Large part 3D printing method

A 3D printing, large-scale parts technology, applied in arc welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems of increasing production cost, reducing production efficiency, large stress deformation of parts, saving production cost, improving production efficiency, Avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

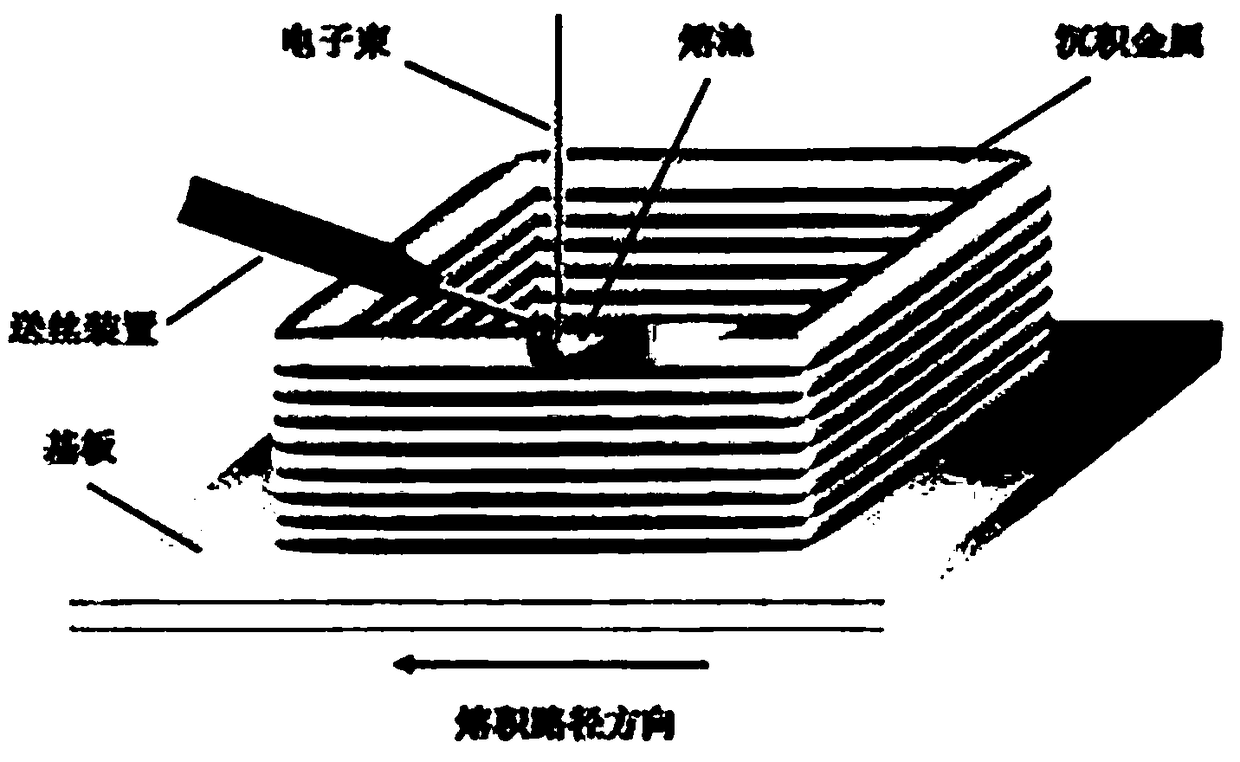

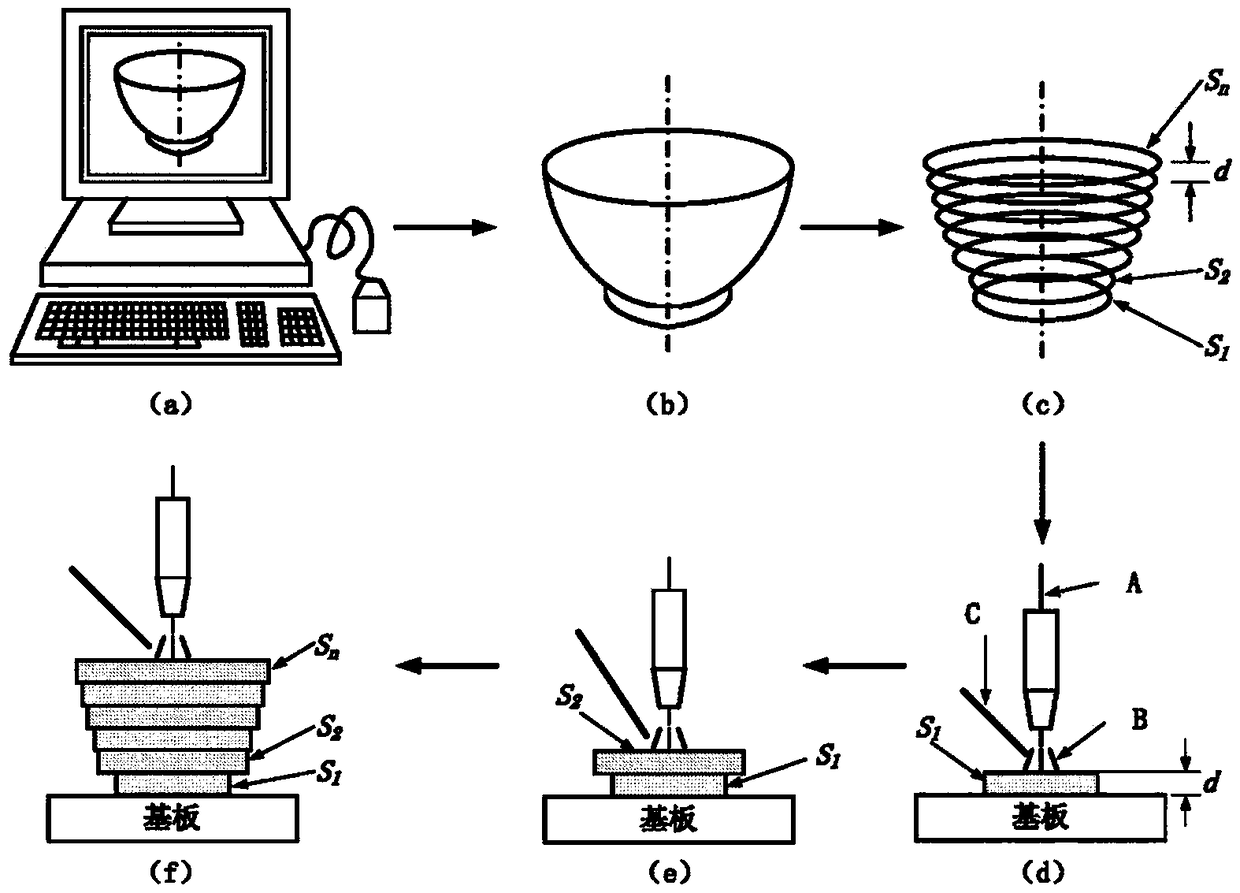

Method used

Image

Examples

Embodiment 1

[0045] A TC4 titanium alloy ring 3D printing device with a diameter of 3 m was prepared.

[0046] The device is mainly composed of a wire feeding mechanism, a shape controller, an optical imager, an arc welding torch, an induction heating plate, an ultrasonic micro-forging mechanism, a horn, an infrared camera, a temperature controller, a base and a workbench. The arc welding torch, wire feeding mechanism, optical imager, and workbench are connected to the computer responsible for shape control. The forging mechanism moves up and down, and the control accuracy is 0.01mm;

[0047] The diameter of the wire used in the arc welding torch is 1mm, and the 3D digital model input into the computer program for shape control is UG software; the arc welding torch, wire feeding mechanism, optical imager, and workbench are connected with the computer responsible for shape control. , the trajectory of the workbench and the arc welding torch is controlled by the computer program that inputs...

Embodiment 2

[0049] A 6061 aluminum alloy frame 3D printing device with a side length of 2m was prepared.

