Coating tool

A coating and tool technology, applied in the field of coating tools, can solve problems such as deterioration of workability, damage to edge parts and bags, and inclusions stuck into the side, etc., to achieve the prevention of deterioration of precision, excellent wear resistance, and suppression of internal stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

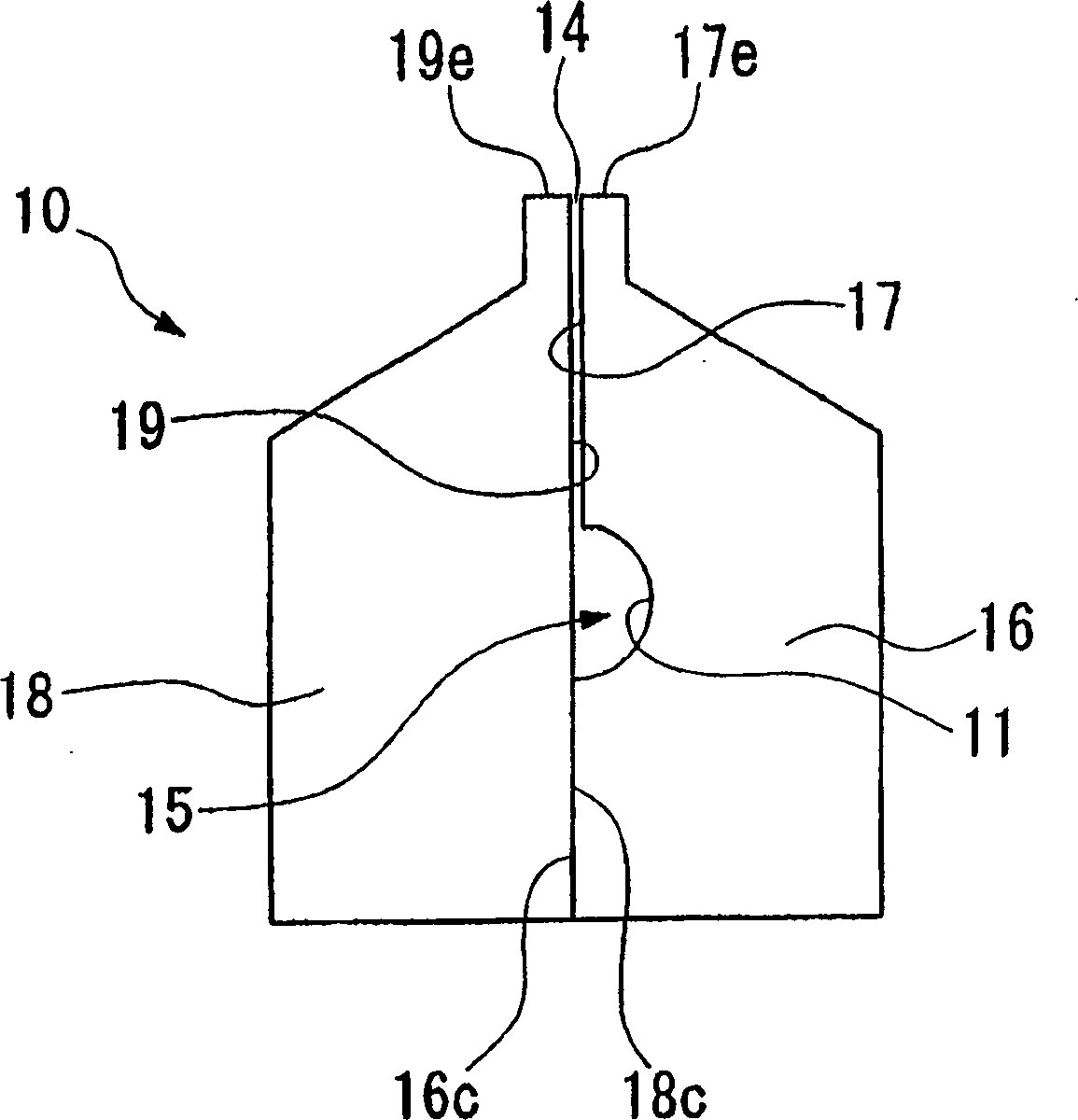

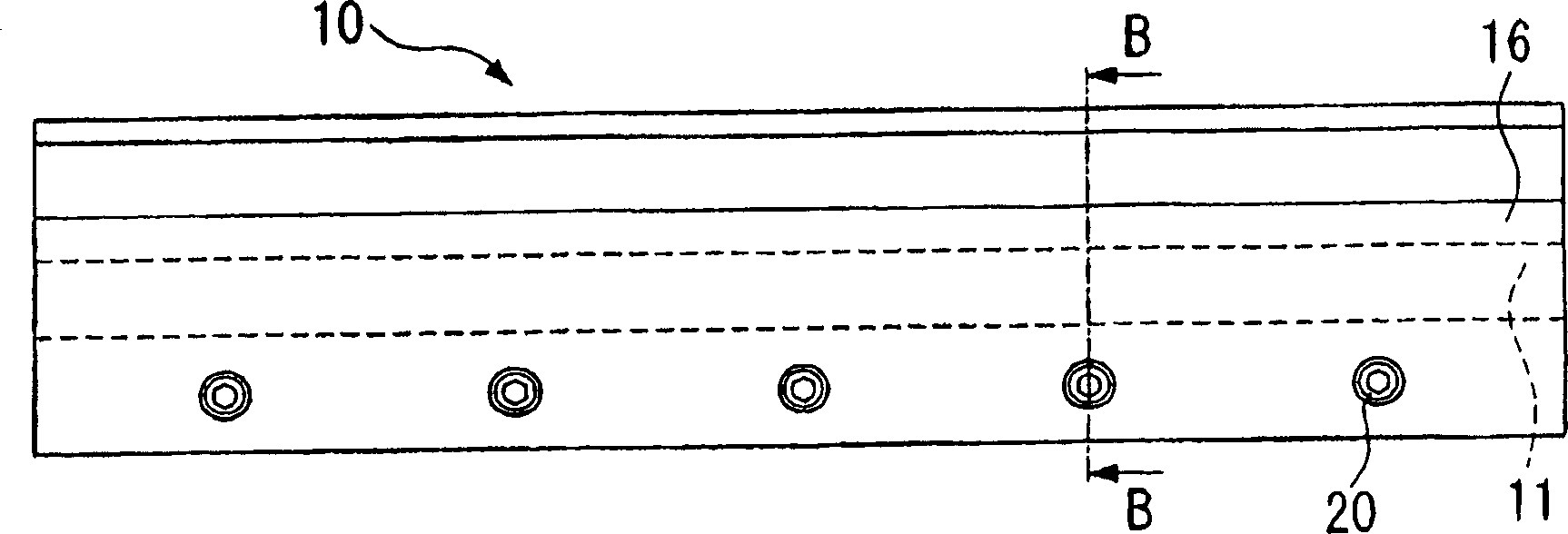

