Vertical hot drawing technology for seamless cylinder

A vertical, hot-drawing technology, applied in the field of metal material processing, can solve the problems of poor surface quality of the workpiece, large difference in drawing wall thickness, increased manufacturing cost, etc. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

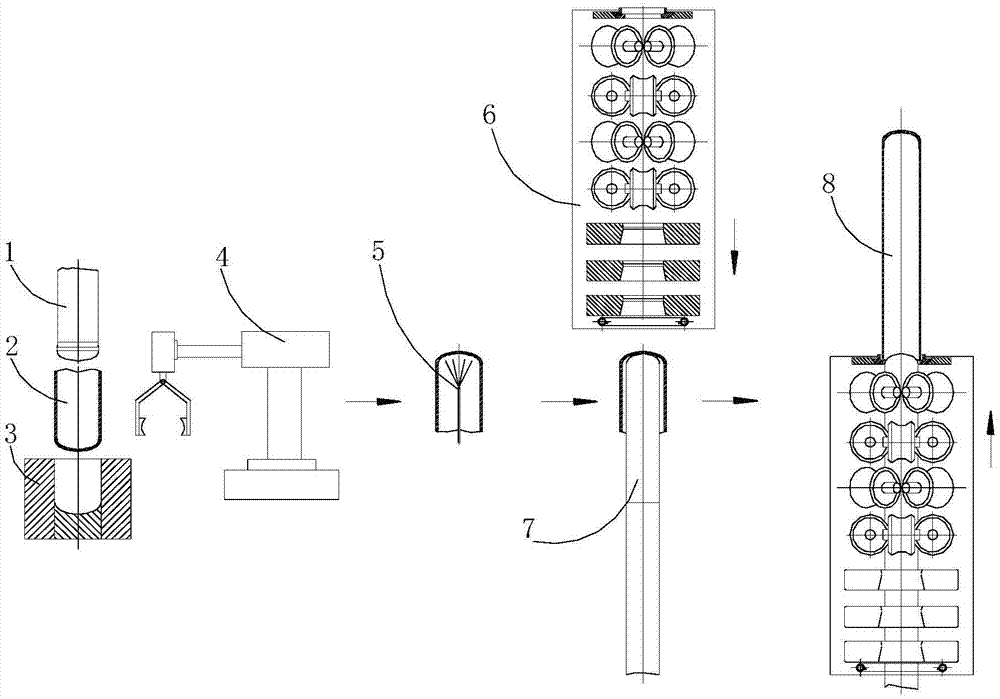

[0023] see figure 1 As shown, a seamless gas cylinder vertical hot drawing process includes the following steps:

[0024] (1), vertical punching blind hole: use a vertical punching machine to punch out a bucket-shaped hot preform 2 from a square bar or a round bar heated to 1100-1200°C and placed along the central axis of the mold; The vertical punching machine includes a punching die upper die 1 and a punching die lower die 3 that cooperate with each other. The punching die lower die 3 is used to place the hot preform bar, and the punching die upper die 1 quickly moves down to punch the hot preform bar. Out of the barrel-shaped hot preform 2, the perforated upper mold 1 rapidly descends at a speed of 60-150mm / s.

[0025] (2) Purge the inner wall of the hot preform: after punching the blind hole, quickly take out the hot preform 2 from the punching machine mold with the manipulator 4 and turn it over 180° quickly, with the mouth of the hot preform facing down, A high-pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com