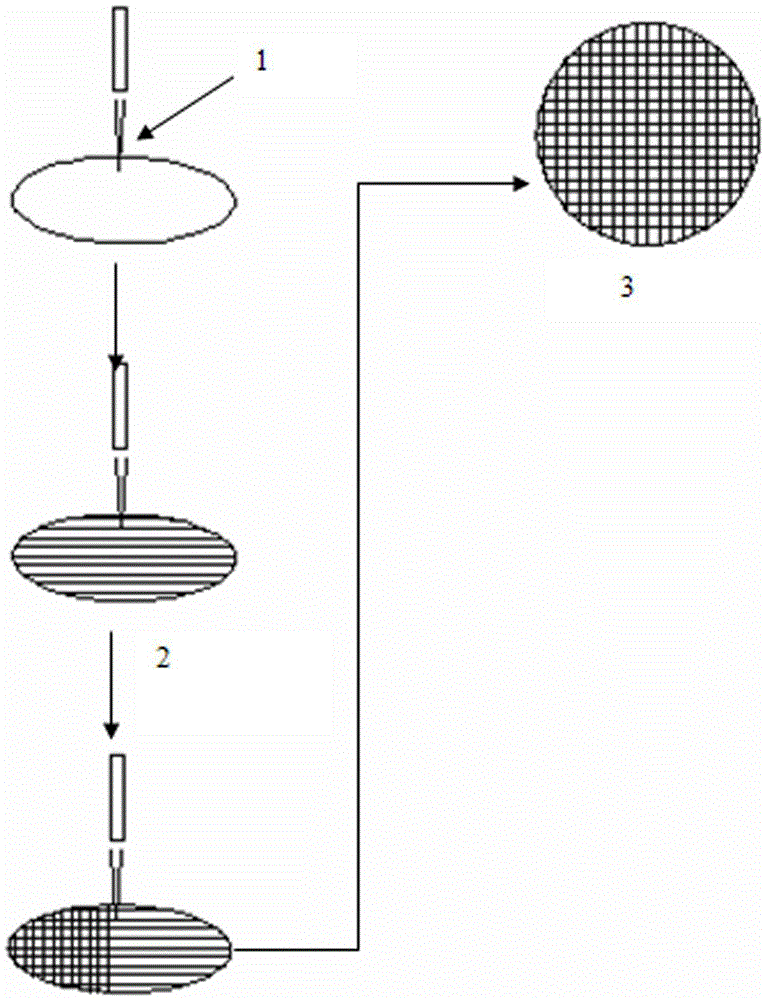

[0027] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

[0028] The specific steps of preparing mesa silicon rectifier devices:

[0029] (1) The N-type monocrystalline silicon wafer with a thickness of 280-290μm and a resistivity of 30-40Ω·cm is subjected to phosphorus and boron diffusion at a high temperature of 1250±5°C to form a PN junction silicon wafer.

[0030] (2) Oxidize the above-mentioned silicon wafer at 1120±5℃. After forming the oxide layer, use a spin coater to drop 2-3ml negative photoresist on the surface of the silicon wafer to coat the surface of the silicon wafer with a layer of light. Resist protective layer.

[0031] (3) After installing a lithography plate on the upper and lower plate racks of the lithography equipment and aligning them, place the silicon wafer be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com