Preparation method of core-shell polymer microspheres encapsulated with functional core material

A polymer and core material technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve problems such as the mismatch between the polymerization speed and the phase separation speed, the reduction of the barrier effect of the capsule core, and the defects of the polymer shell, so as to achieve the encapsulation performance. Excellent, defect structure reduction, small wall thickness deviation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

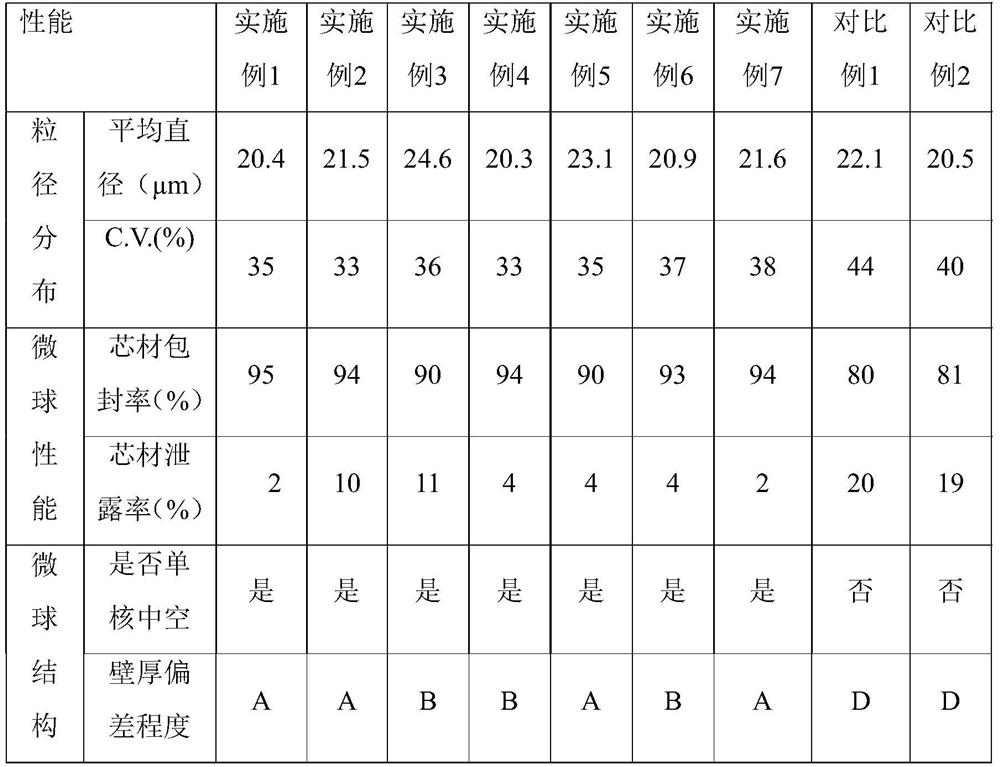

Examples

preparation example Construction

[0019] In the preparation method of the core-shell polymer microspheres encapsulated with functional core materials of the present invention, the following steps are included:

[0020] (1) oil phase preparation step: the step of preparing the oil phase by mixing the polymerizable monomer, functional core material, crosslinking agent, and initiator;

[0021] (2) water phase preparation step: mixing stabilizer, co-stabilizer, inorganic salt, polymerization inhibitor, Janus particles and deionized water to prepare water phase;

[0022] (3) emulsification step: the step of mixing the oil phase obtained in the step (1) and the water phase obtained in the step (2) and emulsifying to obtain a suspoemulsion;

[0023] (4) Polymerization reaction step: the step of subjecting the suspoemulsion obtained in the step (3) to a polymerization reaction at a temperature of 20 to 100° C. for 10 to 30 hours.

[0024] In the preparation method of the core-shell polymer microspheres encapsulated w...

Embodiment 1

[0108] As polymerizable monomers, acrylonitrile, methyl methacrylate, methacrylic acid, and N,N-dimethylacrylamide are added to a beaker in a ratio of 60:30:5:5 in terms of mass and mixed to form a Single phase spare. The aforementioned monomer phase, hexadecane, azobisisobutyronitrile, and triethylene glycol dimethacrylate were mixed in a ratio of 66:30:2:2 by mass, and configured into an oil phase for later use.

[0109] Add deionized water, sodium chloride, silica sol, Janus particle 1, cetyltrimethylammonium bromide, potassium dichromate by mass in a ratio of 67.9:10:20:0.1:1:1 Mix in the beaker to configure the aqueous phase for later use.

[0110] In the aforementioned Janus particle 1, the A side is polyacrylonitrile, the B side is polyacrylic acid, and the W side is polyacrylonitrile. A :W B = 1.5:1, the particle size is 250 nm, and the grafting rate on both sides is 5% (the grafting rate is the ratio of the mass of the added monomer to the mass of PEOS).

[0111] ...

Embodiment 2

[0116] As polymerizable monomers, methyl methacrylate, methacrylic acid, and N,N-dimethylacrylamide were added to a beaker in a ratio of 70:25:5 by mass, and mixed to prepare a monomer phase for later use. The aforementioned monomer phase, hexadecane, azobisisobutyronitrile, and triethylene glycol dimethacrylate were mixed in a ratio of 66:30:2:2 by mass, and configured into an oil phase for later use.

[0117] Add deionized water, sodium chloride, silica sol, Janus particle 1, cetyltrimethylammonium bromide, potassium dichromate by mass in a ratio of 67.9:10:20:0.1:1:1 Mix in the beaker to configure the aqueous phase for later use.

[0118] The aforementioned oil phase and water phase were mixed in a mass ratio of 25:75, and emulsified under an emulsifying machine to obtain suspoemulsion 2.

[0119] The suspoemulsion 2 was subjected to gradient temperature polymerization. That is, firstly, the reaction was carried out at a temperature of 50°C for 10 hours, then the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com