A production method of bellows with high precision, high stability and long life

A technology with high stability and production methods, applied in chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems of single production process of bellows, dislocation of bellows corrugations, poor overall stability, etc. , to achieve the effect of convenient and reliable clamping, uniform corrugation and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

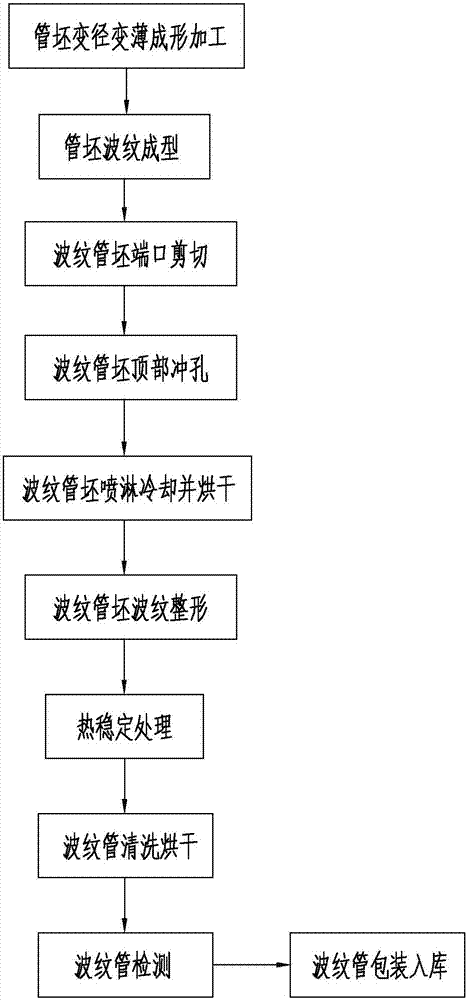

[0031] Such as figure 1 As shown, it is a production method of a bellows with high precision, high stability and long life in the present invention, which is mainly aimed at the production process of the bellows, and specifically includes the following steps:

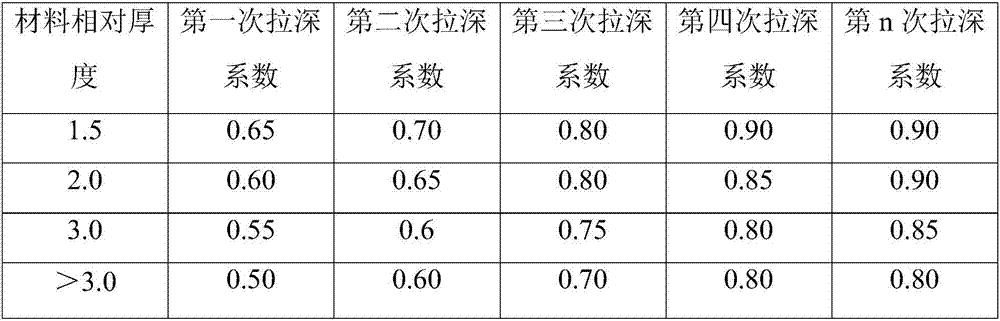

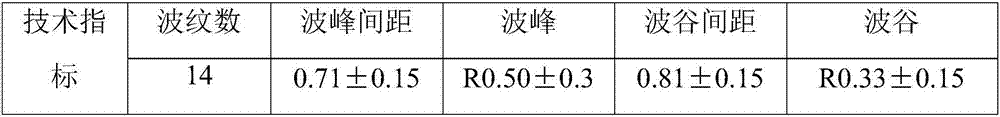

[0032] (a) Tube billet reducing and thinning forming process: the load-carrying capacity of the elastic sensitive element is related to many material parameters of the elastic sensitive element, such as the material used for the elastic sensitive element, corrugation type, corrugation thickness, corrugation layer number, connection The temperature range of the material is -30℃~+120℃. Due to the limitation of the actual installation process, it is not fundamental to change the force. We should start from the safety performance and optimize the constituent materials of the elastic sensitive element itself to improve the strength, fatigue resistance and good rigidity of the elastic sensitive element itself. , toughness an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com