[0050] The device is mainly composed of a wire feeding mechanism, a shape controller, an optical imager, an arc welding torch, an induction heating plate, an ultrasonic micro-forging mechanism, a horn, an infrared camera, a temperature controller, a base and a workbench. The arc welding torch, wire feeding mechanism, optical imager, and workbench are connected with the computer responsible for shape control. The forging mechanism moves up and down, and the control accuracy is 0.008mm; the diameter of the wire material used in the arc welding torch is 1.5mm, and the 3D digital model input into the computer program for shape control is Pro / E software; the arc welding torch, wire feeding mechanism, optical imager, working The table is connected to the computer responsible for shape control. During the printing process, the trajectory of the workbench and the arc welding torch is control...

Embodiment 3

[0052] A Cu-Ag-Zr alloy sleeve 3D printing device with a diameter of 2.5 m was prepared.

[0053] The device is mainly composed of a wire feeding mechanism, a shape controller, an optical imager, an arc welding torch, an induction heating plate, an ultrasonic micro-forging mechanism, a horn, an infrared camera, a temperature controller, a base and a workbench. The arc welding torch, wire feeding mechanism, optical imager, and workbench are connected with the computer responsible for shape control. The micro-forging mechanism moves up and down, and the control accuracy is 0.01mm; the diameter of the wire used in the arc welding torch is 2mm, and the 3D digital model input into the computer program for shape control is Solidworks software; the arc welding torch, wire feeding mechanism, optical imager, workbench and The computer responsible for shape control is connected. During the printing process, the trajectory of the workbench and the arc welding torch is controlled by the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Power supply | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com