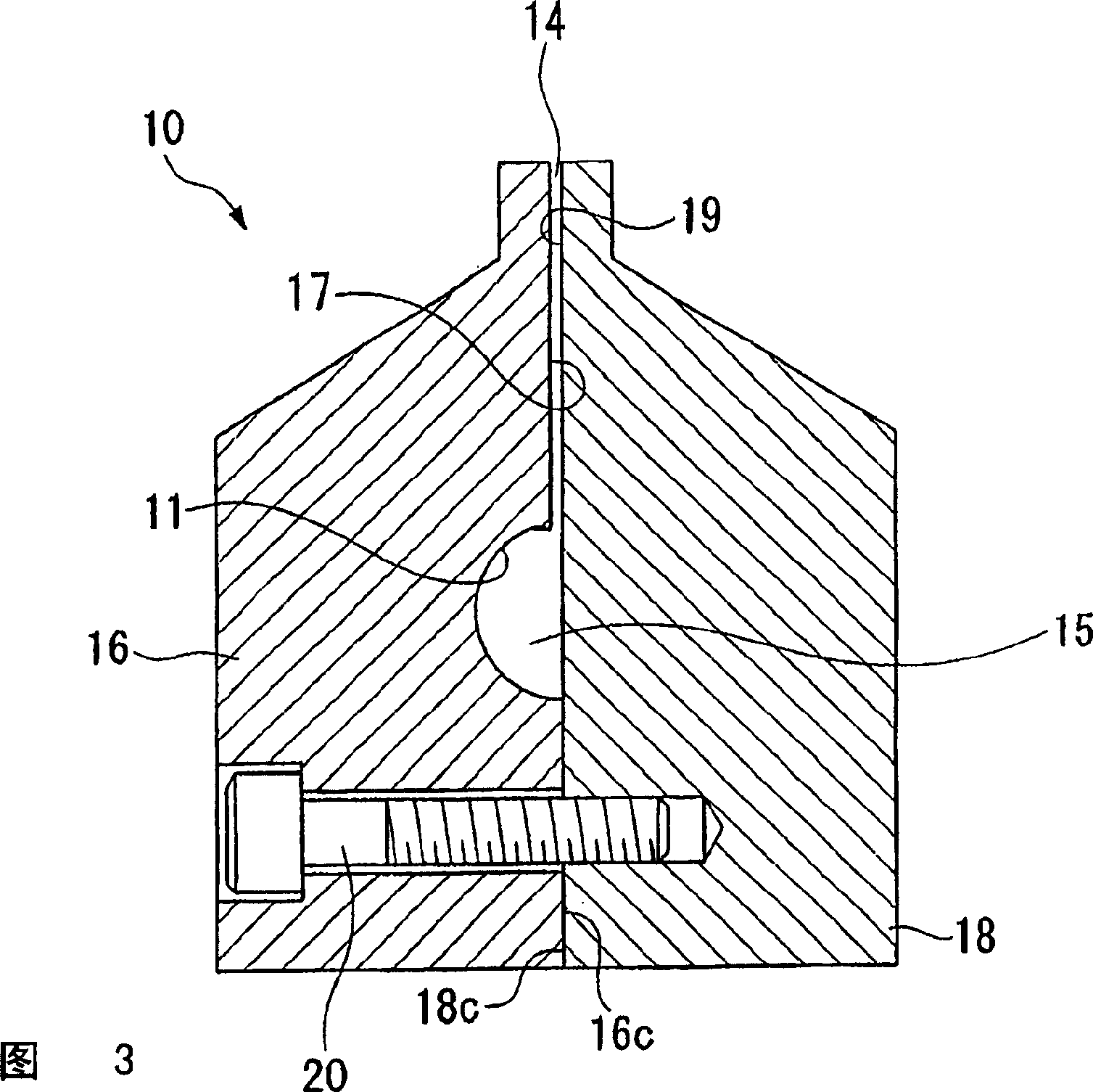

[0043] figure 1 It is the figure which observed the applicator head (tool main body) 10 of the 1st embodiment used for the applicator from the longitudinal direction, figure 2 yes figure 1 The right side view of Figure 3 is figure 2 The B-B section view.

[0044] The applicator head 10 is divided into slits 14 by arranging the opposing side surfaces (hereinafter referred to as slit surfaces) 17, 19 of a pair of head members 16, 18 with a certain gap. The mouth of the slit 14 is opened at the front end of the applicator head 10 . The head members 16, 18 protrude from the opening of the slit 14 to form front end surfaces 17e, 19e, and the application liquid is applied from the front end surfaces 17e, 19e.

[0045] The head member 16 constituting the applicator head 10 has grooves 11 formed in a semicircular shape in the longitudinal direction on the slit surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com