Thick-wall pipe production system

A production system and thick-walled pipe technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve problems such as poor thermal conductivity, long cooling time, and sag, and meet the requirements of reducing sag resistance and production speed Improve and speed up cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

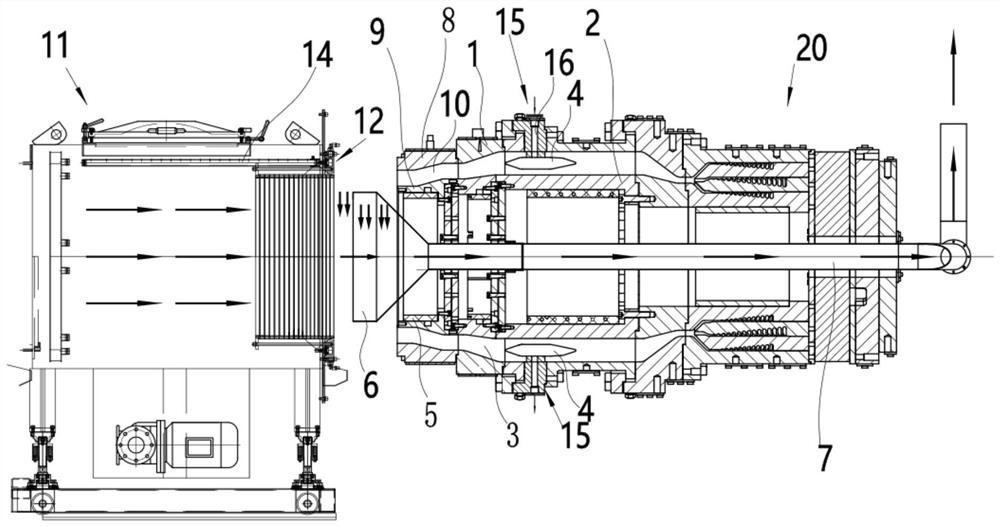

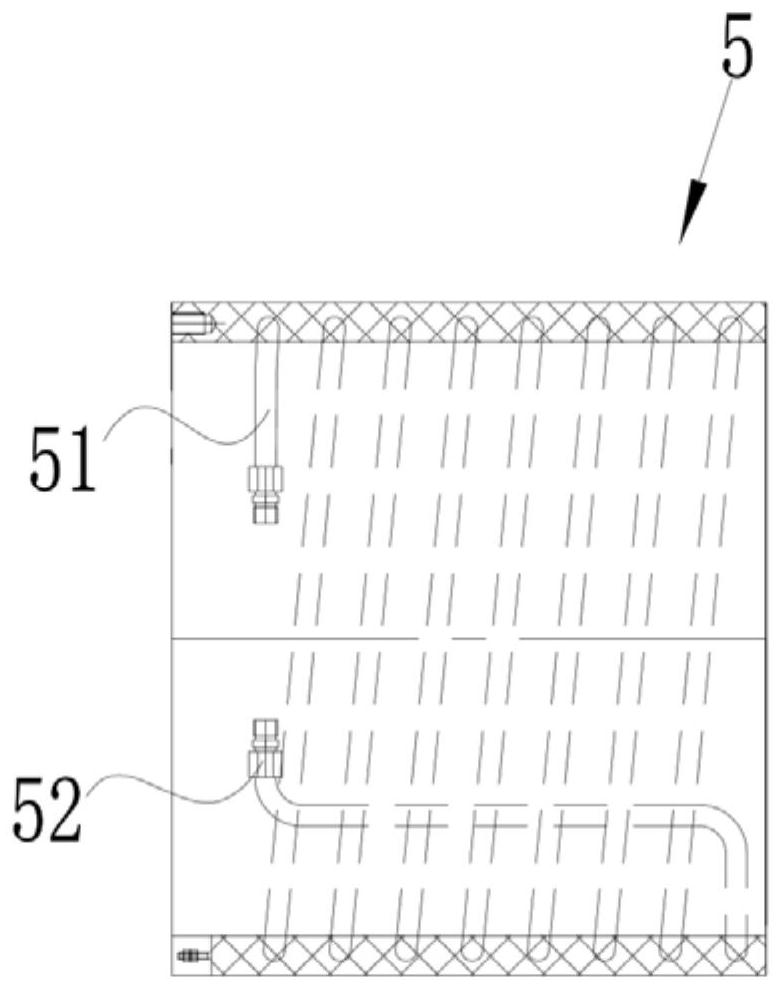

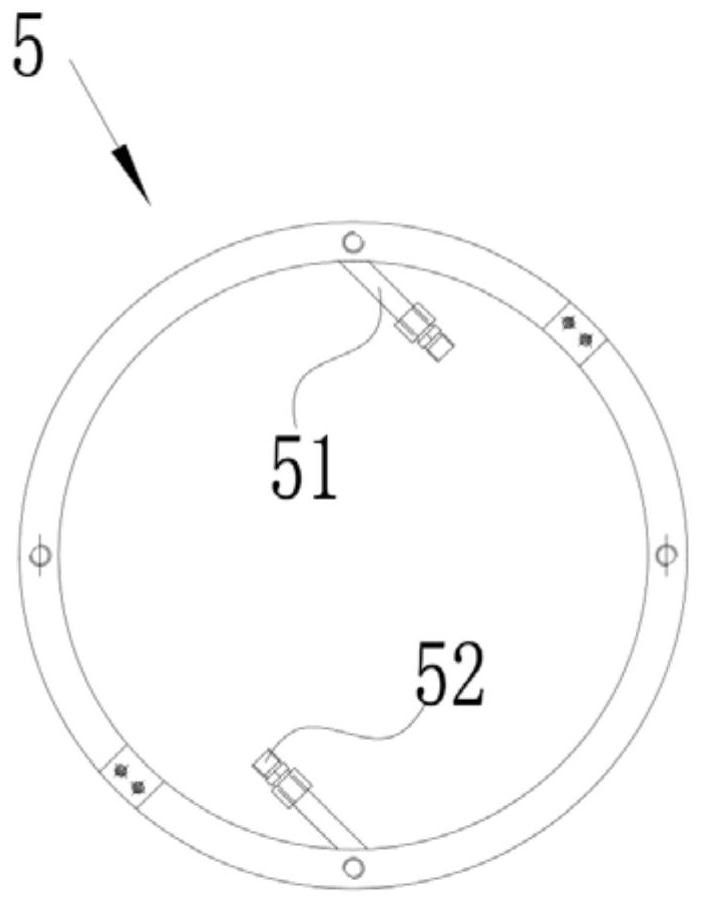

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. The "front side" direction in the manual refers to figure 1 The left side in the, on the contrary, the "rear side" in the specification refers to figure 1 on the right side of the .

[0019] Such as Figure 1 to Figure 3 As shown, a thick-walled pipe production system includes a mold device 20 and a cooling and shaping device 11, the mold device 20 is used to extrude the molten material, and the cooling and shaping device 11 is used to cool the extruded tube blank, And make the inner diameter and outer diameter of the tube blank reach the standard value.

[0020] The mold device 20 includes an outer mold 1 and an inner mold 2 , and a billet moving channel 3 is formed bